文章编号:1004-0609(2015)-07-1781-09

电磁搅拌法制备的半固态2A50合金的显微组织演变

张晨阳,赵升吨,王永飞

(西安交通大学 机械工程学院,西安 710049)

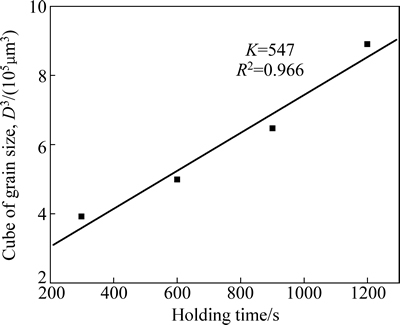

摘 要:分析搅拌电流和搅拌频率等工艺参数对电磁搅拌法(EMS)制备的2A50铝合金半固态坯料显微组织的影响,并研究不同工艺参数制备的2A50半固态坯料二次重熔后的显微组织演变过程。结果表明,随着搅拌电流及搅拌频率的增大,半固态 2A50合金的显微组织由树枝晶转变为越来越细小均匀的近球状晶,且二次重熔后的球状晶粒也越来越圆整。搅拌参数为30 A和30 Hz时,二次重熔后的半固态2A50合金的球状晶粒平均尺寸约为80 μm,形状因子约为0.76,进一步增加搅拌电流或者搅拌频率,显微组织没有明显的改善。二次重熔过程中半固态2A50合金平均晶粒尺寸随着保温时间的延长而逐渐增大,Ostwald粗化机制促进了晶粒的球化程度的增加。最终获得半固态2A50合金的晶粒粗化速率为547 μm3·s-1。

关键词:2A50铝合金;半固态;电磁搅拌;显微组织

中图分类号:TF111 文献标志码:A

Microstructural evolution of semisolid 2A50 alloy prepared by electromagnetic stirring

ZHANG Chen-yang, ZHAO Sheng-dun, WANG Yong-fei

(School of Mechanical Engineering, Xi’an Jiaotong University, Xi’an 710049, China)

Abstract: The effects of stirring current and stirring frequency on the microstructural evolution of semisolid 2A50 alloy prepared by electromagnetic stirring (EMS) were analyzed, and microstructure evolution of semisolid 2A50 alloy prepared by different technological parameters after partial remelting were investigated. The results show that with increasing the stirring current and frequency, the microstructures of semisolid 2A50 alloy evolve from coarse dendrites to fine and quasi-globular solid particles. Moreover, after partial remelting, these microstructures become more spherical with increasing the stirring current and stirring frequency. As the stirring parameters are 30 A and 30 Hz, the average particle size is about 80 μm and the shape factor is about 0.76. Further increasing the stirring current and frequency makes no obvious improvements of microstructure. Besides, average particle size constantly increases with prolonging the holding time because that Ostwald ripening can improve the degree of spheroidization. The current coarsening rate constant of semisolid 2A50 alloy is 547 μm3·s–1 at 590 ℃.

Key words: 2A50 aluminum alloy; semisolid; electromagnetic stirring; microstructure

半固态金属加工技术包括半固态坯料的制备、重熔(对触变成形而言)、成形这3个主要技术环节[1]。其中,最为关键的步骤即为获得具有细小球状晶粒均匀分布在共晶液相中的半固态坯料[2]。电磁搅拌法由于其较高的局部剪切速率、易于控制以及避免污染等优点,仍然是最具潜在商业价值的半固态坯料的制备技术,并引起了许多关注[3]。KANG等[4]系统地研究了搅拌电流、搅拌时间以及浇注温度对半固态A356铝合金显微组织的影响,并获得了用于流变成形的显微组织。LI等[5]采用弱电磁搅拌及低过热度浇注法研究浇注温度和搅拌功率对AlSi7Mg合金显微组织的影响,并获得最佳浇注温度为630 ℃,最佳搅拌功率为1.72 kW。JANG等[6]开发出两阶段电磁搅拌法制备Al-Si基活塞合金半固态坯料:第一阶段控制浇注温度及电磁感应强度影响初生Si粒子的形态;第二阶段控制电磁搅拌的温度,获得细小均匀的α(Al)及金属间化合物。ZHU等[7]采用环形电磁搅拌法制备半固态A357坯料,并研究了石墨管内不同通气流量对坯料冷却速率及显微组织细化程度的影响。CHUNG等[8]研究了不同真空度下的电磁搅拌过程中对坯料缩松缩孔缺陷的影响,并指出在真空压力为50 kPa时,微小空洞数量迅速下降。尽管很多研究涉及到电磁搅拌法制备半固态铝合金坯料,但是关于搅拌电流与搅拌频率对半固态2A50铝合金显微组织演变的综合作用的相关研究并不多。2A50铝合金在航空、航天、汽车和动力工业中应用广泛,汽车工业上的形状复杂和中等强度的锻件和模锻件均采用2A50铝合金制造[9]。但是传统的2A50铝合金采用浇铸成型,晶间偏析倾向严重,热处理后溶解于晶粒内部的合金元素偏析严重,抗拉强度和伸长率都下降。电磁搅拌处理不仅会有效地破碎大块的晶间析出物,而且会进一步改善晶粒的形状,进而提高该合金的综合性能[10]。

本文作者分析了电磁搅拌法制备半固态2A50坯料过程中不同的搅拌电流及搅拌频率下制备的半固态坯料的显微组织演变;并研究了二次重熔后坯料的显微组织演变规律;最后确定最佳搅拌参数,并进一步研究了最佳搅拌参数制备的半固态2A50合金的显微组织随保温时间的演变规律。

1 实验

本实验中采用的实验材料为商用2A50铝合金,其化学成分及固液相线如表1所列。该材料的固液相线温度通过DSC实验获得。电磁搅拌试验设备的上部为中频感应加热炉,下部为电磁搅拌器,电磁搅拌器由不锈钢坩埚,电阻加热丝,隔热层,冷却水管以及三相两级电机的定子组成(见图1)。隔热层及冷却系统用于避免金属熔体及电阻加热器的热辐射作用损害电磁搅拌器。电磁搅拌过程中预设的搅拌电流及搅拌频率由欧瑞E2000变频器提供。

将2A50铝合金原料在中频感应加热炉中熔化,在(650±5) ℃保温30 min并进行除气,随后将金属液浇注到预热至350 ℃的坩埚中(直径为60 mm,高度为170 mm),最后按照预设的搅拌电流和搅拌频率进行电磁搅拌,搅拌时间为200 s,搅拌结束后立即淬火。二次重熔时,试样在Ar保护氛围中迅速加热至590 ℃

表1 2A50铝合金的化学成分及固液相线

Table 1 Chemical compositions and thermal characters of 2A50

图1 电磁搅拌试验设备示意图

Fig. 1 Schematic diagram of EMS experimental set-up

并分别保温5~20 min。当试样移出电阻炉后,迅速淬火。试样在打磨、抛光后采用5%(体积分数)HF腐蚀。在OLYMPUS GX5光学显微镜上进行显微组织分析。平均晶粒尺寸(D)和形状因子(Fs)通过式(1)和(2)获得。形状因子的大小从0到1,0代表针状粒子,1代表完全的球形粒子。

(1)

(1)

(2)

(2)

式中:A为晶粒面积;N为晶粒数目;P为晶粒周长。

2 结果与讨论

2.1 不同电磁搅拌电流及搅拌频率下2A50铝合金显微组织的演变过程

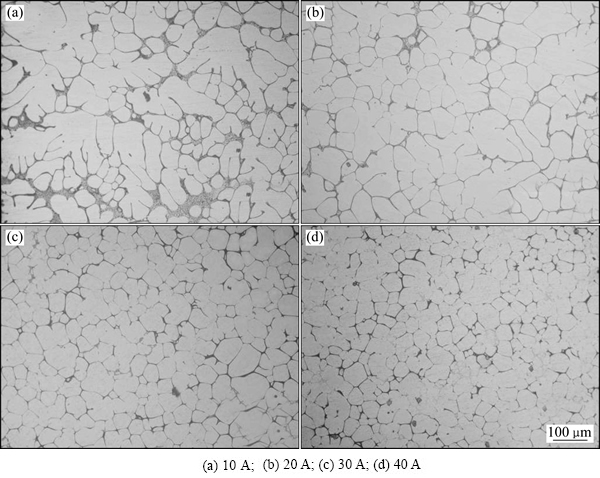

在搅拌频率为30 Hz、不同搅拌电流下2A50铝合金的显微组织如图2所示。由图2可以看出,随着搅拌电流的增大,粗大的枝晶逐渐被破碎形成细小的近球状晶粒,并且近球状晶粒在共晶相中分布越来越均匀。当搅拌电流为10 A时,显微组织中存在大量未破碎的粗大枝晶组织(见图2(a))。增大搅拌电流至20 A,枝晶数量减少,但是部分初生α(Al)蔷薇状晶粒的形状不规则,且分布不均匀(见图2(b))。随着搅拌电流进一步增大,晶粒被进一步打散,晶界更加清晰,细小独立的近球状晶粒均匀地分布在共晶相中(见图2(c)和(d))。

图2 搅拌频率为30 Hz时不同搅拌电流下2A50铝合金的显微组织

Fig. 2 Microstructures of 2A50 Al alloy prepared at different stirring currents under constant stirring frequency of 30 Hz

图3所示为搅拌电流为30 A、不同搅拌频率下2A50铝合金的显微组织。由图3可知,随着搅拌频率的增大,粗大枝晶臂不断被破碎,形成越来越均匀细小的近球形晶粒。当搅拌频率为10 Hz时,2A50铝合金的显微组织中仍然存在粗大的枝晶臂(见图3(a))。当搅拌频率为20 Hz时,初生α(Al)较为粗大,并且簇集在一起形成团簇(见图3(b))。当搅拌频率进一步增加, 如近球状晶粒更加细小圆整,并且分布更加均匀(见图3(c)和(d))。由图2和3可得,采用更高的搅拌电流及搅拌频率,2A50铝合金显微组织的改善并不明显。因此,电磁搅拌参数30 A和30 Hz可以作为电磁搅拌法制备半固态2A50坯料的优化参数。

由图2和3可见,搅拌电流和搅拌频率对2A50合金的显微组织演变过程均有巨大的影响。搅拌电流对磁感应强度的作用可以由KANG等[11]根据实际测量结果而提出的经验公式来表示:

B=Ir (3)

式中:B为磁感应强度;r为感应距离;I为搅拌电流。

而熔体所受到的电磁搅拌力为

(4)

(4)

式中:F为金属熔体所受电磁力;J为电流密度;λ为金属溶液的电导率;v为金属熔体切割磁感应线的速度。

由式(3)可知,频率固定,搅拌电流越大,则电磁搅拌器内磁感应强度越大,进而金属熔体所受的电磁搅拌力越大(见式(4))。这导致初生相上更多的二次枝晶臂熔化或者断裂,并随着熔体的强制对流而漂移[12],低过热度且温度均匀的熔体中容易大量增殖形成细小的等轴粒子[13]。故随着搅拌电流的增大半固态坯料的显微组织越来越细小,如图2(c)和(d)所示。同时搅拌频率越大,金属熔体的旋转速度越大,进而坯料各处所受到的搅拌力越大,如式(4)所示。因此,搅拌频率的增加导致共晶液体对晶粒冲刷速度增大,这将有利于打断或熔化更多的枝晶臂,且晶粒之间更加频繁的碰撞、摩擦和剪切使晶粒向更稳定的球形转化[14],如图3(c)和(d)所示。同时在高剪切速率下,高强度的强制对流有利于漂移晶粒的大量增殖以及熔体中的质量传输,减薄了凝固前沿边界层的厚度,促进了枝晶向球状晶粒转化[15]。但是当频率过高时,有效旋转速度的增加并不明显,相反其实际渗透区域的厚度减少[16],故当搅拌频率增加至40 Hz后,半固态坯料的显微组织并没有得到明显的改善。

图3 搅拌电流为30 A不同搅拌频率下2A50铝合金的显微组织

Fig. 3 Microstructures of 2A50 Al alloy prepared at different stirring frequencies under constant stirring current of 30 A

2.2 二次重熔后2A50铝合金的显微组织演变过程

若电磁搅拌法制备的半固态坯料用于触变成形工艺,则需要对坯料进行二次重熔[17]。因此,有必要研究不同搅拌电流及频率下的半固态2A50铝合金在二次重熔过程的显微组织演变过程。当保温温度分别为580、585和590 ℃且保温时间为10 min时,2A50铝合金半固态坯料二次重熔后的显微组织如图4所示。保温时间为580 ℃时,半固态坯料中液相偏少,晶粒相互粘结在一起导致晶界模糊(见图4(a))。随着保温 温度进一步升高,液相分数逐渐增加,二次重熔后晶粒更加圆整,晶界更加清晰。考虑到不同参数下制备的半固态坯料的晶粒细化程度不同,较高的重熔温度有利于液相完全隔离出独立的晶粒,便于研究不同参数下的二次重熔后坯料的晶粒演变规律,故选择二次重熔温度为590 ℃。

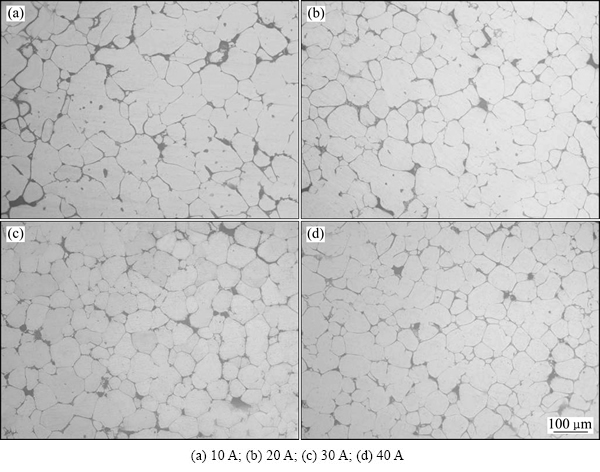

搅拌频率为30 Hz时不同搅拌电流下2A50铝合金在590 ℃保温10 min时的显微组织如图5所示。由图5可知,随着搅拌电流的增加,二次重熔后球状晶粒越来越细小均匀,球化程度越来越高。当搅拌电流为10 A时,重熔前显微组织中残留的枝晶臂发生了明显球化,演化成为粗大的、形状不规则的晶粒(见图5(a))。当搅拌电流增至20 A,重熔后的α(Al)晶粒略微细化,粗大晶粒的数量减少,但是晶粒大小不均匀,部分晶粒形成团簇(见图5(b))。随着搅拌电流的进一步增加,重熔后的球状晶粒变得更加细小,形态更加圆整,并均匀地分布在液相基体中(见图5(c)和(d))。

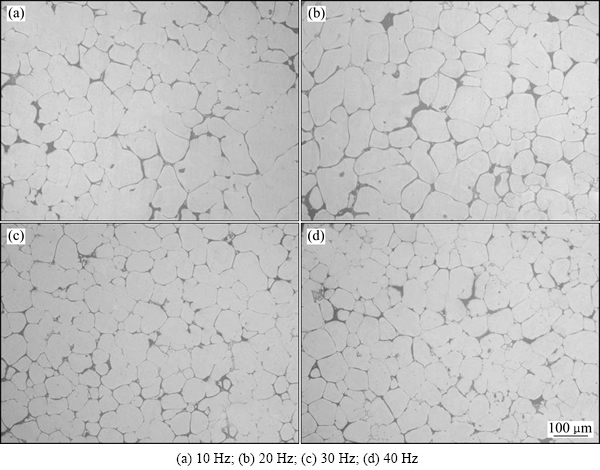

图6所示为搅拌电流为30 A时不同搅拌频率下2A50铝合金在590 ℃保温10 min时的显微组织。由图6可知,随着搅拌频率的增大,重熔后的显微组织由粗大的团簇晶粒逐渐转化为均匀分布的球状晶粒,且晶粒越来越圆整。搅拌频率为10 Hz时,显微组织中存在由蔷薇状晶粒转化而来的粗大的晶粒,故晶粒大小不均匀(见图6(a))。而当搅拌频率为20 Hz时,粗大晶粒数量减小,晶粒更加圆整且分布更加均匀(见图6(b))。随着搅拌频率的进一步增大,重熔后的球状晶粒变得更加细小圆整,分布更加均匀(见图6(c)和(d))。

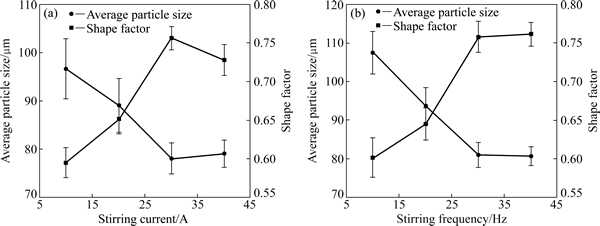

图7所示为半固态2A50坯料在590 ℃保温10 min时的平均晶粒尺寸和形状因子随搅拌电流及搅拌频率的变化曲线。从图7可以看出,搅拌电流和搅拌频率对平均晶粒尺寸以及形状因子的影响规律类似,即随着搅拌电流及搅拌频率的增大平均晶粒尺寸减小,球化程度逐渐提高。其主要原因是电磁搅拌后的半固态坯料的初始晶粒尺寸越小,分布越均匀,则重熔后得到的球状晶粒越小越圆整[18]。搅拌电流及搅拌频率越大,坯料凝固初期折断或者熔断的枝晶臂数量越多,生成独立的初生晶粒越多,使得二次重熔后共晶相中球状晶越多,分布越均匀,形状越圆整。特别是在30 A、30 Hz时,平均晶粒尺寸达到最小值,平均晶粒尺寸为80 μm,形状因子为0.75。进一步增加搅拌电流或者搅拌频率对晶粒尺寸影响不大。触变成形工艺要求半固态坯料的平均晶粒尺寸小于100 μm且形状因子大于0.6,故30 A、30 Hz可设为电磁搅拌法制备半固态2A50坯料的合理参数。

图4 不同重熔温度下保温10 min时二次重熔后半固态坯料的显微组织

Fig. 4 Microstructures of semisolid alloy under different isothermally holding temperatures for 10 min

图5 搅拌频率为30 Hz时不同搅拌电流下制备的半固态坯料在590 ℃下保温10 min后的显微组织

Fig. 5 Microstructures of semisolid alloy prepared at different stirring currents and 30 Hz after isothermally holding at 590 ℃ for 10 min

图6 搅拌电流为30 A时不同搅拌频率下制备的半固态坯料在590 ℃下保温10 min的显微组织

Fig. 6 Microstructures of semisolid alloy prepared at different stirring frequencies and 30 A after isothermally holding at 590 ℃ for 10 min

图7 二次重熔后2A50合金平均晶粒尺寸和形状因子随搅拌电流和搅拌频率的变化曲线

Fig. 7 Variations in average particle size and shape factor for 2A50 alloys after isothermally holding at 590 ℃ for 10 min with stirring current (a) and stirring frequency (b)

2.3 二次重熔过程中保温时间对半固态2A50铝合金显微组织演变的影响

图8所示为搅拌参数为30 A、30 Hz时制备的2A50铝合金坯料在590 ℃下不同保温时间后的显微组织。图9所示为相应的平均晶粒尺寸和形状因子随保温时间的变化曲线。由图8和9 可得,随着保温时间的延长,晶粒尺寸不断增大,并且球化程度越来越高,20 min时晶粒形态稍有恶化的趋势。保温5 min时,共晶液相只有部分融化且主要分布在相邻晶粒之间的三角处,晶界模糊,大部分晶粒粘连在一起,一些相邻的接触面位相差较小的晶粒在表面张力的作用下接触并发生合并长大以减小界面面积降低系统能量(见图8(a))。随着保温时间的增长,晶界处的液相不断增加(见图8(b)),当满足2γs/l≤γs/s时(γs/l为固液界面能,γs/s为固相晶粒晶界能),液相就可以润湿晶粒的晶界[19],使团簇晶粒互相独立开来,单个晶粒变得更加圆整。故晶界清晰并形成连续网状。进一步延长保温时间,较大的固相粒子以界面能和和界面曲率为驱动力继续粗化,球化程度进一步提高,而小晶粒逐渐溶解,甚至消失,这符合Ostwald熟化规律(见图8(c))。由凝固力学可知,合金的平衡熔点与晶粒表面的曲率的关系如式(5)所示[20]:

(5)

(5)

式中: 为平衡熔点的降低量;TM为相变平衡温度;κ为固相的平均表面曲率;Vs为固相体积;σ为表面张力;

为平衡熔点的降低量;TM为相变平衡温度;κ为固相的平均表面曲率;Vs为固相体积;σ为表面张力; (负值)为固液相焓摩尔的变化。

(负值)为固液相焓摩尔的变化。

半固态坯料中不同晶粒有不同的表面曲率,在某些晶粒的端部凸起处,其κ为正,则 为正,即该处的平衡熔点降低,曲率越大,晶粒端部的平衡熔点降低越多,这导致二次重熔过程中晶粒尖端逐渐被熔化。晶界附近的固相溶质在高曲率区域熔化并沉积到低曲率区域,降低初生相固液界面的表面曲率,促进形状不规则的晶粒向近球状转化。同样地,由于小粒子的表面曲率大于大粒子的,故小粒子的平衡熔点低于大粒子的,故小粒子会逐渐熔化消失,引起溶剂Al从小晶粒向大晶粒处扩散,最终实现初生相的进一步粗化,此时单位面积的晶粒数会下降(见图8(c))。

为正,即该处的平衡熔点降低,曲率越大,晶粒端部的平衡熔点降低越多,这导致二次重熔过程中晶粒尖端逐渐被熔化。晶界附近的固相溶质在高曲率区域熔化并沉积到低曲率区域,降低初生相固液界面的表面曲率,促进形状不规则的晶粒向近球状转化。同样地,由于小粒子的表面曲率大于大粒子的,故小粒子的平衡熔点低于大粒子的,故小粒子会逐渐熔化消失,引起溶剂Al从小晶粒向大晶粒处扩散,最终实现初生相的进一步粗化,此时单位面积的晶粒数会下降(见图8(c))。

当保温时间达到20 min时,部分晶粒周围的液膜厚度明显增加,大晶粒进一步粗化长大,但是其形态开始略微变差。由已有的研究[21]可知,当晶粒足够大时,固液界面可能会变得不稳定,导致其形态开始变得不规则,形状因子下降(见图8(d))。

一般情况均采用LSW (Lifshitz-Slyozov and Wanger)关系研究晶粒的长大及粗化行为[22]。具体表达如式(6)所示:

(6)

(6)

式中:Dt为保温时间为t时的平均晶粒直径;D0为初始保温时的平均晶粒直径;t是保温时间;K是粗化速率常数;n是粗化指数,主要取决于晶粒的长大机制,许多研究表明半固态重熔时,晶粒的长大机制以体积扩散为主,即n=3。

图8 半固态坯料在590 ℃下二次重熔时不同保温时间的显微组织

Fig. 8 Microstructures of semisolid alloy isothermally holding at 590 ℃ for different time

图10所示为电磁搅拌参数为30 A、30 Hz的2A50合金在590 ℃时保温时间t与Dt3的关系曲线。对曲线进行线性回归分析得到的回归方程如式(7)所示:

Dt3=547t +196423 (7)

最终得到粗化速率常数K为547 μs3·s-1。由回归分析可得,回归系数为0.966,曲线拟合良好,平均晶粒尺寸与保温时间具有良好的线性关系,说明动态粗化遵循LSW理论。

图9 590 ℃下平均晶粒尺寸及形状因子随不同保温时间的变化曲线

Fig. 9 Variations in average particle size and shape factor with holding time after isothermally holding at 590 ℃

图10 晶粒直径的立方与保温时间的拟合曲线

Fig. 10 Experimental results of D3 as function of isothermal holding time

3 结论

1) 随着搅拌电流及搅拌频率的增加,电磁搅拌法制备半固态2A50铝合金的显微组织由粗大的枝晶逐渐破碎形成细小的近球状晶粒,并且近球状晶粒在共晶相中分布越来越均匀。

2) 随着搅拌电流及搅拌频率的增大,二次重熔获得的半固态2A50铝合金的球状晶粒越细小均匀,且球化程度越高。

3) 随着保温时间的延长,在Ostwald粗化机制的作用下晶粒平均尺寸逐渐增大,形状因子不断增大。最后得到半固态2A50铝合金在590 ℃下的粗化速率为547 μs3·s-1。

REFERENCES

[1] 李亚庚, 毛卫民, 朱文志, 杨 斌, 朱达平. 连续冷却条件下半固态7075铝合金的流变性能[J]. 中国有色金属学报, 2013, 23(12): 3289-3293.

LI Ya-geng, MAO Wei-min, ZHU Wen-zhi, YANG Bin, ZHU Da-ping. Rheological behavior of semi-solid 7075 aluminum alloy in continuously cooling process[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(12): 3289-3293.

[2] TANG Meng-ou, XU Jun, ZHANG Zhi-feng, BAI Yue-long. New method of direct casting of Al-6Si-3Cu-Mg semisolid billet by annulus electromagnetic stirring[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 1591-1596.

[3] CURLE U A. Semi-solid near-net shape rheocasting of heat treatable wrought aluminum alloys[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 1719-1724.

[4] KANG C G, LEE S M. Development of a new rheology forming process with a vertical-type sleeve with electromagnetic stirring[J]. The International Journal of Advanced Manufacturing Technology, 2008, 39(5/6): 462-473.

[5] LI Sha, MAO Wei-min. Preparation of semi-solid AlSi7Mg alloy slurry with big capability[J]. Rare Metals, 2010, 29(6): 642-645.

[6] JANG Y S, CHOI B H, HONG C P. Effects of two stages of electro-magnetic stirring on microstructural evolution in rheo-diecasting of a near eutectic Al-Si alloy[J]. ISIJ International, 2013, 53(3): 468-475.

[7] ZHU Guang-lei, XU Jun, ZHANG Zhi-feng, BAI Yue-long, SHI Li-kai. Annular electromagnetic stirring-A new method for the production of semi-solid A357 aluminum alloy slurry[J]. Acta Metallurgica Sinica (English Letters), 2009, 22(6): 408-414.

[8] CHUNG I G, BOLOURI A, KANG C. A study on semisolid processing of A356 aluminum alloy through vacuum-assisted electromagnetic stirring[J]. The International Journal of Advanced Manufacturing Technology, 2012, 58(1/4): 237-245.

[9] DU Zhi-ming, CHEN Gang, HAN Fei, CAO Guang-xiang, LIU Jun, LI Hong-wei, CHEN Gang, ZHANG Xin, XIE Shui-sheng. Homogenization on microstructure and mechanical properties of 2A50 aluminum alloy prepared by liquid forging[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(11): 2384-2390.

[10] DU Zhi-ming, CHEN Gang, LIU Jun, XIE Shui-sheng. Tensile properties of as-deformed 2A50 aluminum alloy in semi-solid state. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 1597-1602.

[11] KANG C G, BAE J W, KIM B M. The grain size control of A356 aluminum alloy by horizontal electromagnetic stirring for rheology forging[J]. Journal of Material Processing Technology, 2007, 187: 344-348.

[12] 朱艳丽, 赵君文, 李 微, 朱振宇, 戴光泽, 张 鲲. 电磁搅拌对 7A04 铝合金大体积半固态浆料组织的影响[J].中国有色金属学报,2014, 24(11): 2735-2472.

ZHU Yan-li, ZHAO Jun-wen, LI Wei, ZHU Zhen-yu, DAI Guang-ze, ZHANG Kun. Effect of electromagnetic stirring on microstructure of large-volume semi-solid slurry of 7A04 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2735-2472.

[13] LIU Zheng, MAO Wei-min, ZHAO Zheng-duo. Effect of pouring temperature on semi-solid slurry of A356 Al alloy prepared by weak electromagnetic stirring[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(1): 71-76.

[14] BAI Yue-long, XU Jun, ZHANG Zhi-feng, SHI Li-kai. Preparation of semi-solid slurry at power frequency by annulus electromagnetic stirring method[J]. Transactions of Nonferrous Metals Society of China, 2009, 19: s531-s536.

[15] 周 冰, 康永林, 郜俊震, 祁明凡, 张欢欢. 强制对流搅拌制备铝合金半固态浆料及其组织演变[J]. 中国有色金属学报, 2014, 24(1): 61-68.

ZHOU Bing, KANG Yong-lin, HAO Jun-zhen, QI Ming-fan, ZHANG Huan-huan. Preparation of semisolid aluminum alloy slurry by forced convection mixing and its microstructure evolution[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 61-68.

[16] ROBLES H F C, SOKOLOWSKI J H. Comparison among chemical and electromagnetic stirring and vibration melt treatments for Al–Si hypereutectic alloys[J]. Journal of Alloys and Compounds, 2006, 426(1): 205-212.

[17] 李艳霞, 刘俊友, 张巨成, 李海凤. 高硅含量过共晶铝硅合金半固态重熔组织演变[J]. 中国有色金属学报, 2014, 24(9): 531-536.

LI Yan-xia, LIU Jun-you, ZHANG Ju-cheng, LI Hai-feng. Microstructure evolution of hypereutectic Al-Si alloy with high Si content during semi-solid remelting[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(9): 531-536.

[18] 李元东, 刘兴海, 李艳磊, 索江龙, 周宏伟, 张心龙. 2024 变形铝合金半固态浆料在连续冷却和保温过程中的组织演变[J]. 中国有色金属学报, 2013, 23(1): 61-68.

LI Yuan-dong, LIU Xing-hai, LI Yan-lei, SUO Jiang-long, ZHOU Hong-wei, ZHANG Xin-long. Microstructure evolutions of semisolid slurry of 2024 wrought aluminum alloy during continuous cooling and isothermal holding[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 61-68.

[19] MOHAMMADI H, KETABCHI M, KALAKI A. Microstructure evolution of semi-solid 7075 aluminum alloy during reheating process[J]. Journal of Materials Engineering and Performance, 2011, 20(7): 1256-1263.

[20] 毛卫民. 半固态金属成形技术[M]. 北京: 机械工业出版社, 2004: 8-39.

MAO Wei-min. Semi-solid processing of metals[M]. Beijing: China Machine Press, 2004: 8-39.

[21] GUO Hong-min, LUO Xue-quan, ZHANG Ai-sheng, YANG Xiang-jie. Isothermal coarsening of primary particles during rheocasting[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(8): 1361-1366.

[22] JIANG Ju-fu, WANG Ying, ATKINSON H V. Microstructural coarsening of 7005 aluminum alloy semisolid billets with high solid fraction[J]. Material Characterization, 2014, 90: 52-61.

(编辑 龙怀中)

基金项目:国家自然科学基金重点项目(51335009);陕西省自然科学基金资助项目(2012JQ7032)

收稿日期:2014-12-01;修订日期:2015-03-30

通信作者:赵升吨,教授,博士;电话:029-82667858;E-mail:zhangchenyang1333@126.com