文章编号:1004-0609(2013)S1-s0041-05

Ti-662钛合金棒材的组织和性能

朱宝辉1, 2,陈 林1,胡晓晨1,曾卫东2,刘彦昌1, 2,范存莹1

(1. 宁夏东方钽业股份有限公司 钛材分公司,石嘴山 753000;

2. 西北工业大学 材料科学与工程学院,西安 710072)

摘 要:对Ti-662钛合金棒材进行锻造、固溶及时效处理,利用光学显微镜、SEM 及力学性能试验对该合金3种状态下的显微组织和力学性能进行研究。结果表明:Ti-662钛合金锻棒的组织为初生等轴α+β转变组织,其强度较高,伸长率较大,抗拉强度达到1 149 MPa,伸长率为16.5%;合金经固溶热处理后初生α相明显增多,主要组织为初生α相、马氏体转变的α′相和亚稳β相,合金强度和伸长率有所降低,但断面收缩率有所提高,说明固溶处理有一定的软化作用;经固溶处理后的棒材在时效处理过程中,亚稳态组织析出细小弥散的次生α相,使合金强度明显强化,塑性略有降低,且随着时效温度的升高,强化效果下降,塑性随之提高。

关键词:Ti-662钛合金;棒材;显微组织;性能

中图分类号:TG146.2 文献标志码:A

Microstructure and properties of Ti-662 alloy bars

ZHU Bao-hui1, 2, CHEN Lin1, HU Xiao-chen1, Zeng Wei-dong2, Liu Yan-chang1, 2, Fan Cun-ying1

(1. Titanium Product Plant, Ningxia Orient Tantalum Industry Co., Ltd., Shizuishan 753000, China;

2. School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China)

Abstract: The microstructure and properties of Ti-662 alloy under three conditions were investigated by using optical microscopy (OM), scanning electron microscopy (SEM) and measurements of mechanical properties for the bars processed by forging, solution and aging treatment. The results show that the as-forged microstructures of Ti-662 alloy bars are fine isothermal primary α and transition β phases, the strength and elongation are higher, the tensile strength and elongation of the alloy are 1 149 MPa and 16.5%, respectively. After solution heat treatment, the quantity of primary α phase of the alloy increases significantly, and the microstructures are mainly composed of isothermal primary α, martensite α′ and metastable β phases. The strength and elongation decrease, but the reduction of area increases, which indicate that solution treatment has a softening effect. Fine dispersion secondary α phase precipitates from the metastable structures after solution and in aging process, and the alloy can be strengthened significantly with slightly reduced plasticity. With the increase of the aging temperature, the strengthening effect reduces, and the plasticity increases.

Key words: Ti-662 titanium alloy; bar; microstructure; properties

Ti-662钛合金是一种富β稳定元素的两相钛合金,名义成分为Ti-6Al-6V-2Sn-0.5Fe-0.5Cu,与Ti-6Al- 4V合金相比,Ti-662增加的β相稳定元素极大地改善了其热处理特性,常温及高温性能均有明显的改进,其退火态强度超过了Ti-6Al-4V退火态的强度,同时也可进行固溶时效热处理,达到更高的强度。由于其优异的力学性能、耐热性能(可在400 ℃以下长期使用)、较好的抗氧化和耐蚀性能,优于其他合金的焊接性能等特点,因此,Ti-662钛合金被广泛应用于飞机机身、火箭发动机、核反应堆部件以及石油勘探设备等部件[1-6]。国内相应的牌号是TC10合金,应用比较少。近几年在迫击炮身管上曾有应用,但仅限于军工行业,在其他行业的应用较少,而且相关的研究也鲜见报道[3-6]。

为此,本文作者主要研究不同状态的Ti-662合金棒材的组织及性能,以便为该合金的推广应用提供一定的参考。

1 实验

实验以一级海绵钛(粒度为0.83~12.7 mm)、37% Al-80%Sn、Al-85%V、铜屑、铝豆和铁钉为原料,采用3 t真空自耗电弧炉经过3次熔炼制备铸锭,其化学成分(质量分数)为:5.96%Al、5.93%V、2.17%Sn、0.78% Cu、0.82%Fe、0.106%O、0.032%C、0.007%N和 0.0016%H,其余为Ti。铸锭规格为d 600 mm锭型,采用连续升温金相法测定其相变点为(955±5) ℃。

铸锭在相变点以上β相区进行开坯锻造,经过反复镦拔,变形量达到80%左右开始进行(α+β)两相区锻造。经过反复镦拔锻造至d 110 mm,然后经径向锻造至d 90 mm,对成品棒先进行固溶热处理(880 ℃,1 h, WC),然后分别选用580、600和620 ℃进行时效热处理(保温4 h,AC)[4, 7-8]。锻造设备采用16MN快速液压锻造机和SXP-13径向锻造机。加热和固溶热处理设备为3级精度要求的箱式电阻炉,时效热处理设备为具有2级精度要求的箱式电阻炉。

对锻造态、固溶态和固溶时效态合金棒材分别进行取样。采用Olympus GX51金相显微镜观察显微组织,使用INSTRON 4505和WDW-B100G电子万能试验机分别测试合金的的室温和高温拉伸性能,利用JB-S300A数显摆锤式冲击试验机测试合金的冲击韧性。棒材内部质量采用CTS-2020超声波探伤仪进行检测,并采用JSM-6460扫描电镜和能谱仪对时效态的合金断口、显微形貌及微区化学成分进行观察和分析。

2 结果与讨论

2.1 锻造态合金的组织及性能

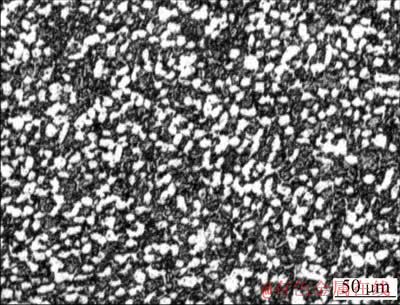

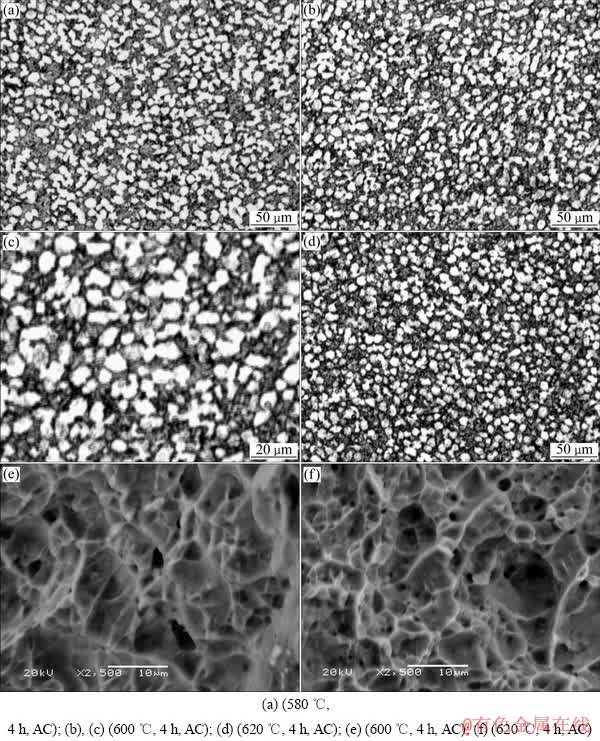

图1所示为Ti-662合金锻造棒材的显微组织。可见锻造态Ti-662合金为典型的α+β两相组织,在β转变基体上分布着细小等轴初生α相(晶粒尺寸接近10 μm),组织较为均匀,等轴初生α相含量约为50%(质量分数),还有条状的次生α相。该显微组织粗略来说是等轴α+β转变组织,细分应是由初生等轴α相、条状次生α相和β相残余组织组成,但仍为等轴组织。

图1 锻造态Ti-662合金棒材的显微组织

Fig. 1 Microstructure of as-forged Ti-662 alloy bars

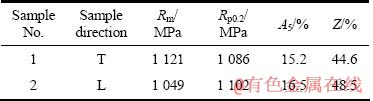

表1所列为锻造态合金棒材的拉伸性能。从表1中可以看出,该合金锻造态的强度都比较高,而且两项塑性指标也非常好,强度和塑性均比较好。虽然纵向拉伸性能略优于横向性能,但纵、横向性能差异较小,整体性能比较均匀,说明合金棒材锻造态的组织和性能均较好。

2.2 固溶态合金的组织及性能

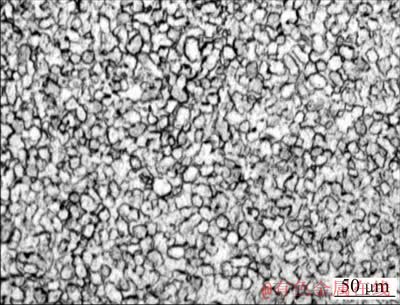

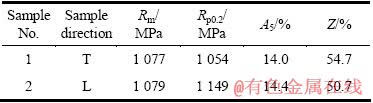

图2所示为Ti-662合金棒材经过880 ℃固溶热处理后的显微组织。与锻造态比较,经固溶处理后初生α相明显增多,由于Ti-662富含β相稳定元素,水淬后的主要组织是初生α相、马氏体转变的α′相以及亚稳态β相[1]。由淬火所得到的马氏体硬度降低而塑性增高,而且存在非平衡相,因而需要进行进一步的时效处理。表2所列为固溶处理后合金棒材的拉伸性 能。经比较发现,经固溶处理后的强度和伸长率比锻造态的均有所下降,但断面收缩率明显提高,说明合金棒材经过固溶水淬处理后不仅可以起到固溶的作用,为时效做准备,同时由淬火所得到的马氏体确实有一定的软化作用。

表1 Ti-662合金棒材锻造态的拉伸性能

Table 1 Tensile properties of Ti-662 alloy for forged bars

图2 固溶态Ti-662合金棒材的显微组织

Fig. 2 Microstructure of solution-treated Ti-662 alloys bars

表2 固溶态Ti-662合金棒材的拉伸性能

Table 2 Tensile properties of solution-treated Ti-662 alloy bars

2.3 固溶时效态合金的组织及性能

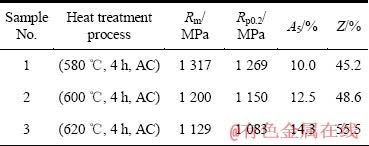

对固溶态棒材分别在580、600和620 ℃进行时效热处理,不同时效温度处理后的固溶时效态棒材显微组织如图3(a)~(d)所示。由图3(a)~(d)可见,随着时效温度的增加,强化次生α相的数目增多并粗化,弥散度变小。时效时产生的强化是由于淬火时形成的亚稳定相继续分解造成的。亚稳态β相分解时其强化效果最大,时效时在β相内析出许多弥散α相,并随着时效温度降低,析出的α相更弥散,从而获得更好的强化效果。亚稳态组织在时效时的分解包含马氏体相和亚稳态β相的分解。马氏体相的分解,是在α相的基体中有β相的析出,基体α相成分接近反应达到平衡时的α相成分。亚稳态β相的分解,是由于Ti-662中包含的Cu和Fe属于β共析型稳定剂,分解后平衡时的相组织是α+β和α+化合物,进一步起到强化作 用[9]。图3(e)和(f)所示为两种时效态拉伸断口的微观形貌,均为等轴韧窝型延性断裂,大韧窝中包含有小韧窝,韧窝的深度是基材可成形性和断裂韧度的一种量度[10],从韧窝形貌可以看出该材料时效态的塑性和韧性也是较好的。

图3 经不同温度时效处理Ti-662合金棒材的显微组织及断口形貌

Fig. 3 Microstructures ((a)-(d)) and fracture morphologies ((e), (f)) of Ti-662 alloy bars aged at different temperatures

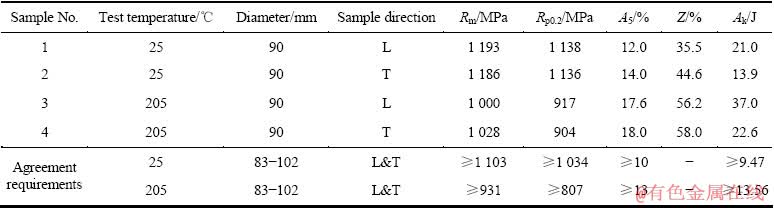

经880 ℃固溶、不同时效温度热处理后Ti-662棒材合金的力学性能见表3。从表3中可以看出,时效温度较低时,强化作用较大,但塑性下降;时效温度较高时,塑性得到提高,强度却明显下降。当时效温度为600 ℃时,强度和塑性得到了较好的匹配。

表4所列为Ti-662合金棒材固溶时效态(STA)典型产品的力学性能。室温和高温材料的纵、横方向的拉伸性能差异不大,材料各向同性较好,高温强度有所下降,塑性提高比较明显,材料的纵、横向拉伸性能都比标准下限指标高很多,强度约高100 MPa,伸长率大20%~40%。材料的室温和高温纵向冲击韧性明显优于横向的,而且差距较大,说明材料的冲击韧性各向异性非常明显,但材料的综合性能远远超出标准下限要求,整体力学性能水平良好。

表3 Ti-662合金棒材不同温度时效的拉伸性能

Table 3 Tensile properties of aged Ti-662 alloy bars at different temperature

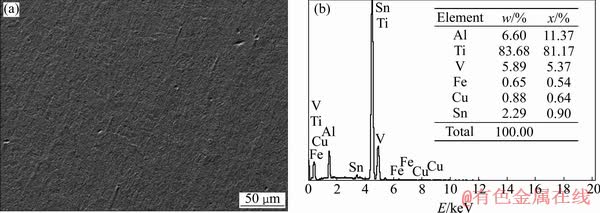

对经固溶时效热处理后的棒材进行超声波探伤检测,质量级别可达到AMS 2631B中A1级,说明材料内部组织均匀,内部质量一致性良好。同时,采用扫描电镜和能谱仪对时效态棒材取样进行显微形貌观察和微区分析,固溶时效态棒材的SEM像及EDS谱见图4。由图4(a)可知,未发现有偏析等冶金缺陷,为了进一步验证成分均匀性,在选定区域用能谱分析微区成分,分析结果显示除了Al元素含量偏高以外(可能是使用氧化铝抛光粉的影响),其他合金元素均在MIL9047标准要求范围之内,说明成品棒材的合金元素分布较为均匀,成分控制较好。

表4 Ti-662合金棒材固溶时效态典型产品的力学性能

Table 4 Mechanical properties of Ti-662 alloy bars in STA for typical products

图4 固溶时效态Ti-662合金棒材的SEM像及EDS谱

Fig. 4 SEM image (a) and EDS pattern (b) of as-solution treated and aged Ti-662 alloy bars

3 结论

1) 固溶处理对Ti-662合金棒材既有固溶作用,又有一定的软化作用。

2) 固溶处理后的棒材经过时效热处理后,Ti-662合金棒材强度明显增加,塑性略有降低,而且随着时效温度升高,强化效果下降,塑性随之提高。

3) 经固溶时效后的Ti-662合金棒材综合性能良好,可以满足中高强高性能需求领域的使用。

REFERENCES

[1] WOOD R A, FAVOR R J. 钛合金手册[M]. 刘静安, 吴煌良, 姚毅中, 译. 重庆: 科学技术文献出版社重庆分社, 1983: 75-86.

WOOD R A, FAVOR R J. Handbook of titanium alloy [M]. LIU Jing-an, WU Hang-liang, YAO Yi-zhong, transl. Chongqing: Chongqing Branch of Science and Technology Literature Press, 1983: 75-86.

[2] 《稀有金属加工手册》编写组. 稀有金属材料加工手册[M]. 北京: 冶金工业出版, 1984: 87.

Rare Metal Process Handbook Compiling Group. Rare metal process handbook [M]. Beijing: Metallurgical Industrical Press, 1984: 87.

[3] 戚运莲, 杜 宇, 刘 伟, 洪 权, 卢亚峰. 热处理温度对TC10钛合金棒材组织与性能的影响[J]. 钛工业进展, 2011, 28(5): 31-33.

QI Yun-lian, DU Yu, LIU Wei, HONG Quan, LU Ya-feng. Effect of heat treatment on microstructure and properties of TC10 titanium alloys [J].Titanium Industry Progress, 2011, 28(5): 31-33.

[4] 陈睿博, 朱宝辉, 赵洪章, 刘彦昌, 胡晓晨, 王 益, 许道玉. Ti-662钛合金热处理工艺[J]. 金属热处理, 2013, 38(3): 97-99.

CHEN Rui-bo, ZHU Bao-hui, ZHAO Hong-zhang, LIU Yan-chang, HU Xiao-chen, WANG Yi, XU Dao-yu. Heat treatment process of Ti-662 titanium alloy [J]. Heat Treatment of Metals, 2013, 38(3): 97-99.

[5] 王晓林, 赵志龙, 张延生, 赵芳利, 毛 麒, 田伟华. TC10合金铸造缺陷在热等静压条件下的弥合机理初探[J]. 铸造, 2013, 60(8): 731-734.

WANG Xiao-lin, ZHAO Zhi-long, ZHANG Yan-sheng, ZHAO Fang-li, MAO Lin, TIAN Wei-hua. Discussion on closing mechanism of TC10 alloy casting defects under HIP [J]. Foundry, 2013, 60(8): 731-734.

[6] 陈国财, 杨文甲, 陈 苏, 晁 雷. 锻造工艺对TC10钛合金棒材性能的影响[J]. 中国有色金属学报, 2010, 20(S1): s25- s27.

CHEN Guo-cai, YANG Wen-jia, CHEN Su, CHAO Lei. Effects of forging technics on performance of TC10 titanium alloy stick [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s25-s27.

[7] MATTHEW J, DONACHIE J. Titanium—A technical guide [M]. ASM International, 1988: 62-68.

[8] 胡晓晨, 陈 林, 朱宝辉, 陈睿博, 刘彦昌, 赵洪章, 王 莉, 郑爱国. 变形方式和热处理工艺对Ti-662合金棒材组织和性能的影响[J]. 钛工业进展, 2013, 30(2): 17-20.

HU Xiao-chen, CHEN Lin, ZHU Bao-hui, CHEN Rui-bo, LIU Yan-chang, ZHAO Hong-zhang, WANG Li, ZHENG Ai-guo. Effect of deformation mode and heat treatment on microstructures and mechanical properties of Ti-662 alloy rod [J]. Titanium Industry Progress, 2013, 30(2): 17-20.

[9] 莫 畏. 钛[M]. 北京: 冶金工业出版社, 2008: 664-668.

MO Wei. Titanium [M]. Beijing: Metallurgical Industry Press, 2008: 664-668.

[10] ENGEL L, KLINGELE H. 金属损伤图谱[M]. 孟锡明, 译. 北京: 机械工业出版社, 1990: 29-40.

ENGEL L, KLINGELE H. An atlas of metal damage [M]. MENG Xi-ming, transl. Beijing: China Machine Press, 1990: 29-40.

(编辑 陈卫萍)

基金项目:宁夏东方钽业股份有限公司自主课题(SJ07-13-2)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:朱宝辉,高级工程师; 电话:0952-2098907;E-mail: zbhwel@163.com