文章编号:1004-0609(2010)S1-s0381-06

电子束冷床熔炼TC4钛合金连铸凝固过程数值模拟

雷文光,于兰兰,毛小南,罗 雷,张英明,侯智敏

(西北有色金属研究院 钛合金研究所,西安 710016)

摘 要:利用PROCAST有限元软件对电子束冷床熔炼TC4钛合金连铸凝固过程进行数值模拟,研究不同工况条件下的温度场分布规律、熔池形状以及组织分布特征。结果表明:在相同的浇注温度条件下,随着铸造速度的增加,熔池加深,糊状区域变浅,初生枝晶半径和二次枝晶臂间距逐渐增加,凝固组织变得粗大。而在铸造速度相同的条件下,随着浇注温度的提高,过热度增大,熔池加深,糊状区域变浅,合金的晶粒尺寸增大。在本实验条件下,选择铸造速度10 mm/min以及浇注温度1 760 ℃作为最佳工艺参数,这有利于在保证较高生产效率的同时,获得组织细小、冶金质量优良的钛合金铸锭。

关键词:钛合金;电子束冷床熔炼;连铸;浇注温度;铸造速度;PROCAST

中图分类号:TG294 文献标志码:A

Numerical simulation of continuous casting solidification process of TC4 titanium alloy during EBCHM

LEI Wen-guang, YU Lan-lan, MAO Xiao-nan, LUO Lei, ZHANG Ying-ming, HOU Zhi-ming

(Titanium Alloy Research Center, Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China)

Abstract: The continuous casting solidification process of TC4 alloy during electro beam cold hearth melting (EBCHM) was simulated by using PROCAST finite element software. The temperature field distribution, the molten pool shape and the distribution characteristics of the microstructure under different conditions were studied. The results show that the deepening of molten pool, shallowing of pasty region, as well as the increasing of primary dendrite radius and secondary dendrite arm spacing under the same pouring temperature were caused by increasing casting speed. While under the same casting speed, the deepening of molten pool, shallowing of pasty region, and the increasing of grain size were caused by increasing pouring temperature. In this experimental condition, the casting speed of 10 mm/min and the pouring temperature of 1 760 ℃ were chosen as the best technique parameters, which are of benefit to ensuring high productive efficiency and obtaining titanium alloy ingot with good metallurgical quality and fine microstructure at the same time.

Key words: titanium alloy; electro beam cold hearth melting (EBCHM); continuous casting; pouring temperature; casting speed; PROCAST

钛合金由于具有密度低、比强度高、耐蚀性能好、高温性能优良等一系列优点,被广泛应用于航空、航天、船舰、石油、化工等重要领域[1]。然而随着钛合金用量的日益增多,对钛合金铸锭的质量要求越来越高,采用传统的真空自耗电弧熔炼(VAR)方法并不能保证彻底消除夹杂和偏析等冶金缺陷,获得高均质、洁净的钛合金铸锭[2-4]。

电子束冷床熔炼(EBCHM)是在20世纪60年代开发、并在80年代迅速发展起来的一种生产洁净钛及钛合金的新型熔炼技术。该技术通过将原料熔化、精炼、铸锭凝固分离,可以有效去除钛合金中的低密度夹杂(LDI)和高密度夹杂(HDI),提高钛合金铸锭冶金质量;并且无需压制和焊接电极,原料可以是海绵钛、车屑、及各种钛残料,一次熔炼就可以得到质量合格的铸锭,大幅降低钛合金的生产成本。因此,电子束冷床熔炼技术作为代替传统真空自耗电弧熔炼技术的先进熔炼工艺,有望在钛合金铸锭生产领域得到广泛应用[5-6]。

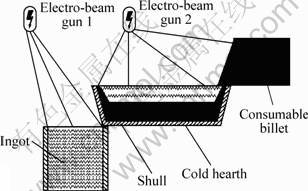

电子束冷床熔炼过程如图1所示。熔炼过程分3个阶段,即原料熔化阶段、冷床精炼阶段和铸模凝固阶段。首先原料被电子束加热熔化,在水冷铜床右端上方流入冷床,然后在冷床中对钛合金进行精炼,从冷床左侧流出,进入结晶坩埚,凝固成铸锭,经拉锭机构进入铸锭室。整个系统的热量由两个电子枪提供:电子枪1维持结晶坩埚内液态熔池表面的温度,避免局部凝固引起铸锭表面质量下降;电子枪2熔化原料和维持冷床内液态金属的温度[7]。

图1 电子束冷床熔炼过程示意图

Fig.1 Schematic diagram of EBCHM melting process

电子束冷床熔炼过程中,熔池温度主要影响夹杂物去除、铸锭表面质量以及铸锭化学成分均匀性,而熔池温度又主要受熔炼速度和加热功率的影响。本文作者利用PROCAST有限元软件对TC4钛合金电子束冷床熔炼的最后阶段即连铸凝固过程进行数值模拟,研究不同工况条件下的温度场分布规律、熔池形状以及组织分布特征,得到最佳熔炼工艺参数,为实现高均质、洁净钛合金铸锭的工业化生产提供理论依据。

1 数学模型

1.1 铸锭凝固传热基本模型

铸锭凝固传热过程一般采用非稳态导热偏微分方程表示[8]:

(1)

(1)

式中:ρ为密度,c为比热容,λx、λy、λz分别为材料在x、y、z方向上的导热系数,Q为材料的内热源(凝固潜热)。为简化计算,这里将材料看作各向同性(即λx=λy=λz=λ),此时式(1)可写成以下形式:

(2)

(2)

1.2 边界条件

1) 结晶器和冷却水之间的对流换热[9]:

(3)

(3)

式中:hc为结晶器和水之间的对流换热系数,Tc为结晶器的温度,Tw为冷却水的温度。

2) 铸锭对周围环境的辐射换热[10]:

(4)

(4)

(5)

(5)

式中:hr为铸锭与周围环境的辐射换热系数,ε为黑 度,kB为波尔兹曼常数,Ts为铸锭温度,Tf为周围环境温度。

在实际连铸过程中,铸锭和周围环境之间存在热辐射。但是,当铸锭拉出结器后,在水冷的作用下,其表面温度不是很高,辐射较小。此外,在结晶器内的液态金属温度较高,表面积也较大,将产生较大的辐射,但是,由于液态金属的不断补充,以及电子枪在熔池表面的热量输入,熔池表面辐射带走的热量可以不予考虑。因此,在整个连铸数值模拟过程中,热辐射的影响可以忽略不计以简化计算。

2 数值模拟前处理

2.1 模型建立及网格划分

本文作者利用Pro/E建立三维几何模型并划分面网格以*ans格式输出,通过自编程序将*ans文件转化为*sm格式文件,再导入ProCAST进行体网格划分,得到mesh文件。为了减少计算时间,利用结构对称性,在建模时只选取结构四分之一进行分析考虑,其结构参数为:圆锭,d220 mm,长300 mm;结晶器有效高度180 mm,壁厚10 mm;1/4底锭,d220 mm,长150 mm。其三维有限元模型如图2所示。

2.2 边界条件及参数设置

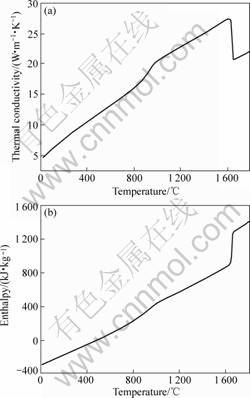

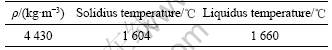

铸件材料为TC4钛合金,其热物性参数主要通过ProCAST热力学数据库计算并根据手册进行修正获得,物理参数如表1和图3所示。结晶器为纯铜,其物理参数如表2所列。

图2 三维有限元模型

Fig.2 Three-dimensional finite element model

图3 TC4合金热导率及热焓随温度的变化

Fig.3 Thermal conductivity (a) and enthalpy (b) with temperatures in TC4 alloy

表1 TC4钛合金热物性参数

Table 1 Thermal physical parameters of TC4 alloy

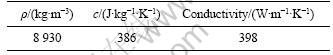

表2 铜结晶器热物性参数

Table 2 Thermal physical parameters of copper mould

铸件与结晶器的界面换热系数为1 000 W/(m2×K),结晶器和水的对流换热系数为5 000 W/(m2×K)。设置以下两种工况,分别对铸锭连铸过程进行数值模拟,研究其温度场的分布规律及组织分布特征。

工况一:相同的浇注温度(1 760 ℃),不同的铸造速度(7,10,14 min/min),对应的前期熔炼速度分别为(70,100,140 Kg/h)。

工况二:相同的铸造速度(10 mm/min)即对应的前期熔炼速度为100 kg/h,不同的浇注温度(1 760,1 860,1 960 ℃)。

3 模拟结果与讨论

3.1 工况一条件下的模拟结果

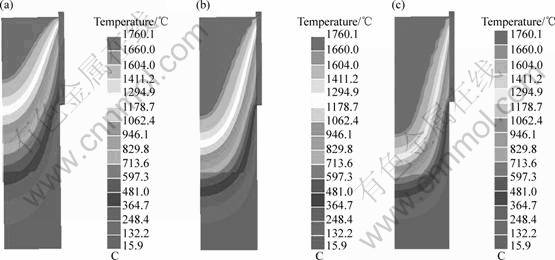

3.1.1 不同铸造速度下的温度场分布

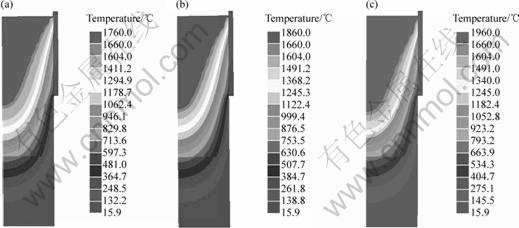

图4所示为TC4合金铸锭在不同铸造速度下的温度场分布。可以看出,铸造速度是影响熔池形状及深度的重要因素,铸造速度越慢,液相线以上的熔池越浅,固相线与液相线之间的糊状区域越深;反之,加快铸造速度,将使液相线下移,熔池加深,糊状区域变浅。因为铸造速度越慢,沿铸锭半径方向以及铸造方向冷却效率越高,铸造方向的温度梯度越小,导致熔池越浅,糊状区域深度越深。

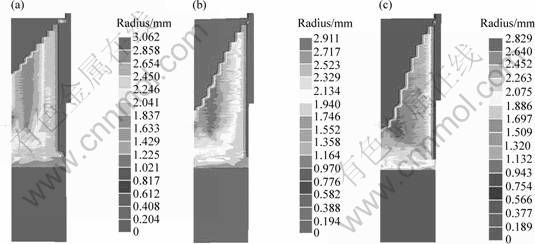

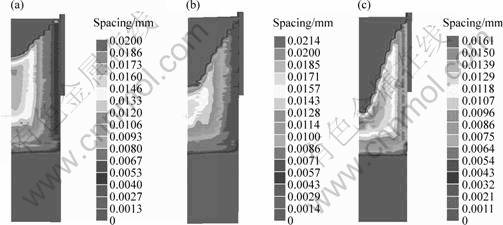

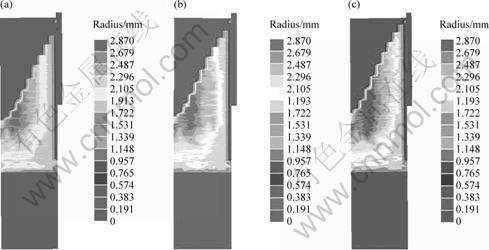

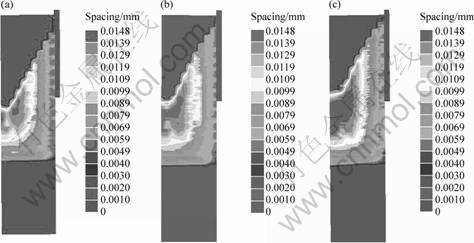

3.1.2 不同铸造速度下初生枝晶半径和二次枝晶臂间距

图5、6所示分别为不同铸造速度下,同一截面初生枝晶的半径大小以及二次枝晶臂间距。可以看出,由于结晶器坩埚壁水冷作用,紧靠坩埚壁形成一层非常薄的激冷组织,越靠近心部,由于水冷作用减弱,形成相对较大的柱状组织。随着铸造速度的增加,初生晶的半径和二次枝晶臂间距均增大。枝晶间距是树枝晶组织细化程度的表征。枝晶间距越小,组织就越细小,分布于其间的元素偏析范围也越小,故越容易通过热处理而均匀化。此外,这时的显微缩松和非金属夹杂物也会更加细小弥散分布,与成分偏析相关的缺陷也会减少,因而越有利于铸锭质量的提高。所以铸造速度对钛合金结晶过程的影响表现为随着铸造速度的提高,铸锭的冷却效率降低,合金的晶粒尺寸增大。铸造速度为14 mm/min时的细晶粒区域明显小于7 mm/min和10 mm/min时的。而在铸造速度为10 mm/min时,既能保证生产效率,又不至于形成过大的晶粒,可以得到较为满意的铸锭质量。故在本实验条件下,选择10 mm/min作为最佳的铸造速度。

图4 不同铸造速度下温度场分布

Fig.4 Temperature field distribution at different casting speeds: (a) 7 mm/min; (b) 10 mm/min; (c) 14 mm/min

图5 不同铸造速度下初生枝晶半径大小

Fig.5 Primary dendrite radius at different casting speeds: (a) 7 mm/min; (b) 10 mm/min; (c) 14 mm/min

图6 不同铸造速度下下二次枝晶臂间距

Fig.6 Secondary dendrite arm spacing at different casting speeds: (a) 7 mm/min; (b) 10 mm/min; (c) 14 mm/min

3.2 工况二条件下的模拟结果

3.2.1 不同浇注温度下的温度场分布

图7所示为TC4合金铸锭在不同浇注温度下的温度场分布。可以看出,随着浇注温度的提高,熔池变深变宽,糊状区域深度变浅。因为浇注温度越高,合金的热焓量越高,导致熔池加深,结晶器壁上的凝壳厚度变薄。但由于电子枪在熔池表面的持续作用,导致这种差异不是很明显。选择合适的浇注温度,适当降低过热度,从而可以减少结晶坩埚内Al元素的挥发损失量,以提高合金的成分的精确性。

3.2.2 不同浇注温度下初生枝晶半径和二次枝晶臂间距

图8、9所示分别为不同浇注温度下,同一截面初生枝晶的半径大小以及二次枝晶臂间距。可以看出,浇注温度越高,初生晶的半径和二次枝晶臂间距越大。浇注温度对钛合金结晶过程的影响表现为随着浇注温度的提高,过热度增大,合金液体的流动性增强,可以有效减少铸造缺陷,但同时会使合金的晶粒尺寸增大。浇注温度在1 960 ℃时的初生晶半径大小和二次枝晶臂间距要明显大于浇注温度为1 760 ℃和1 860 ℃时的铸锭。而在浇注温度为1 760 ℃时,过热度较小,晶粒长大趋势得到有效控制,可以得到较为细小的凝固组织。故在本实验条件下,选择1 760 ℃作为最佳的浇注温度。

图7 不同浇注温度下温度场分布

Fig.7 Temperature field distribution at different pouring temperatures: (a) 1 760 ℃; (b) 1 860 ℃; (c) 1 960 ℃

图8 不同浇注温度下初生枝晶半径大小

Fig.8 Primary dendrite radius at different pouring temperature s: (a) 1 760 ℃; (b) 1 860 ℃; (c) 1 960 ℃

图9 不同浇注温度下二次枝晶臂间距

Fig.9 Secondary dendrite arm spacing at different pouring temperature s: (a) 1760 ℃; 9b) 1860 ℃; (c) 1960 ℃

4 结论

1) 在浇注温度相同的条件下,随着铸造速度的增加,熔池加深,糊状区域变浅,初生枝晶半径和二次枝晶臂间距逐渐增加,凝固组织变得粗大,选择合理的铸造速度以得到性能优良的铸锭。

2) 在铸造速度相同的条件下,随着浇注温度的提高,过热度增大,导致熔池加深,糊状区域变浅,同时会使合金晶粒尺寸增大,选择合理的浇注温度有利于铸锭质量的提高。

3) 在本实验条件下,选择铸造速度10 mm/min以及浇注温度1 760 ℃作为最佳工艺参数,这有利于在保证较高生产效率的同时,获得组织细小、冶金质量优良的钛合金铸锭。

REFERENCES

[1] 付艳艳, 宋月清, 惠松骁, 米绪军. 航空用钛合金的研究与应用进展[J]. 稀有金属, 2006, 30(6): 850-856.

FU Yan-yan, SONG Yue-qing, HUI Song-xiao, MI Xu-jun. Research and application of typical aerospace titanium alloys[J]. Chinese Journal of Rare Metals, 2006, 30(6): 850-856.

[2] BOMBERGER H B, FORES F H. The melting of titanium[J]. JOM, 1984, 36(12): 39-47.

[3] LIU J L, ZHAO Y Q, ZHOU L. Microscopic segregation of Ti-6Al-4V ingot by VAR[C]//L?ETJERING G, ALBRECHT J. Ti-2003 Science and Technology. Weinheim: Wiley-VCH, 2003: l65-167.

[4] van Den AVYLE J A, BROOKS J A, POWELL A C. Reducing defects in remelting processes for high-performance alloys[J]. JOM, 1998, 50(3): 22-25.

[5] 张英明, 周 廉, 孙 军, 韩明臣, 舒 滢, 杨建朝. 钛合金冷床熔炼技术进展[J]. 钛工业进展, 2007, 24(4): 27-30.

ZHANG Ying-ming, ZHOU Lian, SUN Jun, HAN Ming-chen, SHU Ying, YANG Jian-chao. The development of cold hearth melting technique[J]. Titanium Industry Progress, 2007, 24(4): 27-30.

[6] 韩明臣, 张英明, 周义刚, 赵铁夫, 杨建朝, 李 军, 周 廉. TC4合金电子束冷床熔炼过程中LDI和HDI的去除[J]. 稀有金属材料与工程, 2008, 37(4): 665-669.

HAN Ming-chen, ZHANG Ying-ming, ZHOU Yi-gang, ZHAO Tie-fu, YANG Jian-chao, LI Jun, ZHOU Lian. Elimination of LDI and HDI in TC4 alloy during electron beam cold hearth melting[J]. Rare Metal Materials and Engineering, 2008, 37(4): 665-669.

[7] 张英明, 周 廉, 孙 军, 韩明臣, 毛小南, 侯志敏. 电子束冷床熔炼TC4合金的热平衡分析[J]. 钛工业进展, 2008, 25(6): 34-37.

ZHANG Ying-ming, ZHOU Lian, SUN Jun, HAN Ming-chen, MAO Xiao-nan, HOU Zhi-min. Heat balance analysis of electron beam cold hearth melting of TC4 alloy[J]. Titanium Industry Progress, 2008, 25(6): 34-37.

[8] 荆 涛. 凝固过程数值模拟[M]. 北京: 电子工业出版社, 2002: 80-81.

JING Tao. Numerical simulation of solidification process[M]. Beijing: Electronic Industry Press, 2002: 80-81.

[9] 殷 雯, 雷 宏. 对称钢件淬火过程温度场分布的数值模拟[J]. 集美大学学报, 1998, 3(4): 55-59.

YIN Wen, LEI Hong. Numerical simulation of symmetrical workpiece of quenching processes[J]. Journal of Jimei University, 1998, 3(4): 55-59.

[10] 马维策. 7075铝合金大圆锭半连铸凝固过程数值模拟及裂纹倾向性分析分析[D]. 长沙: 中南大学, 2008: 19-20.

MA Wei-ce. Numerical simulation and analysis of crack orientation of 7075 aluminum alloy ingot during the semi-continuous casting solidification process[D]. Changsha: Central South University, 2008: 19-20.

(编辑 李向群)

通信作者:雷文光,助理工程师;电话:029-86250729;E-mail:lwg_2008@163.com