文章编号:1004-0609(2014)01-0061-08

强制对流搅拌制备铝合金半固态浆料及其组织演变

周 冰,康永林,郜俊震,祁明凡,张欢欢

(北京科技大学 材料科学与工程学院,北京 100083)

摘 要:采用自主研发的强制对流搅拌装置(FCR),研究筒体温度、浇注温度和搅拌速度对A356铝合金半固态组织的影响规律,探讨半固态浆料制备过程中的凝固行为。结果表明:适当降低浇注温度、筒体温度和提高搅拌速度均有利于半固态浆料组织的改善,能够制备晶粒细小、圆整、分布均匀的半固态组织;当浇注温度为620~630 ℃、筒体温度为570~580 ℃、筒体转速为200 r/min以上时,均能获得理想的半固态浆料,其初生固相颗粒平均直径在80 μm以下,形状因子在0.75以上;强制对流搅拌装置极大地改变了传统凝固条件下熔体依靠传导单向传热和扩散缓慢传质的状态,使熔体的温度场和成分场趋于一致,破坏了枝晶生长的条件,有利于获得较好的半固态组织。

关键词:A356铝合金;半固态;强制对流;流变成形;组织演变

中图分类号:TG146.2+1;TG249.9 文献标志码:A

Preparation of semisolid aluminum alloy slurry by forced convection mixing and its microstructure evolution

ZHOU Bing, KANG Yong-lin, GAO Jun-zhen, QI Ming-fan, ZHANG Huan-huan

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing100083, China)

Abstract: A356 aluminum alloy semisolid slurry was prepared by self-developed forced convection rheoforming machine (FCR). The effects of barrel temperature, pouring temperature and rotation speed on the microstructure of semisolid slurry were investigated. The solidification behavior of the semisolid slurry preparation was discussed. The results show that reducing the barrel temperature and pouring temperature and increasing the rotation speed appropriately are beneficial to obtain semisolid slurry with fine and spherical solid particles distributed in the matrix uniformly. The desirable semisolid slurry with average primary solid phase diameter of below 80μm and shape factor of above 0.75 can be obtained at pouring temperature of 620-630 ℃, barrel temperature of 570-580 ℃ and rotation speed over 200 r/min. The FCR device can greatly change the situation that the melt relies on diffusion to transfer the heat and mass in traditional solidification conditions. It destroys the generation environment of dendrites. The temperature field and the composition of the melt are going uniformly, which will be advantage to obtain better semisolid microstructure.

Key words: A356 aluminum alloy; semi-solid; force convection; rheoforming; microstructure evolution

半固态技术自发明以来,由于能够获得均匀的细晶组织、提高性能和实现高速近终成形等优点,受到了广泛关注。流变成形技术由于具有成本低、应用范围广、工艺流程短、铸件组织致密以及适合于多种加工方法等优点[1]。近些年来,流变成形技术在国内外受到了普遍重视,许多学者从理论、试验、技术和设备等方面开展了大量的研究,取得了很大的进步,使流变成形技术成为半固态加工领域的新热点[2-4]。

半固态浆料制备是流变成形技术发展最重要的一个环节。到目前为止,已经提出了许多种半固态浆料制备技术,如美国WPI学院的PAN等[5]研究的CRP技术,将两种不同成分或温度的熔融合金混合降温制备半固态浆料;泰国Songkla大学的WANNASIN等[6]开发的GISS技术,在合金凝固时通入气体,利用气泡扰动来制备半固态金属浆料;GUO等[7]开发的LSPSF工艺,将具有一定过热度的合金液浇注到转动的输送管内,进行冷却和剪切来制备半固态浆料;毛卫民等[8]提出的SCP技术,将热合金液浇入立式蛇形浇道中降温和自身重力引起的扰动来制备半固态浆料。

其中,机械搅拌法制备半固态浆料对设备结构要求较高,但各国学者努力融入机械搅拌的原理,逐渐发展出了新的技术和方法:典型的有英国Brunel大学的FAN等[9]开发的双螺旋流变注射机、美国麻省理工学院(MIT)的MARTINEZ等[10]研究的SSR工艺、韩国的SEO等[11]研究的RBSS(Rotational barrel with stirring screw)设备,ZHANG等[12]开发的锥筒式流变成形机,但这些设备基本都还处于实验室研究阶段,存在的问题主要有拆卸清理麻烦、工作状态不稳定,如半固态浆料冷凝粘在设备内,导致设备无法工作。

为此,在金属浆料凝固过程中,利用搅拌叶片对浆料进行搅拌形成对流运动的原理,自行研制了新型机械搅拌制备半固态浆料装置-强制对流流变成形机(Forced convection rheoforming machine,FCR)。FCR设备改进了筒体结构,使搅拌轴和筒体能够很方便的分离,并且在搅拌室内嵌入石墨内衬,减少设备粘料,易于清理。FCR设备结构紧凑、设计合理,能够很方便的和各种成形设备结合开展新的半固态成形工艺。本文作者以A356铝合金为试验对象,研究FCR不同筒体温度和搅拌速度对半固态组织的影响规律,并结合浆料在设备内的流动规律探讨半固态浆料制备过程中的组织形成机理。

1 实验

1.1 实验设备

试验所用设备采用实验室自主发明的强制对流流变成形机(FCR)[13],该设备主要由驱动装置、剪切搅拌装置、温度控制装置和放料装置等组成。无极调速电机通过传动齿轮带动搅拌轴旋转。剪切搅拌机构由搅拌室和搅拌轴组成,其中搅拌轴上装有适合搅拌粘性流体的螺旋带,可以通过调整搅拌速度使得金属熔体在搅拌室内产生流体对流。为防止合金液在搅拌室内冷凝挂料,在搅拌室内壁装有石墨内衬。搅拌桶外壁有加热和冷却元件,通过温度控制箱对筒体温度进行精确控制。放料装置由放料手柄、芯杆和堵塞构成。浆料制备好后,旋转放料手柄,提升堵塞,半固态浆料流出。其具体结构如图1所示。

图1 强制对流搅拌装置结构示意图及实物图

Fig. 1 Schematic diagram (a) and physical diagram (b) of FCR machine

FCR设备的工作原理是采用机械搅拌方式,利用剪切搅拌的原理,通过螺旋搅拌轴的作用,使合金熔体在低于合金液相线温度的筒体内产生流体对流,同时受到冷却和对流混合的作用,破坏枝晶生长的环境,使初生晶粒生长为球形,从而制备出半固态合金浆料。

1.2 实验材料及方法

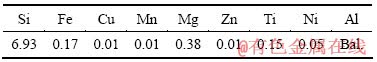

实验采用商用铝合金A356,其化学成分见表1。经差热分析法(DSC)测定,得到A356合金液相线和固相线温度分别为615和560 ℃。

表1 A356铝合金的化学成分

Table 1 Chemical composition of A356 alloy ingot (mass fraction, %)

将A356铝合金锭烘干后放入预热温度为400 ℃的熔化炉内升温至700 ℃融化,进行除气排渣后静置,将合金液降温至630~680 ℃;调整筒体温度600~570 ℃,调速螺杆转速调整为100~400 r/min,石墨柱塞处于关闭状态,搅拌室轴线与水平线呈40°;然后将熔融的铝合金液,浇入至FCR设备内,合金液搅拌轴的作用下产生流体对流,在搅拌一定时间(30 s)后,旋转放料把手,制备好的半固态浆料从出料口处流出。为了更准确地观察制备出的半固态浆料的组织形貌,将制备出的半固态浆料注入到特制的不锈钢坩埚内,立即将坩埚放入水中使浆料快速冷却。

为了对比不同工艺条件下制备的半固态浆料效果,沿坯料轴线方向在中部截取10 mm厚的圆片,并从中取一扇形作为金相试样。试样经过磨平、抛光处理后,采用体积分数为0.5%的HF酸水溶液进行腐蚀,在NEOPHOT 21光学显微镜下对组织进行观察分析。利用ImageTool图像处理软件考察工艺参数对初生固相尺寸、形状因子的影响。初生固相尺寸用等面积圆直径D表示,形状用形状因子F表示,F越趋近于1,初生固相越圆整。具体计算公式为

(1)

(1)

(2)

(2)

式中:A为晶粒面积;P为晶粒界面周长。

2 结果与分析

2.1 不同筒体温度对半固态组织的影响

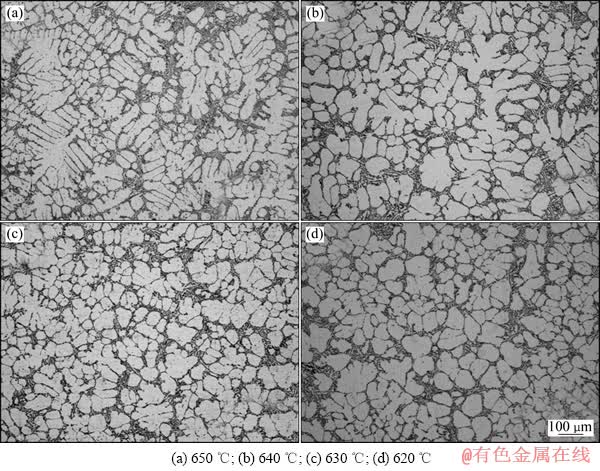

图2所示为在浇注温度为630 ℃、搅拌转速为200 r/min、剪切时间为30 s的工艺条件下不同筒体温度条件下获得的半固态显微组织。图3所示为筒体温度与A356半固态合金晶粒尺寸及形状因子的关系曲线。图中白色的块状或近似球状区域为α(Al)相,深灰色的区域为剩余液相形成的共晶组织。筒体温度为600 ℃,组织中的初生α(Al)相多为蔷薇状或树枝状枝晶,平均尺寸约为150 μm,形状因子仅为0.44,因为筒体温度较高,合金熔体在搅拌室内受到的冷却强度很低,形成的晶核数量很少,出口浆料组织中枝晶的数量较多;当筒体温度为590 ℃时,筒体的温度降低,设备的冷却作用增大,组织中枝晶的数量明显减少,蔷薇状晶粒变多,初生固相平均尺寸为94 μm,形状因子为0.68。当筒体温度降为570~580 ℃时,组织中的蔷薇状晶粒数量减少,近球形晶粒明显增多,外观轮廓圆整,分布均匀,初生固相平均尺寸降到70 μm以下,晶粒形状因子也增加到0.75以上。

图2 不同筒体温度下A356半固态合金的显微组织

Fig. 2 Microstructures of semisolid A356 alloy under different barrel temperatures

图3 筒体温度对A356半固态合金中初生相形貌的影响

Fig. 3 Effect of barrel temperature on primary particle size and shape factor of semisolid A356 alloy

随着筒体温度的降低,合金初生相尺寸减小,数量增加,形貌更加圆整,分布更加均匀。产生这种规律的主要原因在于:筒体温度对半固态浆料制备过程中的合金冷却效果产生直接影响。在合金熔体过热度不变的情况下,筒体温度降低,合金熔体在搅拌室内受到的冷却作用增强,产生的过冷度大,初生晶粒稳定形核的需要的临界功和临界半径减小,更容易形核,形核率提高有利于获得大量细小的初生相。

2.2 不同浇注温度对半固态组织的影响

图4所示为在剪切温度为590 ℃、螺杆转速为200 r/min、剪切时间为30 s的工艺条件下不同浇注温度时获得的半固态合金的显微组织。图4(a)中浇注温度较高为650 ℃,初生相中发现有粗大的树枝状,晶粒尺寸差别很大,分布不均匀;当浇注温度为640 ℃时,组织中枝晶减少,蔷薇状晶粒数量增多,蔷薇状晶粒尺寸较大(见图4(b));当浇注温度进一步降低为630 ℃时,获得的初生相中存在大量蔷薇状晶和少量球状晶,晶粒尺寸明显减小,总体组织均匀性得到改善(见图4(c)),其初生相平均晶粒尺寸为88 μm,形状因子为0.68,当浇注温度降低至620 ℃时,组织中蔷薇状晶粒晶粒向球状晶转化,球状晶的数量增多,晶粒形貌更加圆整,尺寸进一步细化(见图4(d)),其平均晶粒尺寸降到80 μm,形状因子也增加到了0.72。

图4 不同浇注温度下A356半固态合金的显微组织

Fig. 4 Microstructures of semisolid A356 alloy at different pouring temperatures

对比图4(a)~(d)可以发现:随着浇注温度的降低,合金初生相的平均晶粒尺寸逐渐减小,并且其半固态的固相颗粒变得更加圆整、均匀。初生相平均晶粒尺寸D和形状因子F与浇注温度的关系见图5。结合图4和5可以看出,浇注温度会对半固态浆料组织的初生相形貌有直接的影响。其主要原因在于:浇注温度的不同,合金熔体流进FCR设备的冷却速率不同,随着浇注温度的降低,熔体的过热度较小,合金熔体能更快地进入固液两相区间,且在相同的时间内,合金熔体在搅拌机构中达到的过冷度更大,熔体形核需要的临界功和临界尺寸减小,形核率也随之提高,从而有利于获得大量细小的初生固相。

图5 浇注温度对半固态A356合金中初生相形貌的影响

Fig. 5 Effect of pouring temperature on primary particle size and shape factor of semisolid A356 alloy

2.3 不同搅拌速度对半固态组织的影响

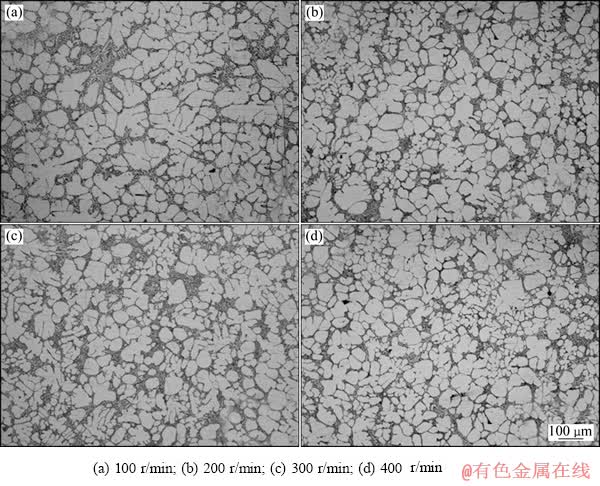

图6所示为浇注温度为630 ℃、筒体温度580 ℃、剪切时间为30 s的工艺条件下不同搅拌速度时获得的A356半固态合金的显微组织。由图6可看出,搅拌速度为100 r/min时,组织中初生固相多为蔷薇状晶粒,很少有枝晶,初生固相平均尺寸约为95 μm,形状因子为0.6,尽管合金熔体在搅拌室对流搅拌强度很小,但得到的组织与普通铸造时的枝晶组织已经完全不同;当搅拌速度为200 r/min时,组织中的蔷薇状晶粒明显减少,近球状晶数量增多,初生固相平均尺寸约为76 μm,形状因子为0.74,分布比较均匀;当搅拌速度增加到300 r/min时,初生固相的晶粒尺寸和球形度进一步减小,初生晶粒的数量增多且分布也很均匀。随着搅拌速度进一步增加到400 min时,初生α(Al)在基体上分布更均匀,但初生晶粒的尺寸及形状因子变化趋势变缓,如图7所示。

从图6和7可以看出,随着搅拌速度的增加,半固态组织中初生固相的形貌逐渐趋于圆整,组织更加细小、均匀。其主要原因在于:搅拌速度的大小关系到合金熔体在搅拌室内对流强度的大小,增加搅拌速度,合金熔体在搅拌室内的对流强度大。对流强度大不仅能使熔体在同样的时间内能达到更大的过冷度,更容易形核,而且能更快地减少熔体的温度差,使熔体内温度场的分布更均匀一致。另一方面,较大的对流强度增加了彼此碰撞的强度和频率,有利于不规则晶粒尖角处的钝化而转变为球状晶。

图6 不同搅拌速度下A356半固态合金的显微组织

Fig. 6 Microstructures of semisolid A356 alloy at different rotation speeds

图7 搅拌速度对A356半固态合金中初生相形貌的影响

Fig. 7 Effects of rotation speed on primary particles and shape factor of semisolid A356 alloy

2.4 FCR制备半固态浆料的组织形成机理

与常规铸造相比,强制对流搅拌条件下熔体的凝固最大的不同在于凝固过程是在激烈运动的条件下进行的;而常规铸造是相对静态的。动态与静态的差别正是凝固过程中不同现象及最终获得完全不同组织的根源所在。

强制对流搅拌装置采用适合高粘度流体搅拌的螺旋式桨叶,合金熔体流入设备内,先从高向低沿着筒壁流动,到达搅拌室底部后,快速旋转的搅拌螺旋杆使合金熔体在搅拌室中形成由高向低的内部轴向流,在内部轴向流压力作用下从搅拌螺旋杆与石墨内衬的缝隙处产生由低向高的反向流动,形成轴向循环对流。此外,沿着搅拌轴圆周方向有跟搅拌方向相同的周向流动,具体流动方式见图8。

由于熔体在剪切搅拌的作用下产生旋转具有周向的旋转流动和轴向的对流,产生了复杂的流体对流。在强烈对流运动的作用下,一方面晶粒随液相流动,自身也发生旋转,由于不断同其他晶粒、叶片和内壁发生接触碰撞,边缘有棱角的地方发生塑性变形,且逐渐变得圆化;另一方面,改变了传统凝固条件下依靠传导单向传热和扩散缓慢传质的状态。在传热方面,熔体在搅拌筒中,由于对流换热强度远大于传统的热量扩散传递,整个合金熔体能在更短时间内降至液相线下,整个熔体处于均匀的过冷状态而不只是合金的外层,熔体的临界形核功和临界形核半径减小,熔体可自发或借助悬浮的有效形核质点大量形核。在传质方面,熔体中物质传输为对流控制而非扩散控制,合金熔体处于快速混合状态,晶粒随熔体不断改变自身的位置且晶粒生长游离出的溶质能及时排走,不会在晶面前沿堆积,使熔体中的宏观成分相对均匀。而且MOLENAAR等[14]的研究揭示了一个重要现象:强迫对流下的晶粒在生长过程中具有自旋行为。使得晶粒在生长过程中不断地变换液—固界面的温度场、成分场。因此,即使某一瞬间内晶粒的各个方向生长速度出现较大差异,晶粒也将在各个方向相对均匀地生长。

图8 搅拌室内合金流动方式示意图

Fig. 8 Flow illustration of melt in FCR device

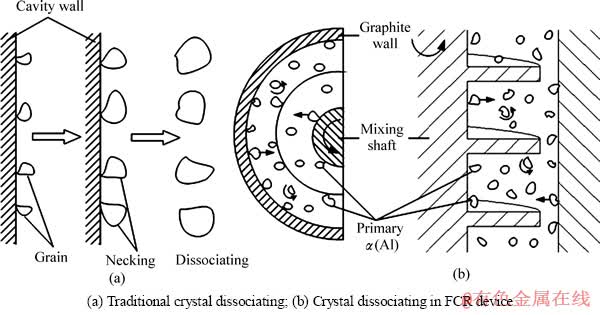

OHNO[15]在研究等轴晶来源时提出了晶粒游离机理,认为在凝固初期合金液在铸型型壁或冷却的液面上形成颈缩形晶粒,在合金液对流作用下脱离型壁或冷却液面产生游离,进入合金熔体内部,如图9(a)所示。图9(b)所示为FCR设备内器壁和螺旋轴之间晶粒的游离示意图。

熔体在相同的过冷度下,依靠内壁、螺旋搅拌杆和旋转叶片为基底的非均匀形核需要的稳定形核功和临界形核半径小,优先形成大量稳定晶核。由于熔体对流搅拌作用,这些晶粒在熔体的冲刷作用下无法形成稳定的凝固壳,晶粒向内部游离,而不是就地生长,内壁、搅拌杆和旋转叶片上又能产生新的晶核,这些都极大地增大熔体中的形核率;晶核数量的增多使晶粒在长大时能更好地发挥相互抑制长大的作用,有利于初生组织的细小圆整。

实际的凝固过程是一个受多种因素控制的复杂的物理化学过程,即使处于强制对流作用下,熔体也不是一个完全均匀体系,晶粒也会出现不规则形状。非规则自由晶最后也基本以球状晶存在,一是由于合金熔体的混合对流作用,晶体处于比较均匀的温度场内,由于熔体比晶粒具有更高的温度,可以认为晶粒处在正温度梯度下生长,而且由于铝合金属于粗糙型晶体生长界面,金属的亚稳极限ΔT*(熔体能够形核的最小过冷度)很小,界面温度差不多和熔点Tf重合,如图10所示。所以,晶体的成长界面只能随着液体的冷却而均匀一致的向液相推移,如果一旦局部有所突出,那么它便进入亚稳极限以上甚至熔点以上的温度区域,成长会立刻消失,甚至被融化掉,所以固液界面始终可以近似的保持平面,非规则自由晶最后也趋向于球化长大。在强制对流的作用下,晶粒随液相流动,自身也发生旋转,由于不断地同其他晶粒、叶片和桶壁发生接触碰撞,边缘有棱角的地方发生塑性变形逐渐球化。

图9 晶粒游离示意图

Fig. 9 Illustration of crystal dissociating

图10 固/液界面附近温度分布

Fig. 10 Temperature distribution near solid-liquid interface

3 结论

1) 强制对流流变成形设备利用搅拌的原理,使合金熔体在搅拌室内受到过冷和对流的作用。试验证明该设备能够制备固相颗粒细小、圆整、分布均匀的A356铝合金半固态浆料。

2) 筒体温度、浇注温度和搅拌速度是影响半固态浆料制备工艺的重要因素,适当降低筒体温度和浇注温度或适当提高搅拌速度均能降低半固态组织的平均晶粒尺寸,增加形状因子。在浇注温度620~630 ℃、筒体温度570~580 ℃、搅拌速度200~300 r/min的参数下都能制备初生固相晶粒尺寸80 μm以下,形状因子0.75以上的较理想半固态组织。

3) 熔体在FCR设备内具有周向的旋转流动和轴向的对流,充分的流体对流极大地改变了传统凝固条件下依靠传导单向传热和扩散缓慢传质的状态。使熔体内的热量和物质快速混合,使熔体在整体上温度和成分相对均匀,这极大地增加形核率,并且晶粒处于不断的运动当中,晶粒处于这种相对均匀的生长环境中,极大地削弱了产生枝晶的条件,使得晶粒在各个方向上均匀长大。

REFERENCES

[1] 康永林, 毛卫民, 胡壮麒. 金属材料与半固态加工理论与技术[M]. 北京: 科学出版社, 2004.

KANG Yong-lin, MAO Wei-min, HU Zhuang-qi. Theory and technology of semi-solid metal forming processing[M]. Beijing: Science Press, 2004.

[2] 张 军, 康永林, 张 帆. A356铝合金半固态流变压铸件力学性能的研究[J]. 特种铸造及有色合金, 2011, 31(8): 718-720.

ZHANG Jun, KANG Yong-lin, ZHANG Fan. Mechanical properties of semi-solid rheo-die casting A356 Aluminum parts[J]. Special Casting & Nonferrous Alloys, 2011, 31(8): 718-720.

[3] DAI Wei, WU Shu-sen,  Shu-lin, LIN Chong. Effects of rheo-squeeze casting parameters on microstructure and mechanical properties of AlCuMnTi alloy[J]. Mater Sci Eng A, 2012, 538: 320-326.

Shu-lin, LIN Chong. Effects of rheo-squeeze casting parameters on microstructure and mechanical properties of AlCuMnTi alloy[J]. Mater Sci Eng A, 2012, 538: 320-326.

[4] YANG Liu-qing, KANG Yong-lin, ZHANG Fan, ZHANG Jun. Microstructure and mechanical properties of rheo-diecasting AZ91D Mg alloy[J]. Transaction of Nonferrous Metals Society of China, 2010, 20(S3): s862-s867.

[5] PAN Q Y, FINDON M, APELIAN D. The continuous rheoconversion process(CRP): A novel SSM approach[C]// ALEXANDROU A, APELIAN D. Proceedings of the 8th International Conference on Semi-Solid Processing of Alloys and Composites. Limassol, Cyprus: Worcester Polytechnic Institute, 2004: 122-129.

[6] WANNASIN J, MARTINEZ R A, FLEMINGS M C. Grain refinement of an aluminum alloy by introducing gas bubbles during solidification[J]. Scripta Materialia, 2006, 55(2): 115-118.

[7] GUO Hong-min, YANG Xiang-jie. Efficient refinement of spherical grain by LSPSF rheocasting process[J]. Mater Sci Tech, 2008, 24(1): 55-63.

[8] 杨小容, 毛卫民, 高 冲. 采用蛇形管通道浇铸法制备半固态浆料[J]. 中国有色金属学报, 2009, 19(5): 869-873.

YANG Xiao-rong, MAO Wei-min, GAO Chong. Preparation of semisolid feedstock by serpentine pipe pouring[J]. The Chinese Journal of Nonferrous Metals, 2009, 19: 869-873.

[9] JI S, FAN Z, BEVIS M J. Semi-solid processing of engineering alloys by a twin-screw rheomoulding process[J]. Mater Sci Eng A, 2001, 299: 210-217.

[10] MARTINS R, FIGUEREDO A D, YURKO J, FLEMINGS M C. Efficient formation of structures suitable for semi-solid forming[C]//The 21th international Die Casting Congress. Cincinnati: PR Newswire, 2001: 47-54.

[11] SEO P K, LEE S M, KANG C G. A new process proposal for continuous fabrication of rheological material by rotational barrel with stirring screw and its microstructural evoluation[J]. J Mater Proc Tech, 2009, 209(1): 171-180.

[12] ZHANG Fan, KANG Yong-lin, YANG Liu-qing, DING Rui-hua. Taper barrel rheomoulding process for semisolid slurry preparation and microstructure evolution of A356 aluminum alloy[J]. Transaction of Nonferrous Metals Society of China, 2010, 20(9): 1677-1684.

[13] ZHOU Bing, KANG Yong-lin, ZHANG Jun, GAO Jun-zhen, ZHANG Fan. Forced convection rheomoulding process for semisolid slurry preparation and microstructure evolution of 7075 aluminum alloy[J]. Solid State Phenomena, 2013, 192/193: 422.

[14] MOLENAAR J M M, KATGERMAN L, KOOL W H. On the formation of the stir cast structure[J]. J Mater Sci, 1986, 21(2): 389-394.

[15] OHNO A. Solidification--the separation theory and its practical applications[M]. Germany: Springer-Verlag Press, 1987.

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(2011CB606302-1);国家高技术研究发展计划资助项目(2013AA031001)

收稿日期:2013-04-27;修订日期:2013-07-12

通信作者:康永林,教授,博士;电话:010-62332335;E-mail:kangylin@ustb.edu.cn