文章编号:1004-0609(2011)08-1881-06

采用热焓平衡旋转磁场装置制备半固态浆料

张小立1, 2,李廷举3,谢水生4

(1. 江苏科技大学金属液态成形实验室,苏州 215600;

2. 江苏科技大学 材料科学与工程学院,镇江 212003;

3. 大连理工大学 材料科学与工程学院铸造工程中心,大连 116024;

4. 北京有色金属研究总院,北京 100088)

摘 要:在旋转磁场驱动金属液高速运动过程中,应用循环冷却水和金属液进行热交换控制金属液的热焓平衡生产A356铝合金半固态浆料,然后分别进行金属型和砂型浇铸,并对浆料在冷却过程中每隔5 min淬火取样浆料的平均冷却速度约为3 ℃/min。结果表明:热焓平衡旋转磁场装置作用下的金属液温度降至液固两相区内,瞬间产生大量均匀分布在金属液内的初生相α(Al)晶核,采用该方法制备的半固态浆料浇铸的铸件的微观组织呈现等轴球晶形貌,610℃时淬火试样的初生相晶粒平均直径为29 ?m,同时在缓慢冷却程中初生相α(Al)晶粒趋向于圆整并粗化。

关键词:半固态浆料;微观组织;热焓平衡;旋转磁场

中图分类号:TG 146.2; TG 249 文献标志码:A

Semisolid slurry produced using

enthalpy equilibrium rotating magnetic fields device

ZHANG Xiao-li1, 2, LI Ting-ju3, XIE Shui-sheng4

(1. Laboratory of Metal Liquid Forming, Jiangsu University of Science and Technology, Suzhou 215600, China;

2. School of Materials Science and Engineering, Jiangsu University of Science and Technology,

Zhenjiang 212003, China;

3. School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China;

4. Beijing General Research Institute for Non-ferrous Metals, Beijing 100088, China)

Abstract: The semisolid slurry of A356 aluminum alloy was prepared using an enthalpy equilibrium rotating magnetic fields device, in which the heat of molten alloy was exchanged using circulating cooling water when the alloy melt was rotating speedily, in order to control the enthalpy equilibrium process of alloy melt. Then the semisolid slurry was respectively poured into the sand mold and metal mold, furthermore, the quenched samples were prepared every 5 min during cooling with cooling rate of 3 ℃/min. The results indicate that the circumstance in the bulk liquid metal would burst into copious nucleation of primary α(Al) near liquidus temperature, and at the same time these primary nucleus distribute uniformly in the alloy melt. The microstructure of castings exhibits equiaxed characteristic morphology, the average diameter of primary α(Al) is 29 μm when quenched at 610 ℃. Meanwhile, the primary α(Al) particles trend to coarsen and spheroidize during slow cooling.

Key words: semisolid slurry; microstructure; enthalpy equilibrium; rotating magnetic fields

材料的微观结构是材料科学和工程的核心内 容,是材料加工和材料性能之间的关键纽带。因此,对材料在成形过程中微观结构的有效控制成为材料工作者的目标之一[1]。对于金属材料来说,凝固是最重要的成形途径。目前,优质铸件生产技术以净终成形、细晶化和成分均匀化等特点成为金属液态成形的主要研发内容[2-3]。半固态金属加工是其中之一,其核心是利用具有球形晶组织或者说触变性浆料在两相温度区间内实现优质铸件成形[4-7]。半固态流变成形工艺以 其工艺流程短、生产成本低以及循环再生性等优点成为半固态加工的发展方向,而获得理想的半固态供给浆料(Slurry on demand, SoD)是实现流变成形的前提条件[8]。

本文作者研究在旋转磁场驱动金属液高速流动过程中,应用循环冷却水和金属液进行热交换,控制其热焓平衡过程以获得优质半固态浆料的工艺;分析在液相线附近利用激冷促进大爆炸形核和控制金属液热量的流失来构建初生相晶核的存活环境,以及观察半固态浆料在缓慢冷却过程中初生相晶粒的生长形貌。

1 实验

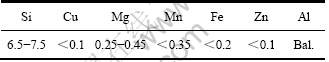

实验材料是在工业生产中广泛应用的A356 铝合金,化学成分如表1所列。A356合金的液、固相线温度分别为 614 ℃和557 ℃。

表1 A356铝合金的化学成分

Table 1 Chemical composition of A356 Al alloy (mass fraction, %)

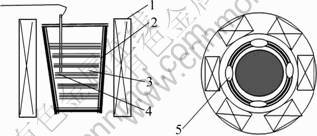

实验装置示意图如图1所示,由3部分组成:三相三极对绕组、功率为10 kW的旋转电磁场发生器;盛放金属液的坩埚,坩埚由间距为20 mm的内、外不锈钢板焊接而成,采用石棉填充作为保温层;焊合在内层坩埚壁上循环水管组成的冷却系统。在本试验中,冷却水管直径为8 mm, 坩埚内层表面涂刷一层耐火材料。

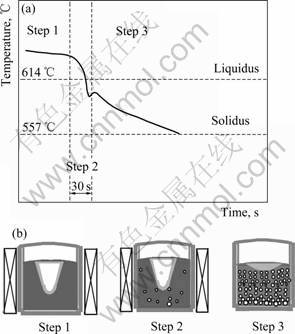

实验步骤示意图如图2所示。1) 熔化后的高温金属液在坩埚内缓慢冷却至稍高于液相线温度时,电磁搅拌器开始工作,对金属液进行强力搅拌;2) 在循环水管中通入冷却水,并持续一段时间;3) 在金属液温度降至液相线以下时(610 ℃),停止冷却水,搅拌器停止工作,随后进行浇铸。实验具体步骤如下:1) 浇注实验。为了验证工艺的有效性,制备的金属浆料分别浇入不锈钢铸型和砂型中,然后观察铸件的微观组织;2) 淬火实验。为了研究金属浆料能否在储存过程中保持有效的球形组织结构,利用上述方法获得的金属液放入加热炉中缓冷,平均冷却速度约为3 ℃/min,每隔5 min 舀取金属浆料进行淬火,观察和分析淬火试样的微观组织。

图1 实验装置示意图

Fig.1 Illustration of experimental device involved in process: 1—EM-stirrer; 2—Crucible; 3—Molten alloy; 4—Thermo- couples; 5—Cycle cooling tube

图2 金属液的典型温度变化曲线和实验工艺过程示意图

Fig.2 Typical thermal curve of alloy melt(a) and schematic diagram of process(b)

试样制备、抛光后用2% HF水溶液进行腐蚀,采用MeF4光学显微镜观察、分析其微观组织特征,采用相关软件对晶粒的直径d,延伸因子x进行定量测量,x定义为晶粒截面外接长方形的长宽比值。如果晶粒截面是球形,那么x的值为1;晶粒越不圆整,x的值就越大。

2 实验结果

2.1 铸件的微观组织

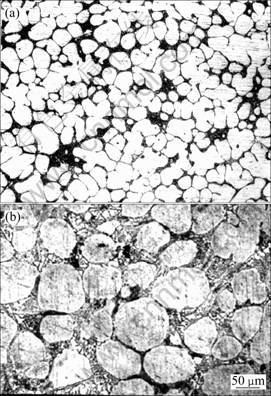

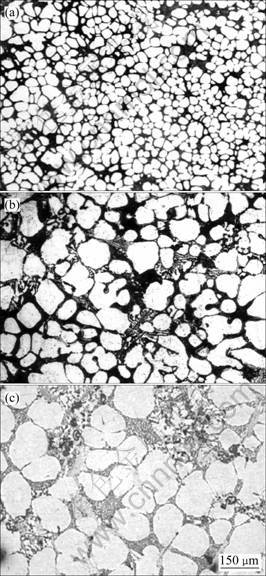

图3所示为在金属型和砂型中浇铸试件的金相照片。由图3可知:试件显示出典型的非枝晶触变性组织,α(Al)晶粒呈现出球形颗粒的外貌;凝固速度慢的砂型铸件中,α(Al)晶粒直径较大,且显得更圆整。为了研究获取的半固态浆料在短暂储存过程中初生相晶粒的形貌变化,采取了一系列等时间间隔的金属液淬火实验,获取淬火试样并观察其微观组织。图4所示为冷却速度3.0 ℃/min冷却过程中不同时间间隔淬火试样的金相组织,图4(a)所示为610 ℃的淬火组织,高密度、极为细小的α(Al)晶粒的组织特征表明金属液中发生过爆发形核过程。随后的淬火组织都表现出非枝晶的形貌,如图4(b)~(c)所示。随着时间间隔的增加,α(Al)晶粒尺寸增大的同时,晶粒形貌演变得更圆整。共晶Si对Al-Si合金的性能有着很大的影响,试验中共晶Si的形貌随着固相率的不同而变化,随着缓慢冷却过程中时间间隔的增加,共晶Si逐渐粗化。

图3 606 ℃时浇注的金属型和砂型铸件的微观组织

Fig.3 Microstructures of castings poured at 606 ℃ in stainless steel mold(a) and sand mold(b)

图4 冷却速度为3.0 ℃/min时冷却过程不同淬火温度下试样的金相组织

Fig.4 Quenched metallurgraphs of sample quenched at different temperatures and cooling rate of 3 ℃/min: (a) 610 ℃; (b) 595 ℃; (c) 580 ℃

2.2 α(Al)晶粒的尺寸和延伸因子

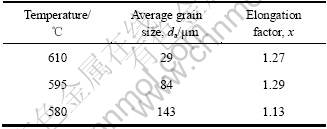

采用相关图像分析软件对初生α(Al)晶粒的尺寸和形状因子进行了分析。对于同一条件下的晶粒至少测量255个,然后取其平均值,其结果如表2所列。随着金属浆料控温时间的延长,淬火组织的晶粒直径增大的同时,形貌趋于圆整,表明高密度晶核的半固态浆料在缓冷存储过程中仍然能够保持等轴球晶的形貌。

表2 不同淬火温度下试样中初生α(Al)晶粒的平均直径和延伸因子

Table 2 Average grain size and elongation factor of different α(Al) grains in samples quenched at different temperatures

3 分析与讨论

施加在金属熔体上的旋转电磁场,驱动金属液主要以层流方式作旋转运动[9-10]。一般认为,强烈搅拌可以使金属液中溶质和温度分布更均匀[11-12]。高速旋转的金属液,不仅避免在插入冷却管时发生凝固,同时促进金属液和冷却管进行充分的热交换,控制整体金属液的热焓平衡,从而使得金属液中的热量被迅速带走,温度降至液相线以下。本文作者提出的流变成形工艺基于以下几点:1) 金属液中初生α(Al)相的爆发形核;2) 这些晶核在整个金属液中均匀分布;3) 晶核在液相中存活并以稳态生长成球形晶粒。其中首要条件就是在金属液中形成高密度的晶核。

3.1 爆发形核

金属液在冷却管外壁上形成的晶核随即被高速旋转的金属液冲刷而脱落,成为液相中的游离晶核,因此可以看成金属熔体在过冷条件下具有足够多的形核质点。根据ATSUMI[13]的凝固过程中分离理论,在过冷液相中的游离晶核是等轴晶形成的前提条件。

根据Rappaz等提出的三参数异质形核模型,晶核密度n与过冷度 的关系满足Gaussian正态分布[14]:

的关系满足Gaussian正态分布[14]:

(1)

(1)

式中: 和

和 分别是对应于最大形核率的平均形核过冷度和Gauss分布标准偏差;nmax是最大形核密度。为了简化,采用以下计算方法:

分别是对应于最大形核率的平均形核过冷度和Gauss分布标准偏差;nmax是最大形核密度。为了简化,采用以下计算方法:

(2)

(2)

式中:fs和r*是金属液冷却至温度T时的固相率和临界晶核半径。固相率由 计

计

算[3],其中 ml是二元合金相图中液相线的斜率,k为溶质分配系数,c0是合金成分。根据经典形核理论,临界形核半径为[3]

(3)

(3)

式中:γsl为晶粒和液相的界面能;Tm为Al的熔点;Lv为熔化潜热; 为过冷度。当

为过冷度。当 =4 K时,把以上各项数值如γsl=16.9×10-6 J/cm2,Lv=733 J/cm3代入式(3)可以得出r*=0.11 μm。因此可以综合式(2)和(3)计算出T = 610 ℃时的最大晶核密度为nmax=6.64×109 mm-3,其中,T =933.5 K,k = 0.114,ml=-697.9 K[14]。

=4 K时,把以上各项数值如γsl=16.9×10-6 J/cm2,Lv=733 J/cm3代入式(3)可以得出r*=0.11 μm。因此可以综合式(2)和(3)计算出T = 610 ℃时的最大晶核密度为nmax=6.64×109 mm-3,其中,T =933.5 K,k = 0.114,ml=-697.9 K[14]。

在铸造条件下过冷金属液中晶粒倾向于枝晶生长方式。根据在扩散或热流控制颗粒生长的情况下晶粒稳定生长的Mullins-Sekerka 条件可知,当晶核尺寸R长大超过临界尺寸Rc时,晶核的稳态生长趋于不稳定,由胞状向枝晶发展[15]。在过冷度均匀的金属液中,颗粒保持稳定生长的临界尺寸可由下式计算[16-17],

(4)

(4)

式中:ks和kl分别是铝合金固、液相导热系数。把各自对应的值ks=166 W/(m?K)和kl=68 W/(m?K)代入式(4),计算得出Rc=16.7r*=1.8 μm。

采用Rc 代替r*代入式(2),计算得出T=610 ℃时满足M-S稳定生长条件的晶核密度 =2.7×106 mm-3,从而建立起非枝晶生长要求的形核密度条件如下:

=2.7×106 mm-3,从而建立起非枝晶生长要求的形核密度条件如下: ≤n≤nmax。由于热起伏引起晶核重熔、晶核合并以及二次形核等,淬火后试样的晶粒密度远小于计算值。如图4(a)中α(Al)晶粒的密度为1.2×103 mm-2,转换单位体积密度为4.16×104 mm-3。

≤n≤nmax。由于热起伏引起晶核重熔、晶核合并以及二次形核等,淬火后试样的晶粒密度远小于计算值。如图4(a)中α(Al)晶粒的密度为1.2×103 mm-2,转换单位体积密度为4.16×104 mm-3。

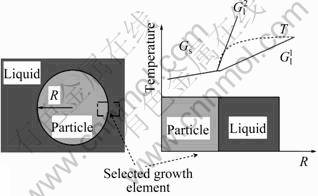

3.2 晶粒的生长

晶粒在生长过程中的形貌是由液固相界面前沿溶质和温度的分布决定的。在无对流情况下,单个颗粒在液相中生长的液固相界面前沿温度场(包括成分过冷)如图5所示[18]。在凝固界面前沿,由于晶粒长大时排出的溶质富集形成了溶质边界层,形成成分过 冷[3, 15],T 是由溶质分布决定的凝固温度分布曲线。对于实际温度分布曲线Gl来说,在 条件下,晶粒选择枝晶生长方式;在

条件下,晶粒选择枝晶生长方式;在 条件下,液相中的温度高于生长前沿的液相线温度,则可能阻止晶粒的生长,甚至重熔,这种情况有利于晶粒以球形或等轴晶形貌生长。

条件下,液相中的温度高于生长前沿的液相线温度,则可能阻止晶粒的生长,甚至重熔,这种情况有利于晶粒以球形或等轴晶形貌生长。

在强烈对流的条件下,高密度晶核形成的场叠加效应[19-20]和搅拌带来的晶核旋转运动[21-22]促进等轴球晶的形成。该条件下场的叠加效应表现在以下几个方面:1) 相邻多个晶核生长排出溶质时,单个晶粒前沿溶质排出速度降低,从而降低了边界层的溶质富集程度, 条件下晶粒有可能以非枝晶方式生长;2) 晶粒生长是一个放热的相变过程,相邻多个晶粒在生长过程中释放到界面前沿的热量促使局部热量的集中,液固界面前沿Gl的分布升高,促使晶粒生长前沿的温度下降速度减慢;3) Ostwald熟化过程不仅仅发生在单个晶粒本身,相邻晶粒局部体表如果存在曲率差,不同晶粒间同样会发生曲率小(类似枝晶尖)的局部消溶;4) 晶粒在生长过程中相互间的接触、碰撞同样有助于球形晶粒的生长。

条件下晶粒有可能以非枝晶方式生长;2) 晶粒生长是一个放热的相变过程,相邻多个晶粒在生长过程中释放到界面前沿的热量促使局部热量的集中,液固界面前沿Gl的分布升高,促使晶粒生长前沿的温度下降速度减慢;3) Ostwald熟化过程不仅仅发生在单个晶粒本身,相邻晶粒局部体表如果存在曲率差,不同晶粒间同样会发生曲率小(类似枝晶尖)的局部消溶;4) 晶粒在生长过程中相互间的接触、碰撞同样有助于球形晶粒的生长。

图5 金属液中单个晶粒生长前沿条件的示意图

Fig.5 Schematic diagram of solid/liquid interface arising from single growing equiaxed particle

由以上分析可以得出以下结论:利用旋转电磁场高速驱动金属液流经冷却管,发生热交换的同时在金属液中爆发形核,形成高密度的晶核,悬浮分散在半固态金属浆料中。在冷却水管降温作用停止后,由电磁搅拌驱动熔体形成的强迫对流造成液相中晶核、溶质和温度的均匀分布[23-24]。在半固态金属浆料继续缓慢冷却过程中,晶核长大,并逐渐粗化。高密度晶核促进晶粒的稳态生长,同时晶粒的合并和熟化过程对颗粒的最终形貌和尺寸有着极大的影响[25]。在开始阶段,晶核的合并起主要作用,但随后熟化是主要内容。因此,随着金属浆料保留时间的延长,颗粒就会逐渐粗化并趋于圆整[26-27]。图4中金相组织中的一个显著现象就是晶粒的尺寸相差很大,即存在许多相对非常细小的晶粒,这可能是由于热起伏和Ostwald熟化形成的部分熔化的残余晶粒。这也说明晶粒重新熔化过程的存在,并随金属液存留时间的延长,晶粒数量减少。在浆料储存过程中,由于固相率随着温度的下降而增加,剩余液相中 Si 成分的含量上升,因而导致共晶 Si 的粗化。在缓慢冷却过程中,由于上述高密度晶核的存在,金属液可以保持稳定的球形晶粒触变性组织,但是粗大的组织对铸件的性能有着不利的 影响。

4 结论

1) 旋转磁场装置通过在液相线温度附近控制A356合金液的热焓平衡产生大爆炸形核,磁场搅拌 作用促进高密度的初生相α(Al)晶核在金属液中的均匀分布,从而制取优质的半固态金属浆料。

2) 高密度初生相晶核均匀分布的半固态浆料在冷却速度为3 ℃/min的驻留过程中,初生相α(Al)晶粒趋向于粗化和圆整。

REFERENCES

[1] BOETTINGER W J, CORIELL S R, GREER A L, KARMA A, KURZ W, RAPPAZ M, TRIVEDI R. Solidification microstructures: Recent developments, future directions[J]. Acta Mater, 2000, 48: 43-70.

[2] KURZ W, TRIVEDI R. Overview, solidification microstructures: Recent developments, future directions[J]. Acta Metall Mater, 1990, 38(1): 1-17.

[3] FLEMINGS M C. Solidification processing[M]. New York: McGraw-Hill, 1974: 38.

[4] FLEMINGS M C. Behavior of metal alloys in the semisolid state[J]. Metall Trans A, 1991, 22: 957-981.

[5] KIRKWOOD D H. Semisolid metal processing[J]. Inter Mater Rev, 1994, 39(5): 173-189.

[6] FAN Z. Semisolid metal processing[J]. Inter Mater Rev, 2002, 47(2): 49-85.

[7] 罗守靖, 田文彤, 谢水生, 毛卫民. 半固态加工技术及应用[J]. 中国有色金属学报, 2000, 10(6): 765-773.

LUO Shou-jing, TIAN Wen-tong, XIE Shui-sheng, MAO Wei-min. Technology and application of semisolid forming[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(6): 765-773.

[8] 张小立, 李廷举, 谢水生, 王同敏, 曹志强, 金俊泽. 半固态加工制浆技术的研究进展[J]. 稀有金属材料与工程, 2009, 38(8): 1495-1500.

ZHANG Xiao-li, LI Ting-ju, XIE Shui-sheng, WANG Tong-ming, CAO Zhi-qiang, JIN Jun-ze. Research & development of semisolid slurry processing technology[J]. Rare Metal Materials and Engineering, 2009, 38(8): 1495-1500.

[9] NIKRITYUK P A, ECKERT K, GRUNDMANN R. A numerical study of unidirectional solidification of a binary metal alloy under influence of a rotating magnetic field[J]. International Journal of Heat and Mass Transfer, 2006, 49: 1501-1515.

[10] 陈兴润, 张志峰, 徐 俊, 石力开. 电磁搅拌法制备半固态浆料过程电磁场、流场合温度场的数值模拟[J]. 中国有色金属学报, 2010, 20(5): 937-945.

CHEN Xing-run, ZHANF Zhi-feng, XU Jun, SHI Li-kai. Numerical simulation of electromagnetic field, flow field and temperature field in semi-solid slurry preparation by electromagnetic stirring[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 937-945.

[11] MEYER J L, EL-KADDAH N, SZEKELY J, VIVES C, RICOU R. A comprehensive study of the induced current, the electromagnetic force field, and velocity field in a complex electromagnetically driven flow system[J]. Metallurgical Transactions B, 1987, 18: 529-538.

[12] 许珞萍, 邵光杰, 任钟鸣, 朱明原, 史 文. 电磁搅拌作用下非树枝晶铝合金组织演变过程的数学描述[J]. 中国有色金属学报, 2002, 12(1): 52-56.

XU Luo-ping, SHAO Guang-jie, REN Zhong-ming, ZHU Ming-yuan, SHI Wen. Semi-quantitative mathematical description of evolution of non-dendritic structure of aluminum alloy under electromagnetic stirring condition[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(1): 52-56.

[13] ATSUMI O. Solidification——The separation theory and its practical applications[M]. Berlin: Springer-Verlag, 1987: 156.

[14] 王同敏, 李廷举, 曹志强, 金俊泽. 等轴球晶凝固多相体系内热溶质对流、补缩流及晶粒运动的数值模拟(Ⅱ): 模型的应用[J]. 金属学报, 2006, 42(6): 591-598.

WANG Tong-min, LI Ting-ju, CAO Zhi-qiang, JIN Jun-ze. Modeling of the thermo-solute convection, shrinkage flow and grain movement during globular equiaxed solidification in a multi-phase system (Ⅱ): Application of model[J]. Acta Metallurgica Sinica, 2006, 42(6): 591-598.

[15] MINKOFF I. Solidification and cast structure[M]. Chichester, Great Britain: John Wiley & Sons Ltd, 1986: 79.

[16] MA Qian. Creation of semisolid slurries containing fine and spherical particles by grain refinement based on the Mullins-Sekerka stability criterion[J]. Acta Materialia, 2006, 54: 2241-2252.

[17] MULLINS W W, SEKERKA R F. Morphological stability of a particle growing by diffusion or heat flow[J]. Journal of Applied Physics, 1963, 34(2): 323-329.

[18] KURZ W AND FISHER D J. Fundamentals of solidification[M]. Aedermannsdorf, Switzerland: Trans Tech Publications, Ltd, 1998: 43-44.

[19] DOHERTY R D, LEE H I, FEEST E A. Microstructure of stir-cast metals[J]. Materials Science and Engineering, 1984, 65: 181-189.

[20] VOGEL A, CANTOR B. Stability of a spherical particle growing from a stirred melt[J]. Journal of Crystal Growth, 1977, 37: 309-316.

[21] 李 涛, 黄卫东, 林 鑫. 半固态处理中球晶形成与演化的直接观察[J]. 中国有色金属学报, 2000, 10(15): 635-639.

LI Tao, HUANG Wei-dong, LIN Xin. Formation of globular structure during semi-solid material processing[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(15): 635-639.

[22] MOLENAAR J M M, KATGERMAN L, KOOL W H, SMEULDERS R J. On the formation of the stircast structure[J]. Journal of Materials Science, 1986, 21: 389-394.

[23] 王 晶, 李培杰, 何良菊, 弭光宝, 钟约先. 电磁搅拌对A356合金熔体结构及其凝固行为的影响[J]. 中国有色金属学报, 2009, 19(12): 2090-2098.

WANG Jing, LI Pei-jie, HE Liang-ju, MI Guang-bao, ZHONG Yue-xian. Influence of electromagnetic stirring on structure of A356 melt and its solidification behavior[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(12): 2090-2098.

[24] SPITZER K H, REITER G, SCHWERDTFEGER K. Rotational electromagnetic stirring in continuous casting of round strands[J]. Metall Trans B, 1986, 17(3): 119-131.

[25] WAN Gang, SAHM P R. Particle growth by coalescence and Ostwald ripening in rheocasting Pb-Sn[J]. Acta Metallurgical and Materials, 1990, 38(11): 2367-2372.

[26] JI S, ROBERTS K, FAN Z. Isothermal coarsening of fine and spherical particles in semisolid slurry of Mg-9Al-1Zn alloy under low shear[J]. Scripta Materialia, 2006, 55: 971-974.

[27] MARTINEZ R A, FLEMINGS M C. Evolution of particle morphology in semisolid processing[J]. Metallurgical and Materials Transactions A, 2005, 36: 2205-2210.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(50374014);江苏省高校博士基金资助项目(35060815)

收稿日期:2010-09-13;修订日期:2010-12-28

通信作者:张小立,讲师,博士;电话:15952871523,0512-56731518;E-mail: houyizh@126.com