预变形对AA2195铝锂合金析出及晶粒细化的影响

张新明,刘颖维,叶凌英,唐建国

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:在细化晶粒的传统机械热处理工艺中的过时效前引入冷轧预变形,研究预变形对AA2195 铝锂合金过时效第二相粒子组态及最终再结晶组织的影响。结果表明:预变形明显降低了过时效第二相沿板材厚度方向分布的不均匀性,并大大减小长度为5~10 μm的棒状第二相,显著增加尺寸为0.8~2.0 μm的第二相,从而提高再结晶时的形核核心。与未采用预变形的板材相比,经60%预变形的板材经轧制和再结晶后表层的晶粒尺寸由未预变形的12.6 μm减小至9.26 μm,其纵横比由1.61减小至1.27;中心层晶粒尺寸由14.62 μm减小至11.27 μm,其纵横比由2.47减小至1.70。过时效前的轧制预变形明显细化并等轴化AA2195 铝锂合金的晶粒。

关键词:AA2195铝锂合金;预变形;第二相粒子;粒子激发形核;机械热处理

中图分类号:TG166.3 文献标识码:A 文章编号:1672-7207(2009)02-0375-08

Effects of pre-deformation on precipitating behavior and grain refinement of AA2195 Al-Li alloy

ZHANG Xin-ming, LIU Ying-wei, YE Ling-ying, TANG Jian-guo

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: In order to investigate the effects of the pre-deformation on second phase particles and recrystallization of AA2195 Al-Li alloy, cold-rolling pre-deformation prior to overaging was exploited in the traditional thermo- mechanical processing for grain refinement. The results show that the pre-deformation reduces the non-uniform distribution of the second phase particles along thickness of the plate, decreases the large rod particles with length of 5-10 μm and increases the particles with diameter of 0.8-2.0 μm dramatically, which results in increasing nucleation sites of recrystallization. In comparison with the sheet without pre-deformation, subsequent rolling and recrystallization decrease the final grain size and grain aspect ratio from 12.6 μm and 1.61 to 9.26 μm and 1.27 in the surface layer, and decrease the grain size and grain aspect ratio in the center layer from 14.62 μm and 2.47 to 11.27 μm and 1.70. Pre-deformation prior to overaging remarkably refine and spheroidize the grain structure of AA2195 Al-Li alloy.

Key words: AA2195 Al-Li alloy; pre-rolling deformation; second phase particles; particle-stimulated nucleation; thermo-mechanical processing

AA2195铝锂合金具有强度高、断裂韧性高和抗应力腐蚀性能较强等特点,是一种优良的航空航天材料[1]。现代航空航天工业对零部件提出轻量化、低成本、高可靠性要求,要求飞行器零部件整体成形,采用超塑性成形技术不仅可以满足这些要求,而且可以进一步提高零部件的整体刚度[2]。铝锂合金超塑成形一般要求材料具有晶粒尺寸小于10 μm的细晶组织,而普通铝合金晶粒尺寸一般比这大得多,获得细晶组织是实现超塑性成形的关键[3]。铝锂合金往往采用机械热处理的方法来细化晶粒[1, 4-6],其工艺路线为:固溶处理→过时效→轧制变形→静态再结晶。通过对过时效后的样品进行大压下量轧制变形使在大尺寸第二相粒子(约1 μm)周围形成强烈的变形区,通过再结晶退火这些强应变区域便可能成为再结晶的形核位置,这个过程称为粒子激发再结晶形核[7]。再结晶形核位置越多,所获得的晶粒越细。因此,超塑性板材预处理中过时效是一个关键工序,其主要目的是获得均匀分布的大尺寸第二相粒子。但大量研究表明,在AA2195铝锂合金中,所获第二相沿板材厚度方向上往往分布不均匀,长度为5~10 μm的棒状第二相轧制时往往破碎,导致机械热处理后的板材晶粒细化程度不高,并且晶粒组织存在分层现象[1]。研究表明[8-9],在6×××铝合金过时效之前采用冷变形可改善第二相的分布状况,提高晶粒细化程度。本文作者在AA2195铝锂合金时效前引入轧制预变形,探求其对第二相析出行为及最终再结晶晶粒尺寸的影响,以提高AA2195铝锂合金晶粒细化程度并减少组织的不均匀性。

1 实 验

实验以AA2195 铝锂合金为研究对象,经过熔炼、半连续铸造、均匀化后,热轧成厚度为10 mm的板材。合金热轧板材经500 ℃固溶处理后,分别进行10%,30%和60%的室温轧制预变形,道次变形量为10%。然后,在400 ℃经过时效处理。接着进行温轧,总变形量为60%~80%,道次变形量为10%~20%,最后,将合金再进行盐浴再结晶退火。

用于SEM观察的样品取自纵截面,经机械抛光后,在KYKY-2800型及Sirion200场发射扫描电镜下利用背反射电子像观察第二相粒子。在对扫描电镜照片进行粒子分布的定量统计分析时,粒子直径按与粒子具有相同投影面积的圆的直径计算。由于粒子呈随机分布,所以,可以用面积分数来代替体积分数[7]。采用能谱(EDS,Energy-dispersive X-ray spectroscopy)对第二相粒子进行相成分分析。再结晶后的样品经机械抛光、电解抛光、阳极化腹膜,在XJP-6A型光学显微镜下观察分析,采用截距法测量晶粒度。测量时每条直线所截的晶粒数不少于50个。再结晶晶粒的平均尺寸按照国家标准(GB/T 3246.1—2000)进行分析、计算。

2 实验结果

2.1 预变形对纤维组织的影响

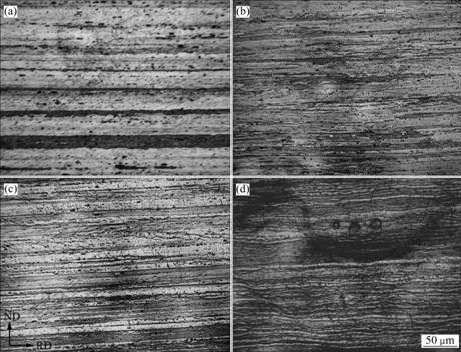

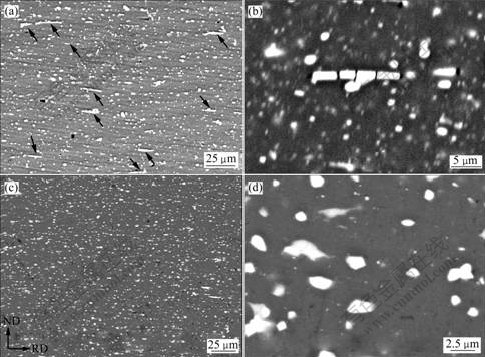

图1所示为不同轧制预变形量对合金晶粒组织的影响。预变形前合金固溶态的显微组织(如图1(a)所示)为典型的变形组织,晶粒较粗大,沿板材厚度方向晶粒尺寸在50 μm以上。图1(b)~(d)所示分别为10%,30%和60%轧制预变形后得到的纤维组织。可见,随着变形量不断增大,晶粒逐渐变得细长,沿板材厚度方向晶粒尺寸减小至10 μm以下。众所周知,晶界、位错等晶体缺陷所在位置是第二相易于形核的位置,同时,大压下量的冷轧预变形可以形成变形带,与晶界相比,变形带具有更大的界面面积,更有利于第二相形核[8-9]。通过30%~60%的冷轧预变形,在板材的整个纵截面形成了均匀分布的变形组织,这可以为第二相提供均匀分布的形核位置,从而达到改善第二相分布的目的。

轧制预变形量:(a) 0; (b) 10%; (c) 30%; (d) 60%

图1 AA2195铝锂合金不同预变形量下的晶粒组织

Fig.1 Grain microstructures of AA2195 Al-Li alloy plates rolled at different reductions

2.2 预变形对第二相分布的影响

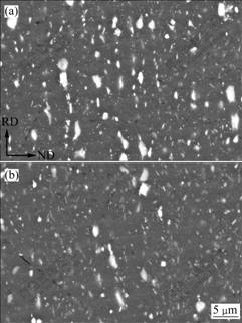

图2所示为合金经400 ℃过时效后第二相的背反射电子像。通过观察发现,第二相在板材纵截面沿厚度方向分布不均匀,靠近轧面的2个表层区域第二相分布比较均匀且体积分数大,而板材的中心层区域大尺寸第二相体积分数明显比表层的小。这种梯度分布的粒子状态在接下来的轧制及再结晶过程中一直存在,是导致最终层状再结晶组织形成的重要原因[1]。

(a) 表层; (b) 中心层

图2 400 ℃过时效的第二相粒子分布

Fig.2 Distributions of second-phase particles in sheet overaged at 400 ℃

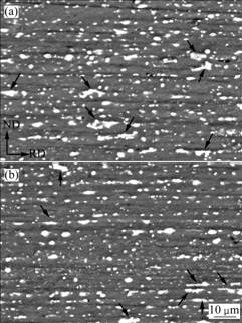

图3所示为合金经10%轧制预变形+400 ℃过时效后的第二相扫描电镜照片,其中,图3(a)和3(b)所示合金分别取自板材纵截面的表层与中心层。经观察发现,预变形的引入明显改善了第二相在板材表层与中心层分布不均匀的状况,但由于轧制本身的变形特点,压下量为10%时,使变形很难完全渗入板材心部,导致中心层引入的晶体缺陷数量较少,能提供的第二相的形核位置有限,致使表层与中心层第二相粒子的分布还存在一定的差别。同时,从图3还可以发现,有一些大尺寸第二相连接成片状(如图中箭头所示)。

(a) 表层; (b) 中心层

图3 10%预变形+400 ℃过时效的第二相粒子的SEM像

Fig.3 SEM images of second-phase particles in plate produced by 10% cold rolled and overaged at 400 ℃

图4所示为合金经30%和60%轧制预变形+ 400 ℃过时效后第二相的扫描电镜照片。其中:图4(a)和4(c)所示合金取自板材纵截面的表层,图4(b)和4(d)所示合金取自板材纵截面的中心层。当轧制预变形量增加到30%和60%时,合金过时效后第二相粒子在表层和中心层的分布区别不大,只是30%预变形+400 ℃过时效后的第二相仍然有一些大尺寸第二相连接成片状的现象。可见,当轧制预变形量增大到30%以上时,由实验结果(图1)可知,在板材的纵截面的厚度方向上形成了均匀分布的变形组织,可以为第二相的析出提供均匀的形核位置,从而基本消除了时效后第二相沿板材厚度方向上的不均匀分布问题。

(a) 30%, 表层; (b) 30%, 中心层; (c)60%, 表层; (d) 60%, 中心层

图4 不同轧制预变形量+400 ℃过时效后第二相的SEM像

Fig.4 SEM images of second-phase particles produced by cold rolled at different reductions and aged at 400 ℃

2.3 预变形对第二相形貌的影响

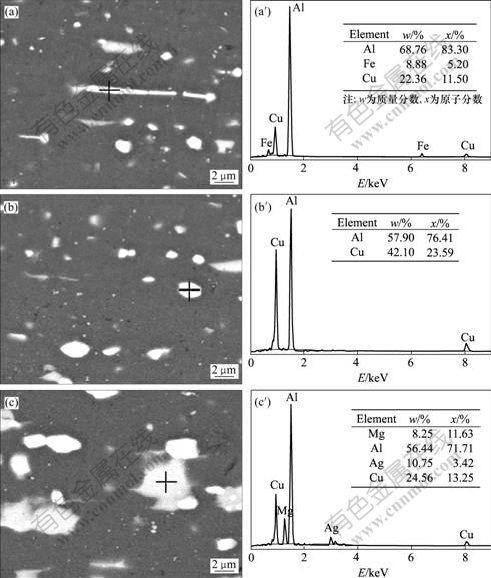

观察图5(a)可以发现,合金经400 ℃ 过时效后存在很多大尺寸的棒状第二相粒子,这些粒子在长度方向的尺寸可达几微米,甚至10 μm以上,如图5中箭头所示。能谱分析结果表明,这些棒状的第二相为富CuFe相,如图6(a)所示。由于这些大粒子在随后的大压下量轧制变形过程中往往破碎(如图5(b)所示),很难在其周围形成强烈的变形区,导致无法为再结晶晶粒形成提供形核位置,所以,这些棒状大粒子的存在不利于最终的晶粒细化。同时,因这些大尺寸第二相粒子富集了很多溶质元素,大大降低了能够激发形核的第二相粒子数量。在过时效前引入轧制预变形,可以明显减少这些棒状的第二相,当预变形量达到60%时(如图5(c)和(d)所示),这些大粒子数量不多,而且第二相已明显球化。采用预变形的合金过时效析出的第二相主要有2种形貌:一种接近球形或椭圆形,另一种呈不规则多边形。这2种粒子的能谱分析结果表明(图6(b)和(c)),粒子所含相分别为富Cu相和富CuAgMg相。

(a) 400 ℃过时效; (b) 400 ℃过时效, 85%轧制; (c), (d) 60%轧制预变形+400 ℃过时效

图5 AA2195铝锂合金第二相的SEM像

Fig.5 SEM images of second-phase particles in AA2195 Al-Li alloy

(a) 棒状;(b) 球形或椭圆形;(c) 不规则多边形

图6 不同形貌第二相的能谱分析

Fig.6 EDS analyses of second-phase particles

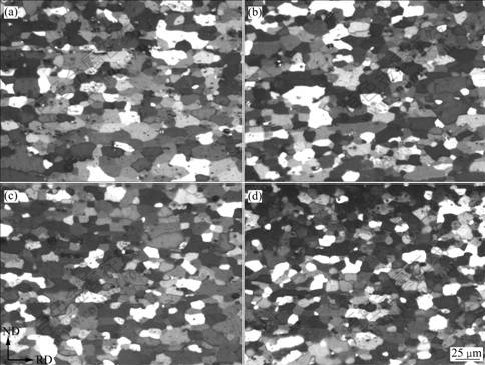

2.4 预变形对再结晶组织的影响

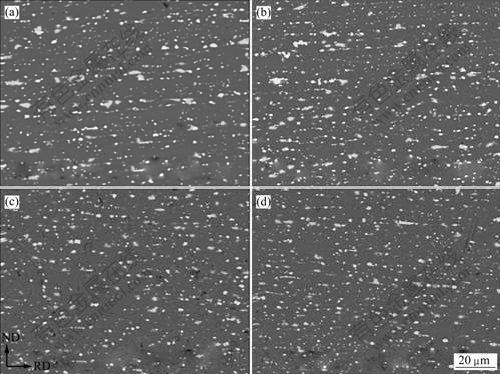

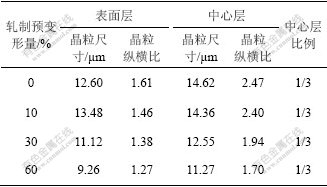

采用机械热处理方法细化铝合金晶粒时,板材最终的再结晶组织往往沿厚度方向呈3层分布:靠近轧面的2个表层晶粒组织细小等轴,而板材中心区域晶粒粗大呈扁平状,每层约占板材总厚度的1/3。这种现象在2195铝锂合金[1]、8090铝锂合金[10]、01420[11]铝锂合金表现得较明显。图7所示为合金经不同形变量的轧制预变形后,再经过时效、轧制及再结晶退火后的表层晶粒组织。从图7可以看出,采用10%预变形的样品(图7(b))与未采用预变形的样品相比(图7(a)),表层晶粒尺寸较粗大;而当轧制预变形量达到30%以上时(图7(c)和(d)),晶粒尺寸明显细化,晶粒形貌更加等轴化。对晶粒尺寸进行定量统计,结果表明(表1),60%轧制预变形对应的板材最终表层的再结晶平均尺寸由未采用预变形的12.6 ?m细化至 9.26 ?m,晶粒纵横比由1.61减小到1.27。在中心层观察到类似的变化趋势,结果如表1所示,只是10%预轧制变形的样品中心层晶粒尺寸要小于未采用预变形的晶粒尺寸,这与其表层的变化趋势不同。

(a) 0; (b) 10%; (c) 30%; (d) 60%

图7 不同轧制预变形量+400 ℃过时效的合金经轧制和再结晶后的晶粒组织

Fig.7 Grain microstructures of plates cold-rolled with different reductions+aged at 400 ℃ and followed by rolling and recrystallization

表1 不同轧制预变形量+400 ℃过时效的合金经轧制和再结晶后的晶粒尺寸

Table 1 Grain sizes of plate cold-rolled with different reductions+ aged at 400 ℃, after rolling and recrystallization

3 分析与讨论

人们对第二相粒子对再结晶行为的影响进行了较深入和广泛的研究。一般认为,大粒子(直径大于1 μm)、间距较大的粒子可以促进再结晶,因为在变形过程中,在这些大粒子周围形成的强变形区可以为再结晶提供形核点和驱动力[7, 12-13];小的、空间紧密分布的第二相对晶界的移动具有钉扎作用(Zener阻力),从而抑制再结晶过程。根据第二相对再结晶的影响规律,人们可以通过合金化或热处理工艺来控制第二相的大小及分布,从而最终控制合金再结晶晶粒尺寸及织构。在基于粒子激发再结晶形核机制的机械热处理细化晶粒的方法中,过时效工艺是一个关键工序,其主要目的是析出能够有效激发形核的大粒子。Humphreys等[7]认为,如果假设大于临界尺寸dg的每个第二相粒子都可以成功激发1个再结晶形核,那么,最终的再结晶晶粒尺寸DN可以近似用下式表示:

。 (1)

。 (1)

式中:Nd为单位体积内直径大于dg的第二相粒子数。

可见,大于临界尺寸的第二相数越多,所获得晶粒细化效果越好。一般认为,在铝合金中可以激发形核的第二相临界尺寸为1 μm,但也有研究表明第二相临界尺寸大于0.75[14]和0.80 μm[15]便可以起到激发形核作用。然而,现有研究所获得板材中的第二相沿板材厚度方向分布不均匀(图2),这样,会使最终的再结晶组织呈层状分布[1],而且其中含有很多尺寸为5~ 10 μm的棒状第二相(图5(a)),这些第二相在轧制过程中往往破碎(图5(b)),很难起到激发再结晶形核的 作用。

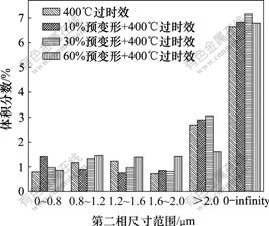

由实验结果(图7)可知,时效前采用轧制预变形,可以明显提高晶粒细化程度,这主要是由于提高了可以激发再结晶形核的第二相数量。合金经400 ℃过时效及不同形变量的轧制预变形+400 ℃过时效后的第二相尺寸和体积分数的定量统计结果如图8所示。可以看出,预变形的引入使时效后第二相整体体积分数略有增加,30%的预变形使第二相体积分数由未采用预变形的6.66%增加到7.18%,而60%预变形又使第二相体积分数回落到6.78%。但是,预变形为30%和60%的样品显著提高了尺寸为0.8~2.0 μm的第二相体积分数,降低了尺寸大于2 μm的大尺寸第二相的体积分数(长为5~10 μm的棒状第二相投影尺寸大于 2 μm),这显著提高了尺寸在0.8~2.0 μm范围内第二相的粒子数,由此显著提高晶粒细化程度。10%轧制预变形的样品与未采用预变形相比,降低了尺寸为0.8~2.0 μm的第二相体积分数而提高了尺寸大于2 μm的大尺寸第二相的体积分数,所以,导致最终的再结晶晶粒变得粗大(图7(b))。

图8 不同时效状态下第二相尺寸与体积分数的关系

Fig.8 Relationships between volume fraction and particle size of second phase for different aging treatments

另外,由实验结果(图3和图4)可知,预变形的引入基本消除了第二相在板材厚度方向上不均匀分布的现象,从而增加了板材中心层可提供再结晶形核的第二相粒子数,提高了板材中心层的晶粒细化程度,减小了晶粒纵横比(表1)。但由于层状晶粒组织的形成同时还受轧制工艺、轧制时板材厚度方向的温度差别等因素影响[1, 11],第二相分布的改善并没有完全消除再结晶组织的分层现象。

4 结 论

a. AA2195铝锂合金在过时效前,采用一定量的轧制预变形,使板材在厚度方向上形成均匀的变形组织,为第二相提供了均匀的形核位置,消除了第二相沿板材厚度方向上分布不均匀性。

b. 轧制预变形使过时效后第二相整体体积分数增幅不大,但30%~60%轧制预变形大大减小了尺寸为5~10 μm的棒状第二相数量,同时,显著增加了尺寸为0.8~2.0 μm的第二相数量,从而提高了再结晶形核的数量。

c. 与未采用轧制预变形的样品相比,60%轧制预变形所对应的板材的最终再结晶组织表层晶粒尺寸由12.6 μm减小至9.26 μm,晶粒纵横比由1.61减小到1.27;中心层晶粒尺寸由14.62 μm减小至11.27 μm,晶粒纵横比由2.47减小到1.70,晶粒明显被细化和 球化。

参考文献:

[1] 杜予晅. 铝锂合金超塑性板材的制备原理与技术[D]. 长沙: 中南大学材料科学与工程学院, 2007.

DU Yu-xuan. Principles and techniques in preparation of superplastic Al-Li sheets[D]. Changsha: School of Materials Science and Technology, Central South University, 2007.

[2] 文九巴, 杨蕴林, 杨永顺, 等. 超塑性应用技术[M]. 北京: 机械工程出版社, 2005.

WEN Jiu-ba, YANG Yun-lin, YANG Yong-shun, et al. Applicant technology of superplasticity[M]. Beijing: China Machine Press, 2005.

[3] Nieh T G, Wadsworth J, Sherby O D. Superplasticity in metals and ceramics[M]. Cambridge: Cambridge University Press, 1997.

[4] 杜予晅, 张新明, 叶凌英, 等. 一种Al-Cu-Li合金的超塑性性能研究[J]. 航空材料学报, 2007, 27(2): 1-5.

DU Yu-xuan, ZHANG Xin-ming, YE Ling-ying, et al. Superplasticity in an Al-Cu-Li alloy[J]. Journal of Aeronautical Materials, 2007, 27(2): 1-5.

[5] DU Yu-xuan, ZHANG Xin-ming, YE Ling-ying, et al. Superplastic behavior of Al-Cu-Li based alloy[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(S3): 1379-1382.

[6] 杜予晅, 张新明, 叶凌英, 等. 过时效工艺对AA2195铝锂合金微观组织的影响[J]. 材料热处理学报, 2006, 27(6): 52-56.

DU Yu-xuan, ZHANG Xin-ming, YE Ling-ying, et al. Influence of over-aging technology on microstructure of AA2195 Al-Li alloy[J]. Transactions of Materials and Heat Treatment, 2006, 27(6): 52-56.

[7] Humphreys F J, Hatherly M. Recrystallization and related annealing phenomena: Second edition[M]. Oxford: Pergamon Press, 2004.

[8] Troeger L P, Starke E A. Particle-stimulated nucleation of recrystallization for grain-size control and superplasticity in an Al-Mg-Si-Cu alloy[J]. Materials Science and Engineering A, 2000, 293(1/2): 19-29.

[9] Troeger L P, Starke E A. Microstructural and mechanical characterization of a superplastic 6××× aluminum alloy[J]. Materials Science and Engineering A, 2000, 277(1/2): 102-113.

[10] Bate P S, Ridley N, Zhang B. Mechanical behaviour and microstructural evolution in superplastic Al-Li-Mg-Cu-Zr AA8090[J]. Acta Materialia, 2007, 55(15): 4995-5006.

[11] 叶凌英, 张新明, 刘颖维, 等. 超塑预处理01420铝锂合金层状晶粒组织的形成机制[J]. 中国有色金属学报, 2007, 17(11): 1-6.

YE Ling-ying, ZHANG Xin-ming, LIU Ying-wei, et al. The formation mechanism of layered grain structure during superplastic pre-treatment in 01420 Al-Li alloy[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(11): 1-6.

[12] Humphreys F J. Nucleation in Recrystallization[J]. Materials Science Forum, 2004, 467-470(Part 1): 107-116.

[13] Doherty R D, Hughes D A, Humphreys F J, et al. Current issues in recrystallization: a review[J]. Materials Science and Engineering A, 1997, 238(2): 219-274.

[14] John A W, Paton N E, Hamilton C H, et al. Grain refinement in 7075 aluminum by thermo-mechanical processing[J]. Metallurgical Transactions A, 1981, 12A(7): 1267-1276.

[15] 张新明, 叶凌英, 杜予晅, 等. 01420铝锂合金的粒子激发再结晶形核[J]. 中南大学学报: 自然科学版, 2007, 38(1): 19-23.

ZHANG Xin-ming, YE Ling-ying, DU Yu-xuan, et al. Particle stimulated nucleation of recrystallization in 01420 Al-Li alloy[J]. Journal of Central South University: Science and Technology, 2007, 38(1): 19-23.

收稿日期:2008-01-08;修回日期:2008-04-09

基金项目:国际科技合作重点资助项目(2006DFA53250);国家重点基础研究发展计划项目(2005CB623706)

通信作者:张新明(1946-),男,湖南安乡人,博士,教授,从事材料科学与工程研究;电话:0731-8830265;E-mail: xmzhang@mail.csu.edu.cn