文章编号:1004-0609(2013)08-2125-08

5A90铝锂合金超塑变形的不均匀性及其对空洞演化的影响

赵 莎1, 2,叶凌英1, 2,张新明1, 2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083)

摘 要:在475 ℃、初始应变速率为3×10-4~1×10-3 s-1的变形条件下对5A90铝锂合金试样进行拉伸,研究合金超塑变形的应变分布以及其对空洞演化的影响。结果表明:合金超塑变形是不均匀的,应变和空洞沿着拉伸方向呈梯度分布。应变量、空洞的尺寸与体积分数由肩部到断口逐渐增大。在不同的应变速率条件下,空洞的长大机制不同。在较高的应变速率(1×10-3 s-1)条件下,空洞以塑性控制长大为主。降低应变速率至8×10-4 s-1以下时,空洞以扩散长大机制为主。而在同一局部应变区域,横截面与纵截面空洞长大机制也不同,横截面空洞呈球状,为扩散控制的长大机制;纵截面空洞呈不规则状,且沿拉伸方向被拉长,为塑性控制的长大机制。

关键词:5A90铝锂合金;超塑性;局部应变;空洞

中图分类号:TG166.3 文献标志码:A

Inhomogeneity of 5A90 Al-Li alloy during superplastic deformation and its effect on evolution of cavity

ZHAO Sha1, 2, YE Ling-ying1, 2, ZHANG Xin-ming1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metals Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China)

Abstract: The local strain distribution during superplastic deformation of 5A90 Al-Li alloy and its effect on the evolution of cavity were studied through uniaxial tension at constant temperature of 475 ℃ and different initial strain rates of 3×10-4-1×10-3 s-1. The results demonstrate that the deformation of alloy is inhomogeneity, the strain and cavity remains non-uniform throughout the gauge. The strain, cavity size and volume fraction were found to increase from the shoulder section to the fracture tip. The cavity growth is different under different initial strain rates. In the case of high strain rate (1×10-3 s-1), the cavity growth is controlled by plastic deformation, and reducing the strain rate to 8×10-4 s-1, the cavity growth is controlled by diffusional process. And in the region with same local strain, the cavity growth mechanism in longitudinal section is different from transverse section. The transverse section with spherical is controlled by diffusional process cavity, while the same longitudinal section with elongated cavity is controlled by plastic deformation.

Key words: Al-Li 5A90 alloy; superplacticity; local strain; cavity

空洞是超塑性变形过程中普遍存在的一种组织形态,一定数量的空洞呈细小而分散状独立存在时,对晶界的滑动是有利的。但当空洞的体积分数与尺寸达到一定程度会限制材料的变形能力[1],导致材料发生断裂。因而,空洞的形核及演变规律对超塑性理论的研究具有重要作用,引起研究者的广泛关注。

超塑性变形可以从两种截然不同的组织开始,或以完全再结晶的细小等轴晶粒开始,或以变形组织开始[1]。一般来讲,空洞易于在第二相或者较大的晶粒处形核长大。近年来,有关空洞的研究更加的精细。BAE等[2-4]通过改变初始的变形条件,研究Al-Mg合金超塑性变形过程中空洞的早期萌生规律及变形机制,并对这一过程进行一定的模拟计算;DU等[5]研究发现,空洞的扩散对Al合金Σ3晶界滑动有强化作用。KAWASAKI等[6]和FIGUEIREDO等[7]通过对材料进行不同道次的等通角挤压变形,得到不同初始状态的细晶组织,研究不同状态的细晶组织对空洞在超塑性变形过程中的影响。而PANCHOLI等[8]对8090铝合金在超塑性变形条件下拉伸变形,发现拉伸试样沿标距的长度方向产生了明显的应变梯度分布,研究了这种应变局部化对材料微观组织发展的影响,并对空洞的分布做了定量分析。

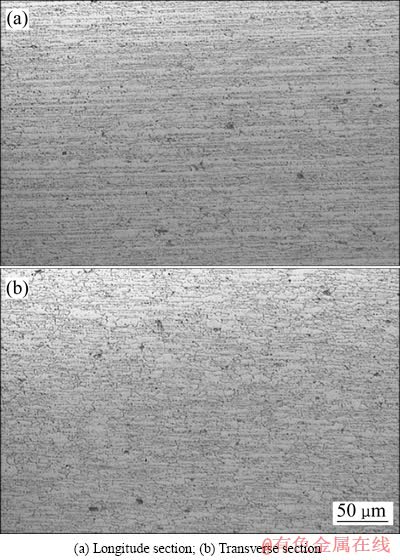

本文作者以5A90铝锂合金超塑性板材为研究对象,其原始晶粒组织中不仅有等轴的再结晶晶粒,而且有长条形的变形晶粒[9],且分布不均匀,如图1所示。具有这样组织的材料其在超塑性变形过程中空洞的发展鲜有报道。在此,本文作者主要研究这种非传统超塑性材料在不同初始应变速率下的局部应变分布特征及对空洞组织演变的影响,探索再结晶晶粒与长条形晶粒共存时的超塑性变形机制,以期丰富现有的超塑性变形过程中空洞的发展理论。

图1 5A90铝锂合金初始状态下的显微组织[1]

Fig. 1 Microstructures of 5A90Al-Li alloy at initial situation[1]

1 实验

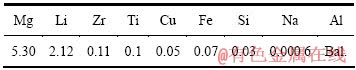

实验材料为按照本课题组建立的形变热处理工艺制备的2 mm厚5A90Al-Mg-Li合金超塑性板材[10],合金板材的实测化学成分如表1所列。

表1 5A90铝锂合金实测化学成分

Table 1 Chemical composition of 5A90 Al-Li alloy (mass fraction, %)

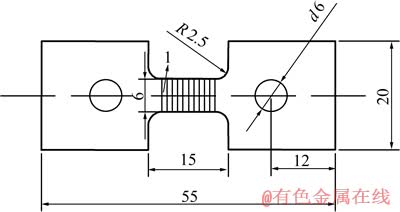

拉伸试样沿轧制方向截取加工而成,尺寸根据文献[10]的推荐,如图2所示。在RWS50拉伸实验机上进行,采用对开式三段电阻丝炉加热,恒温区长度为200 mm,温度波动范围为±1 ℃。

图2 超塑性拉伸试样形状和尺寸

Fig. 2 Shape and size of tensile specimen for superplasticity stretching (Unit: mm)

实验的拉伸温度为475 ℃,样品在2~3 min内升至测试温度,保温15 min后开始拉伸,初始应变速率分别为3×10-4 s-1、8×10-4 s-1和1×10-3 s-1,样品拉伸至断裂。在拉伸测试前,将拉伸试样10 mm长的标距部分每间隔1 mm划上刻线,将标距等分为10等份,测量相邻刻线间的局部应变及观察对应的空洞组织,探求不同初始应变速率下应变及微观组织沿标距长度方向的分布特征,如图2所示。

拉伸实验结束后,测量出平行区域被标记的10个区域变形后的尺寸,包括轧制方向、厚度和宽度3个尺寸,在标记的位置截取变形后的10个区域,从断口处到肩处开始依次做标记,为了更好地显示晶粒的形貌,将取下的试样进行475 ℃、0.5 h的固溶处理及170 ℃、13 h的时效处理。试样经机械抛光后,由混合酸(1%HF+4%HCl+4%HNO3+15%H2O,体积分数)腐蚀,然后在XJP-6A型光学显微镜下,取其横截面与纵截面进行观察,通过ImageJ测量每个空洞的尺寸,得到横截面和纵截面的平均空洞尺寸dT与dL以及平均体积分数fT与fL。

2 实验结果

2.1 局部应变分布

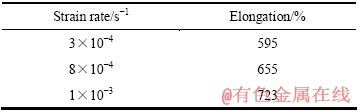

5A90铝锂合金在超塑性拉伸变形后,可以获得较大的超塑性伸长率。本实验在温度为475 ℃、通过改变初始应变速率,得到不同伸长率如表2所列。

表2 475 ℃时不同初始应变速率下5A90铝锂合金的伸长率

Table 2 Elongation of 5A90 Al-Li alloy deformed at 475 ℃ and different initial strain rates

在475 ℃、不同初始应变条件下拉伸断裂后,得到局部应变与标准化距离之间的关系,如图3所示。标准化距离通过将断裂后半个试样中刻线到端口处的距离除以此半个试样标距总长度而获得。由图3可知,离断口越近,局部应变越大,反之,离肩部越近,局部应变大幅度减少。如,在475 ℃、1×10-3 s-1的变形条件下进行拉伸时,试样总的伸长率只有723%,在靠近断口处局部应变达到1 200%~1 500%,在靠近肩部附近,局部应变仅有600%~800%。

2.2 局部应变对空洞的影响

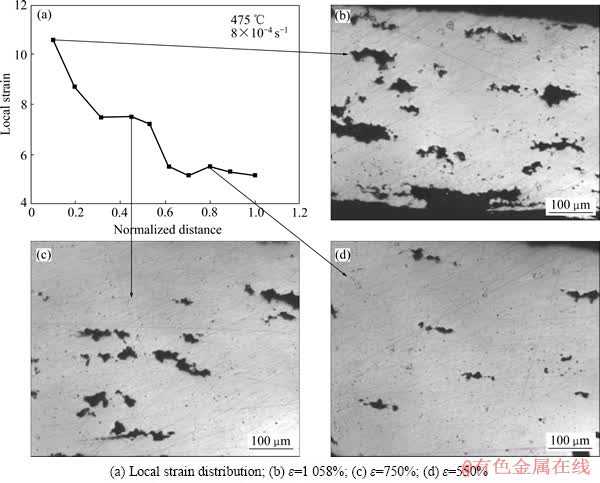

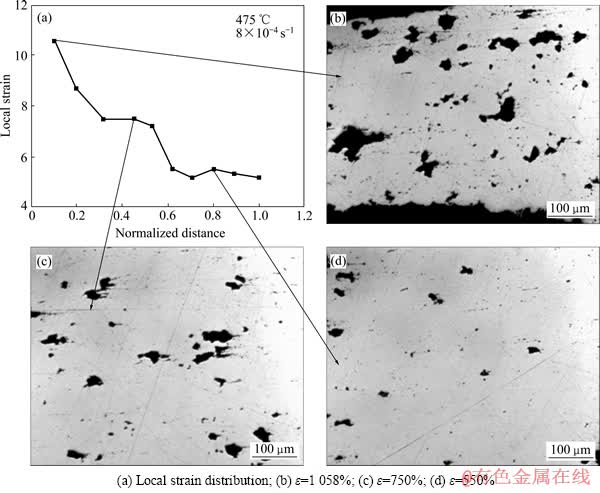

图4和5所示为475 ℃、8×10-4 s-1条件下的拉伸断裂试样不同区域的典型金相组织。从纵截面的金相组织可知(见图4),空洞沿着轧制方向长大的速度大于沿着板法向方向长大的速度,因而空洞出现了沿拉伸方向被拉长的宏观趋势,呈现长条状。而在同等条件下横截面金相组织(见图5)却得到了不一样的趋势,横截面的空洞趋向于球形,且分布也更加均匀。

图3 不同初始应变速率条件下5A90铝锂合金的局部应变与标准化距离之间的关系

Fig. 3 Relationship between local strain and normalized distance of 5A90 Al-Li alloy at different initial strain rates

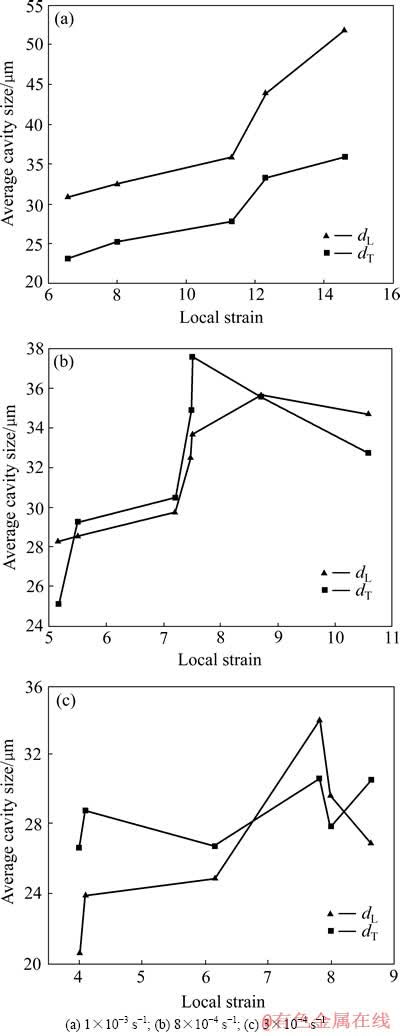

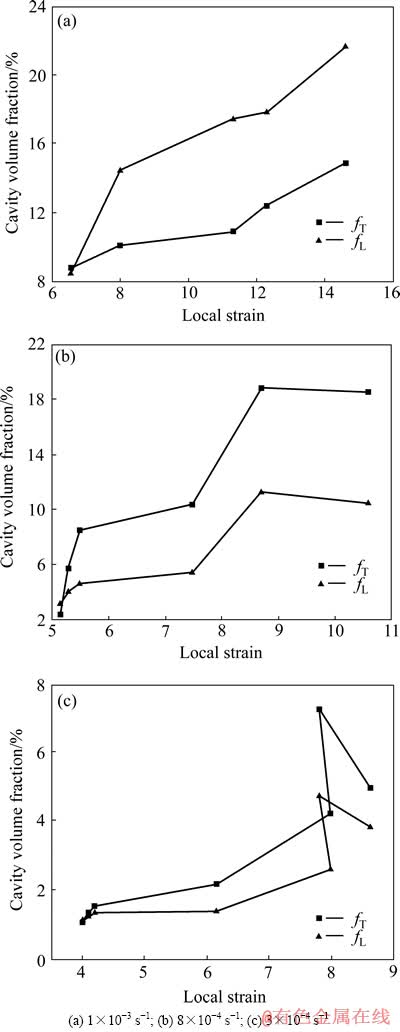

在475 ℃下改变初始的应变速度进行拉伸,得到平均空洞尺寸、体积分数与局部应变之间的关系如图6和7所示。随着局部应变的增大,空洞的尺寸与体积分数呈现上升增大的趋势。

图4 初始应变速率为8×10-4 s-1的条件下5A90铝锂合金局部应变的分布及纵截面的显微组织

Fig. 4 Local strain distribution and microstructures of longitudinal section of 5A90 Al-Li alloy deformed at initial strain rate of 8×10-4 s-1

图5 初始应变速率为8×10-4 s-1的条件下5A90铝锂合金局部应变的分布及横截面的显微组织

Fig. 5 Local strain distribution and microstructures of transverse section of 5A90 Al-Li alloy at initial strain rate of 8×10-4 s-1

在大的初始应变率条件下(1×10-3 s-1),纵截面空洞尺寸达到了50 μm,而降低初始应变速率至3×10-4 s-1时,纵截面最大的空洞尺寸才接近36 μm,如图6(a) 和6(c)所示。可见,应变速率影响空洞的长大。不仅如此,在大的初始应变速度条件下空洞纵截面空洞尺寸dL大于横截面的空洞尺寸dT,如图6(a)所示。随着初始应变速度的减小,开始呈现相反的趋势,在初始应变速度为8×10-4 s-1、3×10-4 s-1时,随着局部应变的增加,横截面与纵截面的空洞尺寸大小出现交叉上升的趋势,如图6(b)和6(c)所示。

图6 不同初始应变速率条件下5A90铝锂合金局部应变与空洞平均尺寸的关系

Fig. 6 Relationship between local strain and average cavity size of 5A90 Al-Li alloy deformed at different initial strain rates

在同一初始应变速率下,对比横截面与纵截面的空洞体积分数fT、fL发现,只有在大的初始应变速度下,如1×10-3 s-1,纵截面的空洞体积分数fL大于横截面的空洞体积分数fT,且纵截面的空洞体积分数fL最大超过了20%,如图7(a)所示。而当初始应变速度减小后,如8×10-4 s-1、3×10-4 s-1,随着局部应变的增大,纵截面的空洞体积分数fL小于横截面的空洞体积分数fT,如图7(b)和7(c)所示。

图7 不同初始应变速率条件下5A90铝锂合金局部应变与空洞体积分数的关系

Fig. 7 Relationship between local strain and cavity volume fraction of 5A90 Al-Li alloy deformed at different initial strain rates

3 分析与讨论

3.1 局部应变分布

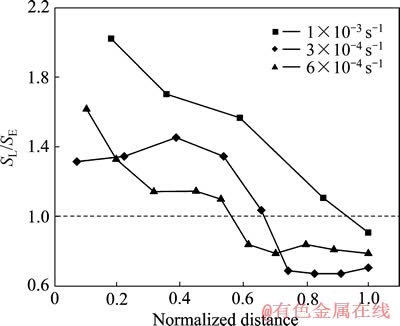

组织超塑性材料因其具有较高的应变敏感性指数m[11],从而在超塑性变形阶段可以抵抗材料的颈缩,获得大的伸长率。但应变敏感性指数m值通常小于1,这样当超塑性变形量较大时,不可避免地将沿拉伸试样长度方向产生应变的梯度分布,即拉伸试样中间部位的局部应变较大,而靠近肩部区域的局部应变较小,如图3所示。将变形断裂后一半试样的局部应变(Local strain, SL)除以该试样总的工程应变(Engineering strain, SE),并将该值与标准化距离的关系绘制成如图8所示的曲线图,便可以清楚地显示出应变沿标距长度方向分布的不均匀性。

由文献[12-13]报道可知,在变形的初始阶段,局部应变沿着变形区域分布是均匀的。而本次实验中,在475 ℃,通过改变初始应变速率将试样拉断后,得到的结果如图3和8所示,局部应变沿拉伸阶段呈梯度分布。由图8可知,随着标准化距离的增大,SL/SE的值不断减小,在标准化距离小于0.6的区域,SL/SE>1,这主要是由于这些区域大的局部应变和比较多的空洞所致。在标准化距离大于0.6的靠近样品肩部区域,SL/SE<1,这主要是由于肩部的存在限制了这些区域的变形及部分肩部的金属流动到这些区域。这种应变分布不均匀本身易在材料内部引起空洞现象。

图8 不同的初始应变速率条件下5A90铝锂合金局部应变(SL)与总的工程应变(SE)之比与标准化距离之间的关系

Fig. 8 Relationship between ratio of local strain to total engineering strain (SL/SE) and normalized distance of 5A90 Al-Li alloy deformed at different initial strain rates

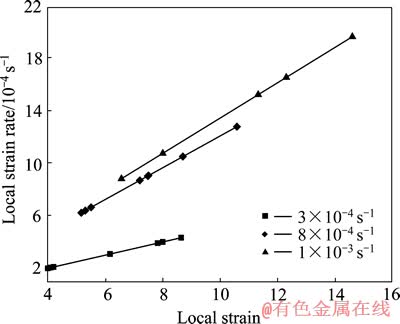

局部应变量的梯度分布,导致试样实际应变速率也成梯度分布。因而可以得到不同初始应变速率条件下各局部应变区域对应的实际局部应变速率,如图9所示。在不同的初始应变速率条件下,接近断口处(局部应变最大)的局部应变速率大于肩口处的局部应变速率,且大于变形的初始应变速率。如图9中,初始应变速率为1×10-3 s-1时,在接近断口处,即局部应变最大时,其实际的局部应变速率高达2×10-3 s-1。因而,475 ℃下,合金在不同的初始应变速率下进行拉伸时,局部应变与实际局部应变率均沿拉伸方向呈梯度分布。

图9 不同的初始应变速率条件下5A90铝锂合金通过计算(局部应变除以时间)得到的局部应变率

Fig. 9 Variation of local strain rate (calculated on basis of rate and time elapsed in testing) with local strain of 5A90 Al-Li alloy deformed at different initial strain rates

3.2 局部应变分布对空洞演化的影响

从图6和7可知,随着局部应变的增大,空洞的体积分数、尺寸随之增大,由此可见,空洞的长大与应变呈依存关系。这与MILLER等[14]的研究有着相似的结果。在超塑性变形的初始阶段,在局部应变速率较高的区域,应力会在三叉晶界及与第二相晶界处产生较多的集中,为释放这些应力集中,空洞易于在此成核。由于5A90铝锂合金超塑变形存在应变局部化的特点,导致在接近断口处,局部应变量与晶粒尺寸增大[10],而空洞本身易于在相对粗大的晶粒出形成。与此同时,如图9所示,断口处的局部应变速率很高,5A90铝锂合金高的应变速率敏感性使此处的流动应力增大,从而降低可以长大空洞的临界尺寸,为空洞的形核与长大提供了有利的条件。随着变形的进行,在塑形变形的最后阶段,空洞除了本身的尺寸增大外,还可以通过聚合或者连接汇集成大的空洞,如图4和5所示,个别空洞通过聚合或连接汇集成较大的空洞,在纵截面尺寸高达90 μm,最后断裂。在这些条件的共同作用下,在局部应变大的区域(局部应变速率较 高)空洞的尺寸和体积分数都较大。

一般认为超塑性变形过程中空洞长大的机制有两种:一种是应力促进空洞沿晶界扩散的长大机制;另一种是空洞周围材料的塑性变形引起空洞长大的机制[15]。空洞的长大机制与空洞的尺寸以及应变速率也有很大的关系。在空洞尺寸小且应变速率小的条件下,空洞以扩散长大机制为主,而在空洞尺寸大,应变速率较大时,空洞主要为塑性变形控制的长大机制[14, 16]。在同一局部应变处,样品的横截面垂直于拉伸轴方向,无应力作用,空洞主要为扩散控制的长大机制,因而在截面上的空洞大多数具有球形的形貌,如图5所示。而样品的纵截面受应力作用,空洞主要为塑性变形控制的长大机制,空洞主要具有不规则的形貌,一般沿拉伸方向伸长,如图4所示。当初始应变速率为1×10-3 s-1,局部的实际应变率也较大(如图9),空洞的长大机制以塑形变形控制为主,存在较大的流变应力,各局部应变区域的塑性流动方向朝着RD方向。而样品横截面仍然是扩散控制的空洞长大机制,因而在在同一局部应变区域,横截面的空洞尺寸小于纵截面的空洞尺寸,如图6(a)所示。降低样品的初始应变速率 (3×10-4 s-1和8×10-4 s-1) 后,空洞以扩散控制的长大机制为主,只有在靠近试样断口处,由于局部应变和应变速率都较高,应力较大,塑性变形控制的空洞长大机制才占了主导地位,使靠近试样断口局部应变区域纵截面的空洞尺寸要略大于横截面的,如图6(b)和(c)所示。

4 结论

1) 5A90铝锂合金超塑性变形存在应变局部化的特点,靠近断口处应变量大,而靠近肩部处应变量小。在初始应变速率为1×10-3 s-1时,接近断口处的局部应变高达1 490%,而接近肩部处应变才650%。

2) 随着局部应变的增大,空洞的尺寸与体积分数也增大。改变初始的应变速率,在同一局部应变区域,对比横纵截面空洞形貌,横截面空洞主要呈现球形状且分布均匀,以扩散控制长大为主;纵截面空洞呈现条状且不规则,以塑形变形控制长大为主。

3) 在不同的初始应变速率条件下,其实际的应变速率沿拉伸长度方向呈梯度分布。在较大的应变速率条件下(1×10-3 s-1),其实际应变速率最高达2×10-3 s-1,空洞以塑形变形控制为主要的长大机制,在此条件下,所有应变区域横截面的空洞尺寸与体积分数小于纵截面的。而当应变速率降低(3×10-4 s-1和8×10-4 s-1)时,只有接近断口处其实际应变速率才较大,空洞的长大机制以扩散控制为主,且在这些某些区域,样品纵截面的空洞尺寸与体积分数才大于横截面的。

REFERENCES

[1] 叶凌英. 细晶铝锂合金板材的制备原理、技术及超塑性变形行为[D]. 长沙: 中南大学, 2010: 23-25.

YE Ling-ying. Fine grain aluminum alloy sheet preparation principle, technology and superplastic deformation behavior[D]. Changsha: Central South University, 2010: 23-25.

[2] BAE D H, GHOSH A K. Cavity growth during superplastic flow in an Al-Mg alloy: Ⅰ. Experimental study[J]. Acta Materialia, 2002, 50(5): 993-1009.

[3] BAE D H, GHOSH A K. Cavity formation and early growth in a superplastic Al-Mg alloy[J]. Acta Materialia, 2002, 50(3): 511-523.

[4] BAE D H, GHOSH A K. Cavity growth during superplastic flow in an Al-Mg alloy: Ⅱ. An improved plasticity based model[J]. Acta Materialia, 2002, 50(5): 1011-1029.

[5] DU Ning-ning, QI Yue, KRAJEWSKI P E, BOWER A F. Aluminum Σ3 grain boundary sliding enhanced by vacancy diffusion[J]. Acta Materialia, 2010, 58(12): 4245-4252.

[6] KAWASAKI M, XU Cheng, LANGDON T G. An investigation of cavity growth in a superplastic aluminum alloy processed by ECAP[J]. Acta Materialia, 2005, 53(20): 5353-5364.

[7] FIGUEIREDO R B, TERZI S, LANGDON T G.. Using X-ray microtomography to evaluate cavity formation in a superplastic magnesium alloy processed by equal-channel angular pressing[J]. Acta Materialia, 2010, 58(17): 5737-5748

[8] PANCHOLI V, KASHYAP B P. Effect of local strain distribution on concurrent microstructural evolution during superplastic deformation of Al-Li 8090 alloy[J]. Materials Science and Engineering A, 2003, 351(1/2): 174-182.

[9] 郑大伟. 1420铝锂合金板材的超塑性变形行为及机理[D]. 长沙: 中南大学, 2010: 23-24.

ZHENG Da-wei. The superplastic deformatiom behavior and mechanism of 1420 Al-Li alloy[D]. Changsha: Central South University, 2010: 23-24.

[10] 吴诗惇. 金属超塑性变形理论[M]. 北京: 国际工业出版社, 1997: 102-104.

WU Shi-dun. The superplastic deformation theory of metal[M]. Beijing: International Industry Press, 1997: 102-104.

[11] 彭大暑. 金属塑性加工原理[M]. 长沙: 中南大学出版社, 2004: 162-165.

PENG Da-shu. Metal plastic processing principle[M]. Changsha: Central South University Press, 2004: 162-165.

[12] MOHAMED F A, LANGDON T G. Flow localization and neck formation in a superplastic metal[J]. Acta Metallurgica, 1981, 29(5): 911-920.

[13] WANG Z C, RIDLEY N, DAVIES T J. Simulation of cavity growth in ceramic materials during superplastic deformation[J]. Scripta Materialia, 1997, 36(5): 579-584.

[14] MILLER D A, LANGDON T G. A cavity growth diagram for high temperature creep[J]. Scripta Metallurgica, 1980, 14(2): 179-182.

[15] 陈浦泉. 组织超塑性[M]. 哈尔滨: 哈尔滨工业大学出版社, 1988: 35-40.

CHEN Pu-quan. Organization superplastic[M]. Harbin: Harbin Institute of Technology Press, 1988: 34-40.

[16] CHOKSHI M J. A model for diffusional cavity growth in superplasticity[J]. Acta Materialia, 1987, 35(5): 1089-1101.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51205419)

收稿日期:2012-08-22;修订日期:2012-12-26

通信作者:叶凌英,讲师,博士;电话:13607435545;E-mail: 30575421@qq.com