文章编号:1004-0609(2016)-06-1228-07

Mg对真空压力浸渗SiCp/Al复合材料组织和性能的影响

陈以心,王日初,王小锋,彭超群,彭 健,孙月花

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用光学显微镜、X射线衍射仪和电子万能试验机等手段研究Mg含量对真空压力浸渗SiCp/Al复合材料组织和性能的影响。结果表明:Mg能提高Al合金的浸渗性能,Mg含量的增加使复合材料致密度升高。Mg促进SiC/Al界面反应的发生,当Mg含量为0~6%(质量分数)时,未观察到明显界面反应产物;当Mg含量为8%时,发生界面反应生成Mg2Si和Al4C3。当Mg含量为0~6%时,由于复合材料致密度的提高及Mg对Al基体的固溶强化作用,导致复合材料强度提高;当Mg含量为8%时,生成的Al4C3降低SiC/Al界面结合力,使复合材料强度下降。当Mg含量为0~4%时,致密度的提高使复合材料热导率上升;当Mg含量为4%~8%时,过量的Mg使Al基体热导率降低,Al4C3的生成使界面热传导受阻,导致复合材料热导率下降。

关键词:SiCp/Al复合材料;真空压力浸渗;显微组织;物相;力学性能;热导率

中图分类号:TG146 文献标志码:A

SiCp/Al复合材料具有热导率高、热膨胀系数可调、强度高和密度低等优点,且其热膨胀系数可通过改变SiC体积分数调节,从而与电子芯片基板热膨胀系数匹配[1]。因此,SiCp/Al复合材料作为新型电子封装用材料受到了广泛关注,在汽车、电子和航空航天等领域具有广阔的应用前景[2]。

合金成分对金属基复合材料的组织与性能有较大影响[3]。对于使用液相浸渗法制备的复合材料,这些影响不仅体现在界面反应、复合材料性能等方面,基体成分对浸渗过程也有影响[4]。向基体中添加合金元素,通过改变微观结构进而改善复合材料性能,是金属基复合材料研究中一种常用的手段[3]。WU等[5]采用挤压铸造法制备Al/金刚石复合材料,研究了Cu对复合材料界面和热物理性能的影响,发现基体中添加3%(质量分数)的Cu后复合材料的热导率从210 W/(m·K)提升至330 W/(m·K)。徐志锋等[6]的研究表明,在真空压力浸渗过程中,不同基体合金对连续SiCf/Al复合材料中的纤维损伤有明显差异,导致复合材料的微观组织及力学性能产生显著变化。对于使用无压浸渗法制备的SiCp/Al复合材料,Al-Mg系合金是一种常用的基体合金[7]。REN等[8]研究了Mg和Si对无压浸渗制备SiCp/Al复合材料的影响,其结果表明Al基体中Mg的添加有利于浸渗过程自发进行。关于合金元素对真空压力浸渗制备的SiCp/Al复合材料组织及性能的影响报导较少。刘玫潭等[9]仅对比了两种Al合金作为基体时相应复合材料的热物理性能。

本文作者选用Al-Mg系合金作为基体合金,通过模压成型和真空压力浸渗制备SiCp/Al复合材料,研究基体合金中Mg含量对复合材料的显微组织、界面反应、力学性能及热导率的影响。

1 实验

本试验中所用SiC颗粒平均粒径为4和51 μm,将粗细两种SiC颗粒按质量比2:1混合均匀后经模压成型并烧结制备预制块。浸渗用Al合金采用普通电阻炉熔铸,熔炼过程中通Ar保护,所用Al、Mg均为高纯铸锭。Al合金中Mg含量分别为0,2%,4%,6%和8%(质量分数,下同)。SiCp/Al复合材料采用真空压力浸渗法制备,其具体工艺参数为上室(预制块)温度650~670 ℃、下室(铝合金熔体)温度 700 ℃、浸渗压力2~4 MPa,保压15 min后随炉冷却。

SiCp/Al复合材料样品经电火花切割、磨样、抛光后,采用XJP-6A型金相显微镜观察复合材料组织。SiCp/Al复合材料及基体Al合金密度采用排水法测得,SiCp/Al复合材料的致密度由式(1)计算得出:

(1)

(1)

式中: 为SiCp/Al复合材料致密度;

为SiCp/Al复合材料致密度; 为SiCp/Al复合材料密度;

为SiCp/Al复合材料密度; 为SiC体积分数;

为SiC体积分数; 为SiC密度;

为SiC密度; 为Al基体体积分数;

为Al基体体积分数; 为基体Al合金密度(

为基体Al合金密度( =65%,

=65%,  =35%,

=35%,  =3.2 g/cm3)。采用Rigaku D/max 2500型X射线衍射分析仪(XRD)鉴定物相。样品经切割、机械打磨、凹坑及离子减薄后,采用Tecnai G2 20 ST透射电镜(TEM)观察显微组织,采用X射线能谱仪(EDS)分析成分。三点弯曲强度由CSS-44100型电子万能试验机测定,压头移动速率为0.5 mm/min,跨距为30 mm,弯曲试样尺寸为4 mm×3 mm×40 mm。采用FEI QUANTA-200型扫描电镜(SEM)观察断口形貌。采用JR-22型激光导热仪测定热扩散系数,试样尺寸为直径10 mm×3 mm,热导率根据测得的热扩散系数和比热容计算得出。

=3.2 g/cm3)。采用Rigaku D/max 2500型X射线衍射分析仪(XRD)鉴定物相。样品经切割、机械打磨、凹坑及离子减薄后,采用Tecnai G2 20 ST透射电镜(TEM)观察显微组织,采用X射线能谱仪(EDS)分析成分。三点弯曲强度由CSS-44100型电子万能试验机测定,压头移动速率为0.5 mm/min,跨距为30 mm,弯曲试样尺寸为4 mm×3 mm×40 mm。采用FEI QUANTA-200型扫描电镜(SEM)观察断口形貌。采用JR-22型激光导热仪测定热扩散系数,试样尺寸为直径10 mm×3 mm,热导率根据测得的热扩散系数和比热容计算得出。

2 结果与分析

2.1 SiCp/Al复合材料的金相组织及致密度

图1所示为采用不同Mg含量作为基体制备的SiCp/Al复合材料的金相照片。从图1可看出,粗SiC颗粒均匀分布于Al基体中,同时细SiC颗粒填充在粗SiC颗粒之间,提高了复合材料中的SiC体积分数。本研究中SiC体积分数为65%,高于由单一粒径SiC作为增强体制备的SiCp/Al复合材料[10]。图1(a)所示为基体中未添加Mg的SiCp/Al复合材料,此时可见明显孔隙(即图片中黑色区域);而从图1(c)可见,当Mg含量为4%时,照片中孔隙数目明显减少。复合材料致密度与基体中Mg含量关系见图2。当Mg含量从0%增加至4%时,致密度从91.1%提升至97.6%,这一阶段少量Mg含量的增加可有效提升复合材料致密度。但当Mg含量从4%增加至8%时,致密度仅从97.6%提升至98.2%,此时Mg含量的增加对复合材料致密度的提升作用变得不再显著。

图1 不同Mg含量SiCp/Al复合材料的金相组织

在真空压力浸渗过程中,忽略SiC表面吸附的气体和孔隙中气体受压缩后产生的反压力,浸渗过程可由Young-Laplace公式描述:

(2)

(2)

式中:ps为毛细管力; 为液-气表面张力;

为液-气表面张力; 为Al液与SiC颗粒润湿角;r为等效孔隙半径。当θ>90°时,毛细管力ps<0,此时毛细管力表现为阻力,需要对Al液施加大小为ps的压力才能使其渗入半径为r的孔隙中。HAN等[11]的研究表明,在650~960 ℃下,Al基体中含质量分数5%的Mg可将Al液与SiC颗粒润湿角降至90°以下,使浸渗变为自发过程;刘玫潭等[12]认为Al熔体中的Mg可降低Al液的表面张力。因此,在外加压力保持不变的前提下,

为Al液与SiC颗粒润湿角;r为等效孔隙半径。当θ>90°时,毛细管力ps<0,此时毛细管力表现为阻力,需要对Al液施加大小为ps的压力才能使其渗入半径为r的孔隙中。HAN等[11]的研究表明,在650~960 ℃下,Al基体中含质量分数5%的Mg可将Al液与SiC颗粒润湿角降至90°以下,使浸渗变为自发过程;刘玫潭等[12]认为Al熔体中的Mg可降低Al液的表面张力。因此,在外加压力保持不变的前提下, 与

与 的减少可使得Al液能渗入半径r更小的孔隙中,SiCp/Al复合材料致密度得到提高。然而,实际浸渗时Al液的流动过程还受粘滞阻力和摩擦力等因素的影响,因此通过液相浸渗法难以获得完全致密的SiCp/Al复合材料[13]。樊子民等[14]研究了Mg含量对无压浸渗制备SiCp/Al复合材料的影响,其研究表明随着Mg含量的增加,Al液在SiC预制块中的浸渗深度增加;当Mg含量达到10%后,Mg的增多不再影响Al液的浸渗深度。由于本研究的制备条件为真空压力浸渗,浸渗过程中气压远高于无压浸渗的气压,因此对Al液的浸润性要求有所降低,表现为添加少量Mg即可将SiCp/Al复合材料的致密度提升至较高水平。

的减少可使得Al液能渗入半径r更小的孔隙中,SiCp/Al复合材料致密度得到提高。然而,实际浸渗时Al液的流动过程还受粘滞阻力和摩擦力等因素的影响,因此通过液相浸渗法难以获得完全致密的SiCp/Al复合材料[13]。樊子民等[14]研究了Mg含量对无压浸渗制备SiCp/Al复合材料的影响,其研究表明随着Mg含量的增加,Al液在SiC预制块中的浸渗深度增加;当Mg含量达到10%后,Mg的增多不再影响Al液的浸渗深度。由于本研究的制备条件为真空压力浸渗,浸渗过程中气压远高于无压浸渗的气压,因此对Al液的浸润性要求有所降低,表现为添加少量Mg即可将SiCp/Al复合材料的致密度提升至较高水平。

图2 不同Mg含量SiCp/Al复合材料的致密度

2.2 SiCp/Al复合材料的物相分析

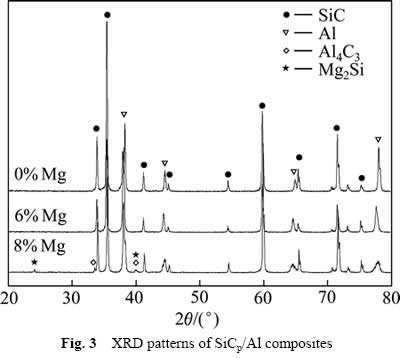

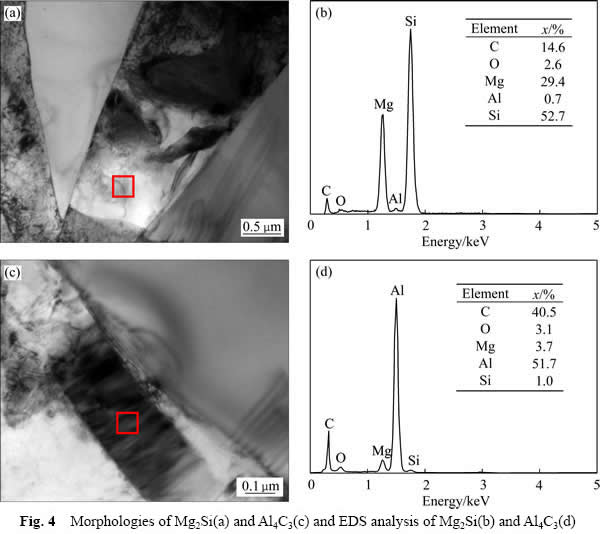

不同Mg含量SiCp/Al复合材料的XRD谱如图3所示。从图3可以看出,当基体中Mg含量为0和6%时,SiCp/Al复合材料XRD谱中仅可见SiC和Al衍射峰。复合材料中Al合金体积分数为35%,在XRD谱中未观察到Al-Mg金属间化合物。当Mg含量为8%时,可观察到Mg2Si和Al4C3衍射峰。此外,没有明显的Al2O3、MgO及MgAl2O4相衍射峰。为进一步确认Mg2Si和Al4C3相的存在,利用TEM观察SiC/Al界面附近形貌,并通过EDS测定相应组织成分。Mg2Si和Al4C3相形貌及其对应能谱如图4所示。

图3 SiCp/Al复合材料的XRD谱

Al4C3的形成由溶解-析出机制控制[15]。在熔融Al液中,SiC分解为C4-和Si4+。而C4-在Al液中溶解度极低,因此,SiC附近的C4-很快达到过饱和态。在能量起伏的作用下,发生反应生成Al4C3沉淀,其总反应式为[14]

4Al+3SiC→3Si+Al4C3 (3)

ROMERO等[16]研究了反应温度对Al4C3形成的影响,其Al基体为1100合金,将热压制备的SiCp/Al复合材料置于680℃下退火10 h,未观察到Al4C3的形成;而在700℃条件下,组织中出现层状Al4C3。ROMERO等[16]认为在680℃下,Al熔体中的Si在SiC/Al界面附近偏聚,导致Si浓度升高,反应(3)受到抑制。本研究中使用真空压力浸渗法制备SiCp/Al复合材料,其SiC预制块与Al合金加热温度均低于700 ℃,且SiC预制块与熔融Al液接触时间较短,Al4C3相的形成被抑制[13]。因此,本研究中以纯Al为基体制备的SiCp/Al复合材料中未出现Al4C3相。

图4 Mg2Si和Al4C3的形貌及能谱分析

然而,当Al基体中的Mg含量达到8%时,SiCp/Al复合材料样品中可检测到Al4C3相,此时Al4C3的形成与Mg2Si有关。溶解于Al熔体中的Si可与Mg反应[17]:

2Mg+SiC→Mg2Si (4)

该反应使SiC/Al界面附近的Si浓度下降,在Mg反应完全之前,Si无法产生偏聚,促进式(3)向正反应方向进行,生成Al4C3沉淀。此时SiC/Al界面总反应式为:

4Al+6Mg+3SiC→Al4C3+3Mg2Si (5)

由于本研究中仅在基体含8%Mg的SiCp/Al复合材料中检测到Mg2Si和Al4C3,因此,在真空压力浸渗制备工艺条件下,Mg浓度对反应(5)的发生有一定影响。

2.3 SiCp/Al复合材料的力学性能及热物理性能

Mg含量与SiCp/Al复合材料弯曲强度及热导率的关系如图5所示。当Al基体中不含Mg时,复合材料弯曲强度为406 MPa;随着Mg含量提升至6%,复合材料弯曲强度升高至446 MPa。当基体中Mg含量达到8%时,复合材料弯曲强度急剧下降至409 MPa。复合材料热导率随基体中Mg含量增加的变化趋势与强度随Mg含量增加的变化趋势类似,当Mg含量为4%时复合材料热导率达到本研究中最大值,当Mg含量超过4%之后,热导率随Mg含量的增加而下降。

图5 不同Mg含量SiCp/Al复合材料的弯曲强度及热导率

从图1(a)和(b)可知,SiCp/Al复合材料中尺寸较大的孔洞主要分布在SiC颗粒之间或SiC/Al界面附近。康炘蒙等[17]的研究表明,此类孔洞对复合材料的强度有较大影响。当基体中Mg含量为2%时,复合材料中仍存在较多孔洞,因此相对于基体中Mg含量为0%时,复合材料弯曲强度提升不显著。当基体中Mg含量为4%时,复合材料已经具有较高致密度,SiC颗粒之间和SiC/Al界面附近无明显孔洞(见图1(c)),因此其强度相对于基体中Mg含量为2%的复合材料有较大提高。而当基体中Mg含量从4%增加至6%时,复合材料致密度变化较小(见图2),因此弯曲强度提升较少。除了通过提高致密度间接影响SiCp/Al复合材料弯曲强度之外,添加Mg可通过固溶强化提高Al基体强度,从而使复合材料强度提高[7]。

当Al基体中Mg含量从6%提升至8%时,Al基体与SiC颗粒发生界面反应(式(5))使SiC颗粒表面部分溶解,导致SiC/Al界面结合能力减弱。此外Al4C3相可与潮湿空气中的水反应,导致复合材料强度下降,其反应式为[18]

Al4C3+12H2O→3CH4+4Al(OH)3 (6)

基体中Mg含量为6%和8%的复合材料断口形貌见图6。由图6(a)可知,当Mg含量为6%时,复合材料中的粗SiC颗粒被拉断,断裂的粗SiC颗粒仍镶嵌在Al基体中,未发现SiC被从基体中拔出形成的凹陷或凸起,断裂机理类似穿晶断裂。这表明此时SiC/Al界面结合状况良好,裂纹无法沿SiC/Al界面优先扩展,使得复合材料具有较高强度。而在图6(b)中,可见明显凹陷以及由细SiC颗粒和Al基体组成的粗糙平面。这是由于SiC/Al界面附近生成的Mg2Si和Al4C3相降低了界面结合力,裂纹得以优先沿界面扩展,导致部分粗SiC颗粒被从Al基体中整颗拔出,复合材料强度下降。

SiCp/Al复合材料中的孔洞除了影响其抗弯强度,还降低其热导率。复合材料热导率与孔率有如下关系[19]:

(7)

(7)

式中:Kc为包含孔洞的复合材料热导率;Km为完全致密复合材料热导率;Vp为复合材料孔率。在本研究中,当Al基体中Mg含量分别为0%和4%时,复合材料孔率分别为8.9%和2.4%,将其代入式(7),可得Kc/Km分别为0.87和0.96。因此,当基体中Mg含量从0%增加至4%时,随着复合材料致密度升高,其热导率得到较大提升。当基体中Mg含量为4%时,复合材料热导率已达完全致密时的96%,此时复合材料致密度的少量提升对其热导率的影响不再显著。由于纯Mg的热导率为156 W/(m·K),低于纯Al的热导率227 W/(m·K),因此,Al合金中的Mg含量增加将降低Al基体的热导率[20]。当SiCp/Al复合材料的致密度、相组成、SiC体积分数及SiC颗粒尺寸无明显变化时,Al基体热导率下降导致复合材料热导率降低[20]。此外,基体中Mg含量为8%时出现的Al4C3相会阻碍SiC/Al界面热传导过程,导致复合材料热导率下降[21]。基于上述原因,当Mg含量高于4%时,Mg含量的增加使复合材料热导率降低。

图6 SiCp/Al复合材料的SEM断口形貌

3 结论

1) Al基体中Mg的加入提高Al液的浸润性能。在真空压力浸渗条件下,SiCp/Al复合材料的致密度随Al基体中Mg含量的增加而升高,当Mg含量为8%时复合材料致密度为98.2%。

2) Al基体中Mg的加入促进SiC/Al界面反应的发生。当Mg含量为0~6%时,Al基体与SiC颗粒不反应;当Mg含量为8%时,Al基体与SiC颗粒反应生成Mg2Si和Al4C3。

3) SiCp/Al复合材料弯曲强度随Al基体中Mg含量增加先升高后降低。由于致密度的提高及Mg对Al基体的固溶强化作用,当基体中Mg含量为6%时,复合材料弯曲强度达到最大值446 MPa;当Mg含量为8%时,Al4C3的生成使SiC/Al界面结合能力减弱,复合材料弯曲强度下降至409 MPa。

4) SiCp/Al复合材料热导率随Al基体中Mg含量增加先升高后降低。孔隙的减少可提高复合材料热导率,但Mg的增加使得Al基体热导率下降,此外Al4C3的生成导致SiC/Al界面热传导受阻,使复合材料热导率下降。因此当基体中的Mg含量4%时,复合材料热导率达到最大值141 W/(m·K)。

REFERENCES

[1] 朱 敏, 孙忠新, 高 锋, 刘晓阳. 电子封装用金属基复合材料的研究现状[J]. 材料导报, 2013, 27(2): 181-183.

ZHU Min, SUN Zhong-xin, GAO Feng, LIU Xiao-yang. Research progress of composites for electronic packaging materials[J]. Materials Review, 2013, 27(2): 181-183.

[2] 张 强, 姜龙涛, 武高辉. 无压浸渗法制备氧化态SiC颗粒增强铝基复合材料[J]. 无机材料学报, 2012, 27(4): 353-357.

ZHANG Qiang, JIANG Long-tao, WU Gao-hui. Fabrication of oxidized SiC particles reinforced aluminum matrix composite by pressureless infiltration technique[J]. Journal of Inorganic Materials, 2012, 27(4): 353-357.

[3] 王西涛, 张 洋, 车子璠, 李建伟, 张海龙. 金刚石颗粒增强金属基高导热复合材料的研究进展[J]. 功能材料, 2014, 45(7): 7001-7015.

WANG Xi-tao, ZHANG Yang, CHE Zi-fan, LI Jian-wei, ZHANG Hai-long. Review on the progress of diamond particles dispersed metal matrix composites with superior high thermal conductivity[J]. Journal of Functional Materials, 2014, 45(7): 7001-7015.

[4] 熊德赣, 程 辉, 刘希从, 赵 恂, 鲍小恒, 杨盛良, 堵永国. AlSiC电子封装材料及构件研究进展[J]. 材料导报, 2006, 20(3): 111-115.

XIONG De-gan, CHENG Hui, LIU Xi-cong, ZHAN Xun, BAO Xiao-heng, YANG Sheng-liang, DU Yong-guo. Advances in research on aluminum silicon carbide electronic packaging composites and components[J].Materials Review, 2006, 20(3): 111-115.

[5] WU J, ZHANG H, ZHANG Y, LI J, WANG X. Effect of copper content on the thermal conductivity and thermal expansion of Al-Cu/diamond composites[J]. Materials & Design, 2012, 39: 87-92.

[6] 徐志锋, 徐燕杰, 余 欢, 王振军, 周珍珍. 基体合金对连续SiCf/Al复合材料显微组织及拉伸强度的影响[J]. 中国有色金属学报, 2015, 25(2): 392-400.

XU Zhi-feng, XU Yan-jie, YU Huan, Wang Zhen-jun, ZHOU Zhen-zhen. Effect of matrix alloy in microstructure and tensile strength of continuous SiCf/Al composite[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 392-400.

[7] BEFFORT O, LONG S,CAYRON C, KUEBLER J, BUFFAT P. Alloying effects on microstructure and mechanical properties of high volume fraction SiC-particle reinforced Al-MMCs made by squeeze casting infiltration[J]. Composites Science and Technology, 2007, 67(3): 737-745.

[8] REN S, SHEN X, QU X, HE X. Effect of Mg and Si on infiltration behavior of Al alloys pressureless infiltration into porous SiCp preforms[J]. International Journal of Minerals, Metallurgy, and Materials, 2011, 18(6): 703-708.

[9] 刘玫潭, 凌嘉辉, 刘家成, 洪晓松, 李国强. 电子封装用AlSiC复合材料热导率影响因素探讨[J]. 半导体光电, 2013, 34(5): 770-774.

LIU Mei-tan, LING Jia-hui, LIU Jia-cheng, HONG Xiao-song, LI Guo-qiang. Influencing factors of thermal conductivity of AlSiC composite[J]. Semiconductor Optoelectronics, 2013, 34(5): 770-774.

[10] MOLINA J M, SARAVANAN R A, ARPON R, CARCIA- CORDOVILLA C, LOUIS E, NARCISO J. Pressure infiltration of liquid aluminium into packed SiC particulate with a bimodal size distribution[J]. Acta Materialia, 2002, 50(2): 247-257.

[11] HAN D, JONES H, ATKINSON H V. The wettability of silicon carbide by liquid aluminium: the effect of free silicon in the carbide and of magnesium, silicon and copper alloy additions to the aluminium[J]. Journal of Materials Science, 1993, 28(10): 2654-2658.

[12] 刘玫潭, 蔡旭升, 李国强. 高性能SiC增强Al基复合材料的显微组织和热性能[J]. 中国有色金属学报, 2013, 23(4): 1040-1046.

LIU Meier-tan, CAI Xu-sheng, LI Guo-qiang. Microstructure and thermal properties of high-performance SiC reinforced Al matrix composite[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 1040-1046.

[13] 徐志锋, 余 欢, 蔡长春, 胡美忠, 严青松, 万 红, 郑玉惠. 真空变压力浸渗法制备高体积分数SiCp/Al复合材料[J]. 中国有色金属学报, 2006, 16(9): 1551-1557.

XU Zhi-feng, YU Huan, CAI Chang-chun, HU Mei-zhong, YAN Qing-song, WAN Hong, ZHENG Yu-hui. Preparation of high volume fraction SiCp/Al composites by vacuum adjustable pressure infiltration process[J]. The Chinese Journal of Nonferrous Metals,2006, 16(9): 1551-1557.

[14] 樊子民, 王晓刚, 田欣伟, 马宁强. SiC/Al基电子封装复合材料的无压浸渗法制备与热性能研究[J]. 铸造技术, 2009, 30(6): 741-744.

FAN Zi-ming, WANG Xiao-gang, TIAN Xin-wei, MA Ning-qiang. Pressureless infiltration and thermal-properties of SiC porous ceramics reinforced Al composites for electronic packaging[J]. Foundry Technology, 2009, 30(6): 741-744.

[15] REN S, HE X, QU X, HUMAIL S I, LI Y. Effect of Si addition to Al-8Mg alloy on the microstructure and thermo-physical properties of SiCp/Al composites prepared by pressureless infiltration[J]. Materials Science and Engineering B, 2007, 138(3): 263-270.

[16] ROMERO J C, ARSENAULT R J. Anomalous penetration of Al into SiC[J]. Acta Metallurgica et Materialia, 1995, 43(2): 849-857.

[17] 康炘蒙, 程小全, 郦正能, 张纪奎, 崔 岩. 微缺陷对高体积分数 SiCp/Al复合材料拉伸性能的影响[J]. 航空材料学报, 2009, 29(2): 85-91.

KANG Xin-meng, CHENG Xiao-quan, LI Zheng-neng, ZHANG Ji-kui, CUI Yan. Effect of microdefects on tensile properties of high volume fraction SiCp/Al composites[J]. Journal of Aeronautical Materials, 2009, 29(2): 85-91.

[18] PECH-CANUL M I, KATZ R N, MAKHLOUF M M, PICKARD S. The role of silicon in wetting and pressureless infiltration of SiCp preforms by aluminum alloys[J]. Journal of Materials Science, 2000, 35(9): 2167-2173.

[19] SHEN X, REN S, HE X, QIN M, QU X. Study on methods to strengthen SiC preforms for SiCp/Al composites by pressureless infiltration[J]. Journal of Alloys and Compounds, 2009, 468(1): 158-163.

[20] 邹爱华. 电子封装SiCp/Al复合材料热导率研究[D]. 南昌: 南昌航空大学, 2007: 44-45.

ZOU Ai-hua. Study on thermal conductivity of Electronic packaging SiCp/Al composites[D]. Nanchang: Nanchang Hangkong University, 2007: 44-45.

[21] KAWAI C. Effect of interfacial reaction on the thermal conductivity of Al-SiC composites with SiC dispersions[J]. Journal of the American Ceramic Society, 2001, 84(4): 896-898.

Effects of Mg on microstructures and properties of SiCp/Al composites prepared by vacuum pressure infiltration

CHEN Yi-xin, WANG Ri-chu, WANG Xiao-feng, PENG Chao-qun, PENG Jian, SUN Yue-hua

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effect of Mg content on the microstructures and properties of SiCp/Al composites prepared by vacuum pressure infiltration was investigated by optical microscopy, X-ray diffractometer and electronic universal testing machine. The results reveal that the addition of Mg enhances the infiltration ability of Al matrix, leading to the increase of relative densities of composites. The addition of Mg promotes the SiC/Al interface reactions, no obvious reaction products are observed when Mg content is 0-6% (mass fraction), while both Mg2Si and Al4C3 form at Mg content of 8%. The strength of composites increases with the increasing content of Mg when Mg content is among 0-6%, due to the increase of relative densities and strengthening of Al matrix by solid solution hardening. When Mg content is 8%, the formation of Al4C3 leads to the decrease the bonding strength of SiC/Al interfaces, undermining the bonding strength of composites. The thermal conductivity of composites increases with the increasing Mg content when Mg content is 0-4%, because of the increases of relative densities. When Mg content is 4-8%, the thermal conductivity of composites decreases as Mg content increases. It is explained by the combined action of excessive Mg undermining the thermal conductivity of Al matrix and Al4C3 weakening the heat transfer of interfaces.

Key words: SiCp/Al composite; vacuum pressure infiltration; microstructure; phase; mechanical property; thermal conductivity

Foundation item: Project(51202296) supported by the National Natural Science Foundation of China; Project (20120162120006) supported by the Research Fund for the Doctoral Program of Higher Education of China

Received date: 2015-07-30; Accepted date: 2016-01-15

Corresponding author: WANG Xiao-feng; Tel: +86-731-88886638; E-mail: 13467516329@163.com

(编辑 龙怀中)

基金项目:国家青年自然科学基金资助项目(51202296);高等学校博士学科点专项科研基金资助项目(20120162120006)

收稿日期:2015-07-30;修订日期:2016-01-15

通信作者:王小锋,博士,副教授;电话:0731-88886638;E-mail: 13467516329@163.com