DOI:10.19476/j.ysxb.1004.0609.2018.12.15

SiC颗粒级配对SiCp/Al复合材料微观结构和性能的影响

王武杰1,洪 雨2,刘家琴1, 3, 4,吴玉程1, 2, 3, 4

(1. 合肥工业大学 工业与装备技术研究院,合肥 230009;

2. 合肥工业大学 材料科学与工程学院,合肥 230009;

3. 有色金属与加工技术国家地方联合工程研究中心,合肥 230009;

4. 安徽省有色金属材料与加工工程实验室,合肥 230009)

摘 要:采用放电等离子烧结技术制备高体积分数SiCp/Al复合材料,研究SiC颗粒级配对复合材料微观结构、热和力学性能的影响。结果表明:放电等离子烧结制备的SiCp/Al复合材料由SiC和Al两相组成,SiC颗粒基本呈均匀随机分布、层次明显,SiC颗粒与Al基体界面结合强度高且无Al4C3等脆性相生成。在双粒径级配的SiCp/Al复合材料中,SiC体积分数从50%增加到65%时,其相对密度从99.93%下降到96.40%;其中,当SiC体积分数为60%时,复合材料的相对密度、热导率、平均热膨胀系数(50~400 ℃)和抗弯强度分别为99.19%、227.5 W/(m·K)、9.77×10-6 K-1和364.7 MPa。

关键词:SiCp/Al复合材料;放电等离子烧结;颗粒级配;热导率;热膨胀系数;抗弯强度

文章编号:1004-0609(2018)-12-2523-08 中图分类号:TG146 文献标志码:A

近年来,随着电子器件功率密度不断增加及其尺寸不断减小,传统的电子封装材料,例如W-Cu、AlN和Kovar合金等,已经不能满足高热耗散和低热应力的要求,发展具有高导热、可剪裁热膨胀的高性能电子封装材料的需求变得越来越紧迫[1-4]。高体积分数SiCp/Al复合材料作为一种新型电子封装材料,可通过复合材料组分设计以满足电子封装材料低密度、高强度、高热导率(Thermal conductivity,TC)、低热膨胀系数(Thermal expansion coefficient,CTE)的要求,SiCp/Al复合材料的应具有高TC(150~200 W/(m·K))和低CTE(6×10-6~10×10-6 K-1),抗弯强度大于310 MPa,密度在3.0 g/cm3左右,因而用作新型电子封装材料拥有广阔的应用前景[5-6]。

在制备高体积分数SiCp/Al复合材料过程中,SiC颗粒与熔融Al的润湿性较差,增加温度可在一定程度上改善Al-SiC的润湿性,但也会生成脆性相和水解相Al4C3[7]。因此,如何抑制复合材料中界面反应的发生,成为制备高性能SiCp/Al复合材料过程中一个至关重要的问题。采用无压浸渗法时需要对颗粒表面进行处理或者在基体合金中添加额外的Si或Mg抑制有害的界面反应[8-9],工艺复杂且生产效率低。粉末冶金法是一种低成本、高效率制备SiCp/Al复合材料方法,可通过合理的制备工艺和颗粒级配,制备出组织致密、SiC体积分数超过60%的复合材料。其中,放电等离子烧结(Spark plasma sintering,SPS)是一种制备高性能、高体积分数SiCp/Al复合材料的快速烧结技术,该技术烧结温度低、升温速度快、烧结时间短、生产效率高,能够有效抑制界面反应的发生[10-13]。

本文采用SPS制备高体积分数SiCp/Al复合材料,探究SiC颗粒级配对复合材料的微观结构、热性能和力学性能的影响。通过采用SPS成功地制备出致密的高体积分数SiCp/Al复合材料,同时抑制Al4C3等脆性相在Al-SiC界面处的生成。本研究结果对于高性能SiCp/Al复合材料的颗粒级配具有重要的指导意义。

1 实验

1.1 材料制备

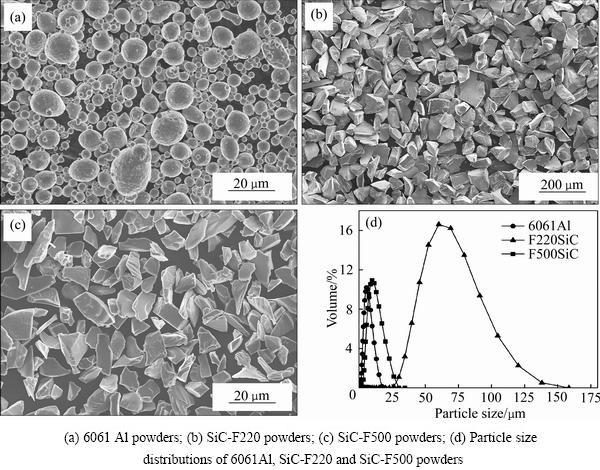

复合材料的基体为6061Al合金粉末,平均粒径为8 μm,纯度>99.9%;增强体为F220-SiC和F500-SiC两种SiC颗粒,平均粒径分别为76 μm和16 μm,纯度>99%。F220-SiC颗粒被用来制备单粒径复合材 料,其中SiC体积分数为40%~60%;F220/F500-SiC混合颗粒被用来制备双粒径级配复合材料,其中SiC体积分数为50%~65%,F220与F500质量比3:1;并对单粒径和双粒径级配的样品进行标记,例如M-50%-SiCp/Al、M-60%-SiCp/Al和B-50%-SiCp/Al、B-60%-SiCp/Al等。采用机械混料的方式把SiC颗粒与6061Al合金粉末充分混合均匀,将混合均匀的粉末装入石墨模具放置于放电等离子快速烧结炉,在真空条件下进行烧结。烧结工艺参数为:烧结温度520 ℃,升温速度50 ℃/min,烧结压力50 MPa,保温时间8 min。

1.2 分析测试

使用MS-2000型激光粒度分析仪测量6061Al合金粉末和SiC颗粒的粒度分布。采用阿基米德排水法测试试样的相对密度。使用ZEISS Axio Lab.A1显微镜观察试样的显微组织,利用SU8020冷场发射扫描电子显微镜观察试样的断口形貌,用X'Pert PRO MPD射线衍射仪分析试样的物相组成。采用LFA457激光导热仪测试材料的热扩散系数,样品尺寸为12.7 mm×3.0 mm,测试温度为室温。使用TMA402F3型热机械分析仪测量CTE,样品尺寸为3 mm×4 mm× 12 mm,测量温度范围为25~400 ℃,升温速率为5 ℃/min,为防止样品氧化,整个测试过程中通入氮气保护。采用SHIMADZU AG-X plus型电子万能试验机测试复合材料的抗弯强度,样品尺寸为3 mm×3 mm×20 mm,跨距为15 mm,加载速率为0.5 mm/min。

2 结果与分析

2.1 复合材料的相对密度与显微组织

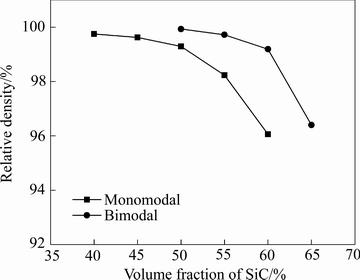

图2所示为SiCp/Al复合材料相对密度随SiC体积分数变化曲线。可以看出,在单粒径复合材料中,当SiC颗粒体积分数在40%~50%之间时,其相对密度高于99%。进一步增加SiC颗粒体积分数时,相对密度迅速下降,当SiC体积分数为60%,复合材料的相对密度仅为96.06%。在双粒径级配复合材料中,复合材料的相对密度随体积分数的变化趋势与单粒径复合材料的相对密度变化趋势相同。当采用双粒径SiC颗粒级配时,细SiC颗粒填充到粗SiC颗粒形成的空隙中,有效增加了混合粉末的松装密度,再与Al合金粉混合后烧结,大大提高了复合材料的致密度,使得SiC颗粒体积分数为60%,其相对密度达到99.19%。

图1 原材料颗粒的SEM像

Fig. 1 SEM images of raw material particles

图2 SiCp/Al复合材料相对密度随SiC体积分数变化曲线

Fig. 2 Relationships between relative density and SiCp/Al composites with different volume fractions of SiC

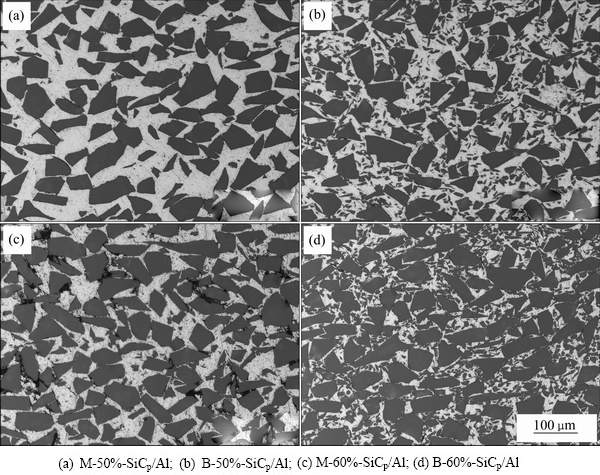

图3所示为不同SiC体积分数的SiCp/Al复合材料的显微照片,图中浅灰色相为Al相,深灰色相为SiC相。当复合材料中SiC体积分数为50%时,M-50%-SiCp/Al复合材料的组织致密、均匀,SiC颗粒呈不规则多边形,界面较为平整,颗粒与基体结合较好,无明显的杂质颗粒,Al连续地包覆在SiC颗粒的周围,没有明显的孔洞等缺陷(见图3(a))。在B-50%-SiCp/Al复合材料中,两种SiC颗粒基本呈均匀随机分布且层次明显,不存在SiC颗粒的偏聚区和贫化区(见图3(b))。在烧结之前,M-60%-SiCp/Al复合材料,粗SiC颗粒形成较大的孔隙,只有部分孔隙被铝合金颗粒填充;而B-60%-SiCp/Al复合材料中含有两种SiC颗粒,细SiC颗粒和铝合金颗粒均匀地填充在粗颗粒的间隙中。因此B-60%-SiCp/Al复合材料拥有较高的松装密度。在烧结过程中,M-60%-SiCp/Al复合材料中粗SiC颗粒表面不规则,颗粒间存在着摩擦力;在烧结压力的作用下,并不能明显地提升其致密度,且基体在孔隙中分布不均匀,部分孔隙不能被熔融的基体填充(见图3(c))。而B-60%-SiCp/Al复合材料中细SiC颗粒和铝合金颗粒共同填充在粗颗粒的间隙中且分布均匀;在加压烧结时,铝合金颗粒熔化并填充在粗/细SiC颗粒的间隙中,烧结之后复合材料拥有较高的致密度(见图3(d))。复合材料致密无孔隙的微观组织、相互连通的Al基体和干净平整无有害界面反应的界面都有助于获得优异的热性能和力学性能。

图3 SiCp/Al复合材料的金相组织

Fig. 3 Metallographs of SiCp/Al composites with different volume fractions of SiC

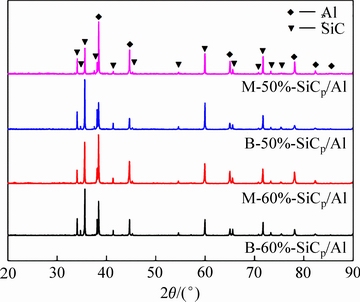

2.2 复合材料的物相分析

在放电等离子烧结过程中,SiC和Al颗粒的烧结过程受到焦耳热、颗粒间放电和垂直单向压力的共同作用,使蒸发-凝固、体积扩散等过程得到加强,加速了烧结致密化过程,因此降低了SiC颗粒和熔融Al的接触温度和接触时间,抑制有害界面发生[9, 14],例如Al4C3脆性相[11-13, 15]等。图4所示为不同SiC体积分数的SiCp/Al复合材料的XRD谱,复合材料中主要为SiC和Al相,没有出现Al4C3等脆性相。另外,没有可检测量的杂质,例如Al2O3、SiO2等,说明本实验使用的SPS烧结工艺适合制备高体积分数SiCp/Al复合材料。

图4 不同SiC体积分数SiCp/Al复合材料的XRD谱

Fig. 4 XRD patterns of SiCp/Al composites with different volume fractions of SiC

2.3 复合材料的热膨胀性能

电子封装材料要求与芯片具有相近的热膨胀系数,以减少芯片与其封装外壳间的热应力,一般要求电子封装材料的CTE值在(6~10)×10-6 K-1。Turner和Kerner分别提出计算复合材料的CTE的理论模型[16-17]。

Turner模型:假设材料内部无内应力存在且材料能协调变形,交变温度场内,忽略空隙和微裂纹的产生,材料内部产生所有的附加应力为张应力和压应力,计算公式为

(1)

(1)

Kerner模型:假设增强体为球形,基体均匀的包覆在增强体的表面,且考虑到复合材料的各相中存在的剪切应力和正应力的影响,计算公式为

(2)

(2)

(3)

(3)

(4)

(4)

式中: 、

、 和

和 分别是复合材料、增强体和基体CTE (SiC,4.5×10-6 K-1;Al,24×10-6 K-1);Vd、Vm分别是增强体和基体的体积;Kd、Km分别是增强体和基体的体积模量(SiC,2.22×1011 Pa;Al,6.76×1010 Pa);Gm是基体的剪切模量(4.1×1010 Pa)。

分别是复合材料、增强体和基体CTE (SiC,4.5×10-6 K-1;Al,24×10-6 K-1);Vd、Vm分别是增强体和基体的体积;Kd、Km分别是增强体和基体的体积模量(SiC,2.22×1011 Pa;Al,6.76×1010 Pa);Gm是基体的剪切模量(4.1×1010 Pa)。

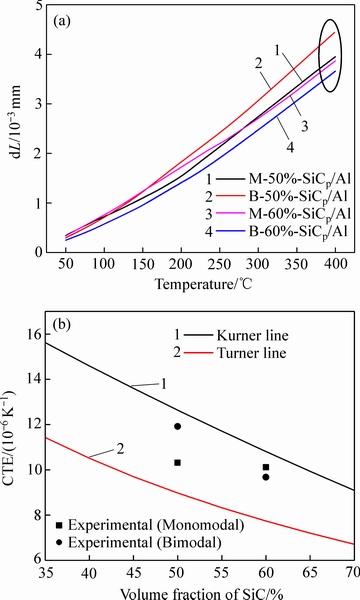

图5 SiCp/Al复合材料伸长量随温度的变化曲线以及SiCp/Al复合材料平均CTE(50~400 ℃)与Kurner和Turner理论计算结果比较

Fig. 5 Relationships between elongation of SiCp/Al composites with different volume fractions of SiC and temperatures(a) and comparison of CTEs predicted theoretically using Turner and Kerner model for SiCp/Al composites with different volume fractions of SiC(b)

图5(a)所示为SiCp/Al复合材料的伸长量随温度的变化曲线。由图5(a)可见,SiCp/Al复合材料伸长量随温度升高逐渐增大。主要原因如下:1) Al基体的CTE随温度升高而增大,导致复合材料的伸长量也随温度升高而增大;2) 当复合材料的测试温度升高后,增强体与基体之间的界面逐渐被破坏,增强体对铝基体膨胀的制约能力减弱,以及复合材料中的残余应力逐渐消除,因此SiCp/Al复合材料的伸长量随温度升高而增大[18-19]。图5(b)所示为SiCp/Al复合材料的平均CTE(50~400 ℃)实验结果与Turner和Kurner理论计算结果比较。M-50%-SiCp/Al复合材料在50~400 ℃的平均CTE为10.3×10-6 K-1略高于M-60%-SiCp/Al复合材料的平均CTE(10.1×10-6 K-1),其原因是M-60%-SiCp/Al复合材料中含SiC体积分数较高,使得复合材料的CTE降低;然而M-60%-SiCp/Al复合材料致密度较低、界面结合较差,制约基体膨胀的能力较弱。因此,在单粒径SiCp/Al复合材料中增加SiC体积分数,其平均CTE略微降低。在相同SiC体积分数的复合材料中,B-50%-SiCp/Al复合材料中SiC颗粒之间的间距减小,严重阻碍位错滑移,使复合材料中仍然保留较高密度位错,相应的内应力较大,从而使材料中原子能量变高,在同等温度下原子活动能力相应更高,其CTE更大[20]。在双粒径SiCp/Al复合材料中,B-50%-SiCp/Al和B-60%-SiCp/Al复合材料的致密度均高于99%,可忽略孔隙对CTE的影响,因此增加SiC体积分数较高可显著降低复合材料的CTE[21],其中B-60%-SiCp/Al复合材料的平均CTE为9.77×10-6 K-1。

由图5(b)可知,实验测得平均CTE介于Turner和Kerner模型的预测值之间。由于Kerner模型中使用增强体是理想的球形而非多边不规则形,在膨胀过程中不规则形SiC颗粒对Al基体膨胀有更强的约束作用,导致实验值低于Kerner模型的预测值。SiCp/Al复合材料内部含有残余应力和少量孔隙,以及基体和增强体在受热膨胀过程中不能协调变形,导致复合材料的CTE高于Turner模型的预测值。

2.4 复合材料的热导率

SiCp/Al复合材料热导率的计算公式如下[22]:

(5)

(5)

式中: 为复合材料热导率(W/(m·K));

为复合材料热导率(W/(m·K)); 、

、 和cp分别为复合材料的热扩散系数(m2/s)、密度(g/cm3)和定压比热容(J/(kg·K))。

和cp分别为复合材料的热扩散系数(m2/s)、密度(g/cm3)和定压比热容(J/(kg·K))。

Euchen假设SiC颗粒与铝基体之间界面结合良好,界面热导(hc)趋于无穷大,在Hasselman-Johnson理论模型的基础上,提出Maxwell-Euchen简化计算模型[23],计算公式为

(6)

(6)

式中:Kc、Kd和Km分别表示复合材料、增强体和基体合金的热导率;Vd为增强体的体积分数。其中6061Al基体合金热导率Km为180 W/(m·K),增强体SiC的热导率Kd为330 W/(m·K)。

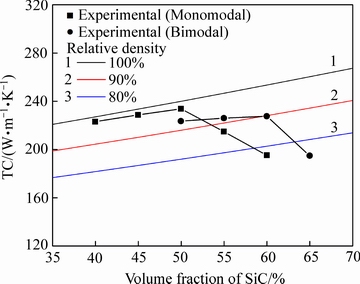

图6所示为不同相对密度的SiCp/Al复合材料热导率随SiC体积分数的变化及其与Maxwell-Euchen理论计算结果的对比。由图6可知,SiCp/Al复合材料的热导率随着SiC体积分数的增加先上升后迅速下降。当复合材料的相对密度高于99%,可忽略孔隙和界面对自由电子和声子的散射作用。因此,当增加SiC的体积分数时,复合材料的热导率增加;当复合材料的相对密度低于99%时,复合材料中孔隙和界面热阻对自由电子和声子的散射作用增加,降低了材料的导热性能[24]。

图6 不同相对密度SiCp/Al复合材料的热导率随SiC体积分数的变化及其Maxwell-Euchen理论计算结果的比较

Fig. 6 Comparison of changing curves of thermal conductivity with volume fraction of SiC for SiCp/Al composites with different relative density by experimental and Maxwell-Euchen model

当单粒径SiCp/Al复合材料中SiC体积分数为40%~50%时,其TC接近Maxwell-Euchen预测值的100%,其中M-50%-SiCp/Al复合材料的TC为233.6 W/(m·K),因此,可以推断SiC-Al界面结合良好,界面热阻较低。然而,B-50%-SiCp/Al复合材料的TC略低于M-50%-SiCp/Al复合材料的TC,其相对密度均高于99%,主要原因是B-50%-SiCp/Al复合材料中含有部分细颗粒,细颗粒的引入增大了SiC-Al界面面积,导致复合材料中界面热阻增加,降低了复合材料整体的TC[25]。因此,当双粒径SiCp/Al复合材料中SiC的体积分数为50%~60%时,其TC略高于Maxwell- Euchen预测值的TC,B-60%-SiCp/Al复合材料的TC为227.5 W/(m·K),高于M-50%-SiCp/Al复合材料的TC。在M-60%-SiCp/Al和B-65%-SiCp/Al复合材料的大量孔隙以及弱结合界面,使其TC低于Maxwell- Euchen预测值的80%。

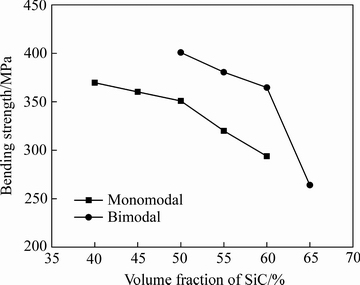

2.5 力学性能与断口形貌分析

图7所示为SiCp/Al复合材料的抗弯强度随SiC体积分数的变化曲线。由图7可以看出,SiCp/Al复合材料的抗弯强度随SiC体积分数的增加逐渐降低,复合材料的抗弯强度均在260 MPa以上,最高可达400 MPa。SiCp/Al复合材料的抗弯强度受到颗粒体积分数、大小、形状、界面结合程度、缺陷含量等因素的共同影响。因此,虽然随着SiC体积分数的增加,复合材料中有效承载增多,有利于提高复合材料抗弯强度;但是复合材料的致密度降低、界面结合减弱、缺陷含量增加,其弱化抗弯强度的作用强于SiC颗粒提高抗弯强度的作用,使得复合材料在低应力状态下断裂,抗弯强度逐渐降低。

图7 不同体积分数SiCp/Al复合材料的抗弯强度

Fig. 7 Bending strengths of SiCp/Al composites of different volume fractions of SiC

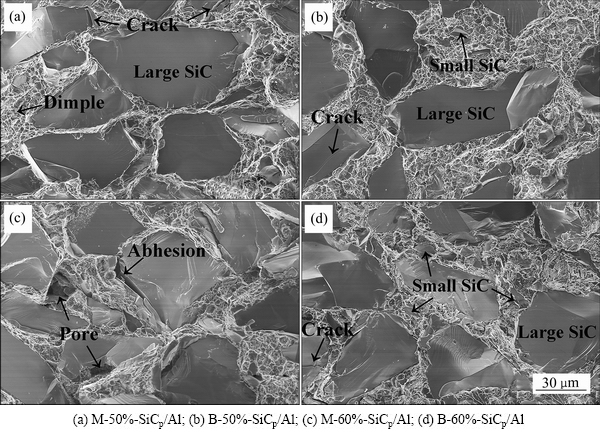

当SiCp/Al复合材料中含相同SiC体积分数时,双粒径SiCp/Al复合材料的抗弯强度高于单粒径复合材料的抗弯强度。一方面,粗颗粒SiC自身缺陷较多且界面面积较大,达到抗弯强度之前,复合材料中粗颗粒的增强体内部已经出现微裂纹(见图8),导致裂纹的扩展并减弱增强体有效承载能力,最终使复合材料在低应力状态下断裂。另一方面,在复合材料中适当添加部分细SiC颗粒,因其自身缺陷较少且界面面积较小而不易产生裂纹,在承受载荷时,故应力能够有效地通过界面由基体向细颗粒增强体上传递。因此,复合材料含相同体积分数的SiC颗粒时,采用颗粒级配增强的复合材料的抗弯强度高于单颗粒增强的复合材料的抗弯强度。

图8 SiCp/Al复合材料的断口形貌

Fig. 8 SEM fractographs of SiCp/Al composites

图8所示为SiCp/Al复合材料的断口形貌。由图8(a)可以看出,复合材料中SiC颗粒解理断裂特征明显,可以看到SiC断裂表面上河流花样、断裂条纹和断裂台阶;Al基体中出现明显的韧窝和撕裂棱,没有出现SiC颗粒拔出或脱粘的现象,SiC-Al界面为强结合界面。由此可以推断得出,SiCp/Al复合材料的断裂类型为基体合金的韧性断裂和增强体颗粒的脆性断裂共存的混合断裂。然而在M-60%-SiCp/Al复合材料的断口表面(见图8(c)),出现未被Al基体填充的孔隙及SiC颗粒与Al基体的脱粘。当细SiC颗粒加入复合材料时(见图8(b)和8(d)),其分布于粗SiC颗粒的间隙中,断裂方式仍为解理断裂,细颗粒的加入使复合材料有效承载面积变大,因此增加了复合材料的抗弯强度。

3 结论

1) 采用放电等离子烧结技术成功制备出高体积分数SiCp/Al复合材料,在单粒径SiCp/Al复合材料中SiC颗粒均匀分布在Al基体中。在双粒径SiCp/Al复合材料中细颗粒SiC填充在粗颗粒SiC形成的孔隙中,SiC颗粒基本呈均匀随机分布且层次明显。

2) SiCp/Al复合材料中主要为SiC和Al相,SiC颗粒与Al基体界面强度高,且无Al4C3等脆性相生成。

3) M-50%-SiCp/Al复合材料的相对密度为99.29%,平均热膨胀系数(50~400℃)为10.3×10-6 K-1,热导率为233.6 W/(m·K),抗弯强度为350.8 MPa。B-60%-SiCp/Al复合材料的相对密度为99.19%,平均热膨胀系数(50~400℃)为9.77×10-6 K-1,热导率为227.5 W/(m·K),抗弯强度为364.7 MPa。表现出了良好的性能,满足电子封装材料的要求。

REFERENCES

[1] TENG Fei, YU Kun, LUO Jie, FANG Hong-jie, SHI Chun-li, DAI Yi-long, XIONG Han-qing. Microstructures and properties of Al-50%SiC composites for electronic packaging applications[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(10): 2647-2652.

[2] ZHU Xiao-min, YU Jia-kang, WANG Xin-yu. Microstructure and properties of Al/Si/SiC composites for electronic packaging[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(7): 1686-1692.

[3] MOLINA J M, SARAVANAN R A, ARPON R, GARCI?A-CORDOVILLA C, LOUIS E, NARCISO J. Pressure infiltration of liquid aluminum into packed SiC particulate with a bimodal size distribution[J]. Acta Materialia, 2002, 50(2): 247-257.

[4] MOLINA J M, NARCISO J, WEBER L, MORTENSEN A, LOUIS E. Thermal conductivity of Al-SiC composites with monomodal and bimodal particle size distribution[J]. Materials Science and Engineering A, 2008, 480(1/2): 483-488.

[5] MONTOYA-DAVILA M, PECH-CANUL M A, PECH-CANUL M I. Effect of bi-and trimodal size distribution on the superficial hardness of Al/SiCp composites prepared by pressureless infiltration[J]. Powder Technology, 2007, 176(2/3): 66-71.

[6] CHU Ke, JIA Cheng-chang, TIAN Wen-huai, LIANG Xue-bing, CHEN Hui, GUO Hong. Thermal conductivity of spark plasma sintering consolidated SiCp/Al composites containing pores: Numerical study and experimental validation[J]. Composites A, 2010, 41(1): 161-167.

[7] SHEN Ping, WANG Yi, REN Li-hua, LI Shi-xin, LIU Yu-hua, JIANG Qi-chuan. Influence of SiC surface polarity on the wettability and reactivity in an Al/SiC system[J]. Applied Surface Science, 2015, 355: 930-938.

[8] TAN Zhan-qiu, LI Zhi-qiang, FAN Gen-lian, KAI Xi-zhou, JI Gang, ZHANG Lan-ting, ZHANG Di. Fabrication of diamond/aluminum composites by vacuum hot pressing: Process optimization and thermal properties[J]. Composites B, 2013, 47(47): 173-180.

[9] MIZUUCHI K, INOUE K, AGARI Y, NAGAOKA T, SUGIOKA M, TANAKA M, TAKEUCHI T, TANI J, KAWAHARA M, MAKINO Y, ITO M. Processing of Al/SiC composites in continuous solid-liquid co-existent state by SPS and their thermal properties[J]. Composites B, 2012, 43(4): 2012-2019.

[10] 杨俊逸, 李小强, 郭亮, 陈维平, 李元元. 放电等离子烧结(SPS)技术与新材料研究[J]. 材料导报, 2006, 20(6): 94-97.

YANG Jun-yi, LI Xiao-qiang, GUO Liang, CHEN Wei-ping, LI Yuan-yuan. Spark plasma sintering technology and its application in preparation of advanced materials[J]. Materials Review, 2006, 20(6): 94-97.

[11] 尹法章, 郭 宏, 贾成厂, 张习敏, 张永忠. 放电等离子烧结制备高导热SiCp/Al电子封装材料[J]. 复合材料学报, 2010, 27(1): 57-61.

YIN Fa-zhang, GUO Hong, JIA Cheng-chang, ZHANG Xi-min, ZHANG Yong-zhong. High thermal conductivity SiCp/Al electronic packaging materials prepared by spark plasma sintering[J]. Acta Materiae Compositae Sinica, 2010, 27(1): 57-61.

[12] CHEN W, ANSELMI-TAMBURINI U, GARAY J E, GROZA J R, MUNIR Z A. Fundamental investigations on the spark plasma sintering/synthesis process: I. Effect of dc pulsing on reactivity[J]. Materials Science & Engineering A, 2005, 394(1/2): 132-138.

[13] HONG Chang-qing, ZHANG Xing-hong, LI Wei-jie, HAN Jie-cai, MENG Song-he. A novel functionally graded material in the ZrB2-SiC and ZrO2, system by spark plasma sintering[J]. Materials Science and Engineering A, 2008, 498(1/2): 437-441.

[14] TOKITA M. Trends in advanced SPS spark plasma sintering systems and technology[J]. Journal of the Research Association of Powder Technology Japan, 1993, 30: 790-804.

[15] FERRO A C, DERBY B. Wetting behaviour in the Al-Si/SiC system: interface reactions and solubility effects[J]. Acta Metallurgica Et Materialia, 1995, 43(8): 3061-3073.

[16] TURNER P S. Thermal expansion stresses in reinforced plastics[J]. J Res NBS, 1946, 37: 239-350.

[17] KERNER E H. The elastic and thermoplastic properties of composite media[J]. Proceedings of the Physical Society, 1956, B69: 808-813.

[18] 李进军, 于家康. 电子封装用SiCp/Al复合材料的热膨胀性 能[J]. 热加工工艺, 2007, 36(6): 1-3.

LI Jin-jun, YU Jia-kang. Thermal expansion properties of silicon carbide particle reinforced aluminum composite[J]. Hot Working Technology, 2007, 36(6): 1-3.

[19] WANG Dong-mei, ZHENG Zhi-xiang, L? Jun, XU Guang-qing, ZHOU Shiang, TANG Wen-ming, WU Yu-cheng. Enhanced thermal conductive 3D-SiC/Al-Si-Mg interpenetrating composites fabricated by pressureless infiltration[J]. Ceramics International, 2017, 43(2): 1755-1761.

[20] 杨梅君. SiCp/Al电子封装复合材料的SPS烧结及性能研究[D]. 武汉: 武汉理工大学, 2006: 1-68.

YANG Mei-jun. Fabrication and properties of SiCp/Al electrical packaging composites by spark plasma sintering[D]. Wuhan: Wuhan University of Technology, 2006: 1-68.

[21] 王 涛. 高体积分数SiC/Al电子封装材料的制备及性能研 究[J]. 硅酸盐通报, 2013, 32(3): 000457-460.

Wang Tao. Fabrication and properties study of high fractional SiC/Al electronic packaging composite[J]. Bulletin of The Chinese Ceramic Society, 2013, 32(3): 000457-460.

[22] KIM Y M, CHOI S W, HONG S K. The behavior of thermal diffusivity change according to the heat treatment in Al-Si binary system[J]. Journal of Alloys & Compounds, 2016, 687: 54-58.

[23] EUCKEN A. Heat transfer in ceramic refractory materials: Calculation from thermal conductivities of constituents[J]. Fortchg Gebiete Ingenieurw, B3, Forschungsheft, 1932, 16: 353-360.

[24] KUMARI L, ZHANG T, DU G H, LI W Z, WANG Q W, DATYE A, WU K H. Thermal properties of CNT-Alumina nanocomposites[J]. Composites Science & Technology, 2008, 68(9): 2178-2183.

[25] TAN Zhan-qiu, CHEN Zhi-zhong, FAN Gen-lian, JI Gang, ZHANG Jie, XU Run, SHAN Ai-dang, LI Zhi-qiang, ZHANG Di. Effect of particle size on the thermal and mechanical properties of aluminum composites reinforced with SiC and diamond[J]. Materials and Design, 2016, 90: 845-851.

Effect of SiC grain gradation on microstructure and performance of SiCp/Al composite

WANG Wu-jie1, HONG Yu2, LIU Jia-qin1, 3, 4, WU Yu-cheng1, 2, 3, 4

(1. Institute of Industry & Equipment Technology, Hefei University of Technology, Hefei 230009, China;

2. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China;

3. National-Local Joint Engineering Research Centre of Nonferrous Metals and Processing Technology, Hefei 230009, China;

4. Laboratory of Nonferrous Metal Material and Processing Engineering of Anhui Province, Hefei 230009, China)

Abstract:SiCp/Al composite with high volume fraction of SiC was fabricated by spark plasma sintering. The effects of SiC grain gradation on the microstructure, thermal performance and mechanical properties of composite were investigated. The results show that the SiCp/Al composites are composed of SiC and Al, no reaction product such as Al4C3 fragility phase produces at the interface, and the SiC particles with two sizes distribute uniformly and randomly. The relative density of the composites containing bimodal SiC particles decreases from 99.93% to 96.4% with increasing the volume fraction of SiC from 50% to 65%. Relative density, thermal conductivity, average thermal expansion coefficient (50-400 ℃), and the bending strength of the composite containing 60% bimodal SiC particles are 99.19%, 227.5 W/(m·K), 9.77×10-6 K-1 and 364.7 MPa, respectively.

Key words: SiCp/Al composites; spark plasma sintering; grain gradation; thermal conductivity; thermal expansion coefficient; bending strength

Foundation item: Project(2014DFA50860) supported by the National Science and Technology Cooperation of China

Received date: 2018-01-05; Accepted date: 2018-05-30

Corresponding author: WU Yu-cheng; Tel: +86-13605513206; E-mail: ycwu@hfut.edu.cn

(编辑 龙怀中)

基金项目:国家国际科技合作专项项目(2014DFA50860)

收稿日期:2018-01-05;修订日期:2018-05-30

通信作者:吴玉程,教授,博士;电话:13605513206;E-mail:ycwu@hfut.edu.cn