文章编号:1004-0609(2012)04-1019-06

铝、镁合金半固态浆料的制备与流变成形新工艺

滕海涛1, 2,熊柏青1,张永安1,李廷举2,张小立2,谢水生1

(1. 北京有色金属研究总院 有色金属材料制备加工国家重点实验室 有研亿金新材料股份有限公司,北京 100088;

2. 大连理工大学 三束材料改性教育部重点实验室,大连 116024)

摘 要:介绍了阻尼冷却管法制备A356铝合金半固态浆料工艺的实验装置及其原理,并进行不同浇注温度的系列实验。结果表明:由于阻尼冷凝管的冷却和搅拌作用,熔体浇注温度越低,在两相温度区间内生成的游离晶核就越多,制备得到半固态铸件的晶粒尺寸就越小,且球化程度越高。在此实验原理及结果分析的基础上,设计真空吸铸-阻尼冷却装置,近液相线温度的AZ91D镁合金液在冷却、剪切的作用下,由液态转变为半固态浆料,然后进入模具完成充型,实现镁合金半固态浆料的制备与铸件流变成形一体化;半固态镁合金熔体具有触变性及更高的黏度,以平稳、层流的充型方式完成充型,能够有效地改善成形件的质量。

关键词:阻尼冷却管法;真空吸铸工艺;半固态浆料;流变成形;显微组织

中图分类号:TG146.2;TG249 文献标志码:A

Novel process for fabrication and rheoformation of aluminum and magnesium alloys semisolid slurry

TENG Hai-tao1, 2, XIONG Bai-qing1, ZHANG Yong-an1, LI Ting-ju2, ZHANG Xiao-li2, XIE Shui-sheng1

(1. State Key Laboratory of Nonferrous Metals and Process, GRIKIN Advanced Materials Co., Ltd.,

General Research Institute for Nonferrous Metals, Beijing 100088, China)

(2. Key Laboratory for Materials Modification by Laser, Ion and Electron Beams, Ministry of Education,

Dalian University of Technology, Dalian 116024, China)

Abstract: The setup and principle of damper cooling tube (DCT) process, which is used to prepare semisolid slurry of A356 aluminum alloy in different pouring temperatures, were introduced. The results show that the microstructures are directly related to the pouring temperature, the lower pouring temperature is, the more stray nuclei produced are, the smaller grain size is and the bigger shape factor is. On the basis of the experimental results and principle, a novel semisolid processing technique, called vacuum suction casting-damper cooling tube (VSC-DCT) process, is used to manufacture high quality components of AZ91D Mg-alloy directly from a near-liquidus metal. The outstanding feature of this investigation is attributed to the fact that the VSC-DCT process combines the semi-solid slurry making and component forming operation into one step, therefore, eliminating the need for specially prepared slurry and subsequent slurry transportation steps. The semisolid metal with higher viscosity can be caused to fill the mold with solid-front fill, and the surface quality of the sheets fabricated by the VSC-DCT method is improved significantly.

Key words: damper cooling tube method; vacuum suction casting; semisolid slurry; rheoforming; microstructure

半固态金属(Semisolid metal, SSM)浆料具有独特的球形晶粒结构,球形晶粒的存在使合金在液固两相区温度下具有触变性能,即在外力剪切作用下,固相分数很高的合金浆料仍具有很好的流动性,因此,能够通过压铸、挤压、模锻成形,并给合金在冷却成形过程中带来一系列的优点,如近终成形、降低铸件气孔率、提高成品件力学性能、延长模具使用寿命以及提高生产效率等。半固态金属成形被誉为21世纪最具前途的金属材料加工技术之一,其中半固态浆料的制备是半固态金属成形工艺中最为重要的环节[1-4]。

半固态浆料的制备方法较多,在熔体温度降至两相区时,采用外力对生长的枝晶进行剪切作用,如对冷却中的熔体进行电磁搅拌或者机械搅拌,一方面可以破碎枝晶生长前端,形成游离晶核,另一方面可以促使温度场和溶质浓度分布均匀化,是一种在合金熔体中获得球形初生相颗粒的有效方法[4-6]。

本文作者自行设计实验装置,利用阻尼冷却管法(Damper cooling tube method, DCT)[7-8]制备A356 铝合金半固态浆料,分析浇注温度与半固态浆料凝固组织的关系。在总结阻尼冷却原理制备半固态浆料的基础上,利用真空吸铸(Vacuum suction casting, VSC)工艺过程中添加阻尼冷却装置,实现镁合金半固态浆料的制备与铸件流变成形一体化,并对得到铸件的凝固组织进行观察分析。

1 阻尼冷却管法制备铝合金半固态浆料

1.1 实验装置

自行设计铝合金半固态浆料制备装置,如图1所示。主要由中间包(主要包括加热炉和不锈钢坩埚)、锥形螺旋结构以及冷却水套组成,控温合金熔体由中间包顶部浇入,锥形浮筒在逐渐注入熔体的浮力作用下浮起,从而使熔体沿螺旋叶面下流,在通水的冷却水套中降温冷却并被剪切搅拌,得到合金的半固态浆料。

图1 阻尼冷却管法制备A356半固态浆料实验装置简图

Fig. 1 Schematic diagram of DCT process for preparing A356 semisolid slurry

1.2 实验原理

阻尼冷却管法是一种制备铝、镁合金半固态浆料和铸坯的工艺方法。在冷却水套中通水,内管壁面可以看成冷却斜槽内壁面,熔体在螺旋面上流动,由于重力和离心力的作用,熔体贴近冷却管壁作向下旋转运动。冷却管内壁面作为热交换面,流速较高的熔体对冷却管内壁上形核生长的晶粒具有冲刷作用。锥形浮筒在中间包内驻留的熔体浮力和旋转角速度的作用下引起涡量场,产生旋转运动,带动螺旋杆转动,从而对熔体具有一定的搅拌作用。

低过热度的熔体在螺旋面上流动时,与冷却管内壁面接触的熔体迅速形核生长,被随后的过热熔体冲刷,脱离管壁,形成游离的晶核。易变向流动的熔体不仅能够促使溶质扩散速度和温度传导速率加快,同时还造成溶质扩散方向和温度传导方向的易变性以及对已形成的游离晶核搅动。经阻尼冷却管冷却和搅拌后,熔体内均匀分布着密度较高的球状晶核,溶质分布和温度场的分布较为均匀化。熔体在铸型内随着温度的进一步降低而凝固,由于在熔体内分布的晶核数量非常多,因此可以把每个游离的晶核和周围的熔体看成一个生长单元,这个生长单元直径数量级在10~100 μm,晶核四周的生长条件如温度梯度和溶质浓度看成是相同的,因此生长单元在冷却过程中向各方向的生长速度基本相同,直至和周围同样生长情形的晶粒接触而结束。

1.3 实验材料

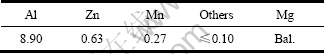

采用最常用的工业铝合金A356,化学成分如表1所列。合金固、液相温度区间:557~613 ℃。

表1 实验用铝合金A356的化学成分

Table 1 Chemical composition of A356 (mass fraction, %)

1.4 实验过程

将A356 合金在感应加热炉加热至850 ℃,保温一段时间后,放入敞口包中散热至合金液相线温度附近保温。选择A356 合金熔体在620~650 ℃温度条件下浇入中间包中,中间包的包底温度是一个关键性因素,因为包底直接和冷却水套连接,水套散热性较大,为了保证熔体不在包底凝固,包底的温度选择高于熔体液相线温度30~40 ℃。流经阻尼冷却管的熔体采用漏斗收集到预热温度到150 ℃金属铸型中。切割铸件进行试样制备,抛光后用2%HF(质量分数)水溶液腐蚀,采用光学显微镜对微观组织进行观察和分析。

1.5 显微组织形貌与分析

图2所示为不同浇注温度下阻尼冷却管法制备的铸坯微观组织。当浇注温度为660 ℃时,在出现枝晶组织的同时,存在小部分退化的枝晶,如图2(a)所示。浇注温度在650 ℃时,经过阻尼冷却管后得到了分散的初生相白色组织为α(Al),如图2(b) 所示。当浇注温度低于635 ℃时,铸件微观组织基本上都是α(Al)固溶体白色颗粒组织,如图2(c)和(d)所示。比较几种工艺条件下的铸件微观组织可以看出,随着浇注温度的降低,球形晶粒数量增多,分布更均匀,晶粒尺寸逐渐减小并且晶粒球化程度逐渐增高。

当浇注温度为650~660 ℃时,由于熔体温度较高,经过阻尼冷却管到达出口处的熔体,其整体温度耗能降至固液两相温度区内,此时熔体中只包含少量的游离晶核,因此,其凝固后的显微组织中也只生成少量初生相。在凝固速度较快的情况下,初生相颗粒的直径相对较小。而浇注温度低于635 ℃时,阻尼冷却管的散热能力能够使得合金熔体在流出时的温度降到了两相区温度区间内,因此在阻尼冷却过程中形成的大量细小的初生相得以保存在熔体中,并在铸型中成为晶粒形核、长大过程中的“外来形核质点”,在冷却过程中长大直至晶粒间接触。阻尼冷凝管对熔体的冷却和搅拌作用促进了初生相晶粒的大量增多,同时降低熔体的出口温度,因此,铸件微观组织晶粒细小、球化程度较高。

2 镁合金的半固态流变成形新工艺

镁合金传统的半固态成形工艺主要分为两种:一是触变成形(Thixoforming)工艺[9-12],即利用预先制备好的非枝晶组织半固态铸坯二次加热至两相区后再模锻成形的方法;二是流变成形(Rheoforming)[13-17]工艺,即先制备半固态浆料,然后将半固态浆料输送到模具或压铸机内直接浇铸或压铸成形,该工艺的最大问题是镁合金半固态金属浆液的保存和输送难度较大,使其应用受到很大限制[18]。

本文作者在前述阻尼冷却管法制备A356铝合金半固态浆料实验工艺及实验原理的基础上,在真空压力吸铸急冷模法制备镁合金薄片工艺[19-20]过程中添加阻尼冷却装置,实现镁合金半固态浆料的制备与铸件的流变成形一体化,避免高温镁合金半固态浆料在输送过程中的氧化、燃烧。

2.1 实验工艺装置

实验设计工艺装置示意图如图3(a)所示,主要包括紫铜结晶器模具、阻尼冷却系统、真空系统装置、惰性气体保护机构、控制阀门及保温坩埚等。其中,阻尼冷却系统设计螺旋结构以及冷却水套(图3(b)),对流经的合金液起到冷却降温及搅拌剪切的作用。

图2 不同浇注温度下金属型铸件的微观结构

Fig. 2 Optical micrographs of A356 castings at different pouring temperatures: (a) 660 ℃; (b) 650 ℃; (c) 635 ℃; (d) 620 ℃

图3 真空吸铸-阻尼冷却管法实现AZ91D镁合金半固态流变成形工艺装置示意图

Fig. 3 Schematic diagrams of VSC-DCT process for rheoforming semisolid of AZ91D Mg alloy(a) and damper-cooling system(b)

2.2 实验材料

实验材料选用AZ91D是典型和最常用的商业性镁合金,化学成分如表2所列。合金固、液相温度区间:468~598 ℃。

表2 实验用镁合金AZ91D化学成分

Table 2 Chemical compositions of AZ91D alloy (mass fraction, %)

2.3 实验过程

按照图3所示实验工艺装置连接各机构,熔炼好的AZ91D镁合金溶液静置于保温坩埚中,通入保护气体(50% Ar+50% CO2+0.3% SF6,体积分数)防止其氧化、燃烧,待合金熔体温度达到620~630 ℃,打开模具与真空系统之间的控制阀,金属液在压力作用下流经阻尼冷却系统,近液相线温度合金溶液在冷却和剪切搅拌的作用下形成富含游离晶核的半固态熔体,然后进入模具型腔完成充型,得到镁合金薄片铸件。试样经镶嵌、抛光和腐蚀后,采用高分辨率光学显微镜(MEF4A)和扫描电镜(SEM,JSM-5600LV)观察并分析其显微组织形貌。

2.4 实验结果与分析

图4所示为利用真空吸铸工艺得到AZ91D镁合金薄片铸件的表面形貌写真,薄片厚度为2 mm。其中,图4(a)所示为630 ℃时未设置阻尼冷却系统[19]情况下得到镁合金薄片铸件表观形貌,可以看出,无阻尼冷却作用下合金液以射流的方式充入铸型,吸管中心流速最大的合金液射向型腔顶部向两侧形成挂流,如图4(a)中箭头所示,并且在铸件表面存在明显的放射状射流痕;在加置阻尼冷却管的条件下得到的铸件的表观形貌,如图4(b)所示,铸件表面质量明显改善,射流痕迹很轻微。

图4 AZ91D镁合金薄片铸件的表观形貌

Fig. 4 Surface appearances of AZ91D castings produced by VSC(a) and VSC-DCT(b) processes

铸件的质量及显微组织与其凝固过程及凝固条件有着密切的关系。真空吸铸-阻尼冷却管法得到AZ91D镁合金薄片铸件的凝固过程实际上分为两个部分:一是近液相线温度的金属液流经阻尼冷却通道时的凝固,在冷却和剪切搅拌的作用下,产生了大量初生α-Mg相晶粒,同时合金熔体温度降低至液相线,产生大量晶核并裹入存活于熔体而形成了半固态浆 料[21];二是生成的半固态镁合金浆料进入模具型腔后,由于紫铜结晶器的激冷而发生的快速冷却凝固,得到最终的薄片铸件。半固态浆料具有触变性及更高的黏度,流动前端以封闭的形式充型,可以有效地避免金属液充型过程中的紊流、卷气,改善合金液的充型行为[1, 22],从而降低铸件气孔率,提高铸件的表观质量。

图5所示为采用真空吸铸-阻尼冷却管法得到半固态充型镁合金薄片铸件的金相组织。图中白色组织为经过阻尼冷却系统后形成的初生α-Mg相晶粒,呈退化的枝晶或玫瑰形貌,而细小的黑色基底是残留的液相进入紫铜结晶器后快速冷却形成的共晶组织。比较图5(a)和(b)可以看出,当吸铸温度降低10 ℃,即从630 ℃降到620 ℃,得到半固态浆料的固相率由8%升高到35%,铸件凝固组织中初生α-Mg相晶粒显著增加。由此可见,在近液相线温度区间,制备得到半固态浆料中初生相晶粒的含量与作业温度有着十分敏感的关系,吸铸温度的很小变化就可以导致铸件显微组织中初生相含量的明显变化[23-24]。在扫描电镜下观察初生相及基底组织详细形貌如图6所示,第一次凝固产生的初生α-Mg相晶粒弥散分布在由半固态浆料中残余液相非平衡凝固生成的基体组织中,而基体组织则是由非常细小的二次α-Mg相及β相构成。

图5 真空吸铸-阻尼冷却管法得到AZ91D镁合金显微组织

Fig. 5 Optical micrographs showing microstructures of AZ91D foils at different pouring temperatures: (a) 630 ℃; (b) 620 ℃

图6 AZ91D薄片铸件的SEM背射像

Fig. 6 SEM back-scattered electron image showing detail microstructure of AZ91D foil

AZ91D镁合金液流经阻尼冷却通道时得到富含大量初生α-Mg相晶粒的半固态浆料。半固态熔体一旦进入模具型腔,由于紫铜结晶器高的传热速率及小而薄的型腔尺寸,残余液相将以极高速率产生大量异质形核而没有机会长大[23-25],因此形成了细小的二次α-Mg相及沿晶界不连续分布的β相基体组织,先前半固态浆料中的初生α-Mg固相颗粒则弥散分布于其中。

3 结论

1) 利用阻尼冷凝管法成功制备A356铝合金半固态浆料;合金熔体浇注温度越低,在两相温度区间内生成的游离晶核就越多,制备得到半固态铸件晶粒尺寸就越小,且球化程度越高。

2) 利用真空吸铸-阻尼冷却装置,实现近液相线温度AZ91D镁合金的半固态浆料的制备与铸件流变成形一体化,半固态镁合金熔体具有触变性及更高的黏度,以平稳、层流的充型方式完成充型,能够有效改善成形件的质量,为镁合金的半固态流变成形工艺的发展提供了一种新的思路;得到半固态薄片铸件的微观组织中初生α-Mg相晶粒呈退化的枝晶或玫瑰形貌,而基体组织则由细小的二次α-Mg相及纤细的、不连续分布于晶界的β相构成。

REFERENCES

[1] FLEMINGS M C. Behavior of metal alloys in the semisolid state[J]. Metallurgical and Materials Transactions A, 1991, 22(5): 957-981.

[2] KIRKWOOD D H. Semisolid metal processing[J]. International Materials Reviews, 1994, 39: 173-189.

[3] RICE C S, MENDEZ P F. Slurry-based semi-solid die casting[J]. Advanced Materials and Processes, 2001, 159(10): 49-52.

[4] FAN Z. Semisolid metal processing[J]. International Materials Reviews, 2002, 47(2): 49-85.

[5] FAN Y, WU G, ZHAI C. Influence of cerium on the microstructure, mechanical properties and corrosion resistance of magnesium alloy[J]. Materials Science and Engineering A, 2006, 433(1/2): 208-215.

[6] KLEINER S, BEFFORT O, WAHLEN A, UGGOWITZER P J. Microstructure and mechanical properties of squeeze cast and semi-solid cast Mg-Al alloys[J]. Journal of Light Metals, 2002, 2(4): 277-280.

[7] YANG H, XIE S, LI L. Numerical simulation of the preparation of semi-solid metal slurry with damper cooling tube method[J]. Journal of University of Science and Technology Beijing, 2007, 14(5): 443-448.

[8] 张小立, 谢水生, 李廷举, 杨浩强, 金俊泽. 阻尼冷却管法制备A356铝合金半固态浆料的研究[J]. 稀有金属材料与工程, 2007, 36(5): 915-919.

ZHANG Xiao-li, XIE Shui-sheng, LI Ting-ju, YANG Hao-qiang, JIN Jun-ze. A356 aluminum semisolid slurry prepared by damper cooling tube process[J]. Rare Metals Materials and Engineering, 2007, 36(5): 915-919.

[9] CZERWINSKI F. On the generation of thixotropic structures during melting of Mg-9%Al-1%Zn alloy[J]. Acta Materialia, 2002, 50(12): 3265-3281.

[10] CZERWINSKI F, ZIELINSKA-LIPIEC A, PINET P J, OVERBEEKE J. Correlating the microstructure and tensile properties of a thixomolded AZ91D magnesium alloy[J]. Acta Materialia, 2001, 49(7): 1225-1235.

[11] CHEN T J, MA Y, LI B, HAO Y. Effects of processing parameters on wear behaviors of thixoformed AZ91D magnesium alloys[J]. Materials and Design, 2009, 30(2): 235-244.

[12] MANSOOR B, MUKHERJEE S, GHOSH A. Microstructure and porosity in thixomolded Mg alloys and minimizing adverse effects on formability[J]. Materials Science and Engineering A, 2009, 512(1/2): 10-18.

[13] FAN Z. Development of the rheo-diecasting process for magnesium alloys[J]. Materials Science and Engineering A, 2005, 413/414: 72-78.

[14] FAN Z, LIU G. Solidification behaviour of AZ91D alloy under intensive forced convection in the RDC process[J]. Acta Materialia, 2005, 53(16): 4345-4357.

[15] JI S, FAN Z, BEVIS M J. Semi-solid processing of engineering alloys by a twin-screw rheomoulding process[J]. Materials Science and Engineering A, 2001, 299(1/2): 210-217.

[16] ZHANG X, LI T, XIE S, TENG H, JIN J. Microstructure analysis of rheoformed AZ91 alloy produced by rotating magnetic fields[J]. Journal of Alloys and Compounds, 2008, 461(1/2): 106-112.

[17] MAO W, ZHEN Z, YAN S, ZHONG X. Rheological behavior of semi-solid AZ91D alloy[J]. Journal of Materials Science and Technology, 2004, 20(5): 580-582.

[18] FRIEDRICH E H, MORDIKE B L. Magnesium technology[M]. Berlin: Springer, 2006: 74-79.

[19] TENG H, ZHANG X, ZHANG Z, LI T, COCKCROFT S. Research on microstructures of sub-rapidly solidified AZ61 magnesium alloy[J]. Materials Characterization, 2009, 60(6): 482-486.

[20] TENG H, LI T, ZHANG X, ZHANG Z. Influence of sub-rapid solidification on microstructure and mechanical properties of AZ61A magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(S1): S86-S90.

[21] XIA K, TAUSIG G. Liquidus casting of a wrought aluminum alloy 2618 for thixoforming[J]. Materials Science and Engineering A, 1998, 246(1/2): 1-10.

[22] ATKINSON H V. Modelling the semisolid processing of metallic alloys[J]. Progress in Materials Science, 2005, 50(3): 341-412.

[23] CZERWINSKI F. Near-liquidus molding of Mg-Al and Mg-Al-Zn alloys[J]. Acta Materialia, 2005, 53(7): 1973-1984.

[24] TENG H, LI T, ZHANG X, BAI F, QI K. Mold-filling characteristics and solidification behavior of magnesium alloy in vacuum suction casting process[J]. Journal of Materials Science, 2009, 44(20): 5644-5653.

[25] WANG Y, LIU G, FAN Z. Microstructural evolution of rheo-diecast AZ91D magnesium alloy during heat treatment[J]. Acta Materialia, 2006, 54(3): 689-699.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50904010, 51004018)

收稿日期:2011-01-19;修订日期:2011-05-16

通信作者:滕海涛,博士;电话:010-82241224;E-mail: seantht@yahoo.com.cn