文章编号:1004-0609(2010)S1-s0404-06

电子束冷床熔炼TC4合金温度场模拟

罗 雷1, 2,毛小南2,雷文光2,于兰兰2,杨冠军2

(1. 西安建筑科技大学 冶金工程学院,西安 710055;

2. 西北有色金属研究院 钛合金研究所,西安 710016)

摘 要:利用ANSYS软件对电子束冷床熔炼TC4钛合金过程进行模拟研究。结果表明:熔体从冷床滴入坩埚之后,主要出现熔体升温、形成稳定熔池、熔体凝固、熔体温度下降和凝固结束这5个阶段。在开始熔炼时,熔体温度较低,升温也比较慢,但随着熔炼的进行,熔体升温加快,并维持在高温状态,最后熔体发生凝固降温,且降温速度很快。降温过程主要分为两个阶段,在快速降温阶段,熔体快速出现部分凝固,而在降温平衡阶段,熔体主要进行补缩。当降温时间达到500 s时,熔体温度基本保持不变。

关键词:电子束冷床熔炼;TC4钛合金;温度场;模拟

中图分类号:TG294 文献标志码:A

Temperature field simulation of electron beam

cold hearth melting TC4 alloy

LUO Lei1, 2, MAO Xiao-nan2, LEI Wen-guang2, YU Lan-lan2, YANG Guan-jun2

(1. School of Metallurgical Engineering, Xi’an University of Architecture and Technology, Xi’an 710055, China;

2. Titanium Alloy Research Center, Northwest Institute for Nonferrous Metal Research, Xi’an 710016, China)

Abstract: From ANSYS simulation, electron beam cold hearth melting process of TC4 titanium alloy was studied. The results show that after the melt trickles from cooling bed down to the crucible, there are five main melting stages, i.e. the melt temperature increasing, a stable pool forming, melt solidification, melt temperature decreasing and solidification ending. At the beginning of melting, the melt temperature is relatively slow, but as the melting progresses, the melt temperature speeds up, and maintains at high temperature, finally solidified melt is cooled, and the cooling speed is fast. The cooling process is divided into two stages. At the rapid cooling stage, some melts solidify rapidly. The equilibrium phase of cooling stage is melt mainly for feeding. When the cooling time reaches 500 s, the melt temperature remains unchanged.

Key words: electron beam cold hearth melting; TC4 titanium alloy; temperature field; simulation

TC4钛合金具有低密度、高比强、耐高温、耐腐蚀等一系列优点,是一种在航空航天、石油化工和兵器工业等各个领域内应用极其广泛的新型材料[1-3]。但是,由于TC4合金是一种具有高化学活性的金属, 在液态下很容易与氧、氮、氢及碳的反应生成脆性物质,因此,TC4合金熔炼必须在较高的真空度或惰性气体(Ar或Ne)保护下进行[4]。传统的真空自耗电弧(VAR)熔炼方法的真空度一般为10-1~10-2Pa,熔炼出的钛锭常常易出现合金元素的偏析以及疏松缩孔等冶金缺陷,而且对废料的利用率极低,大大增加了TC4合金的应用成本[5]。电子束冷床熔炼(EBCHM)技术是从1980年末应用于钛合金熔炼的一种新型熔炼技术,对TC4钛合金中的高密度和低密度夹杂去除效果显 著[6],且对残料的利用率高,熔炼出的铸锭成分均匀,质量良好,大大降低了TC4钛合金的生产成本。

为了提高电子束冷床熔炼TC4钛合金中的各项指标,需要对电子束冷床熔炼参数进行优化,如熔炼功率、熔炼速度、温度控制等。近年来,工程实践中为了寻找最优的工艺和技术方案,并且随着计算机科学技术的发展,人们开始利用计算机并辅助以相应的模拟软件,进行虚拟工程化加工,不仅有利于提高产品的质量,而且省事省力,降低了成本[7]。本文作者采用ANSYS软件对电子束冷床熔炼过程中的温度场进行有限元模拟研究。

1 模拟分析前处理

1.1 ANSYS分析模型的建立和网格划分

ANSYS模拟计算利用的是有限元模型,对于比较简单的几何模型,可以直接生成,生成的模型可以很容易地控制单元和节点的数量、分布等参数。但是,如果模拟需要的几何模型比较复杂,直接生成法不容易实现,一般采用建立实体几何模型或者采用计算机专业建模软件,例如Pro/E、UG等。在该研究中,由于坩埚中熔炼金属的几何尺寸呈轴对称分布,可以将实体模型进行对称简化。本论文中先建立二维简化对称模型,并将平面简化模型旋转为3/4实体模型,如图1所示。

在有限元分析计算中,网格划分是其中最关键的一个步骤,网格划分的好坏直接影响到计算的精度和速度。在ANSYS中,网格划分有3个步骤:定义单元属性(包括实常数)、在几何模型上定义网格属性以及划分网格。网格划分主要有自由网格划分、映射网格划分、拖拉和扫略网格划分、混合网格划分等方 法[8],应用比较广泛的有自由网格划分、映射网格划分。自由网格划分是自动化程度最高的网格划分技术之一,它在面上(平面、曲面)可以自动生成三角形或四边形网格,在体上自动生成四面体网格。映射网格划分是对规整模型的一种规整网格划分方法,本文中采用自由网格划分方式对模型进行网格划分,用ANSYS自带软件划分网格后的模型如图1所示。

1.2 材料的热物性参数及边界条件

采用ANSYS有限元模拟软件对电子束冷床熔炼TC4钛合金凝固过程进行温度场模拟研究时,需要确定材料的热物性参数以及相应的边界条件,其中材料热物性参数主要包括TC4钛合金、铜坩埚和导热水等的密度、导热系数、比热容以及对流换热系数等一系列参数。

图1 ANSYS分析模型

Fig.1 ANSYS analysis model: (a) 1/4 model; (b) 3/4 model

1.2.1 密度

在电子束冷床熔炼过程中,合金熔体以及结晶器等部件的密度随着温度的升高略有变化,但由于对研究影响不大,因此,本文中密度均取为定值,取值分别为:TC4钛合金4 500 kg/m3;纯铜8 960 kg/m3;冷却水1 000 kg/m3。

1.2.2 导热系数和比热容

TC4钛合金在一定温度范围内的导热系数和比热容在文献中可以查出[9],对于其它温度范围的导热系数和比热容,根据已知参数按最小二乘法进行拟合求出。图2所示分别为TC4钛合金的导热系数和比热容随着温度升高而变化的趋势。对于试验中采用的水冷铜坩埚,随着温度的升高其导热系数和比热容变化不大,且对实验没有影响,故水冷铜坩埚的导热系数取常数为401 W/(m?K),水冷铜坩埚的比热容取常数为390 J/(kg?K)。

1.2.3 ANSYS模拟分析中的边界条件及焓值

本模拟研究中,考虑到ANSYS有限元分析软件的需要和对流换热系数的计算问题,故设定水冷铜坩埚的冷却水的进水温度为室温20 ℃,出水温度为60 ℃;坩埚内熔体的初始温度为1 760 ℃。

图2 TC4钛合金导热系数和比热容随温度的变化曲线

Fig.2 Change curves of thermal conductivity(a) and heat capacity(b) of TC4 alloy with temperature

ANSYS分析软件通过定义材料的焓值随温度的变化来考虑相变潜热,焓值的计算公式是密度与比热容的乘积对温度的积分:

(1)

(1)

1.2.4 对流换热系数的计算

电子束冷床熔炼过程中,坩埚壁的冷却水在导管内以湍流方式流动。在工程实际计算中,应用比较广泛的特征方程是湍流(Re>104)强迫对流换热的特征方程[10]:

(2)

(2)

式中:Nuf为流体冷却水的努赛尔数;Ref为雷诺准数,Prf为普朗特系数,Prf =5.55,式(2)的实用范围是Ref = 1×104~1.2×105,Prf =0.7~120; 为考虑边界层内温度分布对对流换热系数影响的温差修正系数;

为考虑边界层内温度分布对对流换热系数影响的温差修正系数; 为考虑流体管道弯曲对对流换热系数影响的弯管修正系数,当流体管道为直管时

为考虑流体管道弯曲对对流换热系数影响的弯管修正系数,当流体管道为直管时 =1;

=1; 为考虑短管管长对对流换热系数影响的短管修正系数;n为常数值,一般当流体被加热时取n=0.4。

为考虑短管管长对对流换热系数影响的短管修正系数;n为常数值,一般当流体被加热时取n=0.4。

根据强迫对流换热系数的特征方程,计算对流换热系数的公式为

(3)

(3)

式中:h0为流体管内冷却水的对流换热系数,W/(m2?K); 为冷却水的导热系数,W/(m?K);d为当量直径,

为冷却水的导热系数,W/(m?K);d为当量直径, ,m;A为流体导管横截面积,m2;L为流体导管横截面周长,即冷却水水流湿润周长,m;

,m;A为流体导管横截面积,m2;L为流体导管横截面周长,即冷却水水流湿润周长,m; 为冷却水的努赛尔数,可以由特征方程式(2)求得。

为冷却水的努赛尔数,可以由特征方程式(2)求得。

2 温度场模拟结果分析

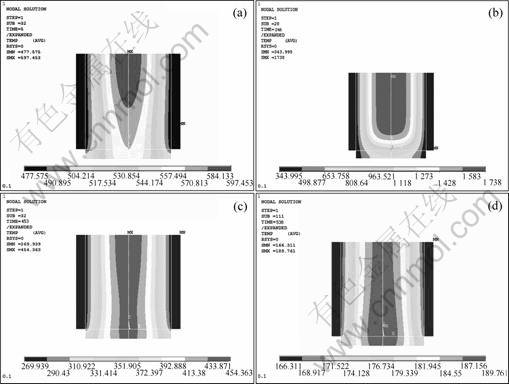

将上面所建立的ANSYS模拟分析模型,通过设定边界条件以及其它一些数值参量,然后进行ANSYS计算模拟,并利用ANSYS软件生成动画的功能,得到电子束冷床熔炼TC4钛合金坩埚凝固过程中,不同时刻TC4钛合金熔体的温度场分布云图(见图3)。

从TC4钛合金熔体的分布云图可以看出,在刚开始熔炼阶段,熔体现在坩埚中形成一个小的熔池,此时由于坩埚壁和冷却水的温度较低,导热效果较好,熔体的温度相对较低(图3(a));随着熔炼的进行,不断有熔体流入坩埚内部,熔炼进入稳定阶段,坩埚内部逐渐形成了比较深的熔池,且熔体的温度上升也很快,此时,熔体中心的温度基本接近熔体的熔点(图3(b));随着熔炼继续进行,熔体逐渐开始冷凝,熔池内部温度向外界传导扩散,熔体的温度开始下降,最后熔体达到完全凝固(图3(c), (d))。

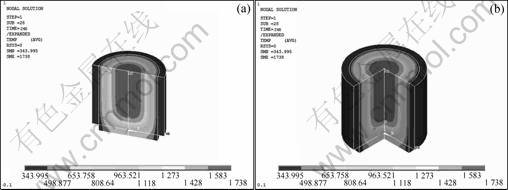

从熔体温度分布场云图来看,电子束冷床熔炼TC4钛合金熔体在坩埚部分主要经过熔体升温、形成稳定熔池、熔体凝固、熔体温度下降、凝固结束5个主要的阶段。熔体处于稳定熔炼阶段的时间最长,是熔炼过程中最主要的环节,我们将稳定熔炼阶段的温度场分布截取三维云图,分别绘制1/2和3/4的截面图形(如图4所示),分析稳定熔炼阶段的温度场分布情况。

图3 不同时刻TC4钛合金熔体温度场分布

Fig.3 Temperature field distribution of TC4 alloy melt at different time: (a) 5 s; (b) 246 s; (c) 453 s; (d) 538 s

图4 稳定熔炼阶段熔体温度场三维分布

Fig.4 Three-dimensional temperature field distribution of melt at melting stability phase: (a) 1/2 section; (b) 3/4 section

从稳定熔炼阶段的温度场三维分布云图(图4)可以看出,由于熔体从冷床滴入坩埚的中部,加上坩埚壁冷却水的作用,从坩埚心部到坩埚四壁,熔体的温度下降非常快,熔体中心温度大约有1 740 ℃,而贴近坩埚壁的熔体温度只有340 ℃左右。熔体中心持续保持高温,有助于电子束冷床熔炼TC4钛合金的熔体在凝固结晶过程中进行补缩,可以显著提高熔炼铸锭的表面质量;高温也可以增加杂质元素的挥发,提高熔炼纯度。但是,熔炼中也会增加Al元素的挥发损失,这是国内外学者研究电子束冷床熔炼的热点问题。

3 降温过程模拟结果与实验验证

在电子束冷床熔炼TC4钛合金熔体的凝固过程中,熔体的温度逐渐下降,利用ANSYS自带的绘图工具绘制了熔体的降温曲线,如图5(a)所示。此外,在电子束冷床熔炼TC4钛合金实验中,采用单波长高温测量仪对熔池中心的温度进行测量并绘制出降温曲线,如图5(b)所示。

图5 熔体心部降温过程中模拟温度场和实测温度曲线

Fig.5 Temperature curves of simulation(a) and measurement(b) at melt center

由图5所示两条降温曲线可以看出,无论实测温度曲线还是模拟温度场曲线,熔体开始降温时的温度都约为1 760 ℃,整个降温过程大概分为两个阶段。前100 s是快速降温阶段:熔体在该阶段内降温很快,主要是因为熔体在开始熔炼阶段,熔体刚滴入坩埚,坩埚壁在开始阶段散热情况相对较好,结果造成了降温较快的现象;在该阶段熔体开始迅速凝固成铸锭。随着时间的推移,降温逐渐趋于平缓,该阶段为温降平衡阶段,此时熔体与坩埚外壁的温度相差不是很大,为铸锭补缩阶段;当降温时间达到500 s时,温度降幅已经很小,坩埚内外温度基本保持平衡状态。最终熔体的温度降低到室温,补缩完成,熔体凝固为TC4钛合金铸锭。

对比两条降温曲线,我们发现,实测降温曲线在降温过程中偶尔会出现少量拐点,而ANSYS模拟温度场曲线则相对比较平滑。造成这种现象的主要原因是在实验过程中,周围环境的影响和测温仪的误差,可能会影响到测量结果,导致出现一定的偏差;而模拟分析过程设定的各项参数均为理想状态下的参数,且对模拟模型做了合理的简化处理。因此,可以认为实测降温结果与模拟温度场的降温结果吻合良好,模拟结果准确可信,为今后的研究提供了良好的理论指导。

4 结论

1) 通过ANSYS模拟发现,电子束冷床熔炼TC4钛合金过程中,熔体从冷床滴入坩埚之后,主要经过熔体升温,形成稳定熔池、熔体凝固、熔体温度下降、凝固结束5个主要的阶段。开始阶段熔体温度相对较低,升温较慢;随着熔炼的进行,熔体升温加快,并长时间维持在高温状态,处于稳定熔炼阶段;最后熔体开始降温凝固,降温速度相对较快。

2) 熔体从熔点开始降温时,整个降温过程分为两个阶段。在快速降温阶段,熔体刚滴入坩埚中,坩埚壁散热情况良好,熔体降温很快,在短时间内迅速开始凝固。随着时间的推移,达到温降平衡阶段,熔体与坩埚外壁环境温差小,降温逐渐趋于平缓,熔体有足够的时间进行补缩;降温时间达到500 s时,坩埚内外温度基本保持平衡。

3) 利用ANSYS有限元模拟分析软件对电子束冷床熔炼TC4钛合金的温度场进行模拟研究,模拟结果与实测结果吻合良好,既证明了实验过程的可靠性,同时也证明了所选用模型的合理可行性。模拟结果可反映熔体在任意时刻的温度场分布情况,为以后的研究提供了很好的理论支持。

References

[1] 张喜燕, 赵永庆, 白晨光. 钛合金及其应用[M]. 北京: 化学工业出版社, 2005.

ZHANG Xi-yan, ZHAO Yong-qing, BAI Chen-guang. Application of titanium alloys[M]. Beijing: Chemical Industry Press, 2005.

[2] 《稀有金属材料加工手册》编写组. 稀有金属材料加工手册[M]. 北京: 冶金工业出版社, 1984.

The Editorial Group of Processing Handbook of Rare Metal Materials. Processing handbook of rare metals[M]. Beijing: Metallurgy Industry Press, 1984.

[3] C. 莱茵斯, M. 皮特尔斯. 钛与钛合金[M]. 陈振华, 等译. 北京: 化学工业出版社, 2005: 32.

LEYENS C, PETERS M. Titanium and titanium alloys[M]. Beijing: Chemical Industry Press, 2005: 32.

[4] GUO Jing-jie, SU Yang-qing, DING Hong-sheng, et al. Evaporation behavior of aluminum during the cold crucible induction skull melting of titanium aluminum alloys[J]. Metallurgical and Materials B, 2000, 31(8): 837-844.

[5] 安 红, 刘俊玲, 范丽颖. 真空自耗电弧炉熔炼钛铸锭的质量控制[J]. 世界有色金属, 2007(8): 25-27.

AN Hong, LIU Jun-ling, FAN Li-ying. Quality control in smelting titanium ingots in vacuum arc-melting furnace[J]. World Nonferrous Metals, 2007(8): 25-27.

[6] MOROZOV E I, MUSATOV M I, CHUCHURYUKIN A D, FRIDMAN S A. Investigation of various methods of melting and casting of titanium alloys[J]. Titanium’80 Science and Technology, 1980(3): 2157-2167.

[7] MEEKISHO L L, CHEN X. Computer modeling: an important tool in materials processing[C]//The Proc of the 1th Inter Conf on Thermal Process Modeling and Computer Simulation. Shanghai: Shanghai Jiao Tong University, 2000, E-5(1): 26-34.

[8] 曹延欣. 有限元分析软件ANSYS及其使用[J]. 大众科技, 2008(2): 55-68.

CAO Yan-xin. Application of finite element software[J]. Popular Science & Technology, 2008(2): 55-68.

[9] 黄伯云, 李成功, 石力开. 中国材料工程大典: 有色金属材料工程 (上)[M]. 北京: 化学工业出版社, 2005.

HUANG Bai-yun, LI Cheng-gong, SHI Li-kai. China materials engineering canon[M]. Beijing: Chemical Industry Press, 2005.

[10] 沈巧珍, 杜建明. 冶金传输原理[M]. 北京: 冶金工业出版社, 2006.

SHEN Qiao-zhen, DU Jian-ming. Principles of transfer in metallurgy[M]. Beijing: Metallurgy Industry Press, 2006.

(编辑 李向群)

基金项目:国家重点基础研究发展计划资助项目(2007CB613802)

通信作者:罗 雷,硕士;电话:029-86250729;E-mail: luolei0301@126.com