文章编号:1004-0609(2013)S1-s0619-05

热轧温度对Ti-45Nb合金棒材微观组织及力学性能的影响

朱宝辉,王培军,刘彦昌,陈睿博,赵洪章,王晓平,郑爱国

(宁夏东方钽业股份有限公司 钛材分公司,石嘴山 753000)

摘 要:对Ti-45Nb钛合金精锻棒材分别在750、800和850 ℃下进行热轧实验,并利用光学显微镜对试样的横向和纵向组织进行观察,对合金的室温强度和塑性指标进行测试。结果表明:在800 ℃温度下热轧时,合金均具有优良的室温强度和塑性,室温强度在420 MPa以上,室温塑性大于25%,显微组织为动态再结晶的细小等轴组织,且随着轧制温度升高,抗拉强度和塑性在800 ℃轧制时同时增高,在850 ℃时又同时降低。通过对成品丝材的组织和性能对比分析可知,750和800 ℃轧制的棒材加工到丝材,性能均满足标准要求,Ti-45Nb合金的最佳热轧温度可以确定为750~800 ℃。

关键词:Ti-45Nb;钛合金;热轧温度;棒材;显微组织;力学性能

中图分类号:TG146.2 文献标志码:A

Influence of rolling temperature on microstructure and mechanical properties of Ti-45Nb alloy bars

ZHU Bao-hui, WANG Pei-jun, LIU Yan-chang, CHEN Rui-bo, ZHAO Hong-zhang, WANG Xiao-ping, ZHENG Ai-guo

(Titanium Product Plant, Ningxia Orient Tantalum Industry Co. Ltd, Shizuishan 753000, China)

Abstract: The titanium alloy forging bars was hot-rolled at 750, 800 and 850 ℃, respectively, the sample longitudinal and horizontal microstructure were observed using an optical microscope, the strength and plasticity of the alloy was tested at room temperature. The results show that hot-rolled alloys under 800 ℃ have excellent strength and ductility at room temperature, the strength at room temperature is over 420 MPa, ductility at room temperature is over 25%, the microstructure consists of fine equiaxed dynamic recrystallization grains. With the rolling temperature rising, the tensile strength and ductility of the bars rolled at 800 ℃ increase, the tensile strength and ductility of the bars rolled at 850 ℃ decrease. Comparative analysis of microstructure and properties of wires, the mechanical properties of the wires made of the bars rolled at 750 ℃ and 800 ℃ can meet the standards. It can be determined that Ti-45Nb alloy optimum hot rolling temperature is 750~800 ℃.

Key words: Ti-45Nb; titanium alloy; rolling temperature; bar; microstructure; mechanical properties

Ti-45Nb合金是华昌公司20世纪70年代开发的一种β型钛合金,具有强度高、热膨胀小、弹性模量低、导热性好、塑性优良、成形性好等特点,被用做航空航天器上的铆钉、固定发动机高温废气中的铝底板装置、超导磁体、有机废水废气处理装置以及植入人体电子装置的壳体等[1]。国外针对Ti-45Nb合金进行了大量的基础研究[2-6],作为一种铆钉材料技术已经比较成熟,并于1974年列入AMS 4982规范中,在航空航天领域已经全面取代纯钛的铆钉材料。该合金与Ti-6Al-4V合金搭配,制成的双金属铆钉已在空客和波音飞机上大量应用。目前,美国在航空航天领域全部改用冷加工性能优异的铌钛铆钉材料[7]。

国内对于该合金的研究起步较晚,目前只有少量的产品试用到航空领域,还有部分产品应用到超导磁体方面,多以棒、饼和环件为主。因此,该合金的研究在国内还属于起步阶段,需要开展更多的基础研究工作[7-12]。本文作者主要研究了不同热轧温度对Ti-45Nb合金棒材组织及性能的影响,以便为后续的丝材加工提供更良好的棒材坯料。

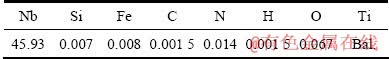

1 实验

合金铸锭经2次真空自耗电弧炉熔炼制备,规格为d 290 mm×680 mm,制备的铸锭化学成分见表1。铸锭在16 MN快锻机和SXP-13型精锻机上经6火次锻造为d 28 mm坯料,接下来在箱式电阻炉中分别采用750、800和850 ℃ 3种温度进行加热,在d 250孔型轧机上进行热轧,共经过21个孔型轧制到d 8.0 mm后,经车削扒皮加工为d7.8 mm的线材坯料,然后采用这些坯料分别加工到d 4.0 mm的丝材,并对丝材进行真空退火(800 ℃,60 min)热处理。

表1 Ti-45Nb合金的化学成分

Table 1 Chemical compositions of Ti-45Nb alloy (mass fraction, %)

对锻造坯料、轧制态的合金棒材和退火态的丝材按标准进行取样。采用Olympus GX51金相显微镜观察金相组织,使用INSTRON 4505电子万能试验机测试合金的的拉伸性能。为了进一步对成品丝材进行测试验证,并采用JSM-6460扫描电镜和能谱仪进行显微形貌观察和微区分析。

2 结果与讨论

2.1 热轧温度对合金显微组织的影响

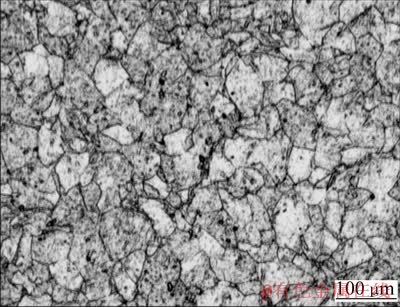

图1所示为Ti-45Nb合金锻造棒材铸造态的显微组织。观察表明经过多火次锻造的Ti-45Nb合金棒材的显微组织细化比较充分,组织较为均匀,相组成为β相,未发现铌不熔块或组织偏析。

图1 Ti-45Nb合金棒材锻造态的显微组织

Fig. 1 As-forged microstructure of Ti-45Nb alloy

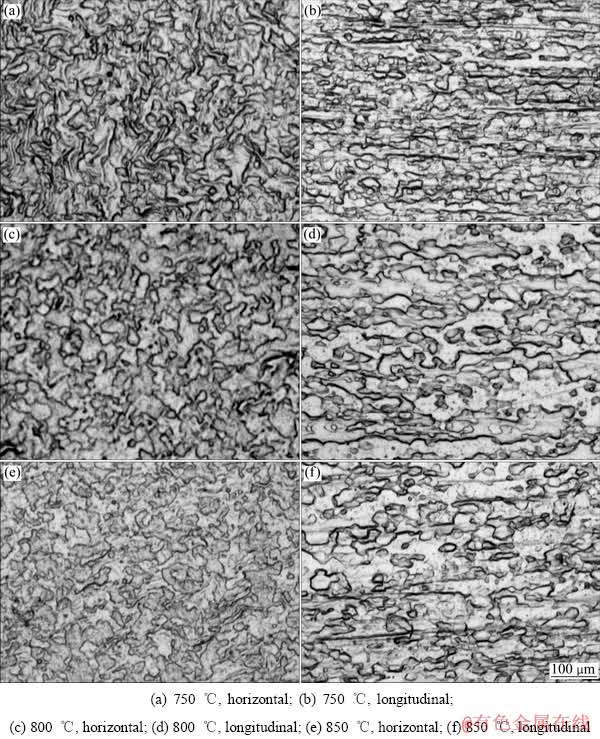

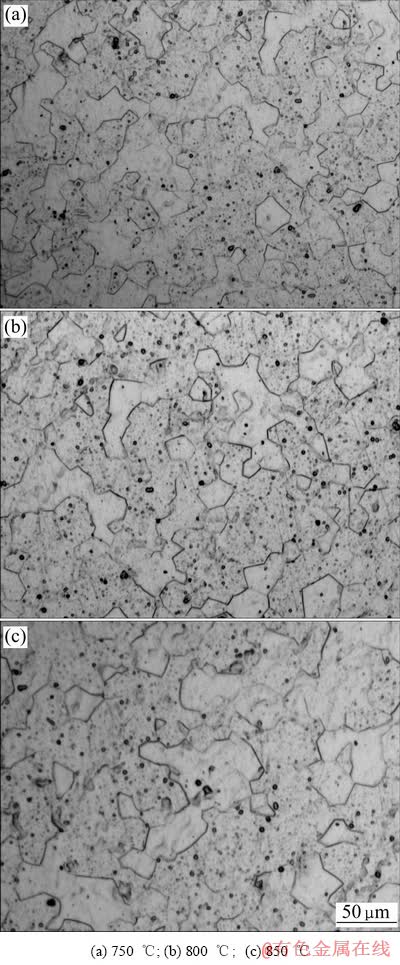

图2所示为Ti-45Nb合金棒坯分别在750、800和850 ℃ 3种温度下热轧到d 8.0 mm棒材的热加工态的横向和纵向的显微组织。从图1可以看出:热轧过程都伴随有金属热变形晶粒拉长和动态再结晶过程新生晶粒的生长,整体上晶粒尺寸明显比棒坯时的晶粒进一步细化。其中,750 ℃热轧合金棒坯的显微组织等轴晶粒最细,纵向变形的拉长组织也非常明显,基本处于一种金属变形晶粒拉长和动态再结晶晶粒球化的平衡状态,在变形组织周围新生出许多的细小等轴晶粒,但动态再结晶不充分。800 ℃热轧合金棒坯的显微组织晶粒略有长大,拉长的变形组织得到进一步消除,动态再结晶比750 ℃的略充分一些,说明该温度热变形是动态再结晶晶粒球化处于优势。850 ℃热轧合金棒坯的显微组织晶粒进一步长大,纵向仍残留一些变形组织,可能是由于轧制速度较快,应变速率较快影响动态再结晶的及时完成。从晶粒尺寸变化来看,750 ℃合金棒坯热轧的显微组织等轴晶粒最细,800 ℃热轧合金棒坯的显微组略有长大,850 ℃热轧合金棒坯的晶粒明显长大,即随着热轧温度的升高,晶粒尺寸逐渐开始增大。从组织均匀性来看,800 ℃热轧合金棒坯的显微组织最均匀。

2.2 热轧温度对合金拉伸性能的影响

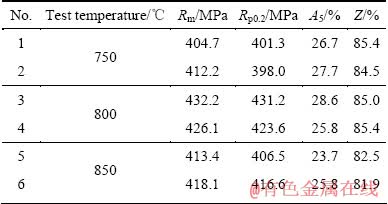

表2所列为Ti-45Nb合金棒材分别在3种温度下热轧后的拉伸测试结果。从表2可以看出:随着轧制温度升高,强度先上升后下降,塑性也是先上升后下降,但差异不是很大。其中,800 ℃热轧合金棒坯的拉伸性能最好,强度和塑性均佳,750 ℃热轧合金棒坯的强度比850 ℃的略低一些,但塑性比850 ℃的要好。

图2 Ti-45Nb合金不同温度热轧棒材的显微组织

Fig. 2 Microstructures of Ti-45Nb alloy bars rolled at different temperatures

表2 Ti-45Nb合金不同温度热轧棒材的拉伸性能

Table 2 Tensile properties of Ti-45Nb alloy bars rolled at different temperatures

虽然3种轧制温度的拉伸性能呈现出先升高又下降的趋势,但3种轧制温度的棒材塑性都比较好。棒材从d 28 mm一火次轧制到d 8 mm,总加工率91.8%,变形量非常大,但热轧后塑性仍然非常好,说明热轧过程动态再结晶的软化过程明显大于变形硬化过程。 因为热轧变形是通过多道次的反复变形来完成,在每一次道次中硬化与软化过程是同时发生的,关键看两者哪种过程占主导。

2.3 成品丝材的显微组织和性能

图3 所示为不同温度热轧的棒材经过拉拔加工到d 4.0 mm丝材退火后的显微组织。从显微组织对比来看,图3(a)和图3(b)的显微组织比较好,前者晶粒略细一些,图3(c)的组织不均匀,晶粒略有长大,即随着热轧温度升高,成品丝材的显微组织也逐渐增大的趋势,这主要还是组织遗传性所致。而且图3的显微组织为静态再结晶所得到的完全无畸变的等轴晶粒,与热轧动态再结晶的显微组织(如图2所示)明显不同,没有变形的拉长组织。

图3 不同温度热轧棒加工成丝材的显微组织

Fig. 3 Microstructures of wires processed by hot rolled bars at different temperatures

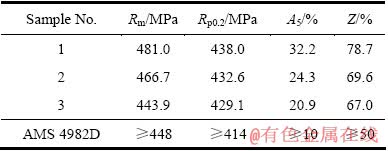

表3所列为不同温度热轧的棒材经过拉拔加工到d 4.0 mm丝材的拉伸性能。其中:试样1、2和3分别是采用750、800和850 ℃热轧的棒坯加工的丝材试样。从表3中的数据对比来看,试样1和试样2的拉伸性能均符合标准要求,试样3的抗拉强度不合格,试样1的强度和塑性最高,试样2其次,试样3强度和塑性均不如前者。即随着轧制温度升高,成品丝材的拉伸性能逐渐下降。结合图3的显微组织比较来看,晶粒较细,拉伸性能也较好,晶粒较大,拉伸性能相应也有所下降,这完全符合霍尔-配奇公式揭示的细晶强化的规律以及细化晶粒可以提高材料强塑性的规律[13]。

表3 不同温度热轧棒加工成丝材的拉伸性能

Table 3 Tensile properties of wires processed by hot rolled bars at 750, 800 and 850 ℃

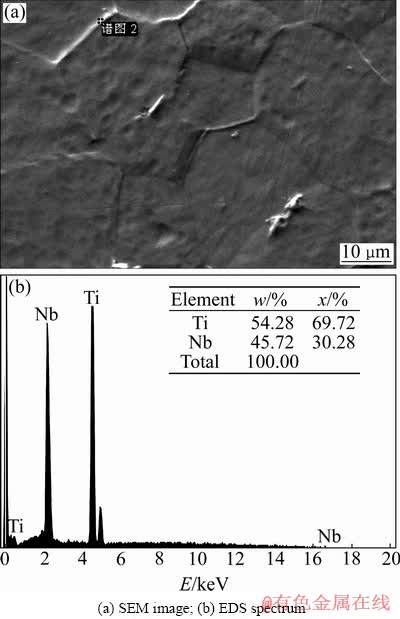

为了进一步对成品丝材进行测试验证,采用扫描电镜和能谱仪对成品丝材试样2进行显微形貌观察和微区分析,退火态丝材的SEM像及EDS谱见图4,从更高倍数的SEM像来看,显微组织为平衡态的等轴组织,没有发现铌不熔块,并在晶界处用能谱分析微区成分铌含量为45.72%,与表1中的铌含量45.92%比较接近,可以说明成品丝材的铌含量分布均匀。由于其他杂质元素含量微小,超出了能谱分析的范围,故而只有铌和钛元素的谱线及含量分析。

图4 退火态丝材的SEM像及EDS谱

Fig. 4 SEM images and EDS spectrum of annealed wire

3 结论

1) 热轧温度对Ti-45Nb棒材的组织和性能影响较大,通过对棒材的分析来看,选用800 ℃轧制组织较好,性能最优。

2) 通过对成品丝材的组织和性能分析来看,选用750 ℃热轧的坯料加工到成品丝材性能最好。

3) 所以,综合分析可以得出Ti-45Nb棒材的最佳轧制温度范围为750~800 ℃。

REFERENCES

[1] 国际钽铌研究中心. 钽铌译文集[M]. 刘贵材, 娄燕雄, 译. 长沙: 中南大学出版社, 2009: 180-186.

International Research Center of Tantalum and Niobium . Translation of tantalum and niobium [M]. LIU Gui-cai, LOU Yan-xiong, transl. Changsha: Central South University Press, 2009: 180-186.

[2] ZORN G, LESMAN A, GOTMAN I. Oxide formation on low modulus Ti45Nb alloy by anodic versus thermal oxidation [J]. Surface & Coatings Technology, 2006, 201: 612-618.

[3] GODLEY R, STAROSVETSKY D, GOTMAN I. Corrosion behavior of a low modulus β-Ti-45%Nb alloy for use in medical implants [J]. Journal of Materials Science: Materials in Medicine, 2006, 17: 63-67.

[4] DUTTA B, KELLER T, RETTENMAYR M, JANTSCH U, LUPTON D F. Effect of ternary Al, Ni additions on hydrogen absorption behaviour of Ti-45Nb alloys [J]. Materials Science and Engineering A, 2004, 382: 57-63.

[5] FENG Xin-jian, MACAK J M, SCHMUKI P. Flexible self-organization of two size-scales oxide nanotubes on Ti45Nb alloy [J]. Electrochemistry Communications, 2007, 9: 2403- 2407.

[6] ZORN G, GOTMAN I, GUTMANAS E Y, ADADI R, SALITRA G, SUKENIK C N. Surface modification of Ti45Nb alloy with an alkylphosphonic acid self-assembled monolayer [J]. Chem Mater, 2005, 17: 4218-4226.

[7] 商国强, 王新南, 唐 斌, 朱知寿, 寇宏超, 张丰收, 常 辉.紧固件用Ti-45Nb合金丝材的性能评价[J]. 中国有色金属学报, 2010, 20(S1): s70-s74.

SHANG Guo-qiang, WANG Xin-nan, TANG Bin, ZHU Zhi-shou, KOU Hong-chao, ZHANG Feng-shou, CHANG Hui. Property evaluation of Ti-45Nb alloy wires used in fastener [J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s70-s74.

[8] 王新南, 朱知寿, 商国强, 童 路, 张丰收, 龚少梅. 紧固件用Ti-45 Nb合金热处理工艺研究[J]. 钛工业进展, 2010, 27(6): 24-26.

Wang Xin-nan, ZHU Zhi-shou, Shang Guo-qiang, TONG Lu, ZHANG Feng-shou, GONG Shao-mei. Study on heat treatment processing of Ti-45Nb alloy used in fastener [J]. Titanium Industry Progress, 2010, 27(6): 24-26.

[9] TANG Bin, KOU Hong-chao, ZHU Zhi-shou, LI Jin-shan, SHANG Guo-qiang, ZHOU Lian. Enrichment behavior of ω clusters in cold-drawn Ti-45Nb filaments [J]. Materials Science Forum, 2011, 689: 315-320.

[10] SHANG Guo-qiang, ZHU Zhi-shou, KOU Hong-chao, WANG Xin-nan, TANG Bin, Li Jin-shan, CHANG Hui. Mechanical property study of Ti-45Nb alloy wires used in fastener [C]// ZHOU Lian, CHANG Hui, LU Ya-feng, XU Dong-sheng. Proceeding of the 12th World Conference on Titanium. Beijing: Science Press, 2011: 1042-1044.

[11] CHEN Yi, TANG Bin, LAI Min-jie, SHANG Guo-qiang, KOU Hong-chao, ZHANG Feng-shou, ZHU Zhi-shou, ZHOU Lian. Deformation and annealing textures of Ti-45Nb wires [C]// ZHOU Lian, CHANG Hui, LU Ya-feng, XU Dong-sheng. Proceeding of the 12th World Conference on Titanium. Beijing: Science Press, 2011: 420-423.

[12] 倪沛彤, 韩明臣, 张英明, 朱梅生, 董亚军. 宇航飞行器紧固件用钛合金的发展[J]. 钛工业进展, 2012, 29(3): 6-10.

NI Pei-tong, HAN Ming-chen, ZHANG Ying-ming, ZHU Mei-sheng, DONG Ya-jun. Development of titanium fasteners applying in space navigation [J]. Titanium Industry Progress, 2012, 29(3): 6-10.

[13] 唐仁正. 物理冶金基础[M]. 北京: 冶金工业出版社, 1997: 240-242.

TANG Ren-zheng. The basis of physical metallurgy [M]. Beijing: Metallurgy Industry Press, 1997: 240-242.

(编辑 陈爱华)

基金项目:宁夏东方钽业股份有限公司自主课题(SJ07-13-9)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:朱宝辉,高级工程师,硕士研究生; 电话:0952-2098907;E-mail: zbhwel@163.com