DOI: 10.11817/j.ysxb.1004.0609.2020-37577

电磁搅拌参数对椭圆坩埚中半固态铝合金熔体流动与凝固组织的影响

赵军超1,刘 政1,李泽文1,孙梦桐2

(1. 江西理工大学 机电工程学院,赣州 341000;

2. 江西理工大学 材料科学与工程学院,赣州 341000)

摘 要:运用ANSYS有限元分析软件对半固态A356铝合金凝固过程中的流场进行模拟,研究电磁搅拌参数(电磁频率和电流强度)对合金熔体流动与凝固组织的影响。结果表明:随着电磁频率和电流强度的增大,半固态铝合金在椭圆坩埚长轴X和短轴Y上的最大电磁力和最大流速均呈现出先增大后减小的趋势,并且长轴X上的最大电磁力和最大流速均大于短轴Y上的;施加电磁搅拌后,电磁力从坩埚的中心处沿半径方向逐步增大,到0.8~0.9倍的坩埚半径处电磁力达到最大,超过该距离后,电磁力又开始急剧降低。椭圆坩埚中电磁力受电流强度的影响更大,而流速受电流强度和电磁频率的敏感度不如电磁力,但电流强度对流速的影响依旧略强于电磁频率;当电磁频率和电流强度分别为30 Hz和5 A时,半固态A356合金初生相的平均等积圆直径为106.1 μm,平均形状因子为0.72,此时制备出的半固态合金组织最好。

关键词:半固态铝合金;电磁搅拌;电磁频率;电流强度;椭圆坩埚

文章编号:1004-0609(2020)-07-1523-12 中图分类号:TG146;TG244 文献标志码:A

利用电磁搅拌法制备半固态合金浆料,其具有不与熔体直接接触、无污染、穿透性强且工艺简单等优势,可以直接有效地作用于合金熔体,使熔体受迫运动,从而对合金的凝固组织产生影响。为了进一步探明电磁场作用下合金熔体流动对凝固组织的影响,人们研究和开发了诸如行波电磁场搅拌[1]、分级电磁搅拌[2]、双向电磁搅拌[3]、双向间歇电磁搅拌[4]、电磁振荡[5]、脉冲磁场[6]、双轴电磁搅拌[7]等,目的都是为了更好地调控半固态合金在电磁场作用下的熔体流动,从而得到符合半固态加工要求的合金浆料。对合金熔体施加电磁场,使合金熔体的凝固过程处于一种非平衡状态,而凝固过程中涉及固相与液相的转变以及电磁场与温度场、流场的耦合,合金熔体的内部情况变得极为复杂,各项物理量的测量也变得非常困难。近年来,随着计算机技术和各种相关实用软件的开发应用,数值模拟技术[8-11]也被广泛地应用到了流体力学、结构分析和冶金过程控制中,解决了过去简单的依靠反复实验和理论知识解决实际生产应用过程中的问题,利用计算机科学中的辅助模拟仿真计算功能已成为材料成型研究的一种重要方法[12-15]。

利用电磁搅拌技术制备半固态合金浆料受诸多因素的影响,但在很大程度上受到外加磁场大小以及分布情况的影响,而磁场的大小和分布受电磁频率、电流强度以及实验仪器的材质等因素影响。目前,国内外学者主要利用的是圆形坩埚来研究电磁搅拌参数对合金组织的影响,而对于非圆坩埚来说,由于其结构不是旋转对称的,各方向上半径不等,在旋转磁场中便会引起熔体内的磁场大小和分布的变化,进而引起电磁力和流场变化,这对正在凝固的合金熔体将会产生影响。而针对在非圆坩埚中,关于电磁搅拌参数(电磁频率和电流强度)对半固态合金熔体流动规律与凝固组织影响的研究很少,因此,有必要对此做进一步研究。本研究运用ANSYS15.0有限元软件建立模型,模拟电磁搅拌下椭圆坩埚中半固态铝合金浆料的流动情况,力争获得在不同电流强度和电磁频率下半固态铝合金熔体的流动规律,并进行实验验证,确定实际电磁搅拌的最佳参数,以获得组织形貌较好的半固态初生相,为研究电磁场作用下的半固态合金熔体的凝固规律及其对凝固组织的影响提供新的思路与方法。

1 数值模拟

通电线圈产生磁场,迫使合金熔体受力运动,故对其流场进行分析时,要用到相关的电磁场Maxwell方程,流体运动的Navier-Stokes方程以及能量平衡方程联立求解。

1.1 电磁场计算模型

电磁场Maxwell方程

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

式中:H为磁场强度;E为电场强度;J为电流密度;B为磁感应强度;t为时间;f为洛伦兹力; 为哈密顿算子。

为哈密顿算子。

1.2 流场计算模型

半固态铝合金浆料的流动属于湍流,利用不可压缩黏性流体动力学中的连续性方程、动量方程方程及湍流模型方程,建立描述二维流动的数学模型,对流场进行了计算。

1.2.1 连续性方程

对于不可压缩流体,其流体密度为常数,连续性方程可简化为

在电磁力作用下,铝合金熔体的流动控制方程应在原有的基础上,在源项中需要附加一项电磁力。

(5)

(5)

(6)

(6)

式中:u为流速; 为有效黏度;

为有效黏度; 为层流黏度系数;

为层流黏度系数; 为湍流黏性系数,

为湍流黏性系数, ;F为电磁体积力。

;F为电磁体积力。

1.2.2 标准 模型

模型

湍动能k方程:

(7)

(7)

湍动能耗散率 方程:

方程:

(8)

(8)

式中:t为时间; 为密度;p为压力;ui、uj为黏度系数在i、j方向上的分量;k为湍动能;

为密度;p为压力;ui、uj为黏度系数在i、j方向上的分量;k为湍动能; 为湍动能耗损率;c1、c2、

为湍动能耗损率;c1、c2、 、

、 为经验常数,分别为1.44、1.92、1.0、1.3。

为经验常数,分别为1.44、1.92、1.0、1.3。

1.3 物理模型

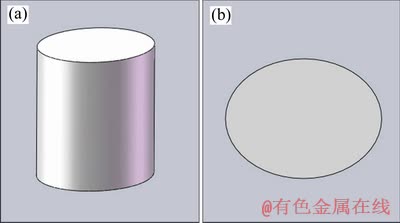

实验用设备为EM100-4T91型多功能电磁搅拌器,主要由本体外壳、铁芯和线圈三大部分构成,电磁搅拌器的工作原理与三相两极式实心转子异步电动机的原理基本相同,因此构建的电磁搅拌器模型,可以按照三相异步电动机的定子模型[16-19]来建立。搅拌器形状尺寸为:外径d 560 mm,内径d 288 mm和高度400 mm;主要的技术参数为:额定电流为150 A,频率为1~35 Hz,极数6,定子外径与内径分别为516 mm和454 mm,接线线圈匝数为120。实验所用非圆坩埚尺寸为长短轴比例为1.3:1的椭圆形坩埚,即长轴半径为42.6 mm,短轴半径为32.75 mm,高度为100 mm,结构模型如图1所示。本实验主要运用有限元分析软件ANSYS15.0构建物理模型,设定电流强度和电磁频率的大小来求解半固态铝合金熔体所受的最大电磁力,再把求得的最大电磁力以外加力源的形式加载到铝合金熔体流场中,分析所用的类型选用标准湍流模型,从而求得电磁搅拌参数对铝合金熔体所产生的最大流速。

图1 椭圆坩埚结构示意图

Fig. 1 Structure profile of oval crucible

1.4 物理模型假设

在对铝合金熔体的电磁场和流场进行模拟时,进行如下假设:

1) A356铝合金熔体视为不可压缩的牛顿流体。

2) 忽略温度对电磁搅拌装置内部材料磁导率、电阻率的影响。在本文研究范围内,温度不会造成半固态铝合金密度的增大或减小。

3) 不计坩埚的厚度,且坩埚不会由于温度的变化而导致坩埚的尺寸膨胀或者收缩。

4) 忽略铝合金熔体运动对电磁场的影响。

5) 对于电磁搅拌器内部冷却水,由于磁导率较小,可视为空气处理,线圈漆包线以及短距离空气等,可忽略其对磁场所带来的影响。

1.5 单元类型以及模拟的相关参数的确定

在利用ANSYS进行铝合金电磁场分布的模拟中,铝合金熔体、空气、通电线圈以及定子均采用PLANE53单元,二维形状为6节点的三角形。把最大电磁力加载到Fluent的流场分析中,采用的单元类型与电磁场模拟相同,仿真只分析铝合金熔体。模型材料的物理属性为:空气、通电线圈以及半固态铝合金浆料的相对磁导率均为1,定子铁芯的相对磁导率为3000,通电线圈的电阻率为1.7×10-8 Ω·m,半固态铝合金的电阻率为2.1×10-7 Ω·m。

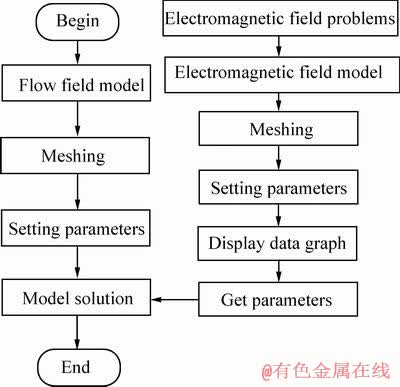

1.6 磁-流耦合模拟流程

模型采用顺序耦合[20]的方法,由于流体对磁场的影响较小,可忽略不计。因此只考虑电磁场对熔体流动所产生的作用。通过对电磁场的模拟结果,可以得到半固态铝合金在各电流强度以及电磁频率的作用下所受的最大电磁力。将最大电磁力作为源附加项加载到fluent的流场分析模块中,然后分析电磁力对铝合金熔体流动的影响,进而说明电流强度与电磁频率对熔体流动的影响,计算步骤如图2所示。

2 模拟结果

2.1 电流强度和电磁频率对最大电磁力的影响

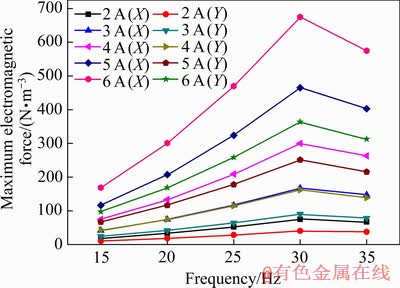

不同电流强度和电磁搅拌频率对半固态铝合金浆料在椭圆坩埚长短轴上产生的最大电磁力如图3所示。

从图3可以明显看出,电流强度和电磁频率均会对坩埚半径上的最大电磁力产生影响。在电流强度一定时,随着电磁频率的逐渐增大,半固态铝合金在坩埚长轴X和短轴Y上所受到的最大电磁力呈现出先增大后减小的趋势,而且在同一频率下长轴X上的最大电磁力大约是短轴Y上的最大电磁力的1.8倍,这也说明在椭圆坩埚中半径越长,其上的最大电磁力越大。在电磁频率一定时,随着电流强度的增大,长轴X和短轴Y上的最大电磁力也逐渐增大。当电磁频率30 Hz时,长轴X和短轴Y上最大电磁力分别由电流强度为2 A时的75 N/m3和40.5 N/m3,增大到电流强度为6 A的675 N/m3和363.6 N/m3,长轴X和短轴Y的最大电磁力均增幅几近800%,而当电磁频率增大到35 Hz时,长轴X和短轴Y上的最大电磁力则略有降低。

图2 计算流程示意图

Fig. 2 Calculation flow diagram

图3 不同电流强度和电磁频率下的最大电磁力

Fig. 3 Maximum electromagnetic force under different current intensities and electromagnetic frequencies

图4 不同电流强度和电磁频率下的电磁力在坩埚半径上的分布

Fig. 4 Distribution of electromagnetic force under different current intensities and electromagnetic frequencies over major axial X((a1), (b1), (c1), (d1), (e1)) and minor axial Y((a2), (b2), (c2), (d2), (e2)) of crucible

图4所示为不同电磁频率下的电磁力在坩埚长轴X和短轴Y上的分布情况。由图4可知,在电流强度一定的情况下,随着电磁频率的增加相应半径位置上的电磁力也逐渐变大,且在同一电磁频率下,在坩埚的长半轴和短半轴的半径方向上,半固态铝合金熔体所受到的电磁力整体上变化趋势相同,都随着半径的增加而呈现出先增大后减小的趋势。从合金熔体中心处到0.8~0.9倍的坩埚半径处的电磁力达到最大,且长轴上的最大电磁力是短轴上的2倍左右,而超过该距离后,长轴和短轴上的电磁力均开始急剧降低。合金熔体的中心到0.4~0.6倍的坩埚长轴半径和短轴半径处,电磁力均出现了一个小幅增加,可能是由于模拟所用的是椭圆坩埚,其内部熔体的电阻率使得电磁场在熔体内的分布变得较为复杂,进而导致电磁力在0.4~0.6倍距离处出现了小幅增加。

2.2 电流强度和电磁频率对熔体最大流速的影响

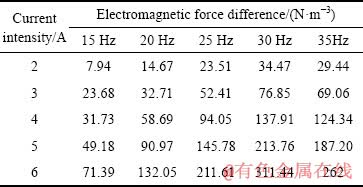

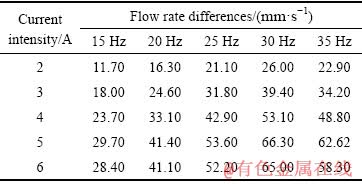

铝合金熔体受到电磁力的作用,熔体在径向上呈现旋转运动。由于磁感电流的集肤效应,使得电磁感应强度分布由外往里逐渐递减,这与陈兴润等[9]、陈志平等[21]研究的结果基本一致。集肤效应导致熔体内部的流场分布也不均匀,在熔体边缘的流速最大,从边缘处到熔体中心位置逐步减小。表1所列为不同电流强度和电磁频率下椭圆坩埚长短轴的电磁力差,可以看出,电流一定时,随着频率的不断增加,电磁力差值呈现出先增大后减小趋势。在电磁频率一定时,随着电流强度的增大,电磁力差呈现出逐渐增大的趋势。

表1 不同电流强度和电磁频率下长短轴的电磁力差

Table 1 Electromagnetic force differences at major and minor axial under different current intensities and electromagnetic frequencies

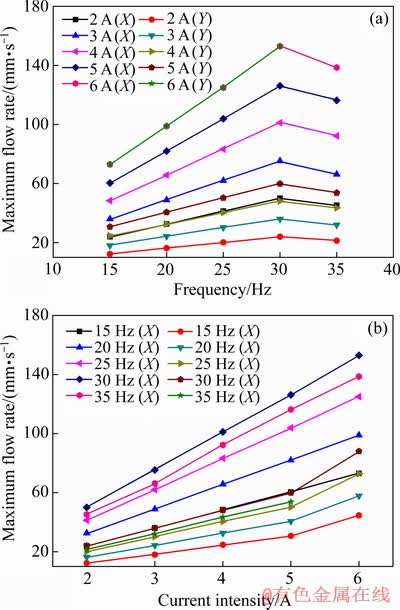

图5所示为不同电流强度和电磁频率下的椭圆坩埚中熔体的流速变化。可以看出,电流强度和电磁频率均会对熔体的最大流速产生影响。如图5(a)所示,在电流强度一定时,随着电磁频率的增加,熔体在长轴X和短轴Y上的最大流速均呈现出先增大后降低的趋势,且长轴X上的流速明显大于短轴Y上的流速,在电磁频率为30 Hz时,熔体所受最大流速达到最大,当电磁频率进一步增大为35 Hz时,熔体所受的最大流速反而降低,且电磁力差的变化趋势与流速一致。

图5 不同电磁频率和电流强度下的熔体的流速

Fig. 5 Flow rates of melt at different electromagnetic frequencies (a) and current intensities(b)

当电磁频率一定时,随着电流强度的增加,熔体在长轴X和短轴Y上的最大流速呈现出增大的趋势,长轴X上的流速明显大于短轴Y上的流速,如图5(b)所示。

熔体在长短轴上的流速不同,定义其差值为流速差,流速差的升高或降低会影响熔体流动的紊乱程度,因为在电磁力的作用下,椭圆坩埚中的熔体做圆周运动时,由于坩埚的径向尺寸是变化的,越是靠近坩埚壁的熔体,其流动速率不等,且呈周期性变化,这种因流速差引起的变化导致相同熔体流层内的流动不稳定,产生紊乱,甚至混沌流动[22-23]。这将对铝合金熔体凝固过程中的质量、热能和动量传输皆有较大影响,继而影响合金最终的凝固组织。表2所列为不同电流强度和电磁频率下椭圆坩埚长短轴的流速差。可以看出,在电流强度一定时,其差值随电磁频率的增加流速差先增大后减小,且在电磁频率为30 Hz时,流速差达到最大;在电磁频率一定时,其差值随着电流强度的增加,其差值也呈现出增大后略减小的趋势。对比5 A与6 A的流速差值,可以看出随着电磁频率和电流强度的增加,熔体所受的电磁力以及熔体的流速都随之增加,但当电流强度升到6 A时,随着电磁力差值的进一步扩大,流速差降低。而流速差的降低会影响熔体中晶粒的细化程度和分布的均匀度。因此,在本实验范围内,电流强度为5 A,电磁频率为30 Hz时是电磁搅拌的最合适电流参数值。

表2 不同电流强度和电磁频率下长短轴的流速差

Table 2 Flow rate differences at major and minor axial under different current intensities and electromagnetic frequencies

3 实验过程

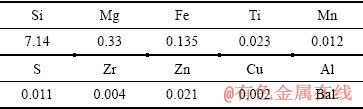

本实验选用的是A356铝合金(国内牌号为ZL101),其主要成分为如表3所列。

表3 A356铝合金主要成分

Table 3 Main components of A356 aluminum alloy (mass fraction, %)

将石墨坩埚预热到200~300 ℃,设定温度为750 ℃使铝锭快速融化;在铝合金铝锭完全熔化后,加入适量覆盖剂(50%NaCl+50%KCl,质量分数),避免铝合金熔体吸气而导致合金被氧化,5 min后清除杂质,然后静置10 min;将坩埚从熔炼炉中取出,添加精炼剂六氯乙烷(99.5%C2Cl6,质量分数),添加量为铝合金熔体的质量分数为0.2%~0.7%,将其分成2~3次放进溶液内并压入坩埚底部,每加入一次后进行除渣,精炼总时间控制在10~15 min。将炉体温度降至650 ℃,匀速浇注到预热360℃的不锈钢铸型(长轴直径为85.2 mm,短轴直径为65.5 mm,长短轴之比为1.3:1;铸型厚度和高度分别为4 mm、100 mm)内;将铸型放入电磁搅拌器中,按照数值模拟设定的电磁频率和电流强度对铝合金熔体进行搅拌,时间为12 s,搅拌结束后对其进行590 ℃保温处理,保温10 min后进行水淬,最后脱模进行后续处理。

金相研磨与组织检测部分工艺流程:预磨→粗磨→抛光→0.5%HF(体积分数)水溶液腐蚀→金相组织观察→获取金相图片→对金相进行形貌及尺寸分析。

最后进行定量金相分析,使用image-Pro-Plus和ORIGIN8.0软件对试样中的平均等积圆直径D和平均形状因子F进行测量计算,其计算公式分别为

(9)

(9)

(10)

(10)

式中:A为初生相的平均面积;P为凝固组织中初生相的平均周长。F值越接近1,合金的晶粒的圆整度越好,晶粒的形貌越理想。

4 实验结果

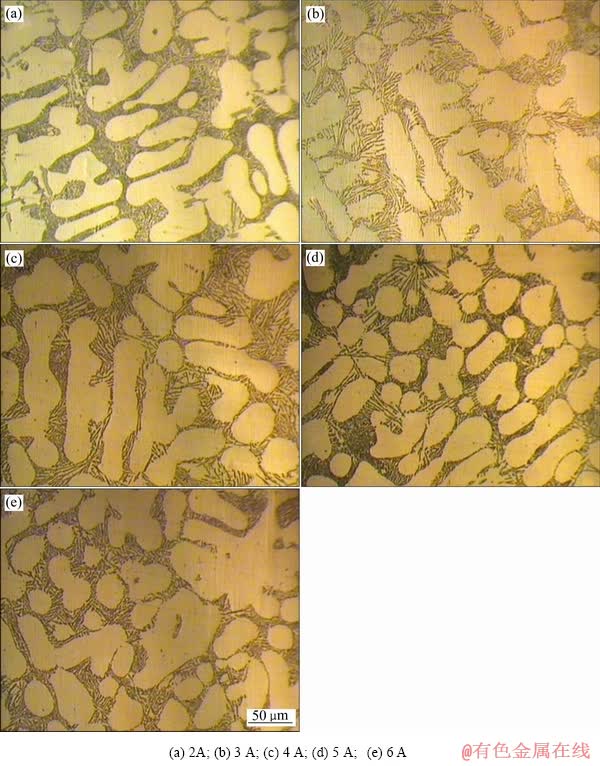

4.1 电流强度对半固态A356合金初生相的影响

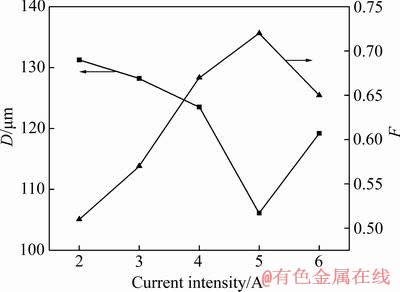

图6所示为电磁频率30 Hz时不同电流强度下半固态A356合金的初生相形貌。图7所示为对应的平均等积圆直径和平均形状因子。电流强度为2 A时,对应图4(a)和(a1)所示,熔体所受的最大电磁力为长轴X上的最大电磁力仅75 N/m3,而短轴Y上的最大电磁力仅41 N/m3。由于电磁参数较低,产生的最大电磁力和流速较小,引起的磁力差和流速差也小(如表1和表2所列),对枝晶结构破碎的程度较低,合金中初生相形貌多为粗大的长条状,此时初生相的平均等积圆直径为131.3 μm,平均形状因子为0.51,如图6(a)所示。随着电流强度增大至3 A,由图4(b)和图5(a)可知,熔体此时所受最大电磁力增大到了167.2 N/m3,产生的流速也由2 A时的50 mm/s增加到此时的75.3 mm/s,初生相的形貌得到改善,开始出现椭圆状晶粒,此时的平均等积圆直径为128.2 μm,平均形状因子为0.57,如图6(b)所示。当电流强度增大到4 A时,对应图4(c)和图5(a)所示,相较之前最大电磁力和最大流速进一步增大,而从此时的金相组织中可以看出,近球状和椭圆状初生相数量进一步增加,此时的平均等积圆直径为123.5 μm,平均形状因子为0.67,如图6(c)所示。当电流强度达到5 A时,由图4(d)和图5(a)可看出,电磁强度和最大流速继续增大,造成的电磁力差和流速差亦增大,分别达到了213.76 N/m3和66.3 mm/s(如表1和表2所列),此时初生相形貌和尺寸得到了明显改善,合金熔体中的初生相得到了极大的细化,大多呈现球状,整体上尺寸较为细小,且分布比较均匀,此时的平均等积圆直径降到106.1 μm,平均形状因子升高到0.72,如图6(d)所示。而电流强度为6 A时,对比图4(e)与图5(a)可知,电磁力和最大流速仍处于增大的趋势,但电磁力差和流速差呈现减小趋势,初生相尺寸相比图6(d)有所增大,开始出现较粗大的蔷薇状初生相,此时的平均等积圆直径增大到了119.2 μm,而平均形状因子略有减小为0.65,如图6(e)所示。

图6 不同电流强度下半固态A356合金初生相形貌

Fig. 6 Primary phase morphologies of semi-solid A356 alloy at different current intensities

图7 不同电流强度下半固态A356合金初生相的平均等积圆直径D和形状因子F

Fig. 7 Average equal-area circle diameter D and average shape factor F of primary phase of semisolid A356 alloy at different current intensities

4.2 电磁频率对半固态A356合金初生相的影响

图8所示为电流强度5 A时不同电磁频率下半固态A356合金的初生相形貌。图9所示为对应的平均等积圆直径和形状因子。在无电磁搅拌时,A356合金的初生相比较粗大,其形貌的圆整度较差,此时的平均等积圆直径为152.8 μm,平均形状因子为0.49,如图8(a)所示。当施加的电磁频率分别为15、20、25和30 Hz时,从图4(d1)和(d2)可以看出,随着电磁频率的增加,熔体在椭圆坩埚长短轴上所受的电磁力呈现出先增加后减小的趋势,熔体的流速也呈现出先增后减的趋势,如图5所示。此时,半固态A356合金的初生相逐渐变得细小圆整,初生相中粗大的树枝晶、长条形晶粒、棒状晶粒逐渐变少,而取而代之的是形貌较好的球状晶粒和近球状晶粒,而且分布也相对比较均匀,如图8(b)~(e)所示,其平均等积圆直径也由15 Hz时的145.3 μm逐渐减小至30 Hz时的106.1 μm,而平均形状因子则由15 Hz时的0.57升高至30 Hz时的0.72。而当电磁频率进一步增加为35 Hz,粗大的枝晶又反而增加,初生相形貌变差,如图8(f)所示,此时的平均等积圆直径由30 Hz的106.1 μm上升到35 Hz的109.23 μm,而平均形状因子则下降到0.7。结合图5(a)与图8可以看出,适当的增大电流以及电磁频率,有利于合金晶粒的细化和分布的均匀性,从而得到较好的初生相形貌。

图8 不同电磁频率下半固态A356合金初生相形貌

Fig. 8 Primary phase morphologies of semi-solid A356 alloy at different electromagnetic frequencies

图9 不同电磁频率半固态A356合金初生相的平均等积圆直径D和形状因子F

Fig. 9 Average equal-area circle diameter D and average shape factor F of primary phase of semisolid A356 alloy at different electromagnetic frequencies

5 分析与讨论

合金凝固过程对熔体施加电磁场,合金内部会产生感应电流,使得半固态熔体受到电磁力的作用产生流动,进而影响熔体凝固时的能量、质量和动量传输过程,最终改变凝固组织的形貌与尺寸。研究结果表明,对半固态合金熔体进行电磁搅拌时,电磁搅拌参数(电流强度和电磁频率)都是通过改变熔体中电磁感应强度的大小和分布,从而改变电磁力和流动速度的大小和分布,且由于椭圆坩埚中半径上有差异,因而电磁搅拌引起的电磁力和流动速度的大小和分布亦不相同。合金熔体在椭圆坩埚做旋转运动时存在着周期性的电磁力差和流速差,这些电磁力差和流速差基本是随着电流强度和电磁频率的增高而增大的,如表1和表2所列,最终将影响半固态合金的凝固过程与凝固组织。但是,这两个参数在电磁搅拌过程中对合金熔体所受到的电磁力差和产生的流速差的作用是不一样的。通过对表1和表2的结果进行分析计算,发现在不同的电流强度下,通过改变电磁频率可使得合金熔体所受到的电磁力差增大幅度为2.25倍至3.3倍,而熔体中流速差的增幅为1.19倍至1.29倍。对于不同的电磁频率,通过改变电流强度可使得合金熔体所受到的电磁力差增大幅度为7.99倍至8.04倍,而熔体中流速差的增幅为1.53倍至1.55倍。因此,可以得知,在椭圆坩埚的电磁搅拌过程中,合金熔体中所受到的电磁力对电流强度和电磁频率都比较敏感,而电流强度对调控电磁力大小的作用要强于电磁频率;而合金熔体受到电磁搅拌时所产生的流速对电磁搅拌工艺参数(电流强度和电磁频率)的敏感程度不如电磁力的,但是,电流强度对熔体流速的影响要略强于电磁频率。这样,在椭圆坩埚中应用电磁搅拌工艺制备半固态合金浆料时,就可以充分地利用电流强度和电磁频率对合金熔体凝固过程的影响程度实施调控,达到优化工艺和保证半固态合金浆料质量的目的。

另外,对图7和图9的结果分析、计算也发现:在电磁搅拌频率(如30 Hz)一定的情况下,增大电流强度,可使得半固态A356合金中初生相的形状因子由2 A时的0.51提高到5 A时的0.72,增加的幅度达到41.2%;而初生相的等积圆直径由2 A时的131.3 μm减小到5 A时的106.1 μm,降低幅度达到19.2%。同样,在电流强度(如5 A)一定的情况下,增大电磁频率,可使得半固态A356合金中初生相的形状因子由15 Hz时的0.57提高到30 Hz时的0.72,增加的幅度达到26.3%;而初生相的等积圆直径由15 Hz时的145.3 μm减小到30 Hz时的106.1 μm,降低幅度达到27%。这也从另一个侧面反映了电磁搅拌工艺中电流强度和电磁频率对半固态A356合金初生相的形貌尺寸的影响程度。

由于椭圆坩埚在结构上不同于传统的圆柱形坩埚,其半径方向中的长短轴上存在电磁力差,使得合金熔体在其中做旋转运动时,流速产生周期性变化,这也将引起熔体中的粘滞力产生周期性变化。因而可使得合金熔体沿着椭圆坩埚边缘流动时出现“加速-减速-加速”的循环运动现象[21],从而改变合金的形核动力学。合金形核动力学改变导致形核率增加是晶粒细化的主要原因[24]。此外,电磁搅拌时引起的熔体流速周期性加减速的变化、大小幅度周期性变化的电磁力(粘滞力)作用在树枝晶上,就相当于对正在生长中的树枝晶承受了“交变载荷”的作用,结果产生了类似于“疲劳”破坏的效果,使得树枝晶更容易破碎。这些树枝晶碎块数量多,则形成更多合金凝固的结晶核心[25-26]。

同时,正是由于椭圆坩埚中长短轴上存在流速差,使得合金熔体在其中做圆周运动时,熔体由于速度的快速增大与减小,使熔体中的热量能够得到快速的散发,进而内部温度快速均匀化,减小了内部的温度梯度,从而使得晶粒优势生长方向的生长速度得到较好的抑制,非优势生长方向与优势生长方向上的生长速度差值变小,有利于晶粒等轴晶的生长方式生长,进而形成形貌良好的近球状和球状晶粒。

在一定的范围内电磁频率和电流强度可以促进半固态合金熔体获得较好的初生相。从数值模拟和实验结果来看,电磁频率为30 Hz,电流强度为5 A时,此时坩埚长短轴上熔体的流速差最大,熔体流动呈现混沌状态,最终获得合金凝固组织中初生相的平均等积圆直径为106.1 μm,平均形状因子为0.72,组织形貌效果最好。

6 结论

1) 通过电磁场模拟分析可知,电磁搅拌对椭圆坩埚中半固态合金熔体的最大电磁力和最大流速皆有影响;随着电磁频率和电流强度的增大,半固态铝合金在椭圆坩埚长轴X和短轴Y上的最大电磁力和最大流速均呈现出先增大后减小的趋势,并且长轴X上的最大电磁力和最大流速均大于对应短轴Y上的。

2) 在电磁搅拌过程中,椭圆坩埚中的长短轴上的最大电磁力随着不同的电流强度和电磁频率增加呈现相同的规律:即从坩埚的中心处沿半径方向逐步增大,到0.8~0.9倍的坩埚半径处的电磁力达到最大值,超过该距离后,电磁力又开始急剧降低。

3) 在椭圆坩埚中实施电磁搅拌时,电流强度和电磁频率都可明显地影响合金熔体中所受到的电磁力,其中电流强度对调控电磁力大小的作用要强于电磁频率;而合金熔体受到电磁搅拌时所产生的流速大小对电流强度和电磁频率的敏感程度不如电磁力,但是,电流强度对熔体流速的影响要略强于电磁频率的。

4) 运用ANSYS有限元分析软件对半固态A356铝合金凝固过程中的流场进行模拟,结果证明椭圆坩埚制备半固态A356合金浆料的合适电磁频率为30 Hz,电流强度为5 A,在此条件下,半固态合金初生相的平均等积圆直径为106.1 μm,平均形状因子为0.72。

REFERENCES

[1] ZHAO Z D, MAO W M, LI S, ZHONG R M. Preparation of semisolid AlSi7Mg alloy slurry though weak traveling-wave electromagnetic stirring[J]. Rare Metals, 2010, 21(6): 139-145.

[2] 刘 政, 周翔宇. 分级电磁搅拌对半固态Al-Cu合金凝固组织的影响[J]. 中国有色金属学报, 2015, 25(1): 49-57.

LIU Zheng, ZHOU Xiang-yu. Effect of staged electromagnetic stirring on solidification structure of semi-solid Al-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 49-57.

[3] 冯鹏发, 唐靖林, 李双寿, 曾大本. 熔体处理和双向电磁搅拌复合快速制浆技术[J]. 中国有色金属学报, 2007, 17(1): 14-23.

FENG Peng-fa, TANG Jing-lin, LI Shuang-shou, ZENG Da-ben. Melt processing and two-way electromagnetic stirring composite rapid pulping technology[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(1): 14-23.

[4] 陈 涛, 刘 政, 刘小梅, 陈志平. 双向间歇电磁搅拌对半固态A356-Ce合金凝固组织的影响[J]. 稀有金属, 2018, 42(1): 29-35.

CHEN Tao, LIU Zheng, LIU Xiao-mei, CHEN Zhi-ping. Effect of two-way intermittent electromagnetic stirring on solidification structure of semi-solid A356-Ce alloy[J]. Rare Metals, 2018, 42(1): 29-35.

[5] 张 琦, 曹 苗, 蔡 进, 赵升吨. 中频电磁振荡法制备半固态铝合金浆料的研究[J]. 稀有金属材料与工程, 2014, 43(8): 1974-1978.

ZHANG Qi, CAO Miao, CAI Jin, ZHAO Sheng-dun. Study on preparation of semi-solid aluminum alloy slurry by medium frequency electromagnetic oscillation[J]. Rare Metal Materials and Engineering, 2014, 43(8): 1974-1978.

[6] ZHANG L, LI W, YAO J P, QIU H. Effects of pulsed magnetic field on microstructures and morphology of the primary phase in semisolid A356 Al slurry[J]. Materials Letters, 2012, 66(1): 190-192.

[7] ITAMURA M, ANZAI K, HIRATA N. Development if generation technology of high quality semi-solid slurry by double-axis-electromagnetic stirrer combined with properly designed cup[J]. Solid State Phenomena, 2013, 192/193(5): 441-446.

[8] PASSALACQUA A, MARMO L. A critical comparison of frictional stress models applied to the simulation of bubbling fluidized beds[J]. Chemical Engineering Science, 2009, 64(12): 2795-2806.

[9] 陈兴润, 张志峰, 徐 骏, 石立开. 电磁搅拌法制备半固态浆料过程电磁场、流场和温度场的数值模拟[J]. 中国有色金属学报, 2010, 20(5): 937-945.

CHEN Xing-run, ZHANG Zhi-feng, XU Jun, SHI Li-kai. Numerical simulation of electromagnetic field, flow field and temperature field in preparation of semi-solid slurry by electromagnetic stirring method[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 937-945.

[10] 朱苗勇, 娄文涛, 王卫领. 炼钢与连铸过程数值模拟研究进展[J]. 金属学报, 2018, 54(2): 131-150.

ZHU Miao-yong, LOU Wen-tao, WANG Wei-ling. Progress in numerical simulation of steelmaking and continuous casting processes[J]. Acta Metallurgica Sinica, 2018, 54(2): 131-150.

[11] BAI Y L, XU J, ZHANG Z F. Numerical simulation on the rheo-diecasting of the semi-solid A356 aluminum alloy[J]. International Journal of Minerals and Materials, 2009, 16(4): 422-426.

[12] 刘 政, 张嘉艺, 邓可月. 基于Fluent的电磁场中铝熔液及其微粒运动轨迹的数值模拟[J]. 有色金属科学与工程, 2015, 6(4): 46-51.

LIU Zheng, ZHANG Jia-yi, DENG Ke-yue. Numerical simulation of aluminum melt and its particle motion trajectory in electromagnetic field based on fluent[J]. Nonferrous Metals Science and Engineering, 2015, 6(4): 46-51.

[13] SMOLJAN B. Computer simulation of it-diagrams of steel[J]. Transactions of Materials and Heat Treatment, 2004, 113(5): 706-709.

[14] LIU C M, YANG L, ZUO H Z. Computer simulation of continuous electromagnetic stirring for marking rheologic semi-solid slurry of ZL112Y aluminum alloy[J]. Chinese Journal of Mechanical Engineering, 2008, 21(6): 108-114.

[15] 陶文琉, 赵升吨, 林文捷. A356铝合金半固态浆料电磁搅拌法制备过程的数值模拟[J]. 机械工程学报, 2012, 48(14): 50-57.

TAO Wen-liu, ZHAO Sheng-dun, LIN Wen-jie. Numerical simulation of preparation process of A356 aluminum alloy semi-solid slurry by electromagnetic stirring method[J]. Chinese Journal of Mechanical Engineering, 2012, 48(14): 50-57.

[16] MAUNU K, PETRI S, JAAKKO L. Numerical and experimental modelling of gas flow and heat transfer in the air gap of an electric machine[J]. International Journal of Thermal Sciences, 2004, 13(3): 264-278.

[17] HAO L L, WU J Y, SUN Y G. Simplified mathematical model of inter-turn short circuit of field windings in hydro-generators and its application[J]. Science China, 2013, 56(4): 898-909.

[18] 陈志平, 刘 政, 陈 涛. 电磁搅拌和数值模拟在半固态铝合金浆料制备中应用的研究现状[J]. 铸造, 2017, 66(7): 702-706.

CHEN Zhi-ping, LIU Zheng, CHEN Tao. Research status of electromagnetic stirring and numerical simulation in preparation of semi-solid aluminum alloy slurry[J]. Foundry, 2017, 66(7): 702-706.

[19] MARQUEZ I A, BOLBORIC V. A dynamic model of the piezoelectric traveling wave rotary ultrasonic motor stator with the finite volume method[J]. Ultrasonics, 2017, 77(3): 69-78.

[20] 汪超台, 李自成. 排气涡轮基于顺序流固耦合传热数值模拟研究[J]. 机械工程学报, 2017, 53(15): 156-164.

WANG Chao-tai. LI Zi-cheng. Numerical simulation of exhaust gas turbine based on sequential fluid-solid coupling heat transfer[J]. Chinese Journal of Mechanical Engineering, 2017, 53(15): 156-164.

[21] 刘 政, 陈志平, 陈 涛. 坩埚尺寸和电磁频率对半固态A356铝合金浆料流动的影响[J]. 金属学报, 2018, 54(3): 435-442.

LIU Zheng, CHEN Zhi-ping, CHEN Tao. Effect of crucible size and electromagnetic frequency on the flow of semi-solid A356 aluminum alloy slurry[J]. Acta Metallurgica Sinica, 2018, 54(3): 435-442.

[22] 刘 政, 张嘉艺, 余昭福. 电磁场作用下中铝合金熔体流动的混沌特征的仿真与分析[J]. 中国有色金属学报, 2015, 25(11): 3026-3032.

LIU Zheng, ZHANG Jia-yi, YU Zhao-fu. Simulation and analysis of chaotic characteristics of melt flow in medium aluminum alloy under electromagnetic field[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(11): 3026-3032.

[23] 刘 政, 张嘉艺, 罗浩林, 邓可月. 混沌对流下的半固态A356铝合金初生相形貌演变研究[J]. 金属学报, 2016, 52(2): 177-183.

LIU Zheng, ZHANG Jia-yi, LUO Hao-lin, DENG Ke-yue. Evolution of the primary phase morphology of semi-solid A356 aluminum alloy under chaotic convection[J]. Acta Metallurgica Sinica, 2016, 52(2): 177-183.

[24] 李 宁, 张 蓉, 张利民, 邢 辉, 段鹏飞, 吴耀燕. 低压交流电脉冲下Al-7%Si合金晶粒细化机理研究[J]. 金属学报, 2017, 53(2): 192-199.

LI Ning, ZHANG Rong, ZHANG Li-min, XING Hui, DUAN Peng-fei, WU Yao-yan. Study on grain refinement mechanism of Al-7%Si alloy under low voltage AC pulse[J]. Acta Metallurgica Sinica, 2017, 53(2): 192-199.

[25] TIMMEL K, ECKERT S, GERBETH G. Experimental investigation of the flow in a continuous-casting mold under the influence of a transverse, direct current magnetic field[J]. Metallurgical and Materials Transactions, 2011, 42: 68-78.

[26] ECKERT S, NIKRITYUK P A, WILLERS B. Electromagnetic melt flow control during solidification of metallic alloys[J]. The European Physical Journal Special Topics, 2013, 220: 123-137.

Effect of electromagnetic stirring parameters on melt flow and microstructure of semi-solid aluminum alloy melts in oval crucible

ZHAO Jun-chao1, LIU Zheng1, LI Ze-wen1, SUN Meng-tong2

(1. School of Mechanical and Electrical Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China;

2. School of Materials Science and Engineering, Jiangxi University of Science and Technology, Ganzhou 341000, China)

Abstract: ANSYS finite element analysis software was used to simulate the flow field in the solidification process of semi-solid aluminum alloy A356, and the effects of electromagnetic stirring parameters, such as electromagnetic frequency and current intensity, on the flow field were studied. The results show that, with the increase of electromagnetic frequency and current intensity, the maximum electromagnetic force and maximum flow velocity of semi-solid aluminum alloy on the long axis X and the short axis Y of oval crucible show a tendency to increase first and then decrease, and the maximum on the long axis X. After the electromagnetic stirring is applied, the electromagnetic force gradually increases from the center of the crucible in the radial direction, it reaches the maximum at the radius of 0.8-0.9 time and starts to decrease sharply beyond the distance. The electromagnetic force is more affected by the current intensity and the flow rate is less sensitive to the current intensity and electromagnetic frequency than the electromagnetic force, but the influence of the current intensity on the flow rate is still slightly stronger than the electromagnetic frequency in oval crucible. When the electromagnetic frequency and current intensity are 30 Hz and 5 A, the average equal-area circular diameter of the primary phase in semi-solid A356 alloy reaches 106.1 μm, and the average shape factor increases to 0.72, the best microstructure of the semi-solid alloy can be obtained in this condition.

Key words: semisolid aluminum alloy; electromagnetic stirring; electromagnetic frequency; current intensity; oval crucible

Foundation item: Projects(51361012, 51864020) supported by National Natural Science Foundation of China; Project (20142bab206012) supported by the Natural Science Foundation of Jiangxi Province, China

Received date: 2019-07-11; Accepted date: 2020-05-28

Corresponding author: LIU Zheng; Tel: +86-797-8312137; E-mail: liukk66@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51361012,51864020);江西省自然科学基金资助项目(20142bab206012)

收稿日期:2019-07-11;修订日期:2020-05-28

通信作者:刘 政,教授,博士;电话:0797-8312137;E-mail:liukk66@163.com