文章编号:1004-0609(2014)04-1041-09

螺旋磁场电磁搅拌的数值模拟

赵 倩1,张兴国1,张环月1,郭建设1,侯晓光2,房灿峰1

(1. 大连理工大学 材料科学与工程学院,大连 116024;

2. 宝钢股份有限公司 设备研究所,上海 201900)

摘 要:建立描述不同磁场搅拌模式下的三维有限元模型,对比研究励磁电流、搅拌频率、搅拌器空间位置对磁感应强度和电磁力的影响规律。结果表明:磁场模拟结果与实测数据吻合良好,磁感应强度随励磁电流的增加呈线性增加;随搅拌频率的增加递减,磁感应强度沿中心轴线的分布表现为“中间大两头小”的特点,在径向铸坯边缘处最大,向中心逐渐衰减。电磁力随励磁电流和搅拌频率的增加而增大,中心轴线上底部电磁力值最大,并沿着轴线方向向上逐渐衰减;半径方向上边缘处的电磁力最大,向铸坯心部方向有小幅度的衰减。不同磁场作用下的计算结果表明:搅拌参数相同时,螺旋磁场具有更强的磁感应强度和电磁力,引起金属熔体沿径向和轴向上更大范围的流动,更有利于改善合金成分分布和凝固组织。

关键词:螺旋磁场;电磁搅拌;有限元分析;数值模拟;电磁力

中图分类号:TG146.4 文献标志码:A

Numerical simulation of spiral magnetic field of electromagnetic stirring

ZHAO Qian1, ZHANG Xing-guo1, ZHANG Huan-yue1, GUO Jian-she1, HOU Xiao-guang2, FANG Can-feng1

(1. School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China;

2. Equipment Institute, Baoshan Iron and Steel Company Limited, Shanghai 201900, China)

Abstract: A new three-dimensional finite element model describing the electromagnetic field distribution in the new-type multi-functional electromagnetic stirrer with different magnetic fields was developed. The influences of the exciting current, stirring frequency and space position of the stirrer on the magnetic induction intensity and electromagnetic force were analyzed. The results show that the simulated magnetic field in the mold is in good agreement with the measured data in the real stirrer. The magnetic induction intensity increases linearly with increasing the exciting current, and decreases with increasing the current frequency. On the same height of mold, the magnetic induction intensity gradually increases from the center to the wall of mold and reaches its maximum in the middle position of the stirrer and becomes smaller towards the end of the mold. The electromagnetic force increases with the increase of the exciting current and the stirring frequency. And the electromagnetic force reaches the maximum value in the bottom and gradually attenuates from the bottom to the top along the axial direction. And along the radial direction, the electromagnetic force slightly decreases toward the center of the ingot. The calculation results under different magnetic fields show that, the spiral magnetic field has stronger magnetic induction intensity and electromagnetic force at the same stirring parameters, which causes intensive flow in a larger zone of the molten metal along the radial and axial direction, thus promotes the formation of ellipsoidal or equiaxed grains and reduces the macrosegregation.

Key words: spiral magnetic field; electromagnetic stirring; finite element analysis; numerical simulation; electromagnetic force

在合金凝固过程中,如果初生相与液相之间密度相差较大,在缓慢冷却条件下凝固时,初生相表现为上浮或下沉,从而导致铸件中组成相及成分分布不均匀,产生重力偏析、中心缩孔缩松等缺陷,严重影响铸坯质量和应用。电磁搅拌技术具有磁力密度梯度大、磁能利用率高、穿透性强等特点,同时具有非接触性,克服了传统机械搅拌容易卷入气、渣而造成渣气孔缺陷等缺点[1-4],对改善铸坯的凝固组织、提高等轴晶率、减轻铸坯中心偏析及缩孔缩松等内部缺陷都有显著的作用[5]。

近几十年来,国内外学者对电磁搅拌技术进行了大量研究[6-11],采用二维或三维数学模型对旋转磁场和行波磁场作用下的磁感应强度和金属受力情况进行了数值模拟,分析金属熔体内的磁场分布和金属液承受电磁力的状况,以期优化电磁搅拌器的设计并获得最佳的搅拌效果。在电磁搅拌过程中,对合金凝固组织有着重要影响的参数主要有搅拌强度、搅拌时间、冷却速度和固相率等。在搅拌时间等参数一定的情况下,合金铸锭的内在质量主要由搅拌强度决定,而搅拌强度又主要取决于搅拌器的输入电流和输入频率。在实际应用中,这两个参数大多参考经验值。因此,探索出搅拌强度与给定电流、频率的关系,对确定最佳的电磁搅拌工艺具有一定的实际意义。

螺旋磁场是由旋转磁场和行波磁场叠加而形成的,目前针对螺旋磁场搅拌下的模拟分析和实验研究工作很少,三维电磁场和电磁力的计算尚未见报道。ZHAO等[12]和赵倩等[13-15]进行了螺旋磁场搅拌下的静态模拟实验,结果表明,相比于旋转磁场和行波磁场,螺旋磁场能够更有效地促进晶粒的细化和等轴晶的转变,而且可以很好地抑制重力偏析。而关于螺旋磁场的大小、方向与空间分布特征却尚未可知,因此,本文作者利用ANSYS商业软件,通过建立描述新型多功能电磁搅拌器内不同磁场搅拌下的三维有限元模型,对不同电磁搅拌参数(励磁电流和搅拌频率)下磁感应强度的分布进行数值模拟,并与实测值进行对比以验证模型的准确性。研究了不同磁场搅拌模式下工艺参数对金属液受力情况的影响规律,如电流-电磁力、频率-电磁力间的关系,希望能为建立更精确的给定参数与搅拌效果的关系,进而为实现螺旋磁场电磁搅拌工艺参数的优化,对合金的凝固组织和缺陷实现有效控制奠定基础。

1 电磁场计算模型

1.1 电磁搅拌基本理论

电磁搅拌的基本理论主要以麦克斯韦方程组为核心,由式(1)~(4)组成。

法拉第电磁感应定律:

(1)

(1)

安培环路定律:

(2)

(2)

高斯磁通定律:

(3)

(3)

高斯电通定律:

(4)

(4)

为使麦克斯韦方程组更加全面地表述电磁场,需补充如下3个描述介质性质的方程式:

(5)

(5)

(6)

(6)

(7)

(7)

式(1)~(7)中:E为电场强度;B为磁通密度;H为磁场强度;J为电流密度;D为电位移矢量;σ为电导率;ρ为自由电荷体密度;ε0、εr、μ0、μr分别为真空介电常数、相对介电常数、真空磁导率、相对磁导率。

计算过程中,电磁力采用时域平均值表示:

(8)

(8)

式中:F为时均电磁力,N/m3;Re为复数的实数部分; 为B的共轭复数。

为B的共轭复数。

1.2 物理模型的建立

图1 实验装置示意图

Fig. 1 Schematic diagram of experimental setup

实验用DJGX-Ф20W型多功能电磁搅拌器由三相两极式直线电动机和三相两极式旋转电机合成,如图1(a)所示。图1(b)所示为电磁搅拌变频电源控制柜,型号为DJKX-270KVA,可对搅拌装置进行参数的设定和控制。

搅拌器内径d 200 mm,外径D 560 mm,高700 mm,线圈通过95 mm2电缆引出,两组线圈单独通电时分别产生旋转磁场和行波磁场,同时通电时两种磁场合成为螺旋磁场。铸型放置在搅拌器中心位置,底部处在H=290 mm位置(H为距搅拌器底部的高度),使铸型内高为110 mm的合金熔体中心与线圈中心重合。为了验证模型的可靠性,模拟计算搅拌器产生的磁感应强度分布情况,并与实测值进行比较。搅拌器内磁感应强度的测量位置如图2所示。

在建立数学模型时进行如下假设:

1) Pb-Sn合金熔体为不可压缩的牛顿流体,应力与应变之间存在线性关系,合金熔液在同一温度下黏度处相同。

2) 不考虑温度对材料粘度和磁导率等参数的影响,模拟中涉及的ε、μ、σ均为常数。

3) 假设合金熔体边界不发生改变,即边界位移是零。

4) 电磁搅拌器内形状复杂的绞线圈简化成具有相同面积的载流区。励磁电流通过对载流区施加电流密度来实现,电流密度大小由线圈匝数、导线横截面积和电流计算出来。

5) 电磁搅拌器内冷却水、不锈钢保护套及绝缘物质等,由于磁导率较小,对模拟结果的影响较小,均用空气代替,采用简化的搅拌器结构。

图2 搅拌器内磁感应强度测量位置

Fig. 2 Measuring positions of magnetic induction intensity of electromagnetic stirrer

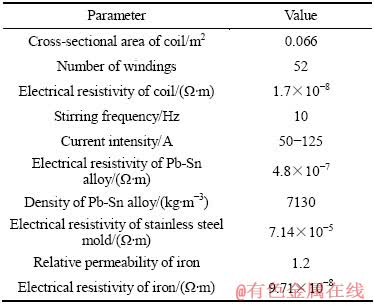

结合上述理论方程及假设,使用ANSYS有限元商用软件建立电磁搅拌有限元物理模型,如图3所示。模拟过程中采用三维实体二十节点六面体单元(SOLID117)进行网格划分和赋予属性,完成实体建模后施加载荷和约束边界条件进行求解计算,使用后处理器查看结果,获得磁感应强度、电磁力等参量分布情况。模拟计算所用的主要计算参数如表1所列。

图3 电磁场计算的实体模型和有限元模型

Fig. 3 Calculation and finite element model of electromagnetic field

表1 计算参数

Table 1 Main computation parameters

1.3 边界条件的处理

初始条件是对系统初始时刻所处状态的描述,与时间t相关。初始条件分为两类,目标函数在各处的值和对时间的变化率,如式(9)和(10)所示。

(9)

(9)

(10)

(10)

式中:v(r, t)是场向量(B、H、r)的函数,这里选择第一类边界条件,即零初始条件。

Az|t=0=0 (11)

边界条件指目标函数在场域边界S上的值,与坐标向量r有关,在物理学中共分为3类边界,这里取第一类边界条件,即在电磁搅拌器外表面加磁力线平行条件。

(12)

(12)

2 结果与分析

2.1 磁感应强度计算与实测结果对比

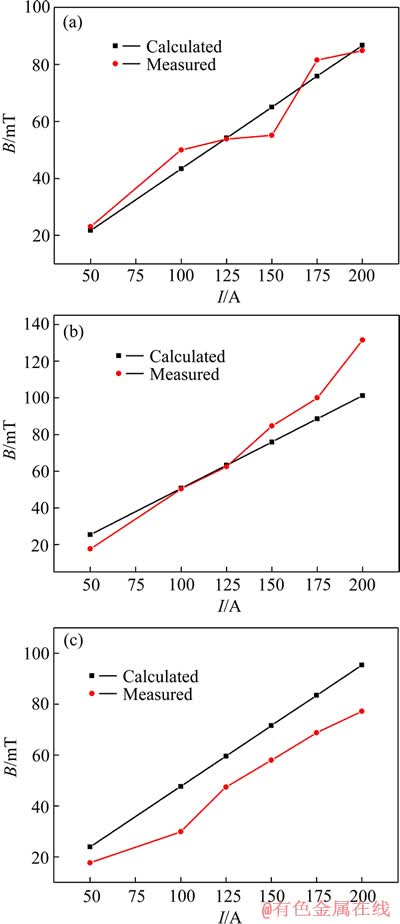

采用TM-601型特斯拉计进行空载条件下铸型中心磁感应强度的测量。研究表明[16],不锈钢坩埚电阻率相对铜合金和铸铁的大,有利于减少涡流损失,提高电磁场的渗透深度和磁场利用率。图4所示为不同磁场形式下铸型中心磁感应强度随励磁电流变化的计算结果与实验数据的比较。由图4(a)~(c)可以看出,磁感应强度随着励磁电流的增大呈线性增加。旋转磁场和行波磁场的计算值与测量值吻合良好,而螺旋磁场下不同励磁电流时的实测值均低于计算值,原因是实际测量值仅为螺旋磁场磁感应强度某一分量值,实际的需三维叠加而成,因而产生一定的测量误差。

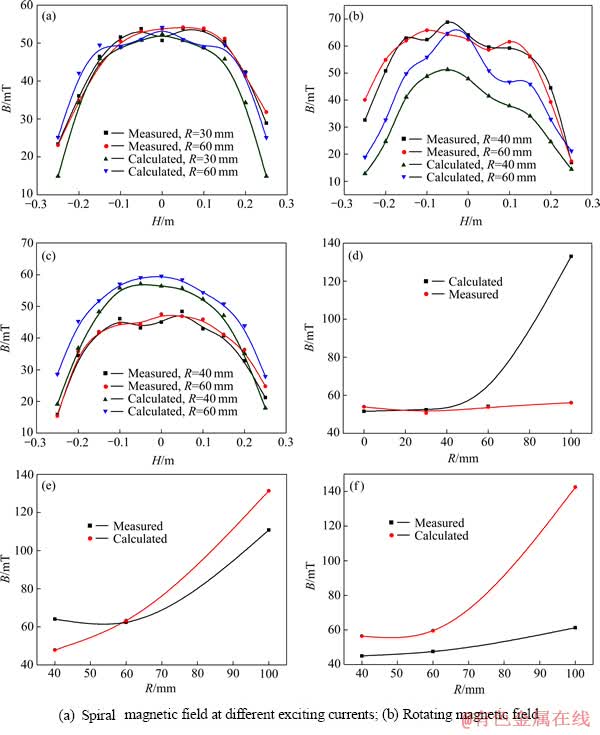

励磁电流I=125 A时,沿搅拌器中心轴线和径向的磁感应强度计算结果与实测数据的比较如图5所示。从图5(a)~(c)可以看出,3种磁场作用下搅拌器中心附近的磁感应强度最大,且沿中心轴线向两端逐渐减小,磁感应强度呈现“中间大两头小”的分布特点,与实际测量结果一致。实测结果表明:行波磁场沿纵向衰减幅度最小,旋转磁场衰减最大,螺旋磁场的衰减幅度介于两者之间,更有利于形成纵截面上较大区域的均匀搅拌。

图4 不同励磁电流下螺旋、旋转、行波磁感应强度实测与计算对比

Fig. 4 Comparison of measured and simulated results of rotating(a), traveling(b) and spiral(c) magnetic induction at different exciting currents

图5 不同磁场作用下磁感应强度沿搅拌器轴向和径向分布的检测结果和计算结果的对比

Fig. 5 Comparison of measured and simulated results of different magnetic induction along axial((a)~(c)) and radial((d)~(f)) in stirrer

电流一定时,搅拌器中心磁感应强度沿半径方向表现为边缘处最大,向中心方向不断衰减,如图5(d)~ (f)所示。旋转磁场和螺旋磁场沿搅拌器径向R<60 mm范围内,中心磁感应强度的计算结果与测量值一致性很好,且分布均匀稳定,磁场覆盖范围较大。但计算结果与测量结果在搅拌器壁处出现显著差异,模拟值远大于测量值,这可能是由以下因素导致的,即器壁的相对磁导率较大,模拟此处磁感应强度得到的值较大,而测量时探头处于器壁处相对磁导率较小的空气位置,导致测量值偏小,因而造成器壁处的模拟值与测量值出现较大偏差。行波磁场有一定的误差,但整体上一致性较好。综合分析可知,旋转磁场沿径向衰减最小,螺旋磁场其次,行波磁场沿径向衰减最为明显,另外,螺旋磁场沿轴线和径向上磁场分布均匀性最好,可以实现大范围的均匀搅拌,对促进等轴晶的形成和改善成分偏析均十分有利。

综上所述,计算值与实测值吻合良好,说明模拟分析结果基本可反映电磁场的变化趋势,从而验证了计算模型与软件算法的可行性。

2.2 电磁力计算结果

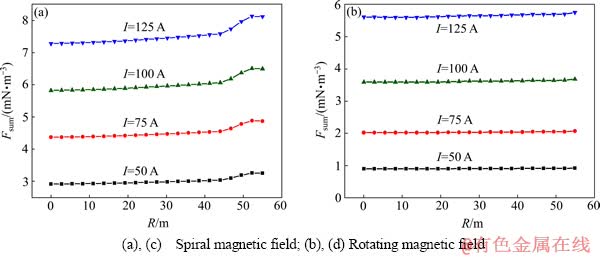

图6所示为不同磁场作用时金属熔体所受电磁力与励磁电流的关系。由图6可见,螺旋磁场作用下金属熔体所受电磁力在铸坯边缘最大,向中心有小幅度的衰减,而旋转磁场时,金属熔体受到的电磁力沿径向分布很均匀,几乎不存在衰减,这与图4所示的磁感应强度分布一致。螺旋磁场和旋转磁场均可实现对整个金属熔体的搅拌,但螺旋磁场产生的电磁力大于旋转磁场产生的电磁力,因此可以产生更强烈的搅拌,而旋转磁场作用下熔体受到的水平方向上的电磁力更为均匀。作用于金属熔体的电磁力值Fsum均随着励磁电流的增大而增加,螺旋磁场条件下的电磁力值呈线性增加,且大于相同参数下旋转磁场,当励磁电流由50 A增至125 A时,边缘处最大电磁力增加2.5倍;旋转磁场作用下电磁力值呈平方增加,最大电磁力增加了约6倍。可见,电磁力受电流大小的影响很明显。

对比图7的计算结果发现,螺旋磁场作用下金属熔体所受电磁力Fr非常小,比Fθ和Fz低两个数量级,可以认为螺旋磁场的切向分量和轴向分量的分布对搅拌强度起决定作用,在电磁力的作用下,金属熔体内主要产生切向和轴向上的大环流,有利于实现金属熔体在横、纵截面上的流动。旋转磁场作用下,金属熔体所受总的电磁力Fsum与Fθ曲线几乎是重合的,说明该磁场下切向分量是产生搅拌的主要原因,金属熔体内主要产生水平方向的流动。两种磁场作用下电磁力分布均表现为中心横截面上边缘最大,逐渐向中心衰减;中心轴线上金属熔体底部受到的电磁力值大,沿着轴线方向靠近铸锭顶部电磁力值呈递减趋势。底部受到的电磁力大易于引起金属熔体在纵截面上的大环流,产生大的搅拌速度[17]。

图6 不同磁场作用下熔体所受电磁力的对比

Fig. 6 Comparison of electromagnetic force of molten metal under different magnetic fields along radial direction

图7 不同磁场作用下熔体所受电磁力沿径向和轴向分布的对比

Fig. 7 Comparison of electromagnetic force of molten metal under different magnetic fields along radial and axial direction

固定电磁搅拌器励磁电流I=125 A,改变搅拌频率模拟计算熔体中心处所受电磁力和磁感应强度大小,得到磁感应强度与频率、电磁力与频率之间的关系曲线,如图8所示。

图8 螺旋和旋转磁场作用下熔体中心所受电磁力与搅拌频率的对比

Fig. 8 Comparison of electromagnetic force (Fsum) of molten metal under different magnetic fields at different frequencies

磁感应强度在金属熔体中的透入深度[18]为

(13)

(13)

式中: 、

、 、f分别为电导率、磁导率和磁场频率。

、f分别为电导率、磁导率和磁场频率。

透入深度随磁场频率的提高而减小,透入深度减小则电磁力主要集中于金属熔体的表面,对熔体内部的搅拌作用减弱。不同磁场下R=60 mm处磁感应强度随频率的变化情况如图8(a)所示。电流一定时,磁感应强度随频率的增大而减小,搅拌作用也相应减弱。对比两种形式磁场随频率的变化趋势可以发现,相同参数下螺旋磁场要强于旋转磁场,在频率较大时差别较小,随着频率减小出现增大趋势。从图8(b)可以看出,旋转磁场和螺旋磁场总的电磁力都随频率的增大而缓慢增大,电磁力随频率的变化趋势与磁感应强度随频率的变化趋势不同,这是因为合金熔体内电磁力的大小不仅与磁感应强度有关,还和熔体与磁场之间的转差率。频率增大使熔体与磁场之间的转差率[19]增大,涡流感应热增加,熔体粒子因碰撞、摩擦几率增大而发生长大的趋势增加,使搅拌效果变差。由此可见,适当的磁场频率能够获得理想的磁场、流场和温度场。

图8(c)和(d)所示为不同磁场作用下,搅拌频率发生改变时金属熔体纵截面上R=500 mm时各点处所受电磁力的比较。可以看出,随着频率的增大,电磁力逐渐增加,但数值变化不大。沿中心轴线方向,螺旋磁场作用下金属熔体中下部所受电磁力较大,且曲线较为平稳,说明电磁力在该位置范围内分布均匀,有利于实现大范围的均匀搅拌。旋转磁场作用下金属熔体底端所受电磁力最大,沿着轴向有较大幅度的衰减,说明旋转磁场产生的电磁力沿轴向分布是非常不均匀的,不利于实现熔体在纵截面的流动和均匀化。

从图8(e)和(f)中可以看出,两种磁场作用下边缘处电磁力值最大,向中心有不同程度的衰减。熔体所受电磁力Fsum随搅拌频率的增加而增加,但整体上增加的幅度不明显。同时可以看出,螺旋磁场下合金熔体任一点所受电磁力值均大于旋转磁场的对应量,即相同参数下的螺旋磁场可以产生更强的搅拌和引起熔体内部更大范围的流动。

3 结论

1) 电磁场模拟结果与实测值吻合良好,验证计算模型与软件算法的可行性,利用ANSYS软件可以计算电磁搅拌装置的电磁场分布。

2) 空载时电磁搅拌器内磁感应强度的分布规律为:随着励磁电流强度的增加而增大,随电源频率的增大而减小;高度方向上,磁感应强度呈现中间大两头小的特征;同一断面上,边缘处磁感应强度大于中心的;相同参数下,螺旋磁场激发的磁感应强度大于旋转磁场激发的磁感应强度;螺旋磁场沿轴向和径向衰减幅度均较小,分布较平稳,磁场覆盖范围较大。

3) 不同磁场产生的电磁力的大小和分布规律为金属熔体受到的电磁力随着励磁电流和搅拌频率的增加而增加;中心横截面上边缘最大,逐渐向中心衰减;中心轴线上金属熔体底部受到的电磁力较大,且沿着轴线方向靠近铸锭顶部电磁力递减。

4) 旋转磁场在金属熔体内主要产生水平方向的流动,螺旋磁场主要产生切向和轴向上的大环流,有利于实现大范围的均匀搅拌。相同参数下的螺旋磁场产生的电磁力强于旋转磁场,对等轴晶的形成和成分偏析的改善有更明显的促进作用。

REFERENCES

[1] 张伟强. 金属电磁凝固原理与技术[M]. 北京: 冶金工业出版社, 2004: 1-3.

ZHANG Wei-qiang. Electromagnetic solidification principles and techniques of the metal[M]. Beijing: Metallurgical Industry Press, 2004: 1-3.

[2] WANG X D, LI T J, FAUTRELLE Y, DUPOUY M D, JIN J Z. Two kinds of magnetic fields induced by one pair of rotating permanent magnets and their application in stirring and controlling molten metal flows[J]. Journal of Crystal Growth, 2005, 275(1): 1473-1479.

[3] EL-BASSYOUNI T A. Effect of electromagnetic forces on aluminum cast structure[J]. Light Metals, 1983, 33(12): 733-741.

[4] 周尧和, 胡壮麒, 介万奇. 凝固技术[M]. 北京: 机械工业出版社, 1998: 156-158.

ZHOU Rao-he, HU Zhuang-qi, JIE Wan-qi. Solidification technology[M]. Beijing: China Mechine Press, 1998: 156-158.

[5] 陈 永. 连铸结晶器电磁搅拌技术[J].钢铁钒钛, 2003, 24(2): 29-33.

CEHN Yong. Mold electromagnetic stirring in the continuous casting[J]. Iron Steel Vanadium Titanium, 2003, 24(2): 29-33.

[6] 陈兴润, 张志峰, 徐 骏, 石力开.电磁搅拌法制备半固态浆料过程电磁场、流场和温度场的数值模拟[J]. 中国有色金属学报, 2010, 20(5): 937-945.

CHEN Xing-run, ZHANG Zhi-feng, XU Jun, SHI Li-kai. Numerical simulation of electromagnetic field, flow field and temperature field in semi-solid slurry preparation by electromagnetic stirring[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(5): 937-945.

[7] 于海岐, 朱苗勇. 圆坯结晶器电磁搅拌过程三维流场与温度场数值模拟[J]. 金属学报, 2008, 44(12): 1465-1473.

YU Hai-qi, ZHU Miao-yong. 3D numerical simulation of flow field and temperature field in a round billet continuous casting mold with electromagnetic stirring[J]. Acta Metallurgica Sinica, 2008, 44(12): 1465-1473.

[8] ZHANG Qi, WANG Tong-min, LI Ting-ju, JIN Jun-ze. Numerical simulation of solidification process of Sn-3.5%Pb hollow billet with stirring magnetic field[J]. Transaction of Nonferrous Metals Society of China, 2007, 17(5): 940-946.

[9] SU Yan-qing, XU Yan-jin, ZHAO Lei, GUO Jing-jie, FU Heng-zhi. Effect of electromagnetic force on melt induced by traveling magnetic field[J]. Transaction of Nonferrous Metals Society of China, 2010, 20(4): 662-667.

[10] CRAMER A, PAL J, GERBETH G. Experimental investigation of a flow driven by a combination of a rotating and a traveling magnetic field[J]. Phys Fluids, 2007, 19: 118109-1-4.

[11] GALINDO V, NIEMIETZ K,  O, GERBETH G. Numerical and experimental modeling of VGF-type buoyant flow under the influence of traveling and rotating magnetic fields[J]. Journal of Crystal Growth, 2012, 360: 30-34.

O, GERBETH G. Numerical and experimental modeling of VGF-type buoyant flow under the influence of traveling and rotating magnetic fields[J]. Journal of Crystal Growth, 2012, 360: 30-34.

[12] ZHAO Q, ZHANG X G, FANG C F. The effects of electromagnetic stirring on solidification structure and macrosegregation of Pb-Sn alloy[J]. Advanced Materials Research, 2012, 482/484: 1447-1452.

[13] 赵 倩, 房灿峰, 侯晓光, 韩彦博, 张 楠, 张兴国. 螺旋磁场对金属凝固过程中成分偏析的影响[J]. 特种铸造及有色合金, 2011, 31(6): 495-500.

ZHAO Qian, FANG Can-feng, HOU Xiao-guang, HAN Yan-bo, ZHANG Zhan, ZHANG Xing-guo. Effects of spiral magnetic field on the composition segregation in the metal during solidification process[J]. Special Casting & Nonferrous Alloys, 2011, 31(6): 495-500.

[14] 张 楠, 赵 倩, 房灿峰, 韩彦博, 郭建设, 侯晓光, 邢清源, 张兴国. 螺旋磁场对Pb-Sn合金成分偏析的影响[J]. 中国有色金属学报, 2012, 22(6): 1731-1737.

ZHANG Nan, ZHAO Qian, FANG Can-feng, HAN Yan-bo, GUO Jian-she, HOU Xiao-guang, XING Qing-yuan, ZHANG Xing-guo. Effects of spiral magnetic field on composition segregation of Pb-Sn alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1731-1737.

[15] 郭建设, 赵 倩, 侯晓光, 房灿峰, 张兴国. 电磁搅拌频率对Pb-Sn过共晶合金凝固组织的影响[J]. 材料研究学报, 2012, 26(3): 267-273.

GUO Jian-she, ZHAO Qian, HOU Xiao-guang, FANG Can-feng, ZHANG Xing-guo. Effects of electromagnetic stirring frequency on the solidification structure of Pb-Sn hypereutectic alloy[J]. Chinese Journal of Materials Research, 2012, 26(3): 267-273.

[16] 陈兴润, 张志峰, 徐 骏. 电磁搅拌法制备半固态浆料过程中电磁场的数值模拟[J]. 特种铸造及有色合金, 2009, 29(12): 1109-1112.

CHEN Xing-run, ZHANG Zhi-feng, XU Jun. Numerical simulation of electromagnetic field in semi-solid slurry prepared by EMS[J]. Special Casting & Nonferrous Alloys, 2009, 29(12): 1109-1112.

[17] 张 琦. 复合电磁场对连铸空心管坯质量的影响[D]. 大连: 大连理工大学, 2007.

ZHANG Qi. Effect of multi-electromagnetic fields on the quality of continuous casting hollow billet[D]. Dalian: Dalian University of Technology, 2007.

[18] 赵志浩, 崔建忠, 左玉波, 张海涛, 张北江. 低频电磁水平半连续铸造中磁场的分布及其对宏观偏析的影响[J]. 铸造, 2005, 54(3): 241-245.

ZHAO Zhi-hao, CUI Jian-zhong, ZUO Yu-bo, ZHANG Hai-tao, ZHANG Bei-jiang. Distribution of magnetic field and its effects on macrosegregation of electromagnetic HDC casting aluminum alloy[J]. Foundry, 2005, 54(3): 241-245.

[19] 毛卫民, 甄子胜, 陈洪涛. 电磁搅拌参数对半固态AZ91D镁合金组织的影响[J]. 特种铸造及有色合金, 2005, 25(9): 536-538.

MAO Wei-min, ZHEN Zi-sheng, CHEN Hong-tao. Effects of electromagnetic stirring parameters on microstructure of semi-solid AZ91D Mg alloy[J]. Special Casting & Nonferrous Alloys, 2005, 25(9): 536-538.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(50875031);中央高校基本科研业务费专项资金资助项目(DOT12ZD205)

收稿日期:2013-05-17;修订日期:2013-10-13

通信作者:张兴国,教授,博士;电话:0411-84706183;E-mail: zxgwj@dlut.edu.cn