文章编号:1004-0609(2011)08-1869-06

煅烧温度对高体积分数SiCp/Al复合材料性能的影响

刘君武,李青鑫,丁 锋,黄思德,郑治祥

(合肥工业大学 材料科学与工程学院,合肥 230009)

摘 要:以F220、F500、F600这3种粒度的磨料级绿SiC混合粉为原料制成预制件,然后将其分别在500、1 100和1 200 ℃煅烧后无压熔渗液态铝合金制备SiC体积分数为62%~64%的铝基复合材料SiCp/Al;研究预制件煅烧温度对SiCp/Al复合材料结构和性能的影响。结果表明:不同温度下煅烧的SiC预制件渗铝后,都能获得结构均匀致密的复合材料;高温煅烧使SiC颗粒氧化形成骨架,导致强度从305 MPa降至285~245 MPa;SiC颗粒表面氧化转变成的SiO2薄膜增加复合材料中的陶瓷含量,使复合材料的热膨胀系数进一步降低;当SiC预制件中SiO2薄膜质量分数达到3.7%~6.7%时,SiCp/Al复合材料界面热阻增大4~6倍,复合材料热导率从184 W/(m·℃)降至139~127 W/(m·℃)。

关键词:SiCp/Al复合材料;预制件;氧化;强度;热学性能

中图分类号:TB 331 文献标志码:A

Effect of calcination temperature on properties of

high volume fraction SiCp/Al composites

LIU Jun-wu, LI Qing-xin, DING Feng, HUANG Si-de, ZHENG Zhi-xiang

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: The SiC performs were prepared by green SiC powder containing three kinds of particle size of F220, F500 and F600, and by aluminum matrix composites reinforced by SiC powder (volume fraction of 62%-64%) were produced by the pressureless infiltration of liquid aluminum alloy into the SiC performs which were calcined at 500, 1 100 and 1 200 ℃, respectively. The effects of calcination temperature on the structure and properties of SiCp/Al composites were investigated. The results show that SiCp/Al composites are all uniform and impact as SiC preforms calcined at different temperatures. When sintered at high temperature, SiC particles are oxidized to form skeleton which leads the bending strength of SiCp/Al composites decreasing from 305 MPa to 285-245 MPa. The SiO2 film transformed from SiC by oxidation promotes the ceramic content in the composites, which results in further decrease of the thermal expansion coefficient of SiCp/Al composites. The interface thermal resistance of SiCp/Al composites increases by 4-6 times due to 3.7%-6.7% (mass ratio) SiO2 film in the SiC preforms, and the thermal conductivity of SiCp/Al composites decreases from 184 W/(m·℃) to 139-127 W/(m·℃).

Key words: SiCp/Al composites; preforms; oxidation; strength; thermal properties

高体积分数SiCp/Al复合材料具有高比强度、比模量和高耐磨性,同时又具有高导热、低膨胀的特点,优异的综合性能使其在机械、汽车、航空航天、微电子等领域有良好的发展潜力[1-4]。在高密度封装、功率微电子领域,SiCp/Al复合材料是当今为数不多的几种轻质封装材料之一[5-6],此时该材料兼有结构(支撑)和功能(散热)的双重用途。在满足强度和热匹配的基础上,其热导率越高、芯片的温升越小,半导体工作的稳定性、可靠性越好。普通磨料级绿SiC原材料来源广、粒度规格丰富、价格便宜。以其为原料,采用SiC预制件浸渗液态铝制备的SiCp/Al复合材料能获得近净成形,性能裁剪空间大,具有显著的低成本优势。现有的研究结果表明[7-9],采用这种方法制备的SiCp/Al复合材料的热导率一般介于120~170 W/(m·℃)之间,波动幅度达30%~40%,且普遍偏低。造成热导率差异较大的原因可能是各研究者采用的磨料SiC的纯度、粒度及SiC在复合材料中的含量不同[7-10],也可能是复合材料制备工艺过程对复合材料的热控能力带来损伤。研究者大多认为复合材料热导率低的主要原因是磨料SiC的热导率不足,而较少考虑制备工艺的影响。

本文作者以同一批次购买的绿碳化硅磨料为原料,采用自行研发的无压浸渗技术制备SiCp/Al复合彩料。在保持SiCp/Al复合材料中SiC含量及粒度配比不变的条件下,探讨SiC预制件制备工艺对SiCp/Al复合材料的力学和热学性能的影响,研究工艺过程对复合材料热导率影响规律及内在原因。

1 实验

本实验选用的铝合金成分为AlSi12Mg8、Fe、Cu、Zn、Mn、Ti等杂质元素的总质量分数低于2%;F220、F500、F600这3种粒度的磨料级绿SiC的比表面当量粒径分别为75.4、16.8和10.1?m,3种SiC粉都是SiC原矿经破碎、水洗、分级得到,未经化学提纯处理,纯度未知。3种SiC颗粒按质量比为6:2:1的配比方案来制备SiC预制件。采用硬脂酸锌作为润滑剂(添加量为0.5%),以10%的聚乙烯醇水溶液作为粘接剂。将上述原料按设计比例分组在滚筒式混料机上混合4 h,然后在手动陶瓷压片机上以100 MPa的压力压制成形陶瓷素坯一批。素坯经干燥处理后分别按如下3种工艺方案制备SiC预制件。方案1:将SiC素坯放入方形陶瓷舟中,向坯体与方舟内壁间隙撒粒径为F46的绿SiC砂至与素坯上端面平齐,然后将样品缓慢升温至500 ℃保温2 h,得到的SiC预制件记为SiC(a);方案2:将SiC素坯放入方形陶瓷舟中缓慢升温至 500 ℃保温2 h,去除粘结剂后冷至常温称量,然后升温至1 100 ℃保温1 h后冷至常温再称量,得到的预制件记为SiC(b);方案3:操作过程同方案2,只是将 1 100 ℃提高至1 200 ℃,得到的预制件记为SiC(c)。将预制件SiC(b)和SiC(c)分别水平放入内壁刷有涂层的陶瓷舟内,将适量的铝合金块分别放置在3种方案制备的SiC预制件上方(方案1的SiC预制件基本无强度,故连同埋粉和舟一起使用)。将3个装置一起推入管式气氛炉中,在氮气气氛下升温至800~850 ℃,保温一段时间后冷却至500 ℃时将渗透装置出炉。待装置冷至常温后,打磨掉上方残留的铝合金即可得到SiCp/Al复合材料(方案1中铝渗入预制件的同时也渗入埋粉,将预制件周围多余部分切除才能得到所要的复合材料)。

采用排水法测定复合材料样品密度;采用D/max-rB型X衍射衍射仪分析物相组成;采用OLYMPUS PME型光学显微镜观察复合材料微观组织结构;力学性能测试在CMT5105型微机控制电子万能试验机上进行,跨距为30 mm;采用X-650型扫描电子显微镜观察复合材料断口形貌并分析颗粒断裂机制;分别使用DIL402C 型膨胀仪和TC-7000H型激光热导仪来测定复合材料的热膨胀系数和热扩散系数,通过热扩散系数计算复合材料的热导率。

2 结果与讨论

2.1 SiC预制件及SiCp/Al复合材料的成分与结构分析

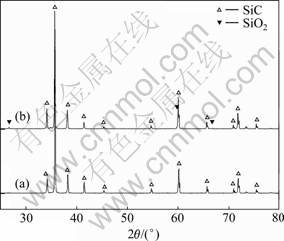

SiC素坯在500 ℃低温煅烧时没有生成SiO2(见图1),说明在该温度下SiC粉体没有氧化,只能将坯体中润滑剂和有机粘结成分去除。与松装粉相比,方案1只是提高了SiC粉体的体积密度,其SiC堆积密度与方案2和3制备的材料相同。当煅烧温度升至1 100 ℃以上时,SiC开始发生明显的氧化[11]。陶瓷粉体表面的SiC原位氧化形成包覆SiC颗粒的SiO2薄膜能将SiC粉体粘结成具有一定强度的陶瓷骨架,能满足后续渗铝工艺所需的强度。其中1 100 ℃烧结得到的预制件强度较差,只能勉强使用;经1 200 ℃烧结时,SiC的氧化会进一步加剧,预制件的强度也明显提高。X射线衍射分析结果(见图1)表明,1 200 ℃煅烧生成的SiO2膜形态为高温型石英。SiC氧化转变成SiO2的过程中会伴随着SiC坯体质量的增加。根据SiC预制件中因SiC氧化而生成SiO2量与预制件的质量增量间存在3:1的比例关系。与500 ℃的质量相比,SiC预制件在1 100 ℃和1 200 ℃煅烧后质量增加分别为1.23%和2.23%,其对应的SiO2含量分别为3.7%和6.7%。

图1 SiCp/Al复合材料的XRD谱

Fig.1 XRD patterns of SiCp/Al composites: (a) SiC powder calcined at 500 ℃; (b) SiC powder calcined at 1 200 ℃

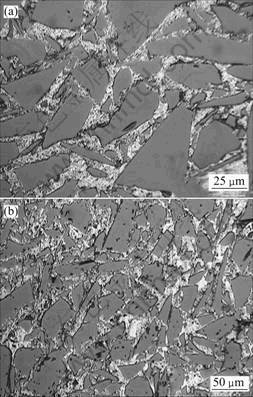

图2所示为SiCp/Al复合材料的金相组织。图2中棱角分明的灰色物质为SiC。从图2可以看出,铝液对SiC渗透完全,复合材料组织致密,没有明显的缺陷。SiC颗粒轮廓清晰、颗粒保存完整,说明SiC没有受到铝液的浸蚀。预制件SiC(a)和SiC(c)渗铝后的金相组织无明显差异。从图2可以观察到,在粗SiC颗粒形成的间隙中不仅有渗入的铝合金,而且还填充了粒度更细的小颗粒SiC,从而提高了SiC在复合材料中的含量,且各种粒度的SiC粉体在铝基体分布 均匀。排水法测试结果显示,本实验所制备的3种SiCp/Al复合材料的密度在2.98~3.01 g/cm3之间,SiC体积分数在62%~64%之间。

图2 SiCp/Al复合材料的金相组织

Fig.2 Metallographs of SiCp/Al composites: (a) SiC(a)/Al composites; (b) SiC(c)/Al composites

2.2 SiCp/Al复合材料的力学性能

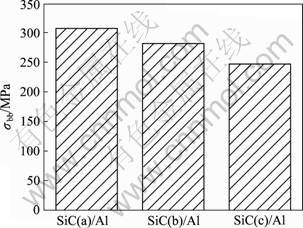

3种SiC预制件渗铝所得到的SiCp/Al复合材料的抗弯强度如图3所示。从图3可以看出:复合材料抗弯强度在245 MPa以上,最高可达305 MPa;SiC素坯通过煅烧形成骨架会导致复合材料的强度下降。随着煅烧温度的提高,SiC氧化加剧,陶瓷骨架强度越高,所得到的复合材料的强度越低。这是因为SiC(a)/Al中的SiC颗粒是游离地分布在连续的铝基体中,脆硬的陶瓷颗粒与韧性金属基体间尚具备一定的形变协调能力。而当SiC固结成三维骨架后,由于陶瓷骨架的刚性(即弹性模量)数倍于铝基体的,所以SiC骨架成为复合材料承载的主体,复合材料的应变是通过陶瓷骨架与铝基体在宏观范围内协调变形来完成。SiC颗粒粘结处SiO2的烧结颈从尺度看要远小于SiC颗粒本身的,陶瓷骨架承受载荷时易在此处产生应力集中,与SiC(a)/Al相比,SiC(b)/Al和SiC(c)/Al受力时,裂纹更易在颗粒接触处萌生,导致复合材料的强度下降。

图3 SiCp/Al复合材料的抗弯强度

Fig.3 Flexural strength of SiCp/Al composites

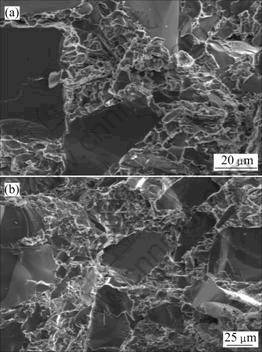

SiC(a)/Al和SiC(c)/Al两种复合材料的断口形貌基本一致(见图4),断口都较为平齐,没发现铝基体塑性变形的痕迹,说明韧性金属的塑性变形受到其周围紧密堆积的SiC刚性陶瓷颗粒的抑制。SiC颗粒都以穿晶解理的方式断裂,断裂的SiC颗粒仍然镶嵌在铝基体中,观察不到SiC颗粒从基体中脱落或界面脱黏的现象,这表明SiC-Al界面结合良好,且SiC煅烧工艺对SiC-Al界面结合无明显影响。高温煅烧后,复合材料强度降低的主要原因不是界面结合强度不足,而是SiC氧化所形成的刚性骨架存在薄弱环节,即SiC粉体间的氧化接触点,裂纹易在此处形成并扩展所致。

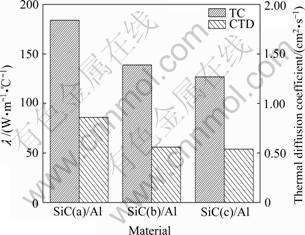

2.3 SiCp/Al复合材料的热导率

3种实验方案制备的复合材料的导热能力测试结果如图5所示。SiC(a)/Al复合材料热导率高达184 W/(m·℃),而SiC(b)/Al和SiC(c)/Al两种复合材料的热导率分别降至139和127 W/(m·℃)。3种复合材料的所用原料相同,唯一的区别是预制件的煅烧温度不同:SiC(a)煅烧温度低,SiC粉体无任何损伤;SiC(b)和SiC(c)分别在1100和1200 ℃煅烧时,SiC氧化在其表面形成SiO2薄膜。当SiO2含量从0增至3.7%,复合材料热导率降幅高达25%,SiO2含量从3.7%增至6.7%时,复合材料热导率降幅不足10%。SiO2含量与热导率变化的数量关系说明SiO2对复合材料热导率的影响不仅与其自身热导率非常低有关(约为1.1 W/(m·℃)[12]),还与其在复合材料中的存在形态有关。如果SiO2是孤立地存在于铝基体中,此时对SiC与铝基体间的热传导无影响,即使其完全不导热(即相当于封闭孔隙),其含量与复合材料热导率服从线性规律,其对热导率的影响力度比本研究得到的结果要弱得多。本研究中,SiO2是以薄膜状态包覆着高导热的SiC颗粒,不仅自身热导率低,还严重阻碍热流在SiC与铝基体之间的流动,对SiC而言,则是形成一层热屏障。热屏障即界面热阻的形成是导致复合材料热导率急剧降低的主要原因。众所周知,影响复合材料热导率的因素除了基体与增强体的热导率、增强体体积分数和颗粒大小外,材料中存在的大量界面也会影响着热导率。可借助Hasselman and Johnson模型对上述实验结果进行定量。该模型考虑了界面热阻的影响,提出了预测单一粒径颗粒增强复合材料热导率的EMA模型[13-14],其计算模型为

(1)

(1)

式中:Keff为复合材料的有效热导率;km和kd分别为基体和增强体的热导率; 为增强体的体积分数;a为增强体的颗粒半径;hc为界面热导。在等比表面积基础上,引入等效粒径的概念[15],根据式(2)计算3种颗粒混合的等效粒径(氧化后SiC颗粒粒径变化很小,近似看作不变)。

为增强体的体积分数;a为增强体的颗粒半径;hc为界面热导。在等比表面积基础上,引入等效粒径的概念[15],根据式(2)计算3种颗粒混合的等效粒径(氧化后SiC颗粒粒径变化很小,近似看作不变)。

图4 SiCp/Al复合材料的断口SEM像

Fig.4 SEM images of fracture of SiCp/Al composites: (a) SiC(a)/Al composites; (b) SiC(c)/Al composites

图5 SiCp/Al复合材料的热扩散系数和热导率

Fig.5 Thermal diffusion coefficient and thermal conductivity of SiCp/Al composites

(2)

(2)

式中:V1、V2、V3和d1、d2、d3分别为F220、F500、F600这3种SiC粉末的体积和比表面当量粒径,Vp为3种粉末的总体积,d则为3种颗粒混合后的等效粒径,可计算出其值为22 μm。

根据HASSELMAN的研究结果[14],未经加热预处理的Al-SiC系统的界面热导为1.2×108 W/(m2 ·℃)。熔渗过程中,Al基体中的Mg大量挥发,熔渗完成后合金中的Mg含量降至1%以下,此时的合金成分与铸铝ZL102基本一致,其热导率约为155 W/(m·℃)[16],SiC的体积分数取0.63。联立式(1)和(2),根据SiC(a)p/Al复合材料热导率184 W/(m·℃)可计算出SiC颗粒的热导率为240 W/(m·℃)。如果SiC颗粒和铝基体的热导率分别为240和155 W/(m·℃),分别将139与127 W/(m·℃)代入式(1)和(2),可计算出SiC(b)p/Al与SiC(c)p/Al界面热导率分别为0.26×108和0.19×108 W/(m2 ·℃)。

上述分析结果说明,工业磨料绿SiC具有和高纯SiC相近的热导率(MOLINA等[17]的研究表明,99.5%的高纯SiC的热导率约为250~260 W/(m·℃)),明显优于铸铝的(铸铝热导率一般低于160 W/(m·℃)[16]),至少与纯铝的相当(99.99%的高纯铝热导率为235 W/(m·℃)左右[16-17])。导致复合材料热导率降低的主要原因是SiC预制件烧结制备过程中形成的粘结相增大了复合材料的界面热阻,增幅达4~6倍。因此,如何降低SiC的损伤,并实现SiC预制件的高效粘结以降低界面热阻是近净成形制备高导热SiCp/Al复合材料的关键。

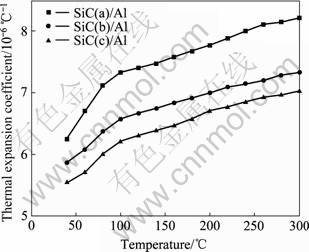

2.4 SiCp/Al复合材料的热膨胀系数

图6所示为不同温度时SiCp/Al复合材料的热膨胀系数。由图6可知,3种材料的热膨胀系数都随随温度的升高而增大,这与大多数研究结果相吻合,其数值约为铸铝ZL102的热膨胀系数的1/4到1/3,说明高体积分数的SiC颗粒抑制铝基体热膨胀的效果显著,使其降低到满足半导体封装应用的要求。随着SiC预制件素坯煅烧温度从500 ℃升至1 100 ℃和1 200 ℃,复合材料室温至100 ℃的平均热膨胀系数从7.33×10-6 ℃-1分别降至6.58×10-6 ℃-1和6.22×10-6 ℃-1。这是由于SiO2的密度低于SiC的,而SiC氧化成SiO2时质量会增加,因此SiC氧化转变成SiO2相当于增加了陶瓷的体积分数,从而更好地抑制铝基体的膨胀,降低SiCp/Al复合材料热膨胀系数。随着煅烧温度的提高,SiO2含量越高,复合材料中陶瓷成分的总含量越高,复合材料的热膨胀系数也就越低。相比之下,SiO2含量对复合材料热膨胀的影响幅度要比对导热的影响幅度弱得多。

图6 不同温度时SiCp/Al复合材料的热膨胀系数

Fig.6 Thermal expansion coefficient of SiCp/Al composites at different temperatures

3 结论

1) 以F220、F500、F600这3种粒度的绿SiC磨料混合粉为原料制备成预制件后,无压熔渗AlSi12Mg8获得体积分数在62%~64%的SiCp/Al复合材料;复合材料结构致密,粗细SiC粉在铝基体分布均匀。

2) SiC颗粒间的SiO2烧结颈成为复合材料承载的薄弱环节,导致SiC颗粒骨架的形成,使SiCp/Al复合材料强度从305 MPa降至285~245 MPa。

3) SiCp/Al复合材料的平均热膨胀系数在6.22×10-6~7.33×10-6 ℃-1之间,满足电子封装的要求;高温煅烧SiC所形成的SiO2增加了铝基体中的陶瓷含量,使复合材料的热膨胀系数降低。

4) SiC氧化形成的3.7%~6.7%SiO2薄膜使SiCp/Al复合材料界面热阻增大4~6倍,是复合材料热导率从184 W/(m·℃)降至139~127 W/(m·℃)的主要原因。

REFERENCES

[1] 王庆平, 吴玉程, 洪 雨, 盘荣俊, 闵凡飞. 无压浸渗制备SiCp/Al复合材料的微观组织及弯曲性能[J]. 中国有色金属学报, 2010, 20(2): 239-243.

WANG Qing-ping, WU Yu-cheng, HONG Yu, PAN Rong-jun, MIN Fan-fei. Microstructure and bending mechanical properties of high volume fraction SiCp/Al composites[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 239-243.

[2] 蔺绍江, 李金山, 胡 锐. 无压浸渗高含量SiCp/Al复合材料的组织及压缩力学性能[J]. 铸造, 2007, 56(3): 275-278.

LIN Shao-jiang, LI Jin-shan, HU Rui. Microstructure and compressive mechanical properties of SiCp/Al composite made by pressureless infiltration technique[J]. Foundry, 2007, 56(3): 275-278.

[3] 张 强, 武高辉, 孙东立, 韩杰才. 高体积分数SiCp/Al复合材料的微观组织与导热性能[J]. 材料科学与工艺, 2006, 14(5): 474-477.

ZHANG Qiang, WU Gao-hui, SUN dong-li, HAN Jie-cai. Microstructure and thermal conduction property of SiCp/Al-Si composite with high reinforcement content[J]. Materials Science and Technology, 2006, 14(5): 474-477.

[4] ARPON R, MOLINA J M, SARAVANAN R A. Thermal expansion behaviour of aluminum/SiC composites with bimodal particle distributions[J]. Acta Materials, 2003, 51: 3145-3152.

[5] 樊建中, 肖伯律, 左 涛, 徐 骏, 石力开. 适合航空航天用SiCp/Al复合材料的性能[J]. 宇航材料工艺, 2005(6): 17-22.

FAN Jian-zhong, XIAO Bo-lü, ZUO Tao, XU Jun, SHI Li-kai. Properties of SiCp/Al composites for aerospace application[J]. Aerospace Materials and Technology, 2005(6): 17-22.

[6] 田大垒, 王 杏, 关荣锋. 电子封装用SiCp/Al复合材料的研究现状及展望[J]. 电子与封装, 2007, 7(3): 11-15.

TIAN Da-lei, WANG Xing, GUAN Rong-feng. Present status and prospects of the researches on the SiCp/Al composite materials for electronic packaging[J]. Electronics and Packaging, 2007, 7(3): 11-15.

[7] LEE H S, JEON K Y, KIM H Y, HONG S H. Fabrication process and thermal properties of SiCp/Al metal matrix composites for electronic packaging applications[J]. Journal of Materials Science, 2000, 35(24): 6231-6236.

[8] 熊德赣, 刘希从, 鲍小恒, 白书欣, 杨盛良, 赵 恂. AlSiC电子封装基片的制备与性能[J]. 中国有色金属学报, 2006, 16(11): 1913-1917.

XIONG De-gan, LIU Xi-cong, BAO Xiao-heng, BAI Shu-xin, YANG Sheng-liang, ZHAO Xun. Fabrication and property of aluminum silicon carbide electronic packaging base plates[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(11): 1913-1917.

[9] 褚 克, 贾成厂, 尹法章, 梅雪珍, 曲选辉. 高体积分数SiCP/Al复合材料电子封装盒体的制备[J]. 复合材料学报, 2006, 23(6): 108-113.

CHU Ke, JIA Cheng-chang, YIN Fa-zhang, MEI Xue-zhen, QU Xuan-hui. Fabrication on electronic package box of SiCp/Al composites with high volume fraction of SiCp[J]. Acta Materiae Compositae Sinica, 2006, 23(6): 108-113.

[10] REN Shu-bin, HE Xin-bo, QU Xuan-hui, ISLAM S H, LI Yan. Effect of Mg and Si in the aluminum on the thermo-mechanical properties of pressureless infiltrated SiCp/Al composites[J]. Composites Science and Technology, 2007, 67: 2103-2113.

[11] SHI Zhong-liang, YANG J M, LEE J C, ZHANG Di, LEE H I, WU Ren-jie. The interfacial characterization of oxidized SiCp/2014 Al composites[J]. Materials Science and Engineering, 2001, 303: 46-53.

[12] REN Shu-bin, HE Xin-bo, QU Xuan-hui, LI Yan. Effect of controlled interfacial reaction on the microstructure and properties of the SiCp/Al composites prepared by pressureless infiltration[J]. Journal of Alloys and Compounds, 2008, 455: 424-431.

[13] HASSELMAN A D P H, KIMBERLY Y D, ALAN L G. Effect of reinforcement particle size on the thermal conductivity of a particulate silicon carbide-reinforced aluminum-matrix composites[J]. Journal of Ceramic Society, 1992, 5(11): 3137-3140.

[14] HASSELAMAN D P H, LLOYD F J. Effective thermal conductivity of composites with interfacial thermal barrier resistance[J]. Journal of Composites, 1987, 21(6): 508-515.

[15] 张 强, 陈国钦, 姜龙涛, 武高辉. 两种粒径颗粒混合增强铝基复合材料的导热性能[J]. 复合材料学报, 2005, 22(1): 47-51.

ZHANG Qiang, CHEN Guo-qin, JIANG Long-tao, WU Gao-hui. Thermal conduction properties of aluminum matrix composites reinforced with dual-sized particles[J]. Acta Materiae Compositae Sinica, 2005, 22(1): 47-51.

[16] 潘复生, 张丁飞. 铝合金及应用[M]. 北京: 化学工业出版社, 2006: 58-285.

PAN Fu-sheng, ZHANG Ding-fei. Aluminum alloy and application[M]. Beijing: Chemical Industry Press, 2006: 58-285.

[17] MOLINA J M, NARCISO J, WEBER L, MORTENSEN A, LOUIS E. Thermal conductivity of Al-SiC composites with monomodal and bimodal particle size distribution[J]. Materials Science and Engineering A, 2008, 480: 483-488.

(编辑 龙怀中)

基金项目:安徽省自然科学基金资助项目(090414187)

收稿日期:2010-08-31;修订日期:2010-12-05

通信作者:刘君武,副教授,博士;电话:0551-2901372;E-mail: jwliu@hfut.edu.cn