DOI:10.19476/j.ysxb.1004.0609.2018.11.10

医用TC4钛合金棒材的显微组织调控及U型钉缩口性能

白鹏飞1,闵小华1,陶晓杰2,钟功诚2,白树玉2,程从前1,赵 杰1

(1. 大连理工大学 材料科学与工程学院,大连 116024;

2. 大连盛辉钛业有限公司,大连 116600)

摘 要:分析对比不同工序后医用U型钉用TC4钛合金棒材的组织性能。结果表明:热拔和高温退火工艺对棒材的再结晶组织有明显影响,而双曲线矫直和低温退火工艺对棒材力学性能的影响较大。730~750 ℃高温退火2 h后,热拔材的再结晶程度比较充分;580~700 ℃低温退火2 h后,矫直材的光学显微组织未发生明显变化,但硬度明显减小。在730~750 ℃高温退火、580 ℃低温退火的条件下对棒材的显微组织进行调控,可获得符合医用TC4钛合金力学性能要求的棒材,且由其加工的U型钉缩口尺寸可控制在0.05 mm以下。

关键词:TC4钛合金;U型钉;缩口尺寸;显微组织;力学性能

文章编号:1004-0609(2018)-11-2249-08 中图分类号:TG146.2+ 3 文献标志码:A

椎弓根螺钉(U型钉)与锁紧螺母和连接棒作为脊柱固定系统,用于治疗脊柱的骨折、畸形等[1-6]。Boucher[7]成功地运用椎弓根螺钉固定腰骶关节,随 后HARRINGTON[8-9],ROY-CAMILLE等[10-11],MAGERL[12]、STEFFEE等[13]、COTREL等[14]先后对椎弓根螺钉进行了优化。Ti-6Al-4V(TC4)钛合金凭借良好的力学性能和生物相容性,被广泛地用于生产U型钉[15-18]。医用TC4钛合金棒材在加工成U型钉前要经过热轧、热拔、电矫直、高温退火、双曲线矫直、低温退火和修磨等一系列复杂的热机械加工。U型钉在加工成型后会出现缩口(U型口发生收缩)现象,缩口尺寸及稳定性是评价U型钉性能的重要指标之一。一般通过检测U型钉外径的直线变化度来表征其缩口尺寸。当U型钉缩口尺寸大于0.05 mm,会导致与其配套的连接棒和锁紧螺母无法准确夹紧定位,给临床应用带来不便,不利于患者的治疗。

国内外生产的医用TC4钛合金棒材的宏观力学性能和合金成分没有明显差别,但加工成U型钉后,会表现出不同的缩口性能。由国外生产的TC4钛合金棒材加工的U型钉,缩口尺寸一般小于0.05 mm、稳定性较好;而国产的TC4钛合金棒材加工的U型钉,缩口尺寸在0.05 mm上下波动、稳定性差。因此,国内医疗厂家多采用进口的医用TC4钛合金棒材生产U型钉。

前期通过对比分析国内外缩口尺寸不同的医用U型钉的性能,发现用于加工U型钉的TC4钛合金棒材纵截面边缘位置的显微组织存在明显差别[19]。由于医用TC4钛合金棒材的加工工艺比较复杂,目前就各工序对棒材显微组织和力学性能以及U型钉缩口性能的影响仍缺乏足够的认识。因此,本研究的主要目的是通过对比不同工序后医用U型钉用TC4钛合金棒材的显微组织和力学性能,分析研究主要工序对棒材组织性能的影响;通过探讨合理的工艺参数,来进一步降低U型钉的缩口尺寸并提高其稳定性。

1 实验

实验材料为医用U型钉用TC4钛合金棒材,主要加工工艺如下:将合金铸锭热轧成直径为17 mm的棒材,挂氧化皮后在一定的温度下进行热拔(d=14 mm)、电矫直和高温退火后,进行双曲线矫直和低温退火处理。棒材化学成分为:Ti 6.01%,Al 4.00%,V 0.17%,Fe 0.12%,O 0.03%,C 0.01%,N 0.001%(质量分数)。利用箱式电阻炉(SX2-4-10),将热拔后的棒材分别在700、730和750 ℃条件下退火0.5、2和10 h。其中700 ℃退火 2 h的棒材经双曲线矫直处理后,分别在580、620、660和700 ℃条件下退火2 h。

将各工序和不同退火工艺后的棒材沿径向各切取一段尺寸为d14 mm×7 mm的横截面试样,然后沿轴向切取尺寸为7 mm×14 mm的纵截面试样。试样经机械化学抛光成镜面后,用腐蚀液(2 mL HF+3 mL HNO3+100 mL H2O)浸蚀20 s。通过MEF4A光学显微镜观察各棒材纵截面边缘位置的显微组织。用HVS1000Z型硬度计测试抛光试样的硬度,沿试样纵截面中轴线等距离测15个点,加载载荷为9.8 N、加载时间为15 s。

将730 ℃、750 ℃高温退火2 h的棒材经双曲线矫直后,分别在580 ℃、640 ℃低温退火2 h,并利用WDW-200型电子万能试验机测试室温拉伸性能,分别进行三组拉伸试验。拉伸试样总长180 mm、平行长度为60 mm,拉伸所用引伸计标距为50 mm,拉伸速率为1 mm/min。将上述高低温退火处理的棒材分别加工15个医用U型钉,然后通过红外线投影法测量U型钉外径直线度的变化来评价其缩口尺寸。

2 结果与分析

2.1 各工序下棒材的显微组织和硬度

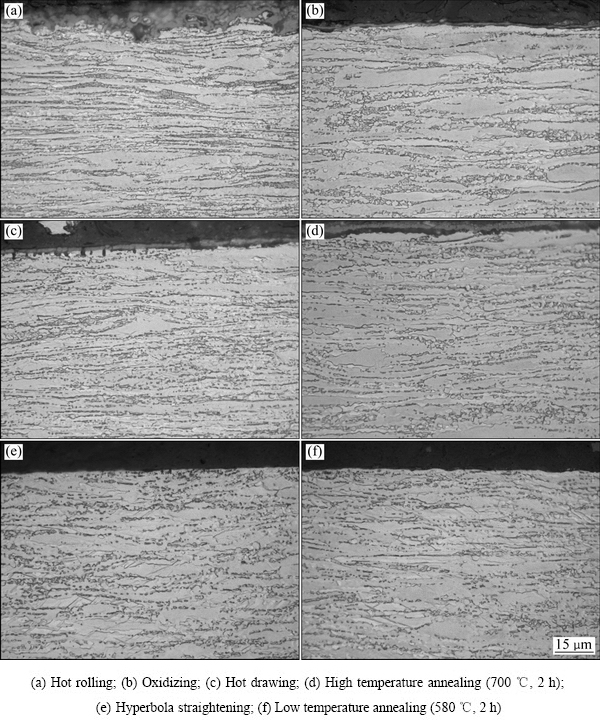

图1 各工序后棒材纵截面边缘位置的显微组织

Fig. 1 Longitudinal-section microstructures at edge position of bar after different procedures (Drawing direction is parallel to horizontal direction)

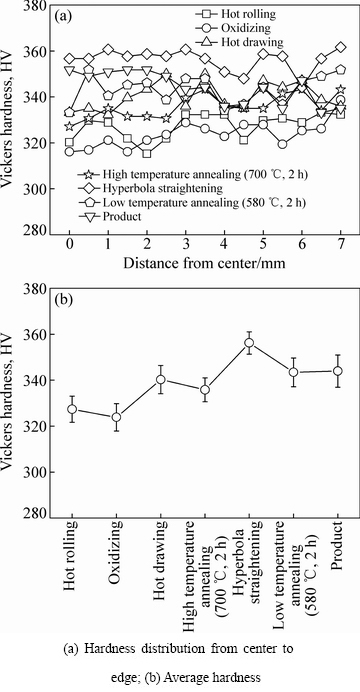

图1所示为不同工序后棒材纵截面边缘位置的光学显微组织。由图1可知,各工序后棒材纵截面的组织均由灰色的α相和黑色的β相组成,且α相均以拉长的变形晶粒为主。棒材纵截面的维氏硬度分布如图2(a)所示,各工序棒材纵截面从中心到边缘位置的硬度有所波动,但变化不明显。图2(b)显示了不同工序后棒材纵截面的平均硬度,挂氧化皮后棒材的硬度约为324 HV,比热轧材减少3 HV;热拔后棒材的硬度(340 HV)比挂氧化皮材的增加16 HV,高温退火后棒材的硬度(336 HV)比热拔材的减少4 HV;双曲线矫直后棒材的硬度(356 HV)增加比较明显、比高温退火材的增加20 HV,经过低温退火的棒材的硬度(342 HV)明显降低、比矫直材的减少14 HV。因此,对棒材力学性能有明显影响的工序主要是热拔、双曲线矫直和高低温退火工艺。

图2 各工序后棒材的纵截面维氏硬度

Fig. 2 Longitudinal-section Vickers hardness of bars after different procedures

前期的研究表明[19],U型钉的缩口尺寸与棒材显微组织的再结晶程度密切相关,当显微组织再结晶充分、且维氏硬度约为330 HV时,加工成型的U型钉缩口尺寸较小。对棒材再结晶组织有明显影响的工序主要是热拔和高温退火。由图1可知,经热拔和(700 ℃,2 h)高温退火后,棒材的显微组织以变形晶粒为主,再结晶程度相当低,硬度变化也不明显(见图2(b))。加大热拔变形量或提高高温退火温度可以改善棒材显微组织的再结晶程度,但当热拔变形量较大时,会加速热拔模具的破损,且热拔后棒材的表面质量和尺寸精度也不易控制。目前可通过适当调整高温退火工艺来改善其再结晶程度。另外,双曲线矫直后棒材的硬度明显增加,但低温去应力退火可有效减小矫直材的硬度。因此,可以通过进一步调整高低温退火工艺来改善棒材的组织性能。

2.2 不同高低温退火工艺对棒材组织性能的影响

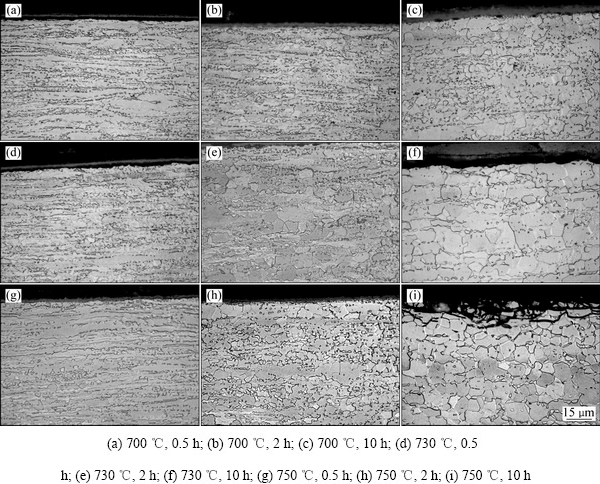

图3所示为热拔的棒材经不同高温退火工艺处理后纵截面边缘位置的光学显微组织。各棒材的显微组织均由灰色的α相和黑色的β相组成,不同退火工艺后显微组织明显不同。由图3(a)~(c)可知,700 ℃退火0.5 h后,α相为拉长的变形晶粒;退火2 h后,出现了少量的α相等轴晶;随退火时间进一步延长(10 h),α相全部为等轴晶。由图3(d)~(i)可知,在730和750 ℃高温退火时,随退火时间的延长,α相逐渐由变形晶粒变为等轴晶;且退火10 h后α相等轴晶发生明显长大。在退火时间相同的条件下,随退火温度的升高,棒材纵截面边缘位置的α相逐渐由变形晶粒变为等轴晶,且温度越高、等轴晶的尺寸越大。

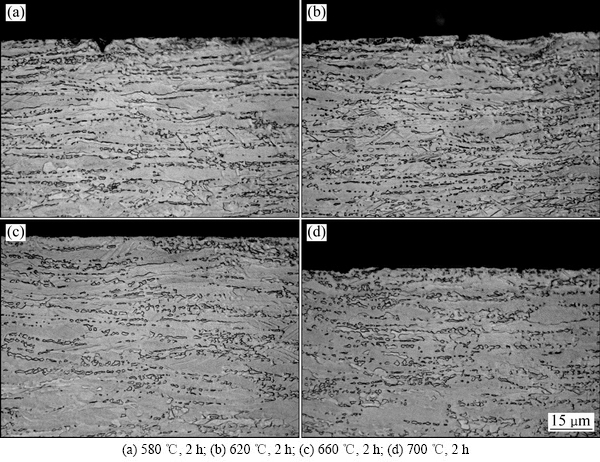

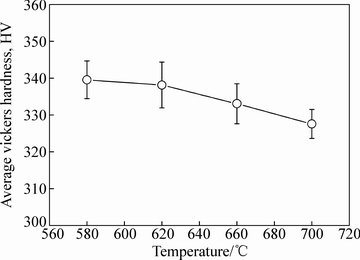

当棒材显微组织的再结晶程度较高时,医用U型钉的缩口主要是由双曲线矫直导致的残余应力引起的,通过低温去应力退火可以减小或消除残余应力。图4所示为热拔材经(700 ℃,2 h)退火和双曲线矫直处理,再经不同低温退火工艺处理后纵截面边缘位置的光学显微组织。由图4(b)可知,580~700 ℃低温退火2 h后的显微组织和(700 ℃,2 h)高温退火的组织(见图1(d))无明显差别,均由灰色的α相和黑色的β相组成,α相为拉长的变形晶粒。图5显示了不同低温退火工艺处理后纵截面的平均硬度。由图5可知,580、620、660和700 ℃退火后的硬度分别为342 HV、338 HV、333 HV和328HV。由上述结果可知,随低温退火温度的升高,矫直材的光学显微组织不发生明显变化,但其硬度逐渐降低。

图3 热拔材经不同高温退火工艺后纵截面边缘位置的显微组织(水平方向为热拔方向)

Fig. 3 Longitudinal-section microstructures at edge position of hot drawing bar after different high temperature annealing procedures (Drawing direction is parallel to horizontal direction)

图4 矫直材经不同低温退火工艺后纵截面边缘位置的显微组织(水平方向为热拔方向)

Fig. 4 Longitudinal-section microstructures at edge position of straightening bar after different low temperature annealing (Drawing direction is parallel to horizontal direction)

图5 矫直材经不同低温退火工艺后纵截面的平均硬度

Fig. 5 Longitudinal-section average hardness of straightening bar after different low temperature annealing procedures

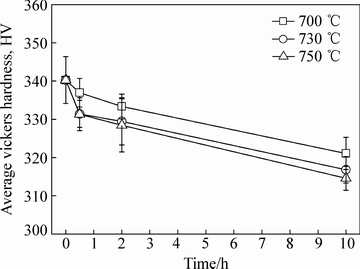

图6 热拔材经不同高温退火工艺后纵截面的平均硬度

Fig. 6 Longitudinal-section average hardness of hot drawing bar after different high temperature annealing procedures

图6所示为热拔材经不同高温退火工艺处理后纵截面的平均硬度。由图6可知,随退火温度的升高和退火时间的延长,棒材的硬度逐渐降低。730 ℃、750 ℃退火2 h时棒材的硬度约为328 HV,低于700 ℃退火2 h时棒材的硬度(340 HV);且730 ℃、750 ℃退火10 h时棒材的硬度也相差不大,分别为315 HV和317 HV,小于700 ℃退火10 h时棒材的硬度(321 HV)。由上述结果可知,在730~750 ℃退火2 h后,棒材显微组织的再结晶程度比较充分,硬度也能控制在330 HV左右。

2.3 高低温退火工艺组合下棒材的组织性能及U型钉的缩口尺寸

热拔材经730 ℃、750 ℃高温退火2 h,再结晶比较充分,棒材纵截面边缘位置的α相为等轴晶。双曲线矫直材从580 ℃到700 ℃低温去应力退火2 h后,硬度逐渐减小。为了进一步调控棒材的组织性能并探讨高低温退火工艺对U型钉缩口性能的影响,将热拔后的棒材分别在730 ℃、750 ℃高温退火2 h,双曲线矫直处理后分别在580 ℃、640 ℃低温退火2 h。将经过730~580 ℃、730~640 ℃、750~580 ℃和750~640 ℃高低温退火的棒材,依次标记为试样1、2、3和4。

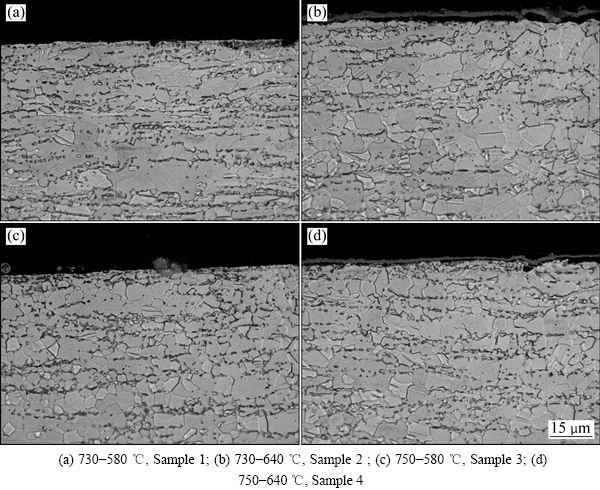

图7 不同高低温退火后纵截面边缘位置的显微组织(水平方向为热拔方向)

Fig. 7 Longitudinal-section microstructures at edge position of bar after different high and low temperature annealing (Drawing direction is parallel to horizontal direction)

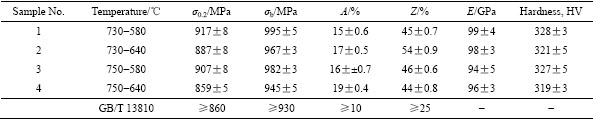

表1 不同退高低温火工艺后TC4钛合金棒材的力学性能

Table 1 Mechanical properties of TC4 alloy bars after different high and low temperature annealing procedures

图7所示为经过不同高低温退火工艺后棒材边缘位置的光学显微组织。由图7可知,各棒材α相无明显差别,均以等轴晶为主。如表1所示,试样1、2、3和4的硬度分别为328 HV、321HV、327 HV和319 HV,且通过分析拉伸曲线的弹性区域,估算出弹性模量分别为99、98、94和96 GPa。由表1可知,试样1、2和3的屈服强度、抗拉强度、断后伸长率以及断面收缩率都高于GB/T—13810[20]中对医用TC4钛合金棒材拉伸性能的要求,而试样4的屈服强度(859 MPa)有所下降。将不同退火工艺后的棒材加工成如图8所示的医用U型钉。各条件下U型钉的缩口尺寸如图9(a)所示,试样1和3 U型钉的缩口尺寸均匀且小于0.05 mm;试样2和4分别有3个和4个U型钉的缩口尺寸超过0.05 mm。图9(b)显示了U型钉的平均缩口尺寸,可知各棒材加工的U型钉的缩口尺寸均在0.05 mm以下,但试样1和试样3加工的U型钉的缩口稳定性更好。由上述结果可知,经730~750 ℃高温退火、580 ℃低温退火的工艺处理后,可获得力学性能符合医用TC4钛合金要求的棒材,且加工的U型钉缩口尺寸小于0.05 mm、稳定性良好。

图8 医用U型钉图

Fig. 8 Photo of medical U-shaped nail

图9 不同高低温退火工艺后医用U型钉缩口尺寸

Fig. 9 Necking size of U-shaped nails after different high and low temperature annealing

在高温退火温度较高的条件下,棒材变形组织再结晶程度提高的同时,棒材的强度有所下降且弯曲变形加剧。为保证棒材的直度,双曲线矫直时需要更大的压力,致使冷加工残余应力增大。为减小残余应力引起的较大缩口尺寸,需要增大低温去应力退火温度,而棒材在残余应力减小的同时会再次弯曲变形。因此,降低U型钉缩口尺寸并提高其稳定性,需要综合考虑各加工工艺的影响。

3 结论

1) 热拔和高温退火工艺对棒材的再结晶组织有明显影响,而双曲线矫直和低温退火工艺对棒材的力学性能影响较大。

2) 在730~750 ℃高温退火2 h,棒材显微组织的再结晶程度比较充分,硬度也能控制在330 HV左右。580~700 ℃低温退火2 h,随退火温度的升高,棒材的光学显微组织不发生明显变化,但其硬度逐渐降低。

3) 在730~750 ℃高温退火、580 ℃低温退火的条件下对棒材的显微组织进行调控,可获得力学性能符合医用TC4钛合金要求的棒材,由其加工的U型钉缩口尺寸可控制在0.05 mm以下,且稳定性好。

REFERENCES

[1] 贾宗海. 新型可灌注椎弓根螺钉的优化设计及力学检测[D]. 济南: 山东大学, 2011.

JIA Zong-hai. The optimum design and mechanical test of the novel annulated pedicle screw[D]. Ji’nan: Shandong University, 2011.

[2] 张亘瑷. 定向灌注椎弓根螺钉的设计和实验研究[D]. 广州: 南方医科大学, 2008.

ZHANG Gen-ai. Design and biomechanical evaluation of a pedicle screw with capability of directional injection[D]. Guangzhou: Southern Medical University, 2008.

[3] VILLAVICENCIO A T, SERXNER B J, MASON A, NELSON E L, RAJPAL S, FAES N, BURNEIKIENE S. Unilateral and bilateral pedicle screw fixation in transformationallumbar interbody fusion: radiographic and clinical analysis[J]. World Neurosurgery, 2015, 83(4): 553-559.

[4] KIM H J, KANG K T, PARK S C, KWON O H, SON J, CHANG B S, LEE C K, YEOM J S, LENKE L G. Biomechanical advantages of robot-assisted pedicle screw fixation in posterior lumbar interbody fusion compared with freehand technique in a prospective randomized controlled trial—Perspective for patient-specific finite element analysis[J]. The Spine Journal, 2017, 17(5): 671-680.

[5] MAHESH B, UPENDRA B, VIJAY S, ARUN K, SRINIVASA R. Perforations and angulations of 324 cervical medial cortical pedicle screws: a possible guide to avoid lateral perforations with use of pedicle screws in lower cervical spine[J]. The Spine Journal (Official Journal of the North American Spine Society), 2016, 17(3): 457-465.

[6] LAL H, KUMAR L, KUMAR R, BORUAH T, JINDAL P K, SABHARWAL V K. Inserting pedicle screws in lumbar spondylolisthesis–The easy bone conserving way[J]. Journal of Clinical Orthopaedics and Trauma, 2017, 8(2): 156-164.

[7] BOUCHER H H. A method of spinal fusion[J]. The Journal of Bone and Joint Surgery, 1959, 41(2): 248-259.

[8] HARRINGTON P R. Technical details in relation to the successful use of instrumentation in scoliosis[J]. Orthopedic Clinics of North America, 1972, 3(1): 499-567.

[9] HARRINGTON P R. Spinal instrumentation in the treatment of severe progressive spondylolisthesis[J]. Clinical Orthopaedics and Related Research, 1976, 117: 157-163.

[10] ROY-CAMILE R, ROY-CAMILE M, DEMEULENAERE C. Osteosynthesis of dorsal, lumbar, and lumbosacral spine with metallic plates screwed into vertebral pedicles and articular apophyses[J]. La Presse Médicale, 1970, 78(32): 1447-1448.

[11] ROY-CAMILE, SAILLANT G, MAZEL C. Internal fixation of the lumbar spine with pedicle screw plating[J]. Clinical Orthopaedics and Related Research, 1986, 203: 7-17.

[12] MAGERL F. External skeletal fixation of the lower thoracic and the lumbar spine[J]. Clinical Orthopaedics and Related Research, 1984, 189(189): 125-141.

[13] STEFFEE A D, BISCUP R S, STITKOWSKI D J. Segemental spine plates with pedicle screw fixation. A new internal fixation device for disorders of the lumbar and thoracolumbar spine[J]. Clinical Orthopaedics and Related Research, 1986, 203(203): 45-53.

[14] COTREL Y, DUBOUSSET J. A new technic for segmental spinal osteosynthesis using the posterior approach[J]. Orthopaedics and Traumatology (Surgery and Research), 2014, 100: 37-41.

[15] HUANG Z Y, WANG Q Y, WAGNER D, BATHIAS C. A very high cycle fatigue thermal dissipation investigation for titanium alloy TC4[J]. Materials Science and Engineering A, 2014, 600: 153-158.

[16] 房卫萍, 陈 沦, 史耀武, 虞文军, 毛智勇, 唐振云. 损伤容限钛合金的研究进展及应用现状[J]. 材料工程, 2010(9): 95-98.

FANG Wei-ping, CHEN Lun, SHI Yao-wu, YU Wen-jun, MAO Zhi-yong, TANG Zhen-yun. Research development and application of damage tolerance titanium alloy[J]. Journal of Materials Engineering, 2010(9): 95-98.

[17] 黄正阳, 郭子静, 文光平, 李 庆. 不同工艺退火后TC4合金的力学性能[J]. 金属退火, 2015, 40(9): 175-179.

UANG Zheng-yang, GUO Zi-jing, WEN Guang-ping, LI Qing. Mechanical properties of TC4 alloy annealed with different processes[J]. Heat Treatment of Metals, 2015, 40(9): 175-179.

[18] GRIZA S, ANDRADE C E C, BATISTA W W, TENTARDINI E K, ETROHAECKER T R. Case study of Ti6Al4V pedicle screw failures due to geometric and microstructural aspects[J]. Engineering Failure Analysis, 2012, 25(10): 133-143.

[19] 白鹏飞, 闵小华, 陶晓杰, 钟功诚, 白树玉, 程从前, 赵 杰. 显微组织对医用TC4钛合金U型钉缩口的影响[J]. 材料导报A, 2017, 31(7): 146-150.

BAI Peng-fei, MIN Xiao-hua, TAO Xiao-jie, ZHONG Gong-cheng, BAI Shu-yu, CHENG Cong-qian, ZHAO Jie. Effect of microstructure on necking of medical U-shaped nail of TC4 titanium alloy[J]. Materials Review A, 2017, 31(7): 146-150.

[20] 黄永光. 外科植入用钛及钛合金标准发展现状[J]. 钛工业进展, 2010, 27(1): 1-8.

HUANG Yong-guang. Developments of titanium and titanium alloy and standardization for surgical implant[J]. Titanium Industry Progress, 2010, 27(1): 1-8.

Microstructure control of medical TC4 alloy bar and necking property of U-shaped nail

BAI Peng-fei1, MIN Xiao-hua1, TAO Xiao-jie2, ZHONG Gong-cheng2, BAI Shu-yu2, CHENG Cong-qian1, ZHAO Jie1

(1. School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China;

2. Dalian Suntec Titanium Co., Ltd., Dalian 116600, China)

Abstract: Comparing with microstructure and mechanical property of TC4 alloy bar after different procedures. The results show that the recrystallization microstructure of the bar is found to be affected significantly by high temperature annealing, while the mechanical property is affected by hyperbola straightening and low temperature annealing. The recrystallization degree of hot drawing bar is sufficient after being annealed at 730-750 ℃ for 2 h. Optical microstructure of straightening bar does not change significantly, but the Vickers hardness decreases evidently after being annealed at 580-700 ℃ for 2 h. When the high and low temperature annealing are performed at 730-750 ℃ and 580 ℃, respectively, the mechanical property of the bar is suitable for the medical TC4 alloy based on the microstructure control. In addition, the necking size of U-shaped nail processed from the bar is desirable to be lower than 0.05 mm.

Key words: TC4 titanium alloy; U-shaped nail; necking size; microstructure; mechanical property

Received date: 2017-09-20; Accepted date: 2018-03-20

Corresponding author: MIN Xiao-hua; Tel: +86-13149898722; E-mail: minxiaohua@dlut.edu.cn

(编辑 龙怀中)

收稿日期:2017-09-20;修订日期:2018-03-20

通信作者:闵小华,教授,博士;电话:13149898722;E-mail:minxiaohua@dlut.edu.cn