文章编号:1004-0609(2014)02-0371-09

半固态7050铝合金材料的触变力学模型

李志龙,刘允中,游 江

(华南理工大学 国家金属材料近净成形工程技术中心,广州 510640)

摘 要:为了系统研究半固态7050铝合金的触变力学行为,采用Gleeble-3500热模拟试验机对SIMA法制备的半固态7050铝合金进行单向压缩试验,利用SPPS数理统计软件拟合材料本构模型,最后通过MSC.MARC软件进行半固态轧制过程的数值模拟。结果表明:7050铝合金的压缩流变应力与温度、应变速率以及应变具有相关性,在0.1~10 s-1的应变速率范围内,流变应力随温度的升高而明显降低,随应变速率和变形量的增大而增大;利用压缩试验测得真应力—真应变关系,可以建立半固态7050铝合金分阶段触变变形的粘塑性本构模型,该模型基于半固态材料的力学特性,并考虑液相分数的影响;模拟计算得到的稳态轧制力约为25 MPa,与实际轧制实验结果基本吻合,证明所建立的本构模型是合理的。

关键词:半固态;热模拟;本构方程;轧制

中图分类号:TG146.2 文献标志码:A

Constitutive model for thixo-forming of semi-solid 7050 alloy

LI Zhi-long, LIU Yun-zhong, YOU Jiang

(National Engineering Research Center of Near-net-shape Forming Technology for Metallic Materials,

South China University of Technology, Guangzhou 510640, China)

Abstract: In order to investigate the thixo-forming deformational behavior of 7050 aluminum alloy systematically, the semi-solid material prepared by SIMA method was studied on the Gleeble-3500 material thermo-simulation machine via uniaxial compression tests. The viscoplastic model of flow stress at semi-solid temperature was established by using SPSS software. At last, the rolling process was simulated by MSC.MARC finite element software. The results show that, the compression flow stress of 7050 aluminum alloy has a close relationship with temperature, strain rate and strain. In the strain range from 0.1 s-1 to 10 s-1, the flow stress decreases significantly with the temperature increasing and rises considerably with the strain and strain rate increasing. The two-stage viscoplastic model of flow stress is established by using the obtained true strain—true strain rate curves, which considers the mechanical properties of semi-solid state material and liquid fractions. The simulation results show the stable rolling force is around 25 MPa, which agrees with experimental results. So, the established constitutive equations are reasonable.

Key words: semi-solid; thermo-simulation; constitutive equations; rolling

7050铝合金为 Al-Zn-Mg-Cu系合金,具有较高的结构强度、断裂韧性和抗应力腐蚀断裂等良好的综合性能,是目前航空、航天领域广泛采用的一种轻型结构材料[1]。金属触变成形是在20世纪70年代发展起来的一种新的加工工艺,该技术是利用金属由液相向固相转变或固相向液相转变过程中所具有的特性进行加工[2-3]。控制半固态金属的变形行为对成形过程十分关键,因此,有必要对其变形过程进行相关的研究[4-5]。

近年来,数值模拟技术在航空合金加工领域得到了广泛的应用,一系列合金 (AZ91D,6063) 的半固态本构方程已经被建立,这对预测半固态加工中变形特征、制订半固态加工工艺过程具有重要的意义。GUNASEKERA[6]考虑了半固态液相体积分数和应变速率的影响,提出了流动应力与应变速率之间的关系;IWASAKI等[7]通过对A1-5%Mg合金进行剪切试验的研究,指出合金的半固态变形行为与液相分数有关;KIUCHI等[8]分别对半固态铝合金和铜合金的流动和变形进行研究,提出了“K-Y-Y”模型,并通过有限元模拟对模型进行了验证;KOEUNE等[9]在传统的计算模型基础上建立起了新本构模型,此模型既能够适用于单相变形的数值模拟过程,也能够适用于固液相共存变形的数值模拟过程。已有的研究工作主要集中在高液相率剪切变形行为方面,对于要求液相率低的触变变形过程研究较少,且还没有半固态7050铝合金本构方程的相关研究报道。同时,鉴于半固态材料变形时的高应变速率敏感性,有必要针对实际触变轧制过程应变速率的变化情况来研究半固态7050铝合金的变形行为。因此,本文作者利用Gleeble-3500热模拟试验机对半固态7050铝合金进行单向压缩实验,得到真应力—真应变曲线,分别分析变形温度、应变速率和变形程度对流变应力的影响,建立分阶段的半固态7050合金高温粘塑性本构关系模型,同时采用MSC.MARC软件模拟半固态7050铝合金的轧制过程,最后实验验证数值模拟结果的合理性。通过研究7050铝合金半固态流变应力行为建立合理的流变应力模型,可以较准确的描述变形温度、应变速率以及变形程度对流变应力的影响,为工业上7050铝合金大构件的热成型工艺设计与优化提供可靠的理论指导。

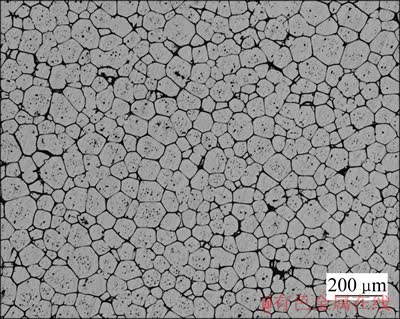

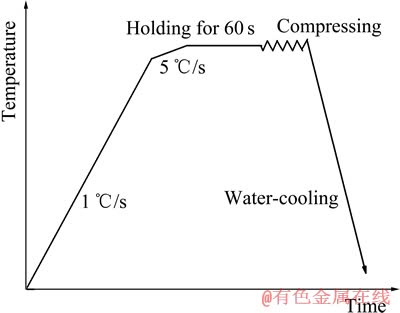

1 实验

首先采用应变诱导熔化激活法(Strain induced melt activation method,简称SIMA法)制备半固态坯料,其工艺路线为:铸锭的正挤压—半固态温度区间等温处理—水冷,其中正挤压是在200 t四柱液压机上进行的,挤压坯料加热到450 ℃,模具加热到300 ℃,挤压比为11.11。保温过程是在585 ℃下进行的,等温时间为25 min。最终获得的试样显微组织如图1所示,为平均晶粒尺寸90 μm的近球形晶粒。半固态压缩实验在Gleeble-3500热模拟试验机上进行,该设备采用电流加热,能够满足合金重熔时对温度精确控制的要求,其加热过程如图2所示。实验完成后,立即将试样进行水冷,以保持其内部组织。对压缩后试样的纵截面磨平、抛光、腐蚀后,进行金相观察。

图1 试验用半固态7050铝合金的显微组织

Fig. 1 Microstructure of 7050 aluminum alloy at semi-solid state

图2 热压缩加热工艺图

Fig. 2 Route chart of heating process in hot compression

压缩变形过程的参数包括等温温度、应变速率和总应变。变形温度是根据DSC结果确定的:试验用7050铝合金的液相线为635 ℃,固相线为524 ℃。由于在实际的半固态轧制过程中,合金的液相率不宜过高,因此,选择等温温度分别为528、540、555和565 ℃。根据实验室双辊轧制过程平均应变速率计算公式: ,其中v为轧辊线速度,l是接触弧长在水平方向上投影长度,△h为变形高度,H为轧制试样高度,可以估算出轧制平均应变速率

,其中v为轧辊线速度,l是接触弧长在水平方向上投影长度,△h为变形高度,H为轧制试样高度,可以估算出轧制平均应变速率 4.25 s-1。因此,确定半固态7050铝合金的压缩变形速率分别为0.1、0.5、1、10 s-1。实验中试样的总应变确定为0.7左右。

4.25 s-1。因此,确定半固态7050铝合金的压缩变形速率分别为0.1、0.5、1、10 s-1。实验中试样的总应变确定为0.7左右。

2 结果与讨论

2.1 单向压缩试验

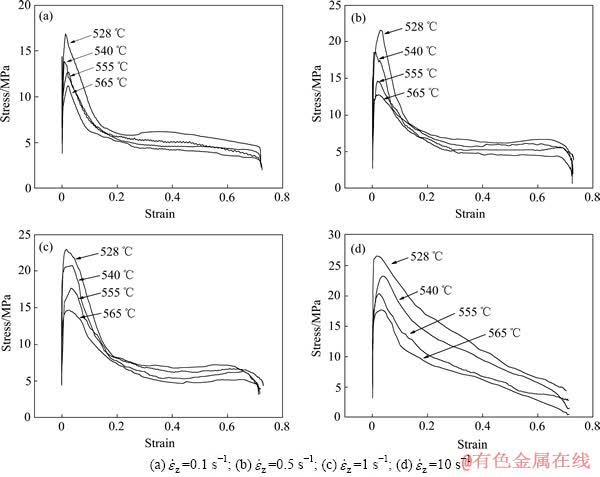

不同温度和应变速率下的压缩真应力—真应变曲线如图3所示。从图3可以看出,各个曲线的变化趋势基本相似,可以将其分成3个阶段[10]:第一阶段,当应变小于0.05时,流变应力迅速增大并达到峰值。半固态7050铝合金在变形前经历二次重熔,其组织可以看成是由液相和固相组成的骨架组成。在压缩变形初期,圆柱试样的中心等静压力大,液相从中心向外围流动而发生宏观的液相转移,固相颗粒搭成的骨架尚未破坏,此时流变应力表现为快速升高,这一阶段的变形机制主要为液相的流动和固液混合流动。第二阶段,当应变为0.05~0.1之间时,在外力的作用下,固相颗粒的骨架被破坏,随后的变形主要是通过固相颗粒之间的滑移和塑性变形实现的。固相颗粒之间的滑移是通过剪切力来实现的,这就造成了固相颗粒的边界处受拉而产生孔洞,从而来协调固相颗粒间的滑移,并且孔洞沿着液相迅速扩展,导致固相液相的分离,出现流变应力迅速下降,宏观上表现为试样表面的破裂现象。第三阶段,当应变超过0.1后,流变应力保持在一个稳定状态,试样破裂后液相不断被挤出。固相之间液相的减少使得固相粘结在一起发生塑性变形,此时流变应力基本在稳态附近波动。

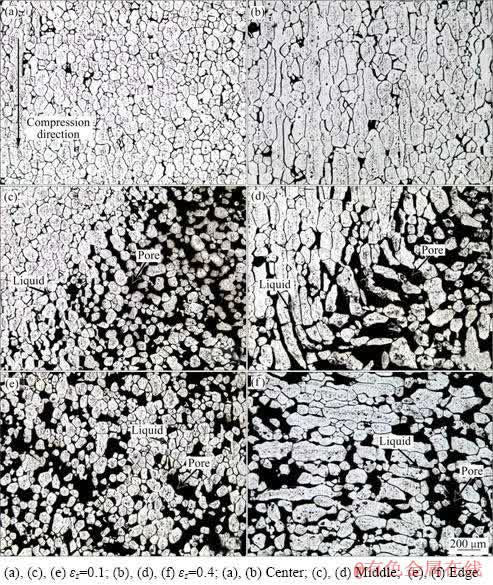

图4所示为半固态压缩后从中心到边缘的显微组织图,压缩方向如图4(a)箭头方向所示。当应变量为0.1时,如图4(a)、(c)和(e)所示,晶粒的形状未发生改变,仍为球形,只是边缘的液相量比中心高,并且过渡区域内的晶粒和液相显著地向边缘流动,这说明在变形初期主要是液相由中心向边缘流动;当应变量提高到0.4时,如图4(b)、(d)和(f)所示,试样中心的晶粒由于滑移产生的剪切力发生塑性变形而被拉长[11-13],并且边缘的晶粒有团聚现象出现,过渡区域内变形的晶粒和液相一起向边缘流动,这说明在变形的中后期主要是发生晶粒的滑动和塑性变形。

图3 不同温度和应变速率下半固态7050铝合金压缩真应力—真应变曲线

Fig. 3 Compression true stress—true strain curves of semi-solid 7050 aluminum alloy with different temperatures and strain rates

图4 半固态压缩后不同部位的显微组织

Fig. 4 Microstructures at different positions after deformation

同时,由图3(d)还发现,当变形速率为10 s-1时,曲线的下降趋势稍微不同于其他曲线。这是由于应变速率较大时,孔洞的形成跟不上形变过程,即裂纹的扩展跟不上形变。此时变形接近固相变形过程,所以在压缩过程中流变应力下降趋势变缓,基本上不出现应变速率较低时的稳定曲线阶段。同时,尽管不同变形条件下的稳定阶段的应力值相差较小,但峰值相差较大。峰值的大小取决于固相晶粒间的粘合力和合金内部的摩擦力,应变速率越快,晶粒运动越快,合金内部的摩擦力越大;温度越低,晶粒液相越少,晶粒间缺少液相的润滑,摩擦力越大,同时温度低,液相流动性差,晶粒间的粘合力也越大[14-15]。总之,变形温度越低,应变速率越高,流变应力的峰值越高。

2.2 跳跃试验

通过单向压缩试验研究了半固态7050铝合金的压缩变形的力学行为,同时还研究了流变应力峰值和最小值的变化特征。这些行为特征与合金微观结构有密切的关系,同时合金的微观结构又受到外部条件的影响,例如温度、应变速率以及变形量。但在单向压缩试验中,无论是应力的峰值还是最小值都不能获得半固态材料对温度、应变速率和变形量敏感性的客观评价,因此,进行了温度、应变速率以及应变的跳跃试验。

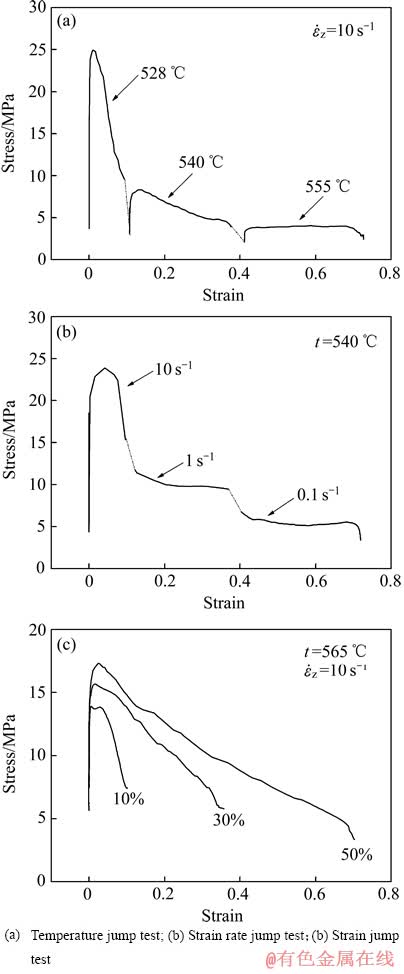

图5所示为半固态7050铝合金的温度和应变速率跳跃试验,突变点的应变分别为0.1、0.4。其中,图5(a)所示为温度突升的曲线,升温速率3 ℃/s,到达设定温度保温10 s后,压缩至设定的应变量,然后重复此过程直至完成实验,整个压缩过程始终是同一个试样;图5(b)所示为应变速率突降的曲线。由图5(a)可以看出,当温度在528 ℃时,流变应力表现出一个峰值,峰值应力与图3(a)中的峰值应力相接近;当温度突变到540 ℃时,流变应力则表现出一个较小的峰值,但峰值应力远远低于图3(b)中的峰值应力。当温度突变到555 ℃时,流变应力无峰值出现,表现出稳定值。这些结果表明,在较低的温度下,合金内部结构的调整跟不上合金变形的过程,表现出流变应力的迅速增加。当温度较高时,液相流动、晶粒滑动等过程能够协调形变的发生,流变应力表现出平稳趋势。由图5(b)可以看出,当应变速率突降时,应力立即减小,在10 s-1阶段会表现出峰值。当应变突减时,流变应力立即减小到另一水平。在0.1和1 s-1阶段,随着应变的增加,应力缓慢减小,曲线的变化趋势越来越平缓。这一结果表明,在较低的应变速率下,结构的调整完全可以适应应变速率的变化。

图5 半固态7050铝合金跳跃试验

Fig. 5 Jump tests of semi-solid 7050 aluminum alloy

图5(c)所示为不同应变量的半固态7050铝合金真应力—真应变曲线。由图5(c)可以看出,随着变形量的增加,真应力的峰值增大,且峰值过后流变应力的变化趋势越来越平缓。峰值应力随着变形量的增大而升高,这是由于变形量增大时,变形越来越接近固相的变形,流变应力随变形量的增大而越来越高。当变形量较小(10%)时,变形过程主要以液相的流动为主,流变应力很快上升,到达峰值很快下降;当变形量较大(50%)时,液相从中心流向边缘,部分固相颗粒发生接触并产生相互滑动和塑性变形来协调形变的发生,从而流变应力表现出平缓下降的趋势。当变形量介于中间值(30%)时,流变应力曲线也介于两者之间。

综上所述,半固态7050铝合金的变形行为对变形温度、应变速率和变形量较敏感。半固态合金的压缩变形行为与它们密切相关,变形温度、应变速率和应变决定了半固态压缩的主要变形方式。

2.3 粘塑性本构方程的建立

在前面的讨论中可以得知,半固态的7050铝合金在半固态温度区间内的压缩流变应力与变形温度、变形速率以及变形量存在相关性。在对高固相率的半固态金属本构关系描述中可知[16],轴向应力 与轴向应变速率

与轴向应变速率 、轴向应变

、轴向应变 为幂函数关系,而与温度t、液相率fL为指数函数关系。同时由图3的压缩真应力—真应变曲线观察到:当应变

为幂函数关系,而与温度t、液相率fL为指数函数关系。同时由图3的压缩真应力—真应变曲线观察到:当应变 <0.1时,曲线存在峰值,并且应力上升很快;当应变

<0.1时,曲线存在峰值,并且应力上升很快;当应变 >0.1时,流变应力变化平缓。因此,采用分阶段的方法建立粘塑性本构方程。同时考虑到在变形初期流变应力主要受到液相的影响,变形中后期流变应力主要受固相滑动和变形的影响,因此对轴向应力

>0.1时,流变应力变化平缓。因此,采用分阶段的方法建立粘塑性本构方程。同时考虑到在变形初期流变应力主要受到液相的影响,变形中后期流变应力主要受固相滑动和变形的影响,因此对轴向应力 与轴向应变速率

与轴向应变速率 、轴向应变

、轴向应变 、温度t和液相率fL之间的关系假设如下:

、温度t和液相率fL之间的关系假设如下:

(其中

(其中  ),

), <0.1 (1)

<0.1 (1)

,

, >0.1 (2)

>0.1 (2)

式中: 为轴向应力;

为轴向应力; 为轴向应变速率;

为轴向应变速率; 为轴向应变;t为变形温度;fL为液相率;

为轴向应变;t为变形温度;fL为液相率; 为几何参数(

为几何参数( =1.5);a0、a1、a2、a3、a4、b1、b2、b3均为常数;tM为纯金属溶剂的熔点;tL为合金的液相线温度;K为平衡分配比值。

=1.5);a0、a1、a2、a3、a4、b1、b2、b3均为常数;tM为纯金属溶剂的熔点;tL为合金的液相线温度;K为平衡分配比值。

对式(1)和(2)两边取对数,即把非线性回归转化成线性回归处理,得

,

, <0.1 (3)

<0.1 (3)

,

, >0.1 (4)

>0.1 (4)

式(3)和(4)可用一次数学模型表示:

,

, <0.1 (5)

<0.1 (5)

,

, >0.1 (6)

>0.1 (6)

式中: ,

, ,

, ,

, ,

, ,

, ,

, ,

, ,

, ,

, ,

, ,

, ,

, ,

, 。

。

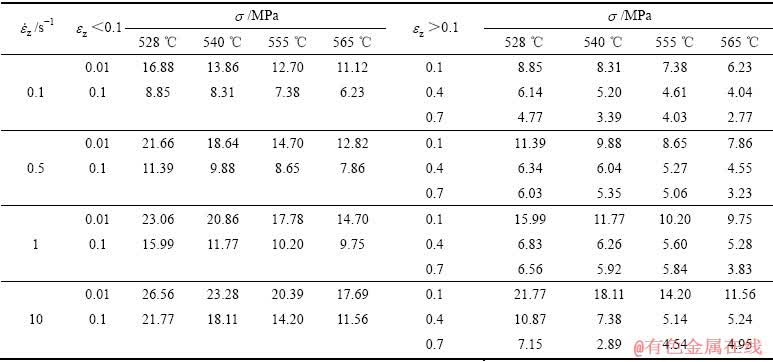

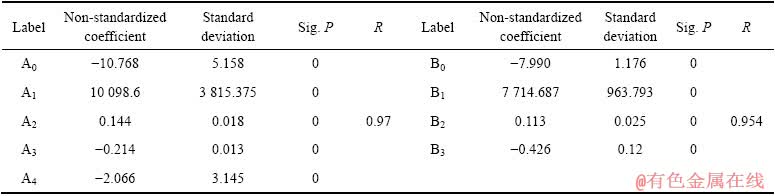

半固态压缩实验材料选用直径为10 mm,高为15 mm的半固态7050铝合金,在Gleeble-3500热模拟试验机上进行试验,其真应力—真应变曲线如图3所示。在回归分析计算过程中,取应变分别为0.001、0.1、0.4和0.7时的应力,如表1所示。利用SPSS数理统计软件进行统计检验指标与回归系数的计算,求出回归系数与各项统计指标的值,见表2。

通过式(3)~(6)的换算,将相关参数代入式(1)和(2),可得:

(

( ),

), <0.1 (7)

<0.1 (7)

,

, >0.1 (8)

>0.1 (8)

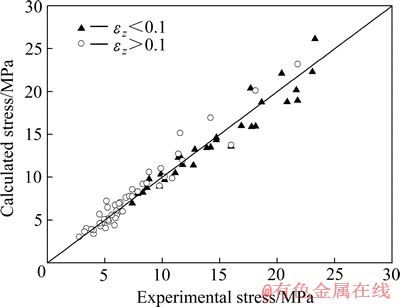

式(7)和(8)为半固态7050铝合金的压缩应力对应变速率、压缩应变、温度以及液相分数的粘塑性本构方程。从表2中可以看出估算值及其检验结果,两阶段的相关系数分别为0.951和0.954,同时各个参数的相伴概率值sig. p<0.001。说明回归系数与0有显著差别,该回归方程有意义。图6所示为实验所得的流变应力值与计算值的比较,可见流变应力的计算值与实验值在45°直线附近,即说明计算值与实验值符合较好。

表1 轴向应力 与轴向应变

与轴向应变 、应变速率

、应变速率 、温度t的原始数据

、温度t的原始数据

Table 1 Original data of stress , strain

, strain  , strain rate

, strain rate  and temperature t

and temperature t

表2 非线性回归系数

Table 2 Nonlinear regression coefficients

图6 流变应力实验值与计算值的关系

Fig. 6 Correlation between experimental and calculated stress values

2.4 有限元模拟及实验验证

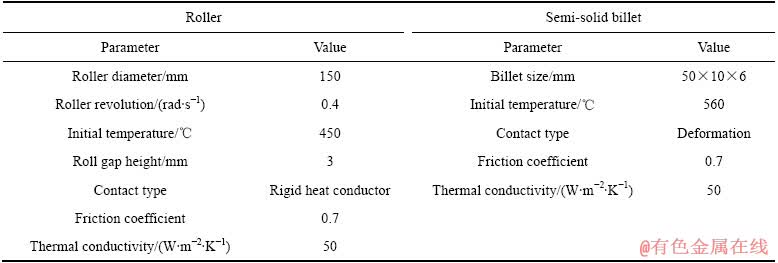

在MARC软件中建立了轧辊和坯料的几何模型[17-20],并将前面建立的粘塑性本构方程导入到该软件中,选择热力耦合分析,模拟完成后,采用卧式轧机对半固态7050铝合金进行了触变轧制的实验研究,其中实验和模拟参数如表3所示。

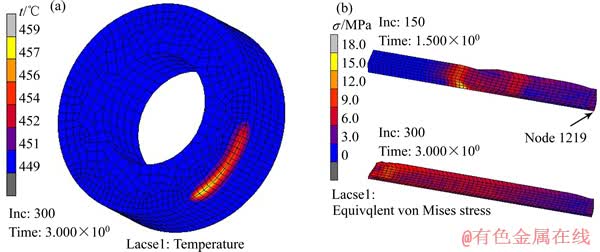

图7(a)所示为轧制完成后轧辊的温度场。由图7(a)可以看出,轧制过程中轧辊热传导过程仅仅是集中在轧辊表面很薄的一层内,温度最高上升了10 ℃左右。图7(b)所示分别为轧制过程中和轧制刚结束时坯料的等效应力云图。由图7(b)可以看出,在轧制过程中最大等效应力出现在轧制变形区,最大等效应力达到了18 MPa;轧制刚结束时,由于尾部还被咬在轧辊中,故等效应力较大,此时整体上等效应力分布均匀,平均等效应力在8 MPa左右。这表明半固态成形具有变形抗力低,等效应力分布均匀的特点。

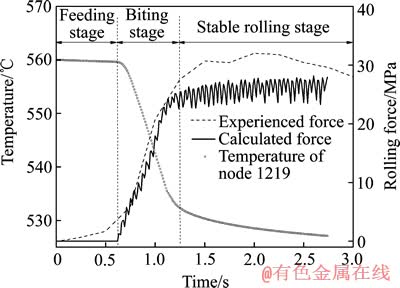

图8所示为坯料顶端节点温度变化历程和轧制力变化的实验、模拟曲线。由图8可以看出,在0.6 s的时候,坯料进入轧辊,此后由于接触热传导,坯料的温度降低。同时,随着温度的降低,半固态坯料的变形抗力增大,于是轧制力也相应升高,稳定阶段的轧制力为25 MPa左右。其中,实验测得的曲线是在与模拟相同工艺参数条件下获得的,轧辊轧制前使用乙炔焰迅速加热到450 ℃,轧制力数据利用与轧辊相连接的力学传感器进行收集。由图8可见,二者之间还是存在一些差别,主要是轧制力的实验值偏大,其原因可能是试样在运送至轧辊的过程中温度有所降低。

表3 有限元模拟的计算输入参数

Table 3 Input parameters for calculation in finite element simulation process

图7 轧辊和坯料的有限元模拟结果

Fig. 7 Finite element simulation results of temperature field of roller (a) and stress field of semi-solid billets (b)

图8 坯料顶端节点温度、轧制力的时间历程曲线

Fig. 8 History plot of front node temperature and rolling force

半固态7050铝合金的轧制力计算曲线和实验曲线都经历了快速上升过程和平稳过程,实验的结果与模拟的结果符合较好,这说明前面建立的本构模型基本上是合理和正确的。

3 结论

1) 温度和应变速率的跳跃实验以及不同变形量的压缩试验表明,半固态7050铝合金的流变应力与压缩温度、应变速率以及应变具有相关性。在在0.1~10 s-1的应变速率范围内,流变应力随温度的升高明显降低;随应变速率的升高而升高;随着变形量增大,流变应力稍有提高。

2) 可用包含轴向应力 与轴向应变速率

与轴向应变速率 、轴向应变

、轴向应变 、温度t和液相率fL的参量描述半固态7050铝合金触变变形行为。

、温度t和液相率fL的参量描述半固态7050铝合金触变变形行为。

3) 半固态7050铝合金触变轧制过程轧制力经历了先快速上升再平稳变化的过程,稳态轧制力为25 MPa。实验结果与模拟结果符合较好,这说明针对半固态轧制过程所建立的本构模型基本上是合理和正确的。

REFERENCES

[1] STALEY J T, LIU J, HUNT W H. Aluminum alloys for aerostructures[J]. Advance Materials and Processes, 1991, 152(4): 17-20.

[2] FLEMMINGS M C. Behavior of metal and alloys in the semi-solid state[J]. Metallurgical Transactions B, 1991, 22(3): 269-293.

[3] LUO Shou-jing, KEUNG W C, KANG Yong-lin. Theory and application research development of semi-solid forming in China[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 1805-1814.

[4] ZHAI Yan-bo, LIU Chang-ming, HAN Zhao-tang, WANG Kai. Semi-solid squeeze casting process of a ZL109 alloy[J]. Rare Metals, 2008, 27(3): 329-334.

[5] BOLOURI A, SHAHMIRI M, CHESHMEH E N H. Microstructural evolution during semisolid state strain induced melt activation process of aluminum 7075 alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 1663-1671.

[6] GUNASEKERA J S. Development of a constitutive model for mushy (semi-solid) materials[C]// Proceedings of the Second International Conference: Processing of Semi-Solid Alloys and Composites. USA: Cambridge Press, 1992: 211-222.

[7] IWASAKI H, MORI T, MABUCHI M, HIGASHI K. Shear deformation behavior of Al-5% Mg in a semi-solid state[J]. Acta Materialia, 1998, 46(18): 6351-6360.

[8] KlUCHI M, YANAGIMOTO J, YOKOBAYASHI H. Flow stress, flow stress, yield criterion and constitutive equation of mushy/semi-solid alloys[J]. CIRP Annals - Manufacturing Technology, 2001, 50(1): 157-161.

[9] KOEUNE R, PONTHOT J P. An improved constitutive model for the numerical simulation of semi-solid thixoforming[J]. Journal of Computational and Journal of Computational and Applied Mathematics, 2010, 234(7): 2287-2296.

[10] 潘 冶, 曹洪波, 孙国雄. 半固态铝硅合金的压缩变形行为与组织变化[J]. 中国有色金属学报, 2005, 15(4): 552-557.

PAN Ye, CAO Hong-bo, SUN Guo-xiong. Compressive deformation behavior and microstructure of semi-solid Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(4): 552-557.

[11] 范 曦, 潘清林, 李建湘, 杨志兵, 刘晓艳, 覃银江. Al-Mn-Mg-Cu-Ni合金热压缩变形的流变行为和组织[J]. 中国有色金属学报, 2010, 20(3): 420-426.

FAN Xi, PAN Qing-lin, LI Jian-xiang, YANG Zhi-bin, LIU Xiao-yan, QIN Yin-jiang. Flow behavior and microstructure of Al-Mn-Mg-Cu-Ni alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 420-426.

[12] SHANG Shu-zhen, LU Gui-min, TANG Xiao-ling, ZHAO Zu-xin, WU Cheng-ming. Deformation mechanism and forming properties of 6061Al alloys during compression in semi-solid state[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 1725-1730.

[13] CHEN Yong-nan, WEI Jian-feng, ZHAO Yong-qing. Compressive deformation and forging behavior of Ti14 alloy in semi-solid state[J]. Materials Science and Engineering A, 2009, 520(1/2): 16-22.

[14] KANG C G, CHOI J S, KIM K H. The effect of strain rate on macroscopic behavior in the compression forming of semi-solid aluminum alloy[J]. Journal of Materials Processing Technology, 1999, 88(1/3): 159-168.

[15] CHEN Yong-nan, WEI Jian-feng, ZHAO Yong-qing, MA Xue-dan, HAO Jian-min. Influence of processing parameters on the deformation behavior of Ti14 alloy containing a small volume of liquid[J]. Rare Metal Materials and Engineering, 2012, 41(2): 199-202.

[16] 马冬威, 李淼泉, 罗 皎, 于卫新, 苏少博, 吴娟利. 基于应变影响的7A09铝合金等温压缩流动应力模型[J]. 中国有色金属学报, 2011, 21(5): 954-960.

MA Dong-wei, LI Miao-quan, LUO Jiao, YU Wei-xin, SU Shao-bo, WU Juan-li. Flow stress model considering contribution of strain in isothermal compression of 7A09 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(5): 954-960.

[17] 胡 勇, 何柏林, 闫 洪. 镁基复合材料半固态压铸过程的数值模拟[J]. 中国有色金属学报, 2010, 20(7): 1260-1266.

HU Yong, HE Bo-lin, YAN Hong. Numerical simulation of semi-solid die casting process of magnesium matrix composite[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1260-1266.

[18] 黄红乾, 曹富荣, 管仁国, 赵占勇, 邢振环. 半固态合金强流变轧制单位轧制压力分布的数学模型和理论研究[J]. 金属学报, 2011, 47 (3): 291-297.

HUANG Hong-qian, CAO Fu-rong, GUAN Ren-guo, ZHAO Zhan-yong, XING Zhen-huan. Mathematical model and theoretical research of unit rolling pressure distribution in rectangular groove during rheo-rolling of semisolid alloy[J]. Acta Metallurgica Sinca, 2011, 47 (3): 291-297.

[19] DU Yan-yan, LU Yi-ping, WANG Tong-min, LI Ting-ju, ZHANG Guo-liang. Effect of electromagnetic stirring on microstructure and properties of Al0.5CoCrCuFeNi alloy[J]. Procedia Engineering, 2012, 27: 1129-1134.

[20] GUAN Ren-guo, ZHAO Zhan-yong, CHAO Run-ze, LIAN Chao, WEN Jing-lin. Simulation of temperature field and metal flow during continuous semisolid extending extrusion process of 6201 alloy tube[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(5): 1182-1189.

(编辑 何学锋)

基金项目:中央高校基本科研业务费重点项目(2011zz0010)

收稿日期:2013-06-14;修订日期:2013-09-28

通信作者:刘允中,教授,博士;电话:020-87110099;E-mail: yzhliu@scut.edu.cn