文章编号:1004-0609(2013)S1-s0353-05

低成本TC4钛合金板材的研制

冯秋元1,庞 洪1,乔 璐1,佟学文1,刘 睿2,叶文君2,王鼎春1,高 颀1

(1. 宝钛集团有限公司 宝钛研究院,宝鸡 721014;

2. 北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088)

摘 要:通过大量添加返回料,采用电子束冷床炉单次熔炼TC4钛合金扁锭。板坯包覆后在可逆式热轧机上轧制出8 mm厚合金板材。结果表明:单向轧制工艺制备的板材,其拉伸性能优于交叉轧制工艺制备板材的伸长率略低;固溶+时效热处理可提高板材的室温拉伸强度;与真空自耗电弧熔炼相比,用电子束冷床熔炼扁锭直接轧制板材,不仅节约原料成本,而且缩短加工流程,显著降低板材的制造成本。

关键词:TC4钛合金;电子束冷床熔炼;板材;性能;低成本

中图分类号:TG146.2 文献标志码:A

Preparation of low-cost TC4 titanium alloy sheet

FENG Qiu-yuan1, PANG Hong1, QIAO Lu1, TONG Xue-wen1, LIU Rui2, YE Wen-jun2, WANG Ding-chun1, GAO Qi1

(1. Baoti Research Institute, Baoti Group Ltd., Baoji 721014, China;

2. State Key Laboratory for Fabrication & Processing of Nonferrous Metals, General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: Through adding enough defective material, TC4 titanium alloy slab ingot was produced by using single electron beam cold hearth melting (EBCHM), then, a sheet with thickness of 8 mm thick was manufactured on reversible hot rolling mill after cladding. The results show that the tensile property of sheet produced by one-way rolling is prior to that of cross-rolling, while the elongation is lower. Solution and aging treatment can improve the tensile strength of sheet at room temperature. Compared to vacuum arc remelting (VAR), using slab ingot produced by EBCHM to manufacture sheet can not only save prime cost of raw material, but also shorten processing procedure, so that remarkably reduce the manufacture cost.

Key words: TC4 titanium alloy; electron beam cold hearth melting; sheet; property; low cost

Ti-6Al-4V(TC4)钛合金是一种典型的α+β型两相钛合金,具有优异的综合性能,大量应用于航空、航天、舰船、兵器、化工、医疗、体育休闲等领域[1-2]。世界上生产的钛合金中,50%以上是TC4钛合金,在宇航工业应用方面,TC4钛合金的使用量占80%以上。TC4钛合金已成为世界上所有钛合金牌号中品种规格较齐全、工业量最大的国际通用型钛合金。然而,成本问题限制了其广泛应用。世界各国,尤其是美、日、俄、中国等都在积极寻找降低成本的方法和工艺[3-7]。钛合金的成本主要取决于原料成本和熔炼、加工成本。为了降低成本,一方面采用廉价元素,降低原料成本[8];另一方面改进生产工艺,降低熔炼和加工成本。目前,世界上提炼海绵钛均采用Kroll法,尚无可行的低成本生产方法取代该方法,因此,在海绵钛生产技术未取得重大突破之前,仅通过使用价格低廉的合金化元素的方法难以使钛合金成本大幅降低。然而,钛合金生产过程中,由于切头、切边、表面车削清理等加工需要,会产生大量的返回料。由于钛合金返回料的成本只有一些筛选、破碎、清理带来的附加成本,不到海绵钛成本的三分之一。若能在合金制备过程中大量利用返回料,则可以显著降低成本。常规生产流程制备的钛合金板材的成本构成中,海绵钛成本占总成本约40%,合金化元素的成本仅占总成本6.7%;熔炼和变形加工成本分别各占总成本约20%和约26%。因此,降低原料成本且缩短加工流程是降低钛合金成本的有效途径[9]。此外,目前常用的钛合金熔炼工艺是真空自耗电弧熔炼(VAR),采用该工艺需要预先压制电极。为保证电极的强度,返回料仅能少量地添加到电极中,回收利用率受到限制,降低成本作用有限。电子束冷床熔炼(EBCHM)技术的日趋成熟为钛合金的低成本化制备提供了重要的技术途径[10]。EBCHM有如下优点[11-13]:1)较好地消除高、低密度夹杂,可获得组织均匀的铸锭;2)可100%利用返回料,而生产Ti-6Al-4V合金的VAR只能利用30%以下的返回料;3)可1次熔炼成锭;4)可生产扁锭,减少后续加工量。本研究采用EBCHM代替传统的VAR,通过大量添加返回料,单次熔炼生产TC4钛合金扁锭;将扁锭表面处理、包覆后直接开坯轧制,制备8 mm厚TC4钛合金板材;同时将VAR和EBCHM铸锭制备板材的制造成本进行了对比。

1 实验

1.1 铸锭熔炼

利用宝鸡钛业股份有限公司德国进口2 400 kW电子束冷床熔炼炉(ALD公司生产)熔炼扁锭。原材料主要由海绵钛、Al-V中间合金、Al豆以及TC4返回料组成,其中返回料约占原材料总量的80%。返回料由公司返回料回收处理生产线进行专业化处理。采用水平进料方式,控制熔炼工艺参数1次熔炼成功TC4钛合金扁锭。

1.2 板材轧制

板坯经表面处理、包覆后在1 200 mm可逆式热轧机上进行开坯轧制。开坯后分单向和交叉轧制两种工艺进行多火次轧制。累积相变点以上的变形量不低于50%,相变点以下变形量不低于70%,获得8 mm厚度规格的板材。

1.3 检测分析

板材经表面酸洗、真空退火处理后,加工成板材拉伸试样。室温拉伸试验在INSTTON5885电子万能材料实验机上进行,金相组织观察在蔡司金相显微镜(Axiovert 200mat)上进行。

2 结果分析与讨论

2.1 显微组织

对EBCHM扁锭沿长度方向进行Al、V、Fe、O主要成分的分析。结果表明:合金成分均符合《钛及钛合金牌号和化学成分》(GB/T 3620.1—2007)标准要求,且成分均匀。图1所示为不同轧制工艺(图1(a)~(d)为单向轧制,图1(e)~(h)为交叉轧制)及热处理后板材的金相显微照片。由图1可见:两种工艺制备的板材热轧态均为α+β两相组织,单向轧制板材可见拉长的条状组织(图1(a)和(b))。固溶+时效处理后的室温组织为等轴状的初生α相和片层状次生相组成的双态组织(图1(c)和(g))。

随着固溶温度升高,等轴状初生α相含量减少,片层状次生α相长大并逐渐球化。950 ℃固溶处理后的组织晶界清晰,片层状结构明显(图1(d)和(h))。等轴组织具有较高的强度、塑性和疲劳强度。双态组织则综合了等轴和片层组织的特点,不仅具有优良的室温性能,而且蠕变性能、疲劳性能及热稳定性良好[14]。因此,通过采取合适的热处理制度,合理控制合金初生α相的晶粒尺寸,以及次生α相的形态及片层厚度,对改善材料的综合性能具有积极作用[15-16]。与单向轧制工艺相比,换向轧制工艺制备的板材,虽然室温拉伸强度略低,但塑性却相对较好。这是由于换向轧制工艺不仅能够消除组织不均匀性,而且可以减小性能的各向异性[17]。

2.2 室温力学性能

表1所示为经不同轧制工艺及热处理后板材的室温拉伸性能。

由表1可知,无论采用单向轧制还是交叉轧制,两种工艺制备的热轧态板材的室温力学性能均满足《钛及钛合金板材》(GB/T 3621—2007)标准要求,说明采取的轧制工艺是合适的。同时,单向轧制工艺制备的板材的拉伸强度比交叉轧制工艺制备的板材的要高,而延伸率则略低。对板材进行固溶+时效热处理后,板材的拉伸强度显著提高,其中经950 ℃、1 h、水淬+540 ℃、4 h、炉冷处理后板材的屈服强度和抗拉强度最大,且没有明显的塑性下降。合金板材强度的提高一方面是经高温固溶处理后初生α相尺寸大大减小,减少了裂纹在初生α相中萌生的可能性;另一方面是通过加工态中β相转变为马氏体,马氏体分解成更为细小的α相来实现的[18]。合适的固溶+时效热处理可消除或减少晶界上析出的连续α相,显著提高力学性能。

图1 不同轧制工艺及热处理后TC4钛合金板材的显微组织

Fig.1 Microstructures of TC4 alloy sheet after different rolling processes and heat treatments (One-way rolling process (a)-(d), Cross-rolling process (e)-(h))

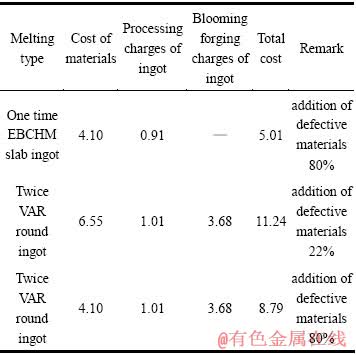

2.3 成本比较

表2所示为用电子束冷床熔炼和真空自耗电弧熔炼铸锭制备板材的费用比较。按投料量1 000 kg计算,当返回料均为正常添加量时,与VAR相比,EBCHM可节省原料成本约37%;而当返回料添加量相同时,由于省去了传统加工流程中圆形铸锭开坯锻造工序,EBCHM扁锭制备板材比用VAR铸锭节省加工费用约43%。由此可见,采用EBCHM扁锭轧制板材不仅能够节约原料成本,而且可以缩短加工流程,是TC4钛合金板材低成本化生产极为有效的技术途径。

表1 经不同轧制工艺及热处理后板材的室温拉伸性能

Table 1 Tensile properties of sheet by different rolling processes and heat treatments

表2 EBCHM与VAR铸锭制备板材费用比较(万元)

Table 2 Cost comparison of sheet produced by EBCHM and VAR ingot (104 yuan)

3 结论

1) 采用电子束冷床熔炼炉(EBCHM)单次熔炼,成功制备出成分均匀的TC4钛合金扁锭;板坯包覆后经多火次热轧,试制出8 mm厚板材,板材的各项技术指标均达到GB/T 3621—2007和使用要求。

2) 单向轧制板材的室温拉伸强度较交叉轧制的高,而伸长率略低;固溶+时效热处理显著提高板材的室温拉伸强度。

3) 返回料均为正常添加量时,与真空自耗电弧熔炼(VAR)相比,EBCHM可节省原料成本约37%;而当返回料添加量相同时,用EBCHM扁锭制备板材比用VAR降低加工成本约43%。

REFERENCES

[1] 全桂彝, 魏寿庸, 全景奎, 陈兴汉. Ф622毫米Ti-6Al-4V合金铸锭的剖析[J]. 稀有金属材料与工程, 1982(1): 11-21.

JIN Gui-yi, WEI Shou-yong, QUAN Jing-kui, CHEN Xing-han. Dissect and analyze of Ф622mm Ti-6Al-4V alloy ingot [J]. Rare Metal Materials and Engineering, 1982(1): 11-21.

[2] 刘 莹, 曲周德, 王本贤. 钛合金TC4的研究开发与应用[J]. 兵器材料科学与工程, 2005, 28(1): 47-50.

LIU Ying, QU Zhou-de, WANG Ben-xian. Research development and application of Ti6Al4V alloy [J]. Ordnance Material Science and Engineering, 2005, 28(1): 47-50.

[3] FROES F H, FRIEDRICH H, KIESE J, BERGOINT D. Titanium in the family automobile: The cost challenge [J]. Journal of the Minerals, Metals and Materials Society, 2004, 56(2): 40-44.

[4] KOSAKA Y, FOX S, FALLER K, REICHMAN S. Properties and processing of TIMETAL LCB [J]. Journal of Materials Engineering and Performance, 2005, 14(6): 792-798.

[5] 郭瑞萍, 孙葆森, 高彬彬. 兵器装备用钛合金的低成本制造技术[J]. 兵器材料科学与工程, 2008, 31(5): 83-86.

GUO Rui-ping, SUN Bao-sen, GAO Bing-bing. Low cost manufacturing technology of titanium alloy used in ordnance equipment[J]. Ordnance Material Science and Engineering, 2008, 31(5): 83-86.

[6] 张文毓. 高性能低成本钛合金研究进展[J]. 航空制造技术, 2011(5): 74-76, 79.

ZHANG Wen-yu. Research progress of high-performance and low cost titanium alloy [J]. Aeronautical Manufacturing Technology, 2011(5): 74-76, 79.

[7] 朱知寿, 商国强, 王新南, 费 跃, 李 军. 低成本高性能钛合金研究进展[J]. 钛工业进展, 2012, 29(6): 1-5.

ZHU Zhi-shou, SHANG Guo-qiang, WANG Xin-nan, FEI Yue, LI Jun. Research and development of low cost and high performance titanium alloys [J]. Titanium Industry Progress, 2012, 29(6): 1-5.

[8] 王 国, 惠松骁, 叶文君, 米绪军. Ti-3.0Al-3.7Cr-2.0Fe低成本钛合金的热压缩变形行为[J]. 中国有色金属学报, 2012, 22(8): 2223-2229.

WANG Guo, HUI Songxiao, YE Wenjun, MI Xujun. Hot compressive behavior of Ti-3.0Al-3.7Cr-2.0Fe low cost titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(8): 2223-2229.

[9] KALINYUK A N, TRIGUB N P, ZAMKOV V N, IVASISHIN O M, MARKOVSKY P E, TELIOVICH R V, SEMIATIN S L. Microstructure, texture, and mechanical properties of electron-beam melted Ti-6Al-4V [J]. Materials Science and Engineering A, 2003, 346(1/2): 178-188.

[10] 毛小南, 罗 雷, 于兰兰, 雷文光. 电子束冷床熔炼工艺参数对TC4钛合金Al元素挥发的影响[J]. 中国有色金属学报, 2010, 20(S1): s419-s424.

MAO Xiao-nan, LUO Lei, YU Lan-lan, LEI Wen-guang. Effects of melting process parameters of electron beam cold hearth on Al element evaporation in TC4 titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s419-s424.

[11] 马荣宝, 陈 峰, 国 斌. 电子束冷床熔炼发展简况及熔炼工艺探讨[J]. 钛工业进展, 2008, 25(5): 37-40.

MA Rong-bao,CHEN Feng,GUO Bin. Development of EBCHR and discussion of its remelting process [J]. Titanium Industry Progress, 2008, 25(5): 37-40.

[12] 于兰兰, 毛小南, 张英明, 侯志敏, 雷文光, 王 琛, 高 平. 电子束冷床炉单次熔炼钛合金铸锭研究进展[J]. 钛工业进展, 2009, 26(2): 14-18.

YU Lan-lan, MAO Xiao-nan, ZHANG Ying-ming, HOU Zhi-min, LEI Wen-guang, WANG Chen, GAO Ping. Development of electron-beam cold hearth single melt process for titanium alloy ingots [J]. Titanium Industry Progress, 2009, 26(2): 14-18.

[13] 陈 峰, 陈 丽, 国 斌, 彭 强, 郭盛祥, 毛玲玲. 电子束冷床熔炼的优与劣[J]. 中国有色金属学报, 2010, 20(S1): s873-s876.

CHEN Feng, CHEN Li, GUO Bin, PENG Qiang, GUO Sheng-xiang, MAO Ling-ling. Advantages and disadvantages of electron beam cold hearth melting [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s873-s876.

[14] 董洪波, 王高潮, 李爱萍. 时效温度对Ti-6Al-4V合金组织性能的影响[J]. 材料热处理学报, 2011, 32(1): 1-4.

DONG Hong-bo, WANG Gao-chao, LI Ai-ping. Effect of aging temperature on microstructure and properties of Ti-6Al-4V alloy [J]. Transactions of Materials and Heat Treatment, 2011, 32(1): 1-4.

[15] ZHUK H V, KOBRYN P A, SEMIATIN S L. Influence of heating and solidification conditions on the structure and surface quality of electron-beam melted Ti-6Al-4V ingots [J]. Journal of Materials Processing Technology, 2007, 190(1/2/3): 387-392.

[16] 王 国, 惠松骁, 叶文君, 米绪军. 固溶处理对Ti-3.0Al- 2.3Cr-1.3Fe钛合金组织与力学性能的影响[J]. 中国有色金属学报, 2012, 22(11): 3015-3021.

WANG Guo, HUI Songxiao, YE Wenjun, MI Xujun. Influence of solution treatment on microstructure and mechanical properties of Ti-3.0Al-2.3Cr-1.3Fe titanium alloy [J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3015-3021.

[17] 郑建民, 雷让歧. 轧制工艺对TC4合金板材组织性能的影响[J]. 钛工业进展, 2008, 25(4): 27-30.

ZHENG Jian-min, LEI Rang-qi. Effect of rolling process on microstructure and properties of TC4 sheets [J]. Titanium Industry Progress, 2008, 25(4): 27-30.

[18] 周 伟, 曲恒磊, 赵永庆, 李 辉, 冯 亮, 陈 军. TC4-DT合金不同热处理后的组织与性能[J]. 金属热处理, 2006, 31(6): 56-57.

ZHOU Wei, QU Heng-lei, ZHAO Yong-qing, LI Hui, FENG Liang, CHEN Jun. Microstructure and mechanical properties of TC4-DT alloy after different heat treatments [J]. Heat Treatment of Metal, 2006, 31(6): 56-57.

(编辑 杨幼平)

基金项目:国家高技术研究发展计划(“863”计划)项目(2013AA09A108)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:冯秋元,高级工程师,博士;电话:0917-3382271;E-mail:fengqiuyuan2003@163.com