文章编号:1004-0609(2010)S1-s0906-08

变形钛及钛合金熔炼技术

李 雄1,庞克昌1,郭 华2,李红恩3

(1. 宝山钢铁股份有限公司 特钢事业部,上海 200740;

2. 沈阳飞机工业(集团)有限公司 冶金处,沈阳110034;

3. 沈阳飞机设计研究所 材料应用室,沈阳 110035)

摘 要:讨论变形钛及钛合金的3种主要熔炼方法。高密度夹杂和低密度夹杂是导致钛及钛合金制品疲劳裂纹和锻造裂纹的两种主要缺陷,真空自耗电弧熔炼(VAR)去除这两种缺陷的能力有限,而电子束冷床炉(EBCHM)和等离子冷床炉(PACHM)熔炼却有很好的效果,但HM+VAR工艺的铸锭仍有低密度夹杂存在。多次VAR熔炼会加剧合金成分不均匀,而CHM熔炼的铸锭成分不均匀程度更大。EB炉适合熔炼纯钛和低合金钛,PA炉适合熔炼钛合金,前者元素挥发较厉害,后者的铸锭中存在气孔和表面冷隔。HM熔炼的扁锭对轧制板材具有成本优势,而对其他类型的产品这种优势可能不复存在。基于成本的考虑,对熔炼技术的掌握程度是一个不可忽视的因素。

关键词:变形钛;钛合金;真空自耗电弧熔炼;电子束冷床熔炼;等离子冷床熔炼;熔炼成本

中图分类号:TF806.82 文献标志码:A

Melting technology of wrought Ti and Ti alloy

LI Xiong1, PANG Ke-chang1, GUO Hua2, LI Hong-en3

(1. Special Steel Business Unit, Baoshan Iron & Steel Co., Ltd., Shanghai 200740, China;

2. Metallurgy Department, Shenyang Aricraft Industries Group, Shenyang 110035, China;

3. Material Application Office, Shenyang Aircraft Design & Research Institute, Shenyang 110034, China)

Abstract: The main three kinds of melt methods were discussed for wrought Ti and Ti alloy. High-density inclusions (HDIs) and low-density inclusions (LDIs) can initiate the fatigue cracks and forging cracks. Both electron-beam cold hearth melting (EBCHM) and plasma-arc cold hearth melting (PACHM) processes have significantly greater capabilities to eliminate LDIs and HDIs compared with the three VAR processes (3-VAR), however LDIs are found in a few HM+VAR heats. Although repeated VAR makes the chemical composition heterogeneity become serious, it is still better than HM. The melting of Ti alloys using EBCHM makes the marked volatile of high vapor pressure alloying elements, EB furnace is more suitable for melting CPTi and low alloy titanium. PACHM is a good process for melting titanium alloy, despite existing gas pores within ingots and cold shuts in the ingot surfaces. There is cost advantage directly rolling into plate and sheet products by HM compared with two VAR processes (2-VAR) to cost Ti and Ti alloy into a rectangular ingot, while the advantage maybe no longer exists for other types of products. Based on cost considerations, technical mastery of the melting should not be ignored.

Key words: wrought titanium; titanium alloy; vacuum arc remelting (VAR); electron-beam cold hearth melting (EBCHM); plasma-arc cold hearth melting (PACHM); melting cost

变形钛及钛合金的熔炼有ESR(电渣熔炼)、VAR(真空自耗电弧熔炼)、EBCHM(电子束冷床熔炼)、PACHM(等离子冷床熔炼)等[1-4]。在美、俄、日、中、德等主要钛及钛合金生产国家,主要采用VAR、EBCHM及PACHM的熔炼方式,据2005年美国矿业年鉴的统计[5]:80%的钛锭采用VAR生产,20%的钛锭采用HM生产。由此可见,VAR仍然是最主要的钛锭生产 方式。

由于现代冶炼技术的进步,钛及钛合金的熔炼方式变得多样化,采用何种熔炼方式决定于质量要求、成本驱动及对熔炼技术的掌握程度。钛及钛合金的熔炼缺陷有硬α夹杂(Hard α inclusions,Type I,也叫低密度夹杂,LDIs)、高密度夹杂(HDIs)、富α相(Type II)、块状α相(Blocky α)、β斑(β Fleck)等。富α相主要出现在锭头,可通过增加熔炼次数或热封顶时减小缩管或增加切头解决;块状α相和β斑则可通过减小锭型或通过扩散处理解决,而硬α夹杂和高密度夹杂的去除则较为困难[6]。美国对飞机重要部件及发动机转动件要求三次VAR或HM+VAR处理,以保证钛锭的纯净度和成分的均匀性,这对于提高低周疲劳性能有好处。冷床炉对去除硬α夹杂和高密度夹杂具有独特的优势,而且单熔法(一次冷床炉熔炼,single melt)可用于降低钛合金冶炼成本,双熔法(HM+VAR,double melt)可用于获取优良品质的钛合金[7-9]。

针对现今主流的3种熔炼方式,本文作者将对其熔炼特点及熔炼成本进行分析,为合理选择熔炼工艺提供依据。

1 熔炼技术分析

20世纪80年代以前,钛及钛合金的生产基本上依靠VAR,进入20世纪80年代后,冷床炉熔炼技术进入钛及钛合金的生产领域,首先是EBCHM,接着是PACHM。1989年美国航空公司的一架DC-10喷气式飞机在索斯市(Sioux city)发生空难,原因是钛合金低密度夹杂导致飞机发动机风扇盘失效,所以美国对低密度夹杂和高密度夹杂进行了严格限制,这为冷床炉在钛合金熔炼领域的发展提供了契机。

1.1 真空自耗电弧熔炼

真空自耗电弧熔炼(VAR)是一种以提高纯净度、细化铸锭组织为目的的半连续工艺技术,VAR炉由水冷铜坩埚、真空系统、电极驱动和控制系统组成,其结构示意图如图1所示。一些较新型的VAR炉水冷套外侧还装有搅动线圈,搅动线圈产生的电磁场和熔化电流产生的电磁场交互作用可以提高熔池金属成分的均匀性[10]。使用的锭要求没有夹杂、偏析小、表面质量好,须经过2~3次熔炼。

图1 VAR炉的结构示意图

Fig.1 Schematic diagram of VAR furnace

夹杂分高密度夹杂和低密度夹杂,前者可用X线检测得到,而后者除非伴随有裂纹,否则用X线和超声波检测不到,所以低密度夹杂因其隐蔽性强而更具危害[11-12]。

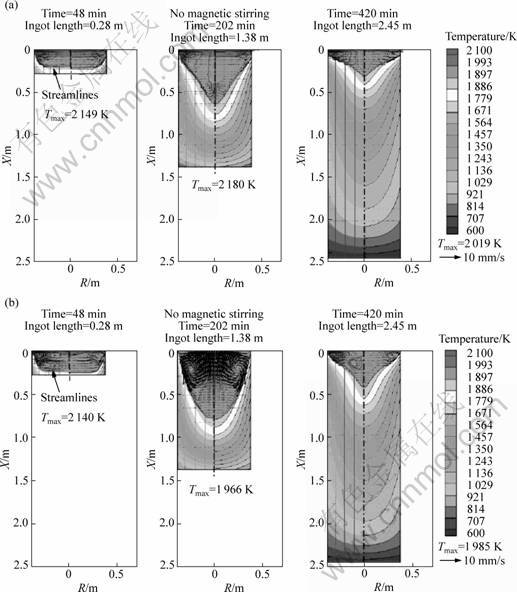

高密度夹杂来源于钛废料中混入的切削工具和钨极焊枪颗粒以及中间合金,在海绵钛生产、电极压制及钛锭熔炼等过程都有可能导致低密度夹杂,如海绵钛生产和电极压制时出现火星或着火燃烧、电极焊接时被污染、熔炼时出现漏气漏水、以及锭表清理时的混入等[6]。高密度夹杂和低密度夹杂的熔点均很高,如WC、Ta、Mo、V的熔点分别为2 800、2 996、2 660和1 900 ℃,TiN的熔点为2 950 ℃。虽然电弧的温度很高,但由于这些夹杂只瞬间暴露于电弧中,不足以使其熔化。高密度夹杂密度比钛大,脱离电极后快速沉淀于熔池底部,VAR对抑制高密度夹杂没有有效的措施。图2所示为CAMPACT-VAR软件模拟VAR熔炼的计算结果[13],其中,R为锭经,X为锭高。冶炼对象为TC4钛合金,锭直径为760 mm。稳态阶段熔化速率为12.5 kg/min,可以推算出熔池液面上升速度为6 mm/min。无磁力搅拌的熔池温度区间和深度分别为1 670~1 900 ℃和0.64 m,有磁力搅拌时熔池温度相对均匀,熔池温度区间和深度分别为1 670~1 690 ℃和0.8 m。TiN在纯钛中的熔化速率有两个试验结果:124~344 μm/min(1 625~1 825 ℃)[14]和304~426 μm/min (1 750~1 783 ℃)[15],假如TiN在TC4中的熔化速度与在纯钛中的一样,且TiN在熔池中的下移速度为50 mm/min,熔化速度取为300 μm/min,熔池中心部位

图2 VAR熔炼Ti-6-4钛合金无磁力搅拌和有磁力搅拌的流场和温度场

Fig.2 Flow and temperature fields in ingot during VAR process for Ti-6-4 alloy: (a) Without magnetic stirring; (b) With magnetic stirring

的TiN如垂直下落在无磁力搅拌时,尺寸小于3.8 mm可以扩散溶解,有磁力搅拌时尺寸小于4.8 mm可以扩散溶解;但距离钛锭中心部位越远,熔池越浅,TiN存在的可能性越大,这必须经过多次熔炼来减小TiN存在的可能性。合金含量更高的钛合金Ti-17和Ti-1023,其熔化速度比TC4的慢,熔池比TC4的浅,夹杂溶解更为困难。鉴于夹杂的危害性,俄罗斯VSMPO-AVISMA公司要求在熔炼前对海绵钛和中间合金进行100%的检查,美国也对钛合金熔炼原料进行了严格规定,如中间合金必须100%经过X线检查,不允许使用钨极氩弧焊,钛回收料进行磁选分离,飞机引擎转动件必须使用Timet公司的海绵钛等[16]。

偏析分微观偏析和宏观偏析,微观偏析源于枝晶间的析出;宏观偏析源于溶质偏聚和液体流动,而这主要受电磁力和浮力的影响,其根本原因在于熔池内的温度梯度和密度差[17]。如β斑是典型的微观偏析,而钛锭截面成分的不均匀性则属于宏观偏析。前一次熔炼出现的成分不均匀性被带入下次熔炼,2~3次熔炼完毕,最终成分偏析较上次熔炼更为严重。由图3的仿真结果可见,从第1次熔炼至第3次熔炼,Fe偏析越趋严重,两次熔炼间电极换向对改善成分均匀性有好处,但其影响小于5%,低功率的Fe偏析程度小于高功率的Fe偏析程度[2]。图4~6所示为元素在稳态熔化区横截面的分布和整个钛锭纵截面的分布[18]。横

图3 Ti-10-2-3三次VAR熔炼时Fe的分布

Fig.3 Fe composition for Ti-10-2-3 by 3-VAR: (a) high power; (b) low power

图4 钛锭稳态熔化区横截面元素含量变化

Fig.4 Change of element content in cross-sections of stable melting ingot areas: (a) Ti-8Cu alloy, d380 mm ingot; (b) Ti-8Ni alloy, d380 mm ingot; (c) BT15 alloy, d380 mm ingot; (d) BT22 alloy, d380 mm ingot; (e) Mn-a OT4 alloy, d850 mm ingot; (f) BT15 alloy, d380 mm ingot

图5 直径380 mm 的BT15锭纵截面Cr元素含量变化(收缩管、孔已切除)

Fig.5 Change of Cr content in top-end of BT15 alloy d380 mm ingot produced without solenoid and shrinkage cavity removal: Section I—At bottom of final pool; Section VI—At top of ingot; Sections II–V—Intermediate sections

图6 计算机模拟的Ti-6Al-4V VAR锭中氧的分布

Fig.6 Predicted oxygen distribution in VAR melted Ti-6Al-4V ingot

向分析可知:Cu、Ni、Cr、Fe、Mn在锭表层的浓度高于内部,而以心部为最高,Mo在心部则呈负偏析状态;纵向分析可知:锭头中心部位Cr的含量最低,而锭尾中心部位Cr的含量最高。无论纵向横向,钛锭不同部位元素浓度都存在显著的差异。降低熔化速度可以减少偏析,但是降低了锭表质量和生产效率。国外往往在锻造或轧制前进行均匀化退火[6],以改善成分均匀性,这一点未引起国内足够的重视。值得注意的是均匀化退火不能消除高密度夹杂和低密度夹杂。

1.2 冷床炉熔炼

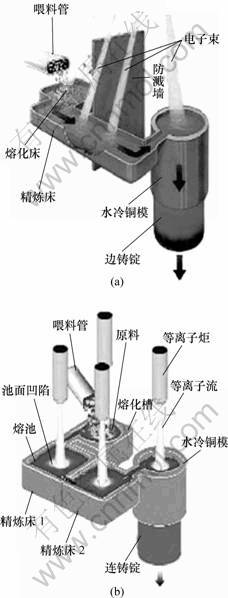

与VAR炉不同的是,冷床炉分为独立的3个区:熔炼区、精炼区和凝固区,3个区均由水冷铜坩埚组成。依据热源的不同分为电子束冷床炉和等离子冷床炉,如图7所示。海绵钛、中间合金、钛回收料在熔炼区熔化后流入精炼区精炼,由于炉床中液态金属的

图7 电子束冷床炉和离子束冷床炉示意图

Fig.7 Schematic diagram of electron-beam cold hearth melting furnace (a) and plasma-arc cold hearth melting furnace (b)

滞留时间和温度可控,高密度夹杂和密度大于液态金属的低密度夹杂完全可被凝壳捕获,而密度小于液态金属的低密度夹杂则可得到完全的分解或溶解,所以液态金属的纯净度优于VAR。EB炉金属熔池表面暴露在高真空环境(0.001~10 Pa)下,十分有利于脱气,但蒸气压较高的元素(Al、Cr、Mn等)很容易挥发,如EB炉熔炼Ti-6-4时,30%的Al被挥发[19],所以EB炉比较适合熔炼纯钛和低合金钛[20]。通过对元素挥发规律及电子束扫描模式、扫描频率和聚焦进行研究,熔池的化学成分已得到较好的控制,目前,EB炉均可成功熔炼Ti-6-4、Ti-6-4 ELI、Ti-17、Ti-6-2-4-2和 Ti-6-2-4-6 [7, 21]。与EB炉的高真空环境不同,PA炉熔炼区和精炼区处于5~100 kPa的高纯氦气氛(99.999%)或氩气氛中,等离子气和炉内气氛均为氦气时,热效率最高(达64%);炉内气压越高,金属元素挥发越少,所以PA炉较适合熔炼钛合金[4, 19]。对于PACHM,惰性气体等离子体在熔池中形成小气泡,在连续铸锭过程中会形成小气孔,影响钛锭的致密性,而且PA锭表面容易形成冷隔。EBCHM时的Al蒸汽以及真空室墙和顶上的沉淀物很可能掉进精炼区而被带入锭内形成富Al区,所以对于重要部件,后续的VAR过程有利于释放出PA锭中的惰性气体和消除EB锭中的Al偏析,并且可以提高铸锭成分的均匀性[6]。对于合金元素含量较高的合金(如Ti-17),将原料压块是控制HM锭成分的有效方式[22]。EBCHM和PACHM都采用连铸方式,在锭表未完全凝固时,抽锭必然影响结晶过程,从而影响铸锭组织的连续性。

通过对原材料、熔炼过程的控制以及冷床炉熔炼技术的使用,两次VAR、三次VAR及CHM+VAR的钛坯和钛棒中的夹杂出现次数得以明显降低,图8所

图8 1 990~2 000年期间高品质钛合金中夹杂出现的 频率[22]

Fig.8 Inclusion frequencies in premium-quality Ti alloys from 1990 to 2000[22]

示为GEAE在1990~2000年的统计数据[22]。除了两例高密度夹杂(分别由EB炉和PA炉熔炼的电极)出现在VAR锭头中, HM+VAR锭的高密度夹杂是0。HM+VAR锭的低密度夹杂出现的概率与三次VAR相似,冷床炉熔炼后磨削会导致HM+VAR锭出现低密度夹杂,但禁止磨削后低密度夹杂仍会出现。原因为低密度夹杂出现在冷床炉熔炼后,且概率可达93%,或是探伤方法不同:HM+VAR锭采用的是分区探伤方法(MZUI),而三次VAR锭采用的是传统超声波探伤方法,分区探伤方法曾检测出被传统探伤方法遗漏的应变诱导的小孔,前者较后者对缺陷更敏感[22]。

2 熔炼成本分析

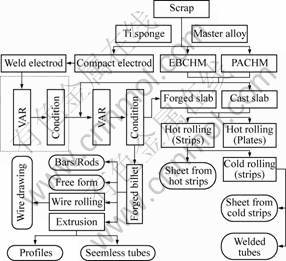

除了有比VAR更好地去除高密度夹杂和低密度夹杂的能力外,冷床炉还拥有降低钛制品成本的潜在优势,如冷床炉可以100%利用钛回收料、不需压制及焊接电极、方形铸锭有利于轧板等。图9所示为不同熔炼方法钛制品的工艺路线图。DMTC(美国国防金属中心)的研究报告认为[23]:冷床炉的原料完全采用钛回收料可以节省19%的成本;直接连铸成扁锭免除锻造工序可节省10%~11%的成本;到最后的成品板,整个过程的成本可以降低28%。但这个结论有一定的局限性,如2005年和2007年美国钛回收料的价格高于海绵钛,对钛回收料需要严格的管理,如清洗、分选、化验及压块等,这些都增加了成本。在生产量不大时凝壳浪费的材料所占比例偏高。虽然美国TIMET公

图9 不同熔炼方法生产的钛及钛合金工艺路线

Fig.9 Processing routes for Ti and Ti alloy produced using different melting methods

司使用的钛回收料达40% [16],但我国钛产业规模远比美国小,钛回收料的管理水平低,通过使用钛回收料来降低成本,在几年内不会有明显的效果。目前,美国的冷床炉扁锭直接轧制的板主要用于民用设施及军用装甲板[24],而高端板坯及非板类件的冶炼工艺往往采用HM+VAR,所以,将两次VAR与一次HM的成本进行比较对于大多数钛产品来说比较有意义。

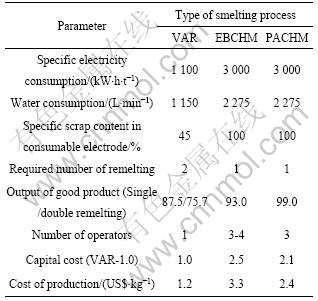

表1所列为专业咨询师SAMPATH对VAR、EBCHR、PACHM熔炼设备的投资估算[25],这三种设备的投资金额大致相当,其中VAR熔炼含两套VAR设备。SAMPATH经估测后认为,轧制1英寸板和2英寸板,VAR的成本分别是EBCHM的1.35和1.76倍, PACHM的1.4和1.4倍。这个结果虽然与DMTC的结论有较大的差异,但能说明由扁锭轧制成板有成本上的优势。但SAMPATH是从原材料、设备及后续的工序(HM锭无需锻造开坯)的角度来考虑,而电耗、水耗、人工成本、HM的元素挥发及凝壳金属的浪费却未进入计算范畴。表2所列为从能源消耗、人工成本、产品收得率等角度对3种熔炼工艺的成本比较,3种熔炼方法中2xVAR的成本与PACHM相当,但低于EBCHM,这种测算方法不适合评估板坯制品。

冷床炉用于冶炼钛在国外有近30年的历史,但近几年我国才引进这项设施。即使冷床炉熔炼拥有可使用低成本原材料及减少工序的优势,但是国内市场小、钛回收料不够、技术储备不足,其优势不能得到有效发挥,而在民用钛市场,用EB炉熔炼的扁锭轧制的纯钛板将拥有成本优势。但10~20年后,用VAR熔炼钛及钛合金仍将是国内市场的主流。

表1 3种熔炼方法设备投资比较

Table 1 Estimated investments for 2-VAR, EBCHM, PACHM equipments[25]

表2 不同熔炼方法参数比较

Table 2 Comparison of different smelting process parameters of Ti

3 结论

1) 冷床炉熔炼的钛锭纯净度优于VAR容量的钛锭。冷床炉对于去除高密度夹杂和低密度夹杂有良好的效果,VAR去除高密度夹杂困难。但HM+VAR锭中低密度出现的概率与三次VAR锭中类似,这可能是因为冷床电极导入或是探伤方法不一样的原因。

2) VAR熔炼次数越多,成分越不均匀;冷床炉熔炼采用连续熔炼连续铸锭的方式,其成分不均匀,对原料采用配料和压块的方式有利于提高铸锭成分的均匀性,但会增加成本。冷床炉熔炼室金属蒸汽沉淀物掉落会造成铸锭局部偏析。

3) EB炉熔炼时,蒸气压高的元素耗损较多,PA锭内部存在气孔且表面存在冷隔;EBCHM和PACHM均采用拉锭的方式,影响了铸锭的结晶过程,其致密性比VAR锭的差。

4) 采用HM+VAR的熔炼方式可提高作为飞机重要部件铸锭的成分均匀性和表面质量。而飞机非重要部件、军用运载工具装甲板和民用市场中,CHM锭已得到广泛应用。

5) HM对于钛板制品的生产具有成本优势,而对于其他制品,HM不具有成本优势。

6) 对成本的影响,除使用的原材料和工艺过程外,对熔炼技术的掌握也至为关键。即使HM技术具有成本优势,但如技术掌握不透,由于质量问题导致的损失将会抵消成本优势。

REFERENCES

[1] SENKOV O N. Metallic materials with high structural efficiency[M]. Netherlands: Kluwer Academic Publishers, 2004: 413-418.

[2] ZAGREBELNYY D, KRANE M J M. Segregation development in multiple melt vacuum arc remelting[J]. Metall Mater Trans B, 2008, 39(2): 281-288.

[3] WATAKABE S, SUZUKI K, NISHIKAWA K. Control of chemical compositions of Ti-6Al-4V alloy during melting by electron beam furnace[J]. ISIJ Int, 1992, 32(5): 625-629.

[4] NISHL S, KUSAMTCHI T, ONOYE T. Arc voltage and heat efficiency during plasma arc melting of titanium[J]. ISIJ Int, 1995, 35(2): 114-120.

[5] U.S. Department of the Interior, 2005 Minerals Yearbook [EB/OL]. [2007-02-01]. http://minerals.usgs.gov/minerals/pubs/ commodity/ asbestos/asbesmyb05.pdf

[6] LUTJERING G, WILLIAMS J C. Titanium[M]. New York: Springer-Verlag Berlin Heidelberg Press, 2003: 27-70.

[7] WOOD J R. Producing Ti-6Al-4V plate from single-melt EBCHM ingot[J]. JOM, 2002, 2: 56-58.

[8] YU K O, CRIST E M, PESA R. Single-melt beta C for spring and fastener applications[J]. J Mater Eng Perf, 2005, 14(6): 697-702.

[9] LOUVIGN? P F. Challenges for the development of titanium in france and in the european industry[C]//Niinomi M eds. Ti-2007 Science and Technology: Proceedings of the 11th World Conference on Titanium (JIMIC5). Kyoto: The Japan Institute of Metals Publishers, 2007: 33-40.

[10] CHAPELLE P, JARDY A, BELLOT J P. Effect of eelectro- magnetic stirring on melt pool free surface dynamics during vacuum arc remelting[J]. J Mater Sci, 2008, 43: 5734-5746.

[11] CHAN K S, PEROCCHIN L, LEVERANT G R. Constitutive properties of hard-alpha titanium[J]. Metall Mater Trans A, 2000, 31(12): 3029-3040.

[12] BELLOT J P, FOSTER B, HANS S. Dissolution of hard-alpha iInclusions in liquid titanium alloys[J]. Metall Mater Trans B, 1997, 28(6): 1001-1010.

[13] KELKAR K M, PATANKAR S V, MITCHELL A. Computational modeling of the vacuum arc remelting (VAR) Process used for the production of ingots of titanium alloys[C]// Niinomi M eds. Ti-2007 Science and Technology: Proceedings of the 11th World Conference on Titanium (JIMIC5). Kyoto: The Japan Institute of Metals Publishers, 2007: 1275-1278.

[14] SHAMBLEN C E, HUNTER G B. Technical information series report[R]. Cincinnati: GEAE, 1986.

[15] BERTRAM L A, ZANNER F J. Modeling of casting and welding processes[J]. TMS-AIME, 1980, 3: 246-255.

[16] SEONG S, YOUNOSSI O, GOLDSMITH B W. Titanium: Industrial base, price trends, and technology initiatives[M]. The RAND Corporation, 2009: 26-28.

[17] ZAGREBELNYY D, KRANE M J M. Segregation development in multiple melt vacuum arc remelting[J]. Metall Mater Trans B, 2009, 40(3): 281-288.

[18] DOBATKIN V I, ANOSHKIN N F. Comparison of macro- segregation in titanium and aluminium alloy ingots[J]. Mater Sci Eng A, 1999, 263: 224-229.

[19] POULSEN E, CHINNIS W, MATT M. Advances in titanium cold hearth melting[J]. Industrial Heating, 2000, 67(1): 49-51.

[20] KUSAMICHLH T, KANAYAMA H, ONOYE T. Temperature measurement of molten metal surface in electron beam melting of titanium alloys[J]. ISIJ Int, 1992, 32 (5): 593-599.

[21] BAKISH R. Optimizing operating efficiency of EBM[J]. Industrial Heating, 2004, 71(2): 39-41.

[22] SHAMBLEN C E, WOODFIELD A P. Progress in titanium- alloy hearth melting[J]. Industrial Heating, 2002, 69(1): 49-52.

[23] TRZCINSKI M. Armor plate produced using 100% titanium scrap solids[R]. Waikoloa: GENE, 2009, 9: 13-16

[24] MONTGOMERY J S, WELLS M G H, ROOPCHAND B. Low- cost titanium armors for combat vehicles[J]. JOM, 1997, 5: 45-47.

[25] SAMPATH K. The use of technical cost modeling for titanium alloy process selection[J]. JOM, 2005, 5: 25-32

[26] LEE Y T, LEE C D. The dissolution of titanium and defect prevention techniques[J]. Machinery and Materials, 2008, 20 (4): 103-114.

(编辑 刘华森)

通信作者:李 雄,高级工程师,博士;电话:021-26032761;E-mail:lee_xong@126.com