文章编号:1004-0609(2015)-01-0049-09

分级电磁搅拌对半固态Al-Cu合金凝固组织的影响

刘 政1,周翔宇2

(1. 江西理工大学 机电工程学院,赣州341000;

2. 江西理工大学 材料科学与工程学院,赣州341000)

摘 要:采用自制变频控制的电磁搅拌装置制备半固态ZL203铝合金浆料,分析不同搅拌时间和搅拌频率下初生α相的形貌和尺寸,研究在连续搅拌过程中变换频率对合金熔体进行分级搅拌的影响。结果表明:分级搅拌可以有效地改善半固态合金浆料的质量;适合于半固态ZL203合金的分级电磁搅拌工艺如下:ZL203合金经670 ℃浇注后,先在40 Hz的频率下搅拌5 s,再在30 Hz的频率下搅拌10 s,并于620 ℃温度下保温5 min。经此工艺制备的半固态ZL203合金铸锭具有较好质量:其中心部区域晶粒平均等积圆直径为85.62 μm,平均形状因子为0.86;边缘区域晶粒的平均等积圆直径为84.52 μm,平均形状因子达到0.85。

关键词:ZL203铝合金;半固态;分级搅拌;Lorenz力

中图分类号:TG146;TG244 文献标志码:A

Effects of stepped electromagnetic stirring on solidification microstructure in semisolid Al-Cu alloy

LIU Zheng1, ZHOU Xiang-yu2

(1. School of Mechanical and Electrical Engineering,

Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. School of Materials Science and Engineering,

Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: The semisolid ZL203 alloy slurry was prepared by a self-made electromagnetic stirring unit with frequency conversion. The morphology and size of primary α(Al) phase were analyzed under different stirring times and frequencies, and the effect of stepped stirring on the melt was researched by changing the frequency during continuous stirring. The results indicate that the quality of semisolid alloy slurry is effectively improved by stepped stirring, and the suitable technology of stepped stirring for semisolid ZL203 alloy is obtained as follows: ZL203 alloy poured at 670 ℃, and stirred at 40 Hz for 5 s, then at 30 Hz for 10 s, and isothermally held at 620 ℃ for 5 min, finally. The quality of semisolid ZL203 alloy ingot is relatively high, in which the average equal-area-circle grain diameter and average morphology factor of primary α phase at the central and edge position are 85.62, 84.52 μm and 0.86, 0.85, respectively.

Key words: ZL203 alloy; semisolid; stepped stirring; Lorenz force

半固态技术作为本世纪最具潜力的一种新加工技术,具有节约能源/材料的特点,应用前景广阔[1-4]。该技术制备的金属材料制品具有较高的成形精度和良好的力学性能。电磁铸造工艺是金属半固态加工中常见的工艺之一[5],该工艺是将液态金属从液相区冷却到固-液两相区后,对其液态和固态混合熔体进行充分的电磁搅拌,获得具有一定固相体积分数、并呈球状形貌的半固态合金浆料后,直接进行压铸的成形方法[6]。

目前,关于电磁搅拌细化晶粒的报道已经很多,相关研究表明[7-9],合适的电磁搅拌参数可以明显地细化合金的微观组织,得到近球状的等轴晶。但是大部分研究主要集中在连续的电磁搅拌对凝固组织的影响,并没有详细地说明电磁搅拌在熔体凝固的初期、中期和后期对组织的影响。相关研究表明,一定的电磁搅拌强度可以很好地细化晶粒,熔体在电磁搅拌情况下受到电磁力的作用,电磁力起到了加快散热、破碎枝晶的作用,但是过高或过低的磁场强度都不利于晶粒更好地细化[10]。部分学者认为[11],磁场强度过大,在金属熔体中产生的感生电流也过大,由此产生过多的焦耳热,因此,过冷度减小,晶粒粗化[11]。ZHANG等[12]对电磁搅拌过程中的电磁场、流场和温度场进行了数值模拟,认为熔体在电磁搅拌过程中的电磁场、温度场和流场的分布是不断变化的,但并未进行实验验证和电磁搅拌工艺的优化。为了探究在电磁搅拌过程中电磁力对熔体的作用机理,本文作者采用ZL203铝合金,在铝合金凝固过程中施加频率大小变化的电磁场,探讨电磁搅拌过程中电磁场在不同阶段对熔体的影响,从而根据此特性来进一步优化电磁搅拌工艺。

1 实验

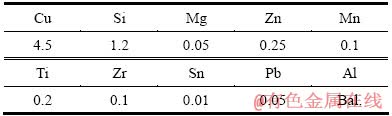

实验所用ZL203合金经Magix(PW2424)X荧光光谱分析,其成分如表1所列。

表1 试验用ZL203合金成分

Table 1 Composition of ZL203 alloy in test (mass fraction, %)

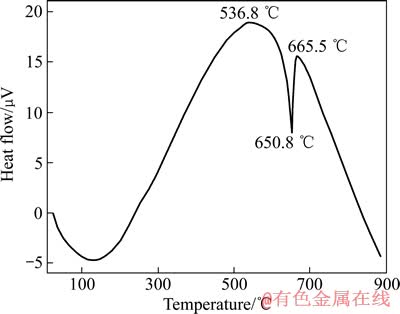

应用差热分析法(Differential thermal analysis,DTA)测定了ZL203铝合金液相线和固相线温度,其结果如图1所示。ZL203合金在536.8 ℃开始出现吸热峰,该温度对应合金的固相线温度,在650.8 ℃处的DTA曲线吸热峰消失,并迅速回升,即该温度对应合金的液相线温度,则合金固液两相区间的温度范围为536.8~650.8 ℃。将ZL203合金加热到约720 ℃使其熔化,在合金彻底熔化后进行扒渣、除气,随后降温至670 ℃,将液态合金浇注到d 55 mm×100 mm,壁厚2.0 mm的不锈铸模中(铸模预先加热到360 ℃)。将液态合金在不同电磁频率下(20、30和40 Hz)搅拌不同时间(10、15和20 s);搅拌结束后迅速转移至保温炉中进行等温保温处理(保温温度620 ℃、保温时间5 min),保温温度比液相线温度低约30 ℃,目的是使熔体处于明显过冷状态,从而形成大量游离态的颗粒状初生α(Al)相,而且能够保证溶质具有充分的时间来进行扩散和热传导,从而使得固-液界面前沿的溶质和温度均匀分布,为晶核生长成粒状组织提供有利的条件[13]。保温结束后,立即取出对其进行水淬。在各试样同一高度处分别截取出10 mm厚的圆柱片,从中取出一个经过圆心的扇形块,采用作金相试样。金相试样经预磨、粗磨、精磨和抛光后,采用0.5%HF(质量分数)水溶液进行显微组织腐蚀,并在金相显微镜下观察,确保晶界清晰。使用ZEISS Axioskop2型光学显微镜,拍取金相照片,再用Image-Pro-Plus软件计算初生α相的平均等积圆直径和平均形状因子,具体计算公式如下:平均等积圆直径D=2(A/π)1/2,平均形状因子F=4πA/L2。式中:A为晶粒面积,L为晶粒周长。D值越小表示晶粒越小,F值越接近1表示晶粒越圆整,晶粒越理想。

图1 ZL203铝合金的DTA曲线

Fig. 1 DTA curve of ZL203 Al alloy

2 实验结果

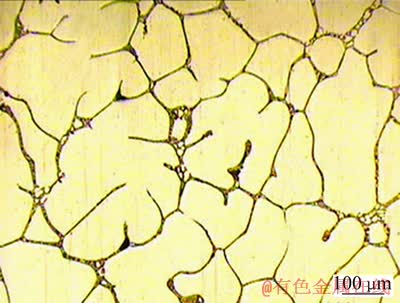

为探讨电磁搅拌对ZL203铝合金初生α相的影响,将未经电磁搅拌处理的合金直接在620 ℃保温5 min后水淬,其铸态组织如图2所示。由图2可见,初生α相呈现为发达的枝晶,枝晶臂也较粗大,晶粒大小不均匀,且圆整度较低,晶粒的平均等积圆直径为137.64 μm,平均形状因子仅为0.60。

图2 未经电磁搅拌的ZL203合金的初生α相形貌

Fig. 2 Morphology of primary α phase in ZL203 alloy without electromagnetic stirring

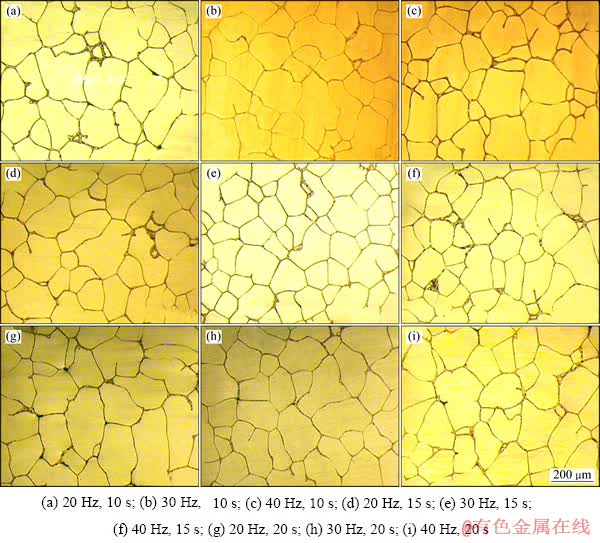

图3所示为经不同电磁搅拌参数搅拌后的ZL203合金初生α相的形貌。对比图2结果可知,经电磁搅拌后,合金得到明显细化,初生α相中几乎不出现树枝晶,但保留了极少数的蔷薇状晶粒。

2.1 搅拌频率对合金组织形貌的影响

对于在磁场B中以速度ν运动的导体来说,存在一感生电动势,故欧姆定律的形式为:J=σe(E+ν×B),σe为材料的电导率,J为电流密度,E为电场强度。所以,电磁力(洛伦兹力(Lorentz)力)可表示为

F=J×B=σe(E+ν×B)×B (1)

在交变磁场B作用下,根据法拉第电磁感应定律,处在螺线管线圈内的熔融金属感生了一个感应电动势ε,并且有

(2)

(2)

式中:S为样品的横截面面积,N为线圈匝数,t为时间。设熔融金属的电阻R一定,交变磁场在金属熔体中产生感应电流I,并且有

(3)

(3)

式中:f为磁场频率,根据式(1)和(3)得出:|F|=J×B∝IB∝B2f。可以看出,频率f越大,金属所受洛仑兹力F增大,从而金属熔体所受的电磁振荡作用加强。

图3 不同电磁搅拌参数下ZL203合金的初生α相形貌

Fig. 3 Morphologies of primary α phase in ZL203 alloy stirred by different electromagnetic parameters

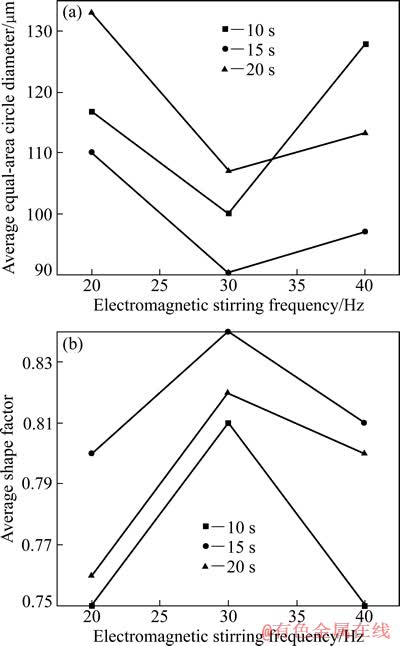

图3所示为相同搅拌时间下搅拌频率对晶粒形貌的影响。由图3可以看出,在同一搅拌时间的条件下,相比较搅拌频率为20和40 Hz时的晶粒,搅拌频率为30 Hz时的晶粒明显得到细化,圆整度得到提升,粗大枝晶消失,晶粒变得更加细小。例如在电磁搅拌时间为10 s的情况下,搅拌频率为20 Hz时,合金组织存在少量枝晶,但晶粒粗大,形状很不规则,平均等积圆直径和平均形状因子分别为116.82 μm和0.75。当频率升高到30 Hz时,各晶粒趋于等轴化,晶粒变小,枝晶数量明显减少,平均等积圆直径和平均形状因子为100.15 μm和0.81。当频率继续升到40 Hz时,晶粒反而变得粗大,出现少量枝晶组织,形状很不规则,平均等积圆直径和平均形状因子分别为127.96 μm和0.75。同样,通过对图3中电磁搅拌时间分别为15和20 s的情况进行分析与探讨,也能得出搅拌频率为30 Hz的组织形貌要优于20 Hz和40 Hz的组织形貌。图4所示为ZL203合金初生α相的平均等积圆直径和平均形状因子随电磁搅拌频率增加的变化趋势图,从图4可直观地看出,电磁搅拌频率为30 Hz时,晶粒的平均等积圆直径最小,平均形状因子最大,从而得出电磁搅拌频率为30 Hz时的合金晶粒尺寸和组织形貌最佳。

图4 电磁搅拌频率对ZL203合金初生α相的平均等积圆直径和平均形状因子的影响

Fig. 4 Effects of electromagnetic stirring frequency on average equal-area circle diameter (a) and shape factor of α-Al phase (b) in ZL203 alloy

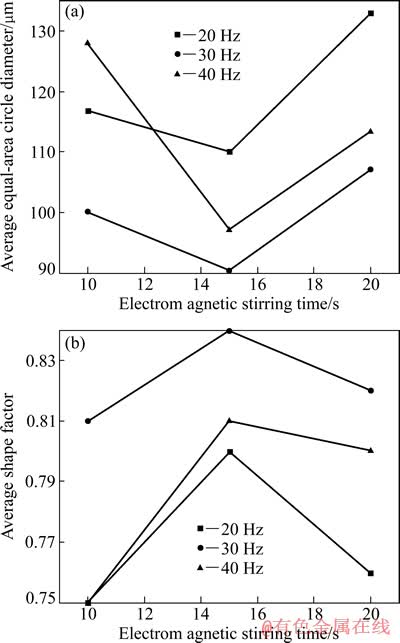

2.2 搅拌时间对合金组织形貌的影响

此外,图3还反映了在同一搅拌频率下搅拌时间对合金组织形貌的影响。由图3可以看出,在搅拌频率相同的情况下,搅拌时间为15 s时的晶粒形貌较搅拌时间为10和20 s的晶粒形貌更佳,晶粒得到了一定程度的细化。例如,当搅拌频率为20 Hz时,搅拌10和20 s的合金初生α相较搅拌15 s的合金初生α相粗大,部分呈条状,形状不规则;搅拌10 s的初生α相平均等积圆直径和平均形状因子分别为116.82 μm和0.75;搅拌20 s的初生α相平均等积圆直径和平均形状因子分别为133.06 μm和0.76;而搅拌时间为15 s时,大部分粗大的晶粒变为细小的等轴晶,条形晶粒数量明显减少,平均等积圆直径和平均形状因子分别为110.16 μm和0.80,晶粒得到了很好的细化,而且圆整度也得到了提高。同样地,通过对另外两列搅拌频率分别为30和40 Hz的情况进行了分析比较,也能够得出搅拌时间为15 s较为理想。图5所示为ZL203合金初生α相的平均等积圆直径和平均形状因子随电磁搅拌时间增加的变化趋势图,从图5可直观地看出,搅拌时间为15 s时晶粒的平均等积圆直径最小,平均形状因子最大,从而得出电磁搅拌15 s的合金晶粒尺寸和组织形貌最佳。

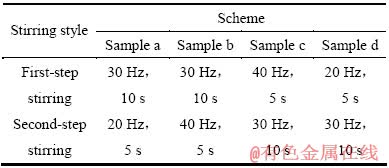

通过以上研究可以发现,在连续搅拌的情况下,搅拌功率和搅拌时间分别为30 Hz和15 s时(试样e,作为与分级电磁搅拌的对比试样),合金初生α相的形貌和尺寸最理想,合金得到一定的细化,其平均等积圆直径和平均形状因子分别为90.38 μm和0.84。虽然连续搅拌可以很好地细化晶粒,但是在电磁搅拌过程中,电磁力对熔体的作用是在不断变化的,连续搅拌结论只能笼统地概括电磁搅拌效果,并不能清晰地说明不同时期的搅拌对熔体的影响。所以为了进一步探究电磁搅拌细化机理,优化搅拌工艺,在此最佳连续搅拌工艺的基础上进行分级电磁搅拌实验,即在搅拌总时间不变的条件下,搅拌过程中改变搅拌频率的工艺手段。为了更好地进行比较,总时间选择为15 s,频率变化区间为20~40 Hz,具体工艺参数如表2所列。

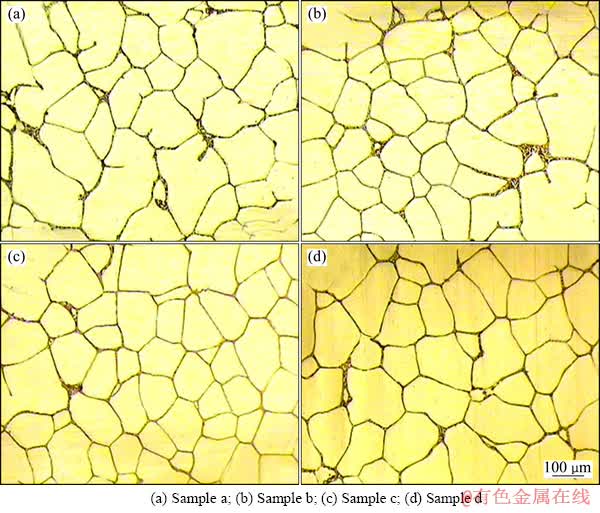

取试样中心和边部位置作为研究试样,将试样经粗磨、细磨、抛光后,用0.5%HF腐蚀晶界,在金相显微镜下观察。图6所示为经过分级搅拌后的合金中心部位的微观组织形貌,并与上述实验最佳工艺制取的对比试样e的中心部位作比较。可以看出,试样a的初生α相形貌和尺寸呈现粗化的现象,枝晶变得粗大,晶粒不规则,平均等积圆直径升高到108.84 μm,而平均形状因子降为0.76。试样b和d中初生α相的形貌和尺寸变化较对比试样e的小,只出现轻度的粗化,平均等积圆直径分别为97.36和94.82 μm,平均形状因子分别为0.81和0.80。而试样c的晶粒得到了一定程度的细化,球状晶粒占组织的大部分,枝晶基本消失,平均等积圆直径降到了85.62 μm,平均形状因子达到了0.86。

图5 电磁搅拌时间对ZL203合金初生α(Al)相的平均等积圆直径和平均形状因子的影响

Fig. 5 Effect of electromagnetic stirring time on average equal-area circle diameter (a) and shape factor of α(Al) phase (b) in ZL203 alloy

表2 分级电磁搅拌方案

Table 2 Scheme of stepped electromagnetic stirring

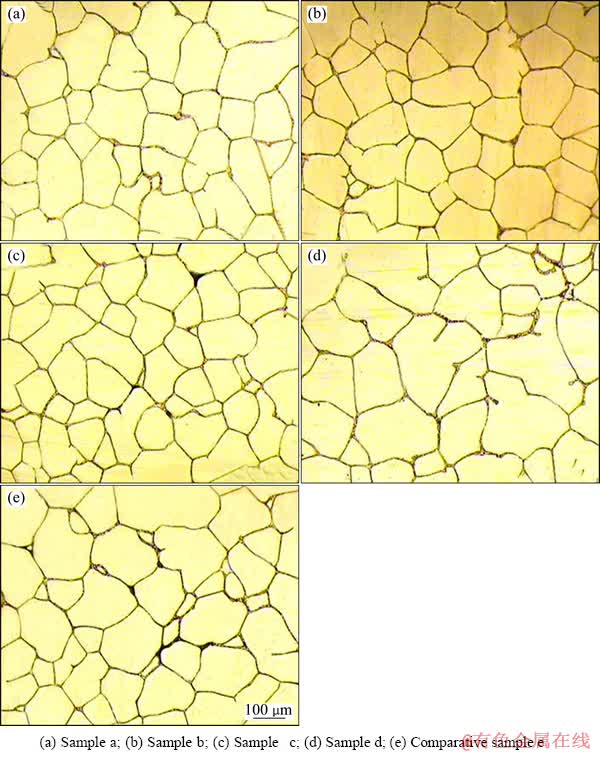

图7所示为对比试样e和分级搅拌下合金边缘部位的组织形貌。由图7可知,试样边缘部分组织形貌的粗化现象较中心部位的更细微(见图7(e)),其平均等积圆直径和平均形状因子分别为98.15 μm和0.83。通过比较,试样d的晶粒较对比试样e粗化严重、枝晶增多,而且晶粒变得细长。而试样c得到了明显的细化,晶粒变小且大小均匀,平均等积圆直径降到了84.52 μm,平均形状因子为0.85。试样a和试样b较对比试样的变化更小,等积圆直径和平均形状因子变化很小。

图6 分级电磁搅拌ZL203合金中心部位的初生α相形貌

Fig. 6 Morphologies of primary α phase in central area of ZL203 alloy prepared by stepped electromagnetic stirring

图7 对比试样和分级电磁搅拌ZL203合金边缘部位的初生α相形貌

Fig. 7 Morphologies of primary α phase in edge area of comparative sample and ZL203 alloy prepared by stepped electromagnetic stirring

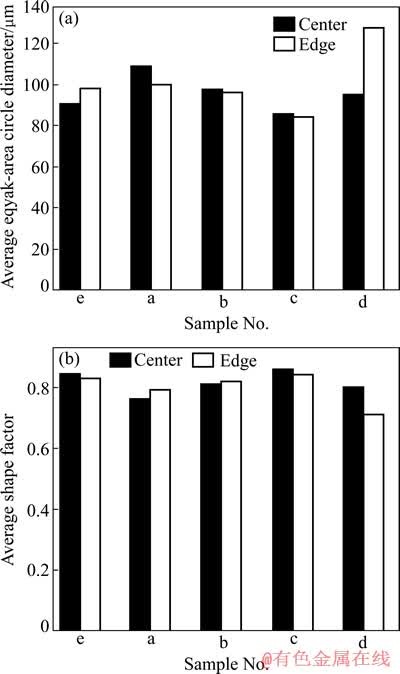

图8所示为经不同分级搅拌工艺的ZL203合金和对比试样中心部位和边缘部位初生α相的平均等积圆直径和平均形状因子。从图8可以看出,对于试样c,无论是中心部位还是边缘部位,其晶粒的平均等积圆直径最小,平均形状因子最大,所以形貌和尺寸最佳。

3 分析与讨论

综上所述,在连续电磁搅拌条件下,合适的电磁搅拌参数可以细化晶粒,使合金晶粒具有较好的微观组织形貌和尺寸,但是搅拌频率和搅拌时间过小或者过大都会使晶粒变得不均匀。而分级搅拌可以在搅拌过程中根据不同时间段来调整频率,使得晶粒形貌和尺寸进一步优化。电磁搅拌细化晶粒主要是通过破碎枝晶、均匀温度场等几方面来提高形核率,传统的连续电磁搅拌在破碎枝晶方面,只是笼统地说明了电磁力对枝晶生长有抑制作用,从而达到细化效果,但是在整个凝固过程中,电磁搅拌并不是一直在破碎枝晶,还伴随着其他作用,例如均匀温度场和溶质场、升高熔体温度等,且这些作用在不同时间段可能存在着主次之分。因此,还需要对电磁搅拌频率应该是先高后低好,还是先低后高好;或者是电磁搅拌频率高低变化时各阶段时间应该如何控制的问题进行更深入地探究。所以,在此就分级搅拌在搅拌频率和搅拌时间的控制方面和传统电磁搅拌做出对比,从而更加详细地显示出分级搅拌的优势。

图8 分级搅拌工艺下ZL203合金中心和边缘部位初生α相平均等积圆直径和平均形状因子

Fig. 8 Average equal-area circle diameter (a) and shape factor (b) of α phase in central and edge of comparative sample and ZL203 alloy prepared by stepped electromagnetic stirring

3.1 电磁搅拌过程中频率的控制

当金属熔液浇入铸型后,由于激冷效应,首先会在型壁上面优先形核,然后这些晶粒沿着热流的相反方向以枝晶的方式向熔体内部生长。此时施加电磁场,熔体受到电磁力的作用,电磁力使得熔体产生强制对流,初生固相颗粒裹在熔体中便随之流动[14]。当液相在流动时产生的作用于固-液界面上的切应力超过枝晶臂的剪切强度,或者流体作用于枝晶臂上的弯曲应力超过其抗弯强度时,可以使得枝晶臂发生断裂[15]。另外,当型壁上的晶粒以枝晶的方式朝内生长时,由于要排除溶质,而液相的强迫流动难以将紧靠型壁处或枝晶根部处这些角落处的溶质原子冲刷出来,因此,这些位置的溶质均匀化条件最差,容易造成溶质富集而导致枝晶臂产生缩颈,在液流的冲刷下极易熔断。这些被打碎和熔断的枝晶臂碎片被对流带到熔体的心部成为了等轴晶的异质形核核心,同时也破坏了熔体中原子团的有序排列, 抑制了原子的团聚,从而使熔体形成更多的形核质心[16]。根据SPITZER等[17]旋转电磁场下电磁力的计算公式,可以进一步推出对熔体施加旋转电磁搅拌时凝固前沿处的电磁力为

(4)

(4)

式中:p为磁极对数;f为搅拌器的供电频率;σ为液态金属导电率;B0为熔体凝固前沿处的磁感应强度;r为凝固前沿处的液芯半径。不难发现,在同一电磁搅拌频率下,电磁力F随着半径r的增大而增大,再根据集肤效应:

(5)

(5)

式中:σ为熔体电导率;μ为导体的磁导率;f为电磁场频率。可以发现集肤深度和电磁场频率成反比,当电磁场频率较高时,电磁场的集肤深度很小,电磁力主要集中在熔体表面,金熔体中电磁力由外向内依次减小,这也导致流速在铝合金熔体边缘达到最大值,即从边缘到中心依次减小,在铝合金熔体中形成搅拌漩涡[12]。所以,在熔体刚浇入铸型后的短时间内施加高频率的电磁场可以很好地破碎和重熔正在从型壁朝熔体内部生长的枝晶,从而异质核心增多,这些游离晶随着熔体一同流动,并在低温下各自长成新的游离晶,增加了晶粒的数目[18],增大形核率。而当频率较低时,集肤深度较大,电磁力主要集中在熔体内部,熔体表面的电磁力大小不足以将树枝晶破碎,从而达不到明显的细化效果。所以在搅拌初期,搅拌的频率相对较高。

随着凝固的进行,枝晶基本被破碎和熔断,枝晶碎片被卷入熔体内部,固相逐渐增多,此时如果仍旧施加高频率的电磁搅拌,熔体边部并无过多枝晶可以用来破碎和熔断,而过剩的电磁力引起的局部高温可能会熔化之前破碎的枝晶碎片,降低异质形核核心数量,并且局部的高温会使得过冷度减小,对形核不利;如果此时适当降低电磁搅拌频率,集肤深度增大,电磁力主要集中在熔体内部,但是涡流电流会随着频率的减小而减小,导致搅拌力下降[19],而且随着凝固过程的进行和前期的电磁搅拌,金属熔体的温度逐渐降低,释放的结晶潜热减少,熔体黏度增加,流动速度减小,搅拌作用同样减弱,影响区域变小,并不会引起局部高温,而是只会起到均匀温度场的作用,使得各处温度基本上是均匀的,初生晶可在整个熔体内同时非均质形核。所以在搅拌的中后期,搅拌频率要相对降低。

3.2 电磁搅拌过程中时间的控制

在3.1节提到了电磁搅拌初期阶段的频率相对较高,而中后期频率相对较低,但是高频率和低频率的控制时间控制为多久,以下将就此问题进行讨论。从传热和传质方面分析,熔体在旋转磁场中流动时,伴随产生热效应,根据ROSENSWEIG的理论[20],粒子在旋转磁场中的功率损耗(P)可以表示为

(6)

(6)

式中:μ0为真空磁导率,x0为平衡磁化率,H0为磁场强度,f为旋转磁场的频率,t为弛豫时间。可见,随着频率f的增大,P也增大,若f过大,则将在熔体局部产生高温,从而导致熔体温度升高,使凝固体系的整体冷速降低,过冷度减小,这对形核不利[21];但是同时,搅拌作用使金属熔体产生水平旋转运动,有利于内外部高低温熔体的混合和熔体热量的释放,加速了熔体的散热。尤其是在凝固开始,熔体会释放出大量的结晶潜热,此时施加电磁搅拌的散热效果更明显,该过程降低了熔体内外部温度梯度,使温度场更均匀,延缓了坩埚壁附近熔体的冷却,同时加速了熔体内部和整体的温度降低,更有利于等轴晶的形成[7]。所以在此阶段,电磁搅拌对熔体存在双重作用,但是存在主次之分。根据实验结果可以发现,图6中试样c边部的晶粒比连续在30 Hz下搅拌15 s(见图3(e))的试样晶粒更细小,组织形貌更加均匀,这就说明前5 s的高频率搅拌对熔体主要起破碎枝晶和均匀温度场的作用,而使温度升高的作用在此阶段是次要的。所以,在搅拌初期时的高频率时间应该控制在5 s。

综上所述,电磁搅拌中后期的频率需降低,但并不是频率降得越低越好,因为晶体在形核后的生长过程中会排出溶质,如果频率降得过低,则不足以引起一定强度的液体流动来将排出的溶质带走。若频率大小适合,则会将这部分排出的溶质带走,使得熔体在凝固过程中的固液界面存在速度差,使由溶质二次分配建立的浓度边界层极薄, 引起的成分过冷度较小,从而使优势生长方向的生长速度受到限制, 导致非优势生长晶向与优势生长晶向的生长速度差变小,使晶粒按等轴方式生长成球状或椭球状晶体[22],有利于等轴晶的形成。而且,搅拌初期,破碎和熔断的枝晶碎片在进入熔体内部的过程中是以自旋运动的方式长大的,晶粒在液流中漂移时,要不断通过不同的温度区域和浓度区域,受到温度和成分波动的冲击,从而其表面处于反复局部熔化和生长的状态中。晶粒的突出生长部位由于曲率较大,具有较高的能量,如果此时施加磁场频率过高,则一些较小的形核质心被熔化,降低形核率;频率过低,则不能将晶粒凸出生长部位熔化,而且不足以将晶粒生长过程中排出的溶质带走,对等轴晶的形成不利;若频率适中,则可以使得晶粒处于一个均匀的温度场和溶质场中,凸出的生长部位被熔化,凹陷的部位由于浓度梯度而择优生长直至圆整。综上所述,中后期的电磁搅拌频率既不能过高,又不能降低过多,应保持一定的流体运动速度。所以在此实验中,图6中试样c的心部晶粒要比连续在40 Hz下搅拌15 s的试样(见图3(f))心部晶粒细小,也比连续在20 Hz下搅拌15 s的试样(见图3(d))心部晶粒细小,验证了此理论,也体现出分级搅拌的优势。故电磁搅拌中后期应当将搅拌频率稍微降低,时间控制在10 s。

综上所述,通过分析电磁搅拌过程中各阶段熔体的传热传质特征,发现分级电磁搅拌较传统的电磁搅拌具有一定优势,针对不同阶段的熔体特征,能够灵活地控制搅拌频率和搅拌时间,从而达到最佳搅拌效果。

4 结论

1) 电磁搅拌工艺可很好地细化ZL203合金,连续电磁搅拌时,在30 Hz的搅拌频率下搅拌15 s,并在620 ℃下保温5 min,其初生α相形貌和尺寸最佳,中心部位晶粒的平均等积圆直径和平均形状因子分别达到90.38 μm和0.84。

2) 分级电磁搅拌较连续电磁搅拌可以更进一步细化晶粒,最佳分级电磁搅拌方案为先在40 Hz下搅拌5 s,然后在30 Hz下搅拌10 s,其中心部位晶粒的平均等积圆直径和平均形状因子分别达到85.62 μm和0.86,边缘部位晶粒的平均等积圆直径和平均形状因子分别达到84.52 μm和0.85。

3) 熔体凝固初期施加较强频率电磁搅拌,凝固中后期稍微降低搅拌频率,可以得到较好的微观组织形貌和晶粒尺寸。

REFERENCES

[1] FAN Z. Semisolid metal processing[J]. International Materials Reviews, 2002, 47(2): 49-85.

[2] ATKINSON H V. Modelling the semisolid processing of metallic alloys[J]. Progress in Materials Science, 2005, 50(3): 341-412.

[3] WANG P, SHI L F, LU G M, CUI J Z. Microstructure and properties of ZL201 alloy obtained by near-liquids electromagnetic casting[J]. Acta Metallurgica Sinica, 2005, 18(5): 653-658.

[4] CHEN Z Z. Preparation ofsemi-solidA356 Al-alloyslurry by introducing grain process[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1307-1312.

[5] 于彦东, 章 龙, 李彩霞. 电磁搅拌对等通道挤压前后Mg-Zn-Ca-Zr合金组织和性能的影响[J]. 中国有色金属学报, 2014, 24(6): 1422-1427.

YU Yan-dong, ZHANG Long, LI Cai-xia. Effects of electromagnetic stirring on microstructure and properties of Mg-Zn-Ca-Zr alloy before and after equal channel angular pressing[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1422-1427.

[6] 左玉波, 赵志浩, 朱庆丰, 崔建忠. 低频电磁铸造细化铝合金组织的机理[J]. 中国有色金属学报, 2013, 23(1): 51-55.

ZUO Yu-bo, ZHAO Zhi-hao, ZHU Qing-feng, CUI Jian-zhong. Mechanism of grain refinement of aluminum alloy achieved by low frequency electromagnetic casting process[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 51-55.

[7] 陈兴润, 张志峰, 徐 骏, 石力开. 电磁搅拌法制备半固态浆料过程电磁场、流场和温度场的数值模拟[J]. 中国有色金属学报, 2010, 20(5): 937-945.

CHEN Xing-run, ZHANG Zhi-feng, XU Jun, SHI Li-kai. Numerical simulation of electromagnetic field, flow field and temperature field in semi-solid slurry preparation by electromagnetic stirring[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 937-945.

[8] GAO S Y, LE Q C, ZHANG Z Q, CUI J Z. Grain refinement of AZ31 magnesium alloy by electromagnetic stirring under effect of grain-refiner[J]. Bull Mater Sci, 2012, 35(4): 651-655.

[9] METAN V, EIGENFELD K. Controlling mechanical and physical properties of Al-Si alloys by controlling grain size through grain refinement and electromagnetic stirring[J]. The European Physical Journal Special Topics, 2013, 220(1): 139-150.

[10] NAFISI S, EMADI D, SHEHATA M T, GHOMASHCHI R. Effects of electromagnetic stirring and superheat on the microstructural characteristics of Al-Si-Fe alloy [J]. Mater Sci Eng A, 2006, 432: 71-83.

[11] BARMAN N, DUTTA P. Effect of process parameters on transport phenomena during solidification in the presence of electro- magnetic stirring[J]. Transactions of the Indian Institute of Metals, 2009, 62(4/5): 469-474.

[12] ZHANG Z F, CHEN X R, XU J, SHI L K. Numerical simulation on electromagnetic field, flow field and temperature field in semisolid slurry preparation by A-EMS[J]. Rare Metals, 2010, 29(6): 635-641.

[13] LIU Z, LIU X M. Characterization on primary phase morphology of semisolid A356 alloy during isothermal holding with fractal[J]. Key Engineering Materials, 2013, 531/532: 67-72.

[14] 张小立, 凌向军, 李廷举, 谢水生, 金云学. 电磁搅拌过程中镁合金半固态浆料初生相颗粒的团簇行为[J]. 中国有色金属学报, 2012, 22(9): 2448-2453.

ZHANG Xiao-li, LING Xiang-jun, LI Ting-ju, XIE Shui-sheng, JIN Yun-xue. Agglomerating behavior of primary solid particles in magnesium alloy semisolid slurry during electromagnetic stirring[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(9): 2448-2453.

[15] SHI H F, ZHANG W Q. Effects of electromagnetic stirring on microstructures of solidified aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(5): 1171-1174.

[16] LI C J, REN Z M, REN W L, WU Y Q. Nucleation and growth behaviors of primary phase in hypoeutectic Al-Cu alloy in high magnetic field[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S1): s1-s6.

[17] SPITZER K H, DUBKE M, SCHWERDTFEGER K. Rotational electromagnetic stirring in continuous casting of round strands[J]. Metallurgical Transactions B, 1986, 17(1): 119-131.

[18] CHEN Z, CHEN C L, WEN X L, ZHU J H, GAO W S. Effect of frequency and intensity of rotating magnetic field on the microstructures of Pb-Sn alloys[J]. Chinese Science Bulletin, 2008, 53(17): 2575-2581.

[19] 杨卯生, 赵爱民, 毛卫民, 高军芳, 钟雪友. 钢的半固态电磁搅拌力场与组织转变[J]. 钢铁研究学报, 2003, 15(4): 18-23.

YANG Mao-sheng, ZHAO Ai-min, MAO Wei-min, GAO Jun-fang, ZHONG Xue-you. Electromagnetic stirring force field and microstructure evolution of semi-solid stee1[J]. Journal of Iron and Steel Research, 2003, 15(4): 18-23.

[20] 陈 钊, 陈长乐, 温晓莉, 文 军. 旋转磁场对凝固组织形成的影响[J]. 物理学报, 2008, 57(10): 6277-6281.

CHEN Zhao, CHEN Chang-le, WEN Xiao-li, WEN Jun. Influence of rotating magnetic field on the formation of solidification microstructure[J]. Acta Physica Sinica, 2008, 57(10): 6277-6281.

[21] REN Z, ZHANG X G. Effect of middle-frequency electromagnetic field on the semi-continuous casting for ZK60 billets[J]. Journal of Wuhan University of Technology: Materials Science Edition, 2010, 25(3): 449-453.

[22] XU G J, WANG Z H, YIN J J, DING Y T, KOU S Z. Effect of rectangle wave pulse current on solidification structure of ZA27 alloy[J]. Journal of Wuhan University of Technology, 2006, 21(1):81-83.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51144009,51361012);江西省自然科学基金资助项目(20114bab206014,20142bab206012);科技落地计划资助项目(KJLD12070)

收稿日期:2014-05-25;修订日期:2014-09-11

通信作者:刘 政,教授,博士;电话:0797-8312428;E-mail:liukk66@163.com