轧制预热时间对01420铝锂合金晶粒细化的影响

叶凌英,张新明,郑大伟

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:采用形变热处理法制备01420铝锂合金细晶板材,研究轧制预热时间对第二相粗化、回溶及最终再结晶组织的影响。研究结果表明:合金在300 ℃/48 h过时效处理过程中析出大量棒状的微米尺寸S相,这些第二相在随后的轧制前400 ℃预热过程中不稳定,首先粗化成球形相,当预热时间超过8 h,又开始逐渐地溶解;在400 ℃预热0~10 h内,第二相分布比较均匀;当预热时间超过12 h,没有溶解的第二相主要分布于晶界处,尺寸较小,是导致最终再结晶组织粗大且呈扁平状的主要原因;随着预热时间的延长,板材轧制和再结晶后的晶粒尺寸逐渐增大,但在预热8 h内增幅较小。板材适宜的轧制预热制度为于400 ℃预热4~8 h。

关键词:01420 铝锂合金;形变热处理;第二相;粒子激发形核;再结晶

中图分类号:TG166.3 文献标志码:A 文章编号:1672-7207(2012)01-0087-06

Effect of pre-heating time on grain refinement of 01420 Al-Li alloy

YE Ling-ying, ZHANG Xin-ming, ZHENG Da-wei

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Fine grained 01420 Al-Li alloy sheet was produced by thermo-mechanical processing. The effects of pre-heating time on precipitate coarsening, dissolution and grain structure were investigated. The results show that a large number of micron-sized, rod-shaped S-phase particles are produced during overaging at 300 ℃ for 48 h. However, these particles are not stable during the following pre-heating at 400 ℃ and they tend to be coarsened to globular particles firstly and then start to dissolve after preheated for more than 8 h. The particles are distributed homogeneously when preheated at 400 ℃ for 0-10 h, but the remained particles are mainly located at grain boundaries when pre-heating duration is over 12 h. This is the main reason of causing the coarse and elongated grain structure. The grain size increases with the increasing preheating time but grows a little in 8 h. The proper pre-heating schedule is at 400 ℃ for 4-8 h.

Key words: 001420 Al-Li alloy; thermo-mechanical processing; second phase particle; particle stimulated nucleation (PSN); recrystallization

01420铝锂合金具有低密度、高比强度、良好的焊接性能和抗腐蚀性能等优点,是一种优良的航空航天结构材料[1-3]。雅克-36和雅克-38的机身全部采用01420铝锂合金制造,获得了很好的减小质量的效果,特别是将它用于米格-29焊接机身时,质量减小24%[1]。但是,未再结晶状态的该合金由于塑性流动的局部化暴露出加工性能和服役性能差的问题。相反,具有细晶组织的01420铝锂合金表现出了较好的塑性和服役性能,特别是还可以获得超塑性[4]。因此,制备细晶01420铝锂合金板材便成为解决其塑性和服役性能差的一条最有效途径。01420铝锂合金可以采用形变热处理法(TMP)来细化晶粒[5-6]。TMP法是目前工业上应用最多的可以生产细晶铝合金板材的方法,其基本工艺路线为:固溶处理→过时效→大压下量轧制变形→静态再结晶[7]。通过对过时效后的样品进行大压下量轧制变形使在大尺寸第二相粒子(粒径约1 μm)周围形成强烈的变形区,在接下来的再结晶退火过程中,这些强应变区域便可能成为再结晶的形核位 置,细晶组织通过粒子激发再结晶形核(PSN)来获得。过时效的主要目的是析出尺寸约1 μm的大尺寸第二相,传统的机械热处理方法中轧制温度低于过时效温度[8-9],轧制前的预热过程对第二相的粒径及分布基本没有影响[10]。但01420铝锂合金塑性差,在低温轧制时容易开裂,轧制前预热温度需高于过时效温度才能保证板材在轧制过程中不开裂,一般选取预热温度为 400 ℃[11-12]。轧制预热过程影响前期过时效过程中已析出第二相粒子的大小与分布,从而影响最终的晶粒尺寸,但关于预热过程对晶粒细化的影响未见相关研究。本文研究轧制前预热时间对第二相的粗化与溶解的影响,并定量比较最终的再结晶晶粒粒径,以期为优化轧制预热制度提供依据。

1 实验

实验用材料为9.2 mm厚的01420铝锂合金热轧板,板材在空气炉中经475 ℃/2 h固溶处理及300 ℃/ 48 h过时效后,在400 ℃预热4~17 h后立即进行轧制,轧辊直径为420 mm,轧制过程中将板材在340~380 ℃进行1次中间退火,退火后采用转向轧制,即将前1次轧制后板材的横向作为再次轧制的轧制方向,总变形量为80%,道次压下量为10%~20%。最后,将轧制得到的板材进行510 ℃/30 min的盐浴再结晶退火。

用于透射电镜观察的试样取自过时效及预热后样品的板平面,在TECNAI G220型透射电境下观察第二相粒子的形貌及粒径。此外,选取这些状态板材的纵截面,经机械抛光、Keller试剂腐蚀后,在KYKY-2800型扫描电镜下利用二次电子像观察第二相的分布。不同状态板材的定性物相分析在D/max 2550 X线衍射仪上进行。再结晶退火后的样品经机械抛光和Keller试剂腐蚀后,在XJP-6A型光学显微镜下观察分析。采用截距法测量晶粒度,测量时每条直线所截的晶粒数不少于50个。再结晶晶粒的平均尺寸按照国家标准(GB/T 3246.1—2000)进行分析计算。

2 结果与讨论

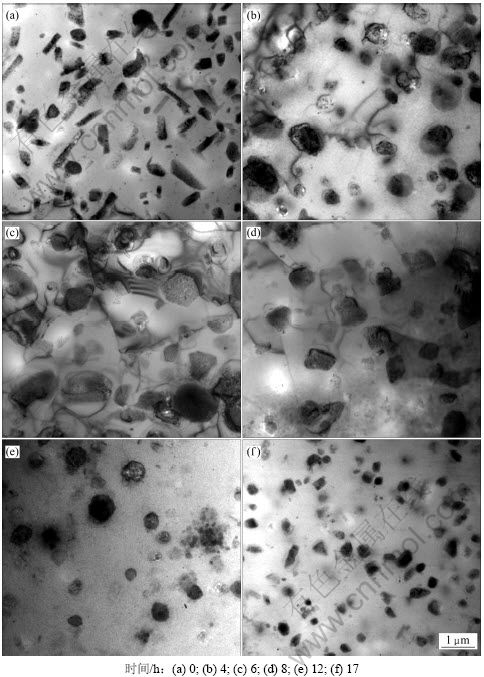

形变热处理方法细化晶粒的机制为粒子激发再结晶形核,第二相的粒径及分布直接影响最终的晶粒尺寸[9]。一般认为,在铝合金中可以起到激发再结晶形核的第二相粒径在1 μm左右,且在变形的过程中不能破碎,一般通过高温过时效来获得大粒径第二相[9]。01420铝锂合金经300 ℃/48 h过时效所获得第二相的形貌及大小如图1(a)所示,主要含有2种形貌的大尺寸第二相,其中大多数为棒状,长度方向约为1 μm;其余为近球形,直径约为0.5 μm。由于01420铝锂合金塑性较差,尤其对于厚度规格较大的板材,需要在400 ℃进行较长时间的保温后才可进行轧制。图1(b)~(g)所示为对300 ℃/48 h过时效后的合金在 400 ℃经不同时间保温后第二相的透射电镜(TEM)形貌像。经观察发现:当在400 ℃保温4 h后,第二相发生了显著的球化与粗化,球化后的第二相直径为1.0~1.2 μm,如图1(b)所示。进一步延长保温时间到6 h,第二相进一步粗化,如图1(c)所示。而后随着保温时间的延长,第二相没有继续粗化反而不断地回溶,如图1(d)~(f)所示。特别是当保温时间延长到17 h时,第二相已减小至0.3~0.5 μm,如图1(f)所示,这些第二相尺寸已小于可以激发再结晶形核的临界尺寸。值得注意的是,在400 ℃保温4~17 h的过程中,尽管第二相先粗化后溶解,但整个过程始终保持着近球形的形貌。实际上,棒状第二相的球化使其在接下来的轧制过程中不易破碎,为再结晶提供了更佳的形核位置,同时可以提高合金的塑性,抑制轧制开裂[12]。

一般认为,当母相基本达到系统的平衡浓度后,析出相将以界面能为驱动力缓慢长大,即发生Ostwald熟化过程[13]。在此过程中,由于小粒子相界面面积比较大,其系统的界面能也较大,对于大粒子来说,小粒子是不稳定的,所以,小粒子会不断地溶解,大粒子不断长大,同样也会发生曲率较大的区段溶解,而曲率较小的区段长大,即发生第二相的球化。当对300 ℃/48 h过时效后的合金在400 ℃进行预热时,实际上该温度已经达到S相的溶解温度[14],但第二相并没有立即溶解,这可能是由于棒状第二相具有较大的曲率而以降低表面能为驱动力发生球化,同时在界面能的驱动下,靠消耗小粒子,使第二相发生了粗化,如图1(b)和(c)所示;当合金释放完界面能后,第二相才在化学驱动力的作用下开始溶解,如图1(d)~(f)所示。

图1 01420铝锂合金第二相透射电镜照片

Fig.1 TEM images of second phase particles of 01420 Al-Li alloy

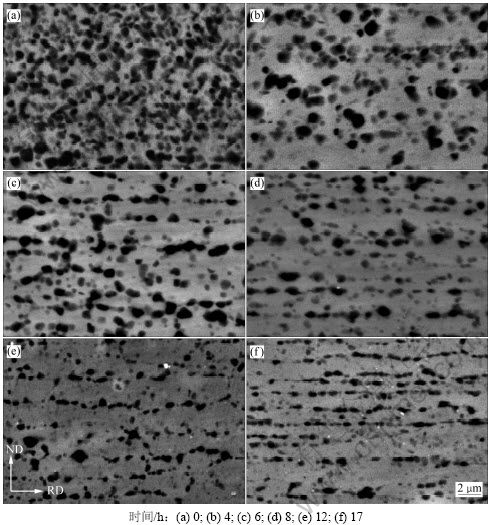

图2所示为合金经300 ℃/48 h过时效后及其又在400 ℃经不同时间保温后第二相在板材纵截面的分布情况。叶凌英等[6]研究表明,第二相在板材的纵截面沿厚度方向分布不均匀,在靠近轧面的板材表面层区域,第二相比较均匀地分布于基体中,而在样品的中心层区域,第二相则主要平行于轧制方向呈条带状分布。图2所示照片均取自板材的表面层。因为01420铝锂合金过时效后的第二相在机械抛光的过程中很容易脱落,所以无法通过扫描电镜(SEM)直接观察到析出相,图2所示均为第二相脱落后留下的孔洞形貌。虽然SEM照片无法反映出析出相的实际尺寸,但其脱落后留下的孔洞仍然可以反映出它们的分布特征。合金经300 ℃/48 h过时效后,第二相分布比较均匀而且数量较多,如图2(a) 所示。接着将其在400 ℃保温4 h后,大尺寸第二相发生了显著的粗化,同时一些小尺寸第二相溶解,但整体分布仍然比较均匀,如图2(b)所示。随着在400 ℃保温时间的进一步延长,第二相的分布逐渐变得不均匀,表现为沿着与轧制方向平行的原始晶界处的第二相被保留下来,而分布于晶粒内部的第二相逐渐溶解,特别是当保温时间延长到12~17 h时,只能观察到一些原始晶界处的第二相,晶粒内部的第二相已经完全溶解。

图2 01420铝锂合金第二相分布情况

Fig.2 Distributions of second phase particles of 01420 Al-Li alloy

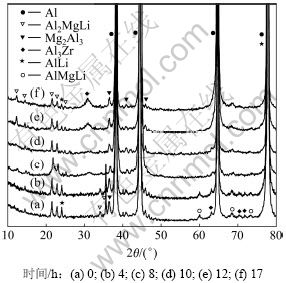

尽管300 ℃/48 h过时效后的合金在400 ℃保温过程中第二相的形貌发生了显著的改变(如图1所示),但从图3中对各个状态合金的X线分析结果来看,它们的衍射图谱基本上是一致的,可知该过程并没有发生相变。01420铝锂合金中主要含有2种第二相:一种为强化相δ′(Al3Li)相,另外一种为平衡相S(Al2MgLi)相。此外,β(Mg2Al3)相、δ(AlLi)相和Al3Zr相也有可能存在于该合金中[15]。一般认为,01420铝锂合金的析出序列为:过饱和固溶体→δ′(Al3Li)→S(Al2MgLi)。Davydov等[14]认为在形成稳定的平衡相S相之前会形成一种过度相S′,S′相的晶体结构与S相不同,但具体结构至今没有表征出来。从图3中的物相分析结果来看,各种状态合金中第二相主要为S和β相,以及少量的δ和Al3Zr相。此外,基体中还含有少量的AlMgLi2相,可能属于过度相S′相。S相通常呈棒状形貌,但结合X线物相分析及TEM的观察结果不难看出,在高温保温后S相也会呈现出球形的形貌。而且,随着在400 ℃保温时间的延长,当预热时间超过8 h后,合金中S相对应的X线衍射峰强度不断地下降,也证实在该阶段预热过程中S相发生了溶解。

图3 01420铝锂合金X线衍射谱

Fig.3 X-ray diffraction patterns of 01420 Al-Li alloy

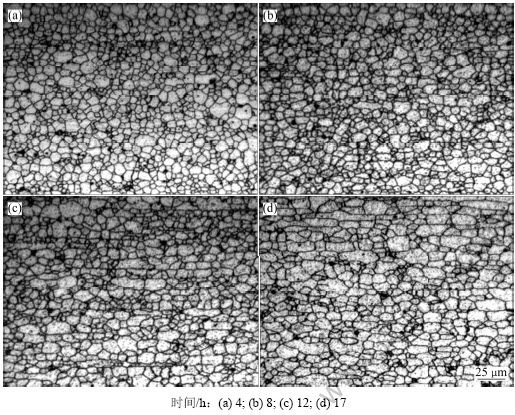

图4 01420铝锂合金的晶粒组织

Fig.4 Grain structures of 01420 Al-Li alloy

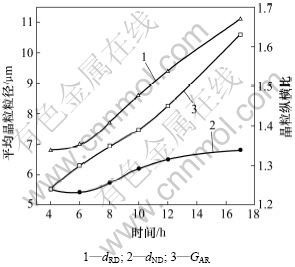

针对本实验中的01420铝锂合金,认为第二相的粒径至少在0.8 μm以上才能起到激发形核作用[5]。但如果第二相聚集在一起呈团簇状分布,尽管团簇中的每一个第二相尺寸可能小于激发形核的临界尺寸,但如果这个团簇的尺寸大于该临界尺寸,也是有可能起到激发再结晶形核的作用的[16]。假设大于该临界尺寸的每一个第二相均可以成功激发一个再结晶晶粒的形核,那么再结晶晶粒尺寸DN可以近似的表示为: (式中:Nd为单位体积内直径大于dg的第二相粒子数目)。实际上,第二相激发再结晶形核的效率很低,通常数十个甚至上百个粒子才可以成功激发一个再结晶晶粒[17]。图4所示为01420铝锂合金经300 ℃/48 h时效处理后,在400 ℃保温不同时间后轧制至80%,再经510 ℃/0.5 h再结晶退火后的晶粒组织。观察区域取自靠近板材纵截面上靠近轧面的表层。采用截距法分别计算沿轧制方向和法向的平均晶粒粒径dRD,dND及晶粒纵横比GAR,其随轧制预热时间的变化如图5所示。从图5可见:在400 ℃预热4 h后,板材轧制和再结晶后沿轧制方向和法向的平均晶粒尺寸分别为6.8 μm和5.5 μm,其晶粒纵横比为1.24;随着保温时间的延长,获得的最终再结晶晶粒组织不断粗化,晶粒形貌逐渐由等轴状转变为扁平状;当保温17 h后,沿轧制方向和法向的平均晶粒尺寸分别增加到11.1 μm 和6.8 μm,其晶粒纵横比为1.63。晶粒组织的显著粗化主要是由第二相的分布特点决定的。由图2(e)和(f)可以看出:当保温时间达到12 h及以后时,大尺寸第二相主要平行于轧制方向呈条带状分布,那么,轧制后在这些第二相周围形成的可以作为再结晶核心的强烈变形区也必将呈类似状态分布,具有这种分布特征的第二相将强烈阻碍晶界沿法向方向的移动,从而形成了如图4(c)和(d)所示的扁平状的晶粒组织。

(式中:Nd为单位体积内直径大于dg的第二相粒子数目)。实际上,第二相激发再结晶形核的效率很低,通常数十个甚至上百个粒子才可以成功激发一个再结晶晶粒[17]。图4所示为01420铝锂合金经300 ℃/48 h时效处理后,在400 ℃保温不同时间后轧制至80%,再经510 ℃/0.5 h再结晶退火后的晶粒组织。观察区域取自靠近板材纵截面上靠近轧面的表层。采用截距法分别计算沿轧制方向和法向的平均晶粒粒径dRD,dND及晶粒纵横比GAR,其随轧制预热时间的变化如图5所示。从图5可见:在400 ℃预热4 h后,板材轧制和再结晶后沿轧制方向和法向的平均晶粒尺寸分别为6.8 μm和5.5 μm,其晶粒纵横比为1.24;随着保温时间的延长,获得的最终再结晶晶粒组织不断粗化,晶粒形貌逐渐由等轴状转变为扁平状;当保温17 h后,沿轧制方向和法向的平均晶粒尺寸分别增加到11.1 μm 和6.8 μm,其晶粒纵横比为1.63。晶粒组织的显著粗化主要是由第二相的分布特点决定的。由图2(e)和(f)可以看出:当保温时间达到12 h及以后时,大尺寸第二相主要平行于轧制方向呈条带状分布,那么,轧制后在这些第二相周围形成的可以作为再结晶核心的强烈变形区也必将呈类似状态分布,具有这种分布特征的第二相将强烈阻碍晶界沿法向方向的移动,从而形成了如图4(c)和(d)所示的扁平状的晶粒组织。

图5 轧制预热时间对再结晶晶粒尺寸的影响

Fig.5 Effect of pre-heating time on recrystallized grain size

3 结论

(1) 01420铝锂合金经300 ℃/48 h过时效处理后,析出大量棒状的S相,这些第二相在随后的轧制前 400 ℃预热过程中不稳定,先是粗化成球形相,当预热时间超过8 h,便开始逐渐地溶解。尽管预热过程中合金的第二相形貌发生了较大的改变,但该过程并没有发生相变。

(2) 在400 ℃预热0~10 h内,第二相分布较均匀;当预热时间超过12 h,第二相主要分布于晶界处,尺寸较小,这是导致最终再结晶组织粗大呈扁平状的主要原因。

(3) 随着预热时间的延长,合金轧制和再结晶后的晶粒尺寸逐渐增大,但在预热8 h内增幅不大。合金适宜的轧制预热制度为400 ℃预热4~8 h。

参考文献:

[1] Fridlyander I N. Aluminum alloys in aircraft in the periods of 1970-2000 and 2001-2015[J]. Metal Science and Heat Treatment, 2001, 43(1): 6-10.

[2] Kaibyshev R, Shipilova K, Musin F, et al. Achieving high strain rate superplasticity in an Al-Li-Mg alloy through equal channel angular extrusion[J]. Materials Science and Technology, 2005, 21(4): 408-418.

[3] Kaibyshev R, Shipilova K, Musin F, et al. Continuous dynamic recrystallization in an Al-Li-Mg-Sc alloy during equal-channel angular extrusion[J]. Materials Science and Engineering A, 2005, 396(2): 341-351.

[4] Kaibyshev O A. Superplsticity of alloys, intermetallides, and ceramics[M]. Berbin: Springer Verlag Press, 1992.

[5] 张新明, 叶凌英, 杜予晅, 等. 01420铝锂合金的粒子激发再结晶形核[J]. 中南大学学报: 自然科学版, 2007, 38(1): 19-23.

ZHANG Xin-ming, YE Ling-ying, DU Yu-xuan, et al. Particle stimulated nucleation of recrystallization in 01420 Al-Li alloy[J]. Journal of Central South University: Science and Technology, 2007, 38(1): 19-23.

[6] 叶凌英, 张新明, 刘颖维, 等. 超塑预处理01420铝锂合金层状晶粒组织的形成机制[J]. 中国有色金属学报, 2007, 17(11): 1744-1749.

YE Ling-ying, ZHANG Xin-ming, LIU Ying-wei, et al. The formation mechanism of layered grain structure during superplastic pre-treatment in 01420 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1-6.

[7] 杜予晅. 铝锂合金超塑性板材的制备原理与技术[D]. 长沙: 中南大学材料科学与工程学院, 2007.

DU Yu-xuan. Principles and techniques in preparation of superplastic Al-Li sheets[D]. Changsha: Central South University. School of Materials Science and Engineering, 2007.

[8] Nieh T G, Wadsworth J, Sherby O D. Superplasticity in metals and ceramics[M]. Cambridge: Cambridge University Press, 1997.

[9] Humphreys F J, Hatherly M. Recrystallization and related annealing phenomena[M]. 2nd ed. Oxford: Pergamon Press, 2004.

[10] John A W, Paton N E, Hamilton C H, et al. Grain refinement in 7075 aluminum by thermo-mechanical processing[J]. Metallurgical Transactions A, 1981, 12A(7): 1267-1276.

[11] 叶凌英, 张新明, 刘颖维, 等. 温度对01420铝锂合金轧制开裂及晶粒细化的影响[J]. 稀有金属材料与工程, 2008, 37(8): 1431-1435.

YE Ling-ying, ZHANG Xin-ming, LIU Ying-wei, et al. Effects of temperatures on rolling failure and grain refinement of 01420 Al-Li alloy[J]. Rare Metal Materials and Engineering, 2008, 37(8): 1431-1435.

[12] 张新明, 叶凌英, 刘颖维, 等. 中间退火及轧制工艺对Al-Mg-Li合金塑性开裂及晶粒细化的影响[J]. 中南大学学报: 自然科学版, 2009, 40(1): 88-93.

ZHANG Xin-ming, YE Ling-ying, LIU Ying-wei, et al. Effects of intermediate annealing and rolling on plastic failure and grain refinement of an Al-Mg-Li alloy[J]. Journal of Central South University: Science and Technology, 2009, 40(1): 88-93.

[13] 程晓农, 戴起勋, 邵红红. 材料固态相变与扩散[M]. 北京: 化学工业出版社, 2006: 74-76.

CHENG Xiao-nong, DAI Qi-xun, SHAO Hong-hong. Solid-state phase transformations and diffusion of Materials[M]. Beijing: Chemical Industry Press, 2006: 74-76.

[14] Davydov V G, Ber L B, Kaputkin E Y, et al. TTP and TTT diagrams for quench sensitivity and ageing of 1424 alloy[J]. Materials Science and Engineering A, 2000, 280(1): 76-82.

[15] Mazilkin A A, Myshlyaev M M. Microstructure and thermal stability of superplastic aluminium-lithium alloy after severe plastic deformation[J]. Journal of Materials Science, 2006, 41(12): 3767-3772.

[16] Ye L Y, Zhang X M, Liu Y W, et al. Effect of two-step aging on recrystallised grain size of Al-Mg-Li alloy[J]. Materials Science and Technology, 2009,

[17] Doherty R D, Hughes D A, Humphreys F J, et al. Current issues in recrystallization: A review[J]. Materials Science and Engineering A, 1997, 238(2): 219-274.

(编辑 邓履翔)

收稿日期:2011-01-23;修回日期:2011-03-23

基金项目:国际科技合作重点资助项目(2008DFR50260);中南大学自由探索计划资助(2011QNZT004)

通信作者:叶凌英(1981-),男,吉林九台人,博士, 从事铝合金晶粒细化及超塑性研究;电话: 0731-88830265;E-mail: yelingying_1981@163.com