文章编号:1004-0609(2010)S1-s0442-05

钛合金VAR过程电弧等离子体流场的数值模拟

孙来喜,薛祥义,杨治军,寇宏超,胡 锐,李金山

(西北工业大学 凝固技术国家重点实验室,西安 710072)

摘 要:依据磁流体动力学理论,运用ANSYS有限元分析软件对真空自耗电弧熔炼过程电弧区流场进行数值模拟。结果表明:在阳极熔池表面熔炼电弧的温度最高,且其附近电弧区压力随着径向距离的增大而增大,而在熔炼电极表面附近,电弧区压力随着径向距离的增加而减小;弧间距的减小不仅使电弧区的流体流动速度减小,而且还导致环路流动范围减小且向坩埚壁靠近。当电极直径为280 mm,熔炼电压为30 V时,理想熔炼弧长可控制在25~40 mm。

关键词:钛合金;真空自耗电弧熔炼;等离子体;流场

中图分类号:TG146.4 文献标志码:A

Numerical simulation of arc plasma fluid field in

VAR process for titanium alloy

SUN Lai-xi, XUE Xiang-yi, YANG Zhi-jun, KOU Hong-chao, HU Rui, LI Jin-shan

(State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: A numerical simulation of arc region fluid field was done by ANSYS finite element analytical software during vacuum are remelting process, which is on the basis of magnetohydrodynamics theory. The results show that the maximum temperature of remelting arc is located on the surface of anode molten pool. The pressure increases with radial distance near anode molten pool surface, but it decreases when radial distance increases near remelting electrode surface. The flow velocity of fluid decreases when the arc length decreases, and the flow region also decreases and moves closer to the crucible wall. The remelting arc length should be controlled between 25 and 40 mm in the event that the electrode diameter is 280 mm and the arc voltage is 30 V.

Key words: titanium alloy; vacuum arc remelting; plasma; flow field

钛合金具有比强度高、耐蚀性强、生物相容性好、无磁性等优点,在航空航天、舰船制造、化工石油、车辆交通、生活用品及医疗设备方面得到了广泛的应用[1-2]。特别是近几年来国家大飞机工程的设置,使得钛合金的研究应用及其产业发展获得了前所未有的机遇,因而开发钛合金铸锭高均质化及凝固缺陷控制技术,成为科研人员的一个重大课题。钛合金熔炼是钛工业生产中极其重要的过程之一,目前钛及钛合金的主要熔炼方法是真空自耗电弧熔炼(VAR)。该过程通常是在直流电弧的高温作用下,电极的熔化和熔体的凝固同时进行,通过真空或惰性气氛保护,自耗电极迅速熔化,液态金属以熔滴的形式通过高温电弧区,最终落入铜坩埚内形成熔池。熔炼电弧作为VAR过程的能量来源,对熔池表面的能量分配和受力情况产生直接影响。一方面,通过影响铸锭的凝固条件来影响最终产品的质量;另一方面,只有保持电弧在两极间的稳定性,才能防止边弧、扩散弧和辉光放电的发生,最终保证熔炼过程的安全性[3-5]。因此,对VAR过程电弧等离子体进行研究具有十分重要的意义。但是VAR过程伴随着复杂的等离子体热传输和流体流动行为,很难对其进行试验和检测[6]。本文作者根据磁流体动力学理论建立了VAR过程电弧等离子体区的数学模型,应用ANSYS有限元软件对电弧等离子体流场过程进行数值模拟,并对流场模拟结果进行分析,为钛合金生产实践奠定基础。

1 电弧等离子体的数学物理模型

1.1 有限元模型及主要参数

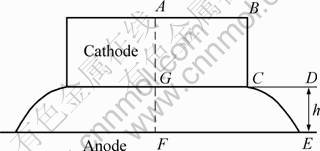

根据VAR熔炼过程,建立电弧计算区域模型如图1所示,主要计算参数如表1所列。熔炼电极(阴极)采用的是纯钛,气体采用纯氩气。模拟过程需要考虑氩气的密度、热导率、比热及黏度随温度不断变化,相关的物理性能参数从文献[7]中查得。

考虑到氩气物理性能参数对温度强烈的依赖关系、计算精度及流场模拟的特殊要求,计算区域的网格划分均采用六面体映射网格,如图2所示。模拟过程采用多场顺序耦合[8-9]的方法,电场、磁场和流场的物理模型保持一致。电弧等离子体是流场计算过程的唯一流体,熔炼电极可以不参与计算,因此只显示电弧区的模拟结果。

图1 计算区域示意图

Fig.1 Schematic diagram of computational region

表1 计算主要参数

Table 1 Main parameters for computation

图2 电弧模型网格划分

Fig.2 Mesh of electric arc model

1.2 基本假设

根据有限元模型和熔炼实际过程,提出如下基本假设:1) 电弧等离子体处于局部热力学平衡(LTE)状态[10];2) 电弧炉内部为纯氩气保护;3) 电弧是光学薄的,即辐射的重新吸收和总的辐射损失相比可以忽略不计;4) 电弧是稳态的、连续的、轴对称的;5) 由于重力和粘性导致的热损失忽略不计。

1.3 控制方程

熔炼电弧是一种带电的流体,因此用磁流体动力学理论对其进行分析和研究。在以上假设条件下,电弧等离子体可以用以下质量、动量和能量守恒方程来描述[11]。

质量守恒方程:

(1)

(1)

径向动量守恒方程:

(2)

(2)

轴向动量守恒方程:

(3)

(3)

能量守恒方程:

(4)

(4)

动量守恒方程中有洛伦兹力项,能量守恒方程中有焦耳热项,需要求解磁感应强度Bθ和电流密度J的分布,这就需要求解麦克斯维方程组:

欧姆定律:

(5)

(5)

电流连续方程:

(6)

(6)

安培环路定律:

(7)

(7)

通过以上控制方程可以看出,模拟计算需要同时涉及电场、磁场和流场三个过程。由于氩气的物性参数同温度有强烈的依赖关系,因此需要在电磁场和流场之间不断耦合计算。

2 结果与讨论

图3所示为在熔炼电压为30 V,弧长为5 cm的条件下计算得到的温度场结果。从图3中可以看出,靠近熔炼电极的温度大约在1 900 K左右,这是因为晶态金属熔化过程中,温度会保持在熔点附近。电弧区温度最大值在阳极熔池表面的中心部位,约为2 235 K。

图3 电压30 V,弧长5 cm时电弧区温度场分布

Fig.3 Temperature distribution of arc region with voltage of 30 V and arc length of 5 cm (K)

研究发现[12],电弧等离子体区的过热度决定了阳极熔池表面的温度,即:

(8)

(8)

式中:TL为液相线温度,K;ΔT为熔池表面的过热度,K;ΔT(I,Di)由式(9)[13]得到:

(9)

(9)

式中:I为电流,kA;Di为铸锭的直径,m。

由公式(8)、(9)可以估算出熔池表面温度大约为2 217 K,这与模拟得到的熔池表面温度结果基本一致(误差小于0.812%)。这说明本文的模拟结果是准确和可靠的。

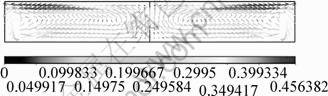

图4所示为计算得到的电弧区速度矢量分布。从图4中可以看出,靠近轴线处的流体从阴极流向阳极,在熔炼电极的阻碍下,改变方向流向坩埚侧壁。在这个过程中,流体的能量开始迅速下降,由于温度梯度的影响,在到达坩埚壁附近时,流体运动剧烈,速度达到最大值。同时,坩埚壁迫使流体转向,最终沿阳极表面流向轴线方向,整个过程构成一个闭合的回路。最终实现了熔炼过程电弧等离子体的热交换。

图4 电压30 V,弧长5 cm时电弧区速度矢量分布

Fig.4 Velocity vector distribution of arc region with voltage of 30 V and arc length of 5 cm (m/s)

图5所示为计算得到的电弧区压力分布。模拟过程以标准大气压(101 325 Pa)为参考压力,计算得到的压力值均为相对压力,因此存在压力为负的情况,即低于标准大气压。从模拟结果可以看出,压力在竖直方向上基本呈现层状分布,距离阳极熔池表面越远,压力越小。

提取距阳极熔池表面不同距离的径向压力分布,绘制曲线如图6所示。可见,靠近阳极熔池表面,电弧区压力随着径向距离的增大而增大,从而产生一定的压力梯度,推动等离子体自坩埚壁向弧柱中心处流动;靠近熔炼电极表面,电弧区压力随着径向距离的增加而减小,从而形成一定的压力梯度,推动等离子体自弧柱中心处向坩埚壁流动。竖直方向上,靠近坩埚壁附近的等离子流主要是来自未电离区的低温氩气下沉所致,而靠近轴线方向的压力梯度变化不大。因此形成的流体流动环路与图4所示的速度矢量分布一致。

图5 电压30 V,弧长5 cm时电弧区压力分布

Fig.5 Pressure distribution of arc region with voltage of 30 V and arc length of 5 cm (Pa)

图6 电弧区不同轴向距离的径向压力分布

Fig.6 Radial pressure distribution of arc region with different axial distances

电弧区压力分布对阳极熔池表面及其内部组织都会产生影响。过大的电弧压力,尤其是在熔池表面径向压力梯度较大的情况下,会导致熔池产生表面变形,甚至产生小孔。但一定的电弧压力会使得铸件内部封闭的缩松和气孔被压实,合金组织致密性得到改善。

熔炼中,电弧长度(弧间距)通常控制在25~50 mm或者更大,太短会造成频繁短路,降低铸锭质量,太长会使电弧移动,击穿坩埚壁[14]。在保证熔炼电压不变的前提下,取弧长L分别为5.0、4.5、4.0、3.5、3.0、2.5 cm,得到了不同弧长条件下的速度分布,如图7所示。通过对比发现,随着弧间距的减小,电弧区的流速会随之减小,环路流动范围也会随之缩小并向坩埚壁靠近。当弧间距为2.5 cm时,弧柱中心部位的流速显著减慢,电弧区热交换能力随之大幅度下降,这

将对铸锭的内部组织产生不利影响。可见,弧间距与电弧等离子体的流动行为密切相关。在保证操作安全的前提下,弧长不应超过电极和坩埚之间的最小距离。结合上述分析结果,根据以下经验公式[15]可以计算得到δ (电极与坩埚之间的距离,mm)为40 mm。

(10)

(10)

式中:d为自耗电极直径,mm;D为坩埚内壁直径,mm。 因此,当电极直径为280 mm,熔炼电压为30 V时的理想熔炼弧长可控制在25~40 mm。

图7 不同弧长条件下的速度矢量分布

Fig.7 Velocity vector distribution with different arc lengths: (a) L=5.0 cm; (b) L=4.5 cm; (c) L=4.0 cm; (d) L=3.5 cm; (e) L=3.0 cm; (f) L=2.5 cm (m/s)

3 结论

1) 在熔炼电压为30 V,弧长为5 cm的条件下,计算得到的电弧区最大温度值为2 235 K,且位于阳极熔池表面的中心部位。

2) 流动的氩气等离子体在电弧区内部形成一个闭合环路;形成的压力分布在竖直方向呈层状分布,距离阳极熔池表面越远,压力越小。在阳极熔池表面附近,电弧区压力随着径向距离的增大而增大;而在熔炼电极表面附近,电弧区压力随着径向距离的增大而减小。

3) 随着弧间距的减小,电弧区的流体流动速度会随之减慢,环路流动范围也会随之缩小并向坩埚壁靠近。当电极直径为280 mm,熔炼电压为30 V时,理想熔炼弧长可控制在25~40 mm。

REFERENCES

[1] 刘 彬, 刘延斌, 杨 鑫, 刘 咏. TITANIUM2008:国际钛工业、制备技术与应用的发展现状[J]. 粉末冶金材料科学与技术, 2009, 14(2): 67-73.

LIU Bin, LIU Yan-bin, YANG Xin, LIU Yong. TITANIUM 2008: Development of international titanium industry, preparation technology and application[J]. Materials Science and Engineering of Powder Metallurgy, 2009, 14(2): 67-73.

[2] 许国栋, 王桂生. 钛金属和钛产业的发展[J]. 稀有金属, 2009, 33(6): 903-912.

XU Guo-dong, WANG Gui-sheng. Development of titanium and its industry[J]. Chinese Journal of Rare Metals, 2009, 33(6): 903-912.

[3] 张英明, 周 廉, 孙 军, 韩明臣, 倪沛彤, 陈杜鹃, 潘志强. 钛合金真空白耗电弧熔炼技术发展[J]. 稀有金属快报, 2008, 27(5): 9-14.

ZHANG Ying-ming, ZHOU Lian, SUN Jun, HAN Ming-chen, NI Pei-tong, CHEN Du-juan, PAN Zhi-qian. Progress of vacuum arc remelting technology of titanium alloys[J]. Rare Metals Letters, 2008, 27(5): 9-14.

[4] 魏剑平, 李华德, 余达太. 直流电弧炉电弧位置控制[J]. 北京科技大学学报, 1999, 21(6): 580-583.

WEI Jian-ping, LI Hua-de, YU Da-tai. Arc direction control in DC electric arc furnace[J]. Journal of University of Science and Technology Beijing, 1999, 21(6): 580-583.

[5] 张晶宇, 范丽娟, 张一鹏, 康 宁. 影响真空自耗电极电弧炉电弧稳定性的因素及对策[J]. 真空, 2003(3): 21-24.

ZHANG Jing-yu, FAN Li-juan, ZHANG Yi-peng, KANG Ning. Influence factors on electrical arc stability of vacuum consumable electrode arc furnace and taken countermeasures[J]. Vacuum, 2003(3): 21-24.

[6] 殷凤良, 胡绳荪, 高忠林, 赵立志. 等离子体电弧数值模拟的研究进展[J]. 兵器材料科学与工程, 2007, 30(6): 59-63.

YIN Feng-liang, HU Sheng-sun, GAO Zhong-lin, ZHAO Li-zhi. Progress in numerical simulation of the plasma arc[J]. Ordnance Material Science and Engineering, 2007, 30(6): 59-63.

[7] CHOO R T C, SZEKELY J, WESTHOFF R C. On the calculation of the free surface temperature of gas-tungsten-arc weld pools from first principles: Part I. Modeling the welding arc[J]. Metallurgical Transactions B, 1992, 23B(6): 357-369.

[8] 党沙沙, 许 洋, 张红松. ANSYS12.0多物理耦合场有限元分析从入门到精通[M]. 北京: 机械工业出版社, 2010: 66-77.

DANG Sha-sha, XU Yang, ZHANG Hong-song. ANSYS12.0 multi-field coupling analysis from entry into proficient[M]. Beijing: China Meachine Press, 2010: 66-77.

[9] 许 洋, 党沙沙, 胡仁喜. ANSYS 11.0/FLOTRAN流场分析实例指导教程[M]. 北京: 机械工业出版社, 2009.

XU Yang, DANG Sha-sha, HU Ren-xi. ANSYS 11.0/FLOTRAN tutorial of flow field analytical examples[M]. Beijing: China Machina Press, 2009.

[10] QIAN F, FAROUK B, MUTHARASAN R. Modeling of fluid flow and heat transfer in the plasma region of the dc electric arc furnace[J]. Metallurgical and Materials Transactions B, 1995, 26: 1057-1067.

[11] WANG Feng-hua, JIN Zhi-jian, ZHU Zi-shu. Fluid flow modeling of arc plasma and bath circulation in DC electric arc furnace[J]. Journal of Iron And Steel Research, International, 2006, 13(5): 7-13.

[12] JARDY A, FALK L, ABLITZER D. The energy exchange during vacuum arc remelting[J]. Ironmaking and Steelmaking, 1992, 19(3): 226-232.

[13] ANDREEV A L, ANOSHKIN N F, BOCHVAR G A. Plavkai litye titanovykh splavov (Melting and casting of titanium alloys)[C]//ALEKSANDROV V K, et al, ed. Moscow: Metallurgiya, 1994.

[14] 李献军. 真空自耗电弧炉熔炼技术和铸锭质量问题[J]. 钛工业进展, 2001(3): 16-22.

LI Xian-jun. Problem of melting technology and ingot quality of vacuum arc remelting furnace[J]. Titanium Industry Progress, 2001(3): 16-22.

[15] 周取定. 中国冶金百科全书: 钢铁冶金[M]. 北京: 冶金工业出版社, 2001: 694.

ZHOU Qu-ding. China metallurgical encyclopaedia: Ferrous metallurgy[M]. Beijing: Metallurgical Industry Press, 2001: 694.

(编辑 李向群)

基金项目:国家重点基础研究发展计划资助项目(2007CB613802)

通信作者:孙来喜,硕士;电话:13572119094;E-mail:kakaroteqiqi@qq.com