文章编号:1004-0609(2013)S1-s0153-06

Mo含量对钛合金晶粒长大行为及力学性能的影响

邱建科,马英杰,吉海滨,雷家峰,刘羽寅,杨 锐

(中国科学院 金属研究所,沈阳 110016)

摘 要:研究了不同Mo含量的Ti-6Al-2Sn-4Zr-xMo (x=2, 4, 6)合金在β单相区的晶粒长大行为,分析了Mo元素对钛合金显微组织及力学性能的影响。结果表明:Mo含量高的合金,晶界迁移激活能大,晶粒长大速度慢。对于不同Mo含量的合金,其晶粒尺寸的离散程度均随晶粒长大而增大。当合金的平均晶粒尺寸相同时,晶粒尺寸离散程度相近。当冷却速率相同时,Mo含量高的合金,其晶粒内部的α集束和片层细小;β晶粒越大α片层越小,这种趋势在Mo含量高的合金中更加明显。另外,Mo含量升高会降低合金的弹性模量,提高合金的断裂强度。

关键词:钛合金;Mo;晶粒尺寸;α集束;α片层

中图分类号:TG146.2 文献标志码:A

Effect of Mo content on grain growth behaviour and mechanical properties of titanium alloys

QIU Jian-ke, MA Ying-jie, JI Hai-bin, LEI Jia-feng, LIU Yu-yin, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The grain growth behaviour of Ti-6Al-2Sn-4Zr-xMo (x=2, 4, 6) alloys was investigated and the effects of Mo element on the microstructures and mechanical properties were analyzed. The results show that the alloy with high Mo content has low grain growth rate because of the high activation energy for the grain boundary migration. For the alloys with different Mo contents, the levels of grain size dispersion all increase with the grain growth, and when they have the same average grain size their grain size dispersion levels are also similar. For the alloys with the same cooling rate from β phase field, higher Mo content alloy has smaller α colonies and lamellaes, larger β grain size has smaller α lamellaes which is more obvious for the alloy with high Mo content. Moreover, the alloy has the lower elastic modulus and higher tensile strength with the increasing Mo content.

Key words: Ti alloy; Mo; grain size; α colony; α lamellae

晶粒长大行为是金属材料中最普遍的现象。在一定的温度和时间下,晶粒会通过原子扩散而长大。晶粒长大的驱动力源自总界面能的降低。随着晶粒长大行为的发生,其单位体积的晶界面积、储存能会下降,最后在一个更高的热力学稳定状态晶粒停止长大[1]。晶粒长大的动力学过程一般可由式(1)描述[2]:

(1)

(1)

式中:t为保温时间, 为t时间时的平均晶粒尺寸,

为t时间时的平均晶粒尺寸, 为初始平均晶粒尺寸,n为晶粒长大指数,k为常数,Qm为晶界迁移的激活能或原子扩散通过晶界的激活能,R为气体常数,T为热力学温度。

为初始平均晶粒尺寸,n为晶粒长大指数,k为常数,Qm为晶界迁移的激活能或原子扩散通过晶界的激活能,R为气体常数,T为热力学温度。

钛合金的力学性能与其显微组织关系密切,原始β晶粒大小作为钛合金显微组织中的一个重要参数,直接影响合金的性能[3],并与β晶粒内部的α集束和α片层大小有直接联系,间接影响合金后续的加工组织[4-5]和使役性能[6-7]。钛合金的晶粒长大行为已有不少研究,但主要集中在某类合金的动力学过程描述,而对合金元素的影响、晶粒长大过程的尺寸分布变化研究较少。

本文作者选取Ti-Al-Sn-Zr-Mo合金作为研究对象,通过变化Mo含量分别制备了Ti6242、Ti6244及Ti6246合金。Mo元素作为Ti的同晶元素,强烈地稳定β-Ti,在诸多高温、高强钛合金中,Mo元素都起着重要的作用[8-9]。研究不同Mo含量下的钛合金晶粒长大行为及力学性能,对合金特性的认识和显微组织的控制都很有帮助。

1 实验

3种合金Ti6242、Ti6244、Ti6246,其名义成分为Ti-6%Al-2%Sn-4%Zr-x%Mo (Ti624x, x=2, 4, 6, 质量分数,%)。合金先在β单相区开坯,温度为(tβ +150) ℃,后在两相区变形,温度为(tβ -30) ℃,3种合金的变形量相同。热处理样品为20 mm×20 mm×10 mm的试样块。β晶粒长大热处理温度为:tβ+20、1 050 、1 100、1 200、1 300 ℃,保温时间为1 h,冷却速率为慢冷(SC, 1 ℃/min)。

运用Image-Pro Plus软件进行晶粒大小统计。采用软件中的面积测量功能,将量取的晶粒面积等效为直径为D的圆面积,D值即为晶粒大小。

选取两组代表性状态进行组织观察和力学性能测试。状态一为3种合金的(tβ+20) ℃处理,状态二为3种合金具有相同的平均晶粒尺寸 2 090 μm,Ti6242、Ti6244、Ti6246的处理温度依次为1 240、1 300 、1 300 ℃)。微观组织观察在Zeiss-Axiover 200MAT金相设备上进行。力学性能测试包括拉伸试验和弹性模量测试。拉伸试验在岛津AG-100KNG上进行,试样尺寸为夹持段M16-工作段d 8,横梁位移速率为屈服前0.72 mm/min,屈服后3.84 mm/min。弹性模量的测试采用动态测量方法——敲击共振法,测试装置为比利时IMCE公司生产的RFDA HTVP 1750-C。

2 090 μm,Ti6242、Ti6244、Ti6246的处理温度依次为1 240、1 300 、1 300 ℃)。微观组织观察在Zeiss-Axiover 200MAT金相设备上进行。力学性能测试包括拉伸试验和弹性模量测试。拉伸试验在岛津AG-100KNG上进行,试样尺寸为夹持段M16-工作段d 8,横梁位移速率为屈服前0.72 mm/min,屈服后3.84 mm/min。弹性模量的测试采用动态测量方法——敲击共振法,测试装置为比利时IMCE公司生产的RFDA HTVP 1750-C。

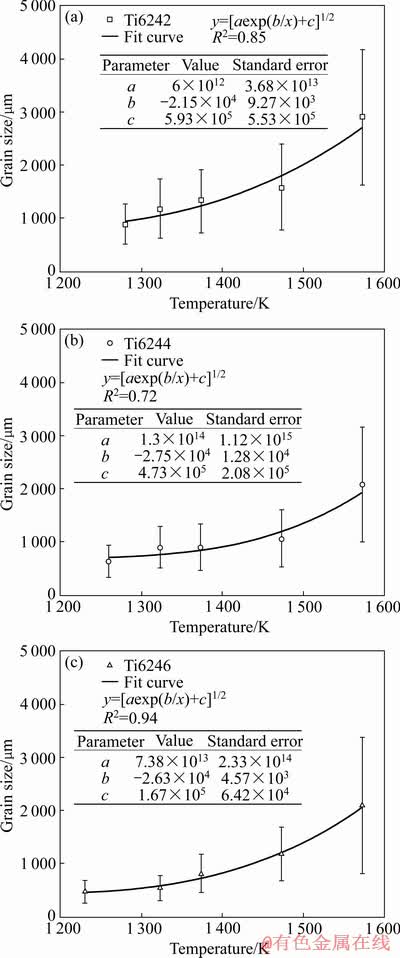

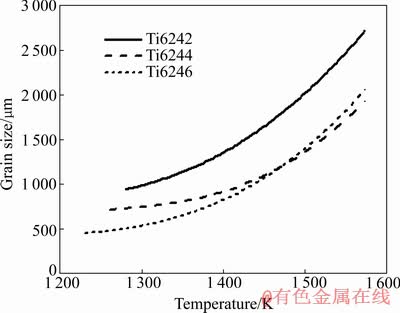

图1 Ti624x(x=2, 4, 6)合金保温1 h时平均晶粒尺寸随温度的变化

Fig. 1 Variation of average grain sizes of Ti624x (x=2, 4, 6) alloys with temperatures held for 1 h

2 结果和分析

2.1 平均晶粒尺寸与温度的关系

图1所示为Ti624x 3种合金的平均晶粒尺寸随温度变化的关系。带有误差棒的数据点为实验过程中的实测点,曲线是根据晶粒长大动力学方程拟合获得。用于曲线拟合的方程,由式(2)演变获得。式(2) 的推导过程可参考文献[1]。式(1)是式(2)的一般写法。虽然研究发现由于固溶原子对晶界迁移的拖拽作用或织构

效应导致晶粒长大指数n一般大于2[2],但其偏差不大,且晶粒长大指数n会随着温度的升高有一定的变化[10-11],因此,为了使平均晶粒尺寸随温度变化关系的描述变为可能,采用n值为2的式(2)进行曲线拟合。

(2)

(2)

通过对式(2)进行变形得到式(3):

(3)

(3)

令 =y,kt=a,-Qm/R=b,T=x,

=y,kt=a,-Qm/R=b,T=x, =c,得到用于最终曲线拟合的式(4):

=c,得到用于最终曲线拟合的式(4):

(4)

(4)

从图1可以看出,随着温度升高,晶粒尺寸逐渐变大,且长大速率增加,整个长大过程呈抛物线增长。将图1中的拟合曲线绘制于图2进行比较,可以看 出:在温度较低阶段,Mo含量低的合金的平均晶粒尺寸明显大于Mo含量高的;在温度较高阶段时仍保持同样的趋势,但Ti6244和Ti6246的晶粒尺寸差别缩小。由曲线拟合获得的参数,可进一步将3种合金的晶界迁移激活能(Qm)值求出,晶界迁移激活能除了与合金本身有关,还受到晶粒长大过程中保温时间的影响[12]。结合式(4)中Qm=-bR可以得出,Ti624x合金保温1 h时的晶界迁移激活能,Ti6242的为178.9 kJ/mol,Ti6244的为228.8 kJ/mol,Ti6246的为218.5 kJ/mol。

图2 Ti624x(x=2, 4, 6)合金平均晶粒尺寸随温度变化的拟合曲线

Fig. 2 Fitting curves of average grain size of Ti624x (x=2, 4, 6) alloys varying with temperature

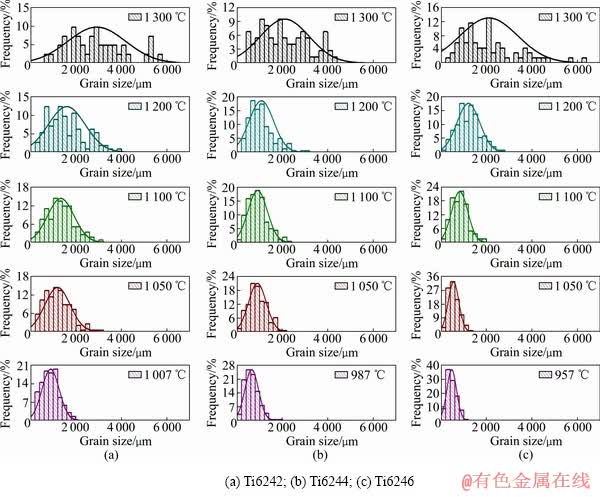

2.2 晶粒尺寸分布与温度的关系

除了平均晶粒尺寸,晶粒尺寸分布也是反映金属材料微观组织在晶粒长大过程中变化的重要特征量[13]。随着温度升高,平均晶粒尺寸和晶粒尺寸分布均发生变化。图3所示为Ti624x (x=2, 4, 6)合金在不同温度下晶粒尺寸分布及正态分布曲线拟合。从图3中可以看出,3种合金的晶粒尺寸分布随温度变化的趋势一致。晶粒尺寸分布的离散程度均随着温度的升高而增大。

图3 Ti624x (x=2, 4, 6)合金在不同温度下晶粒尺寸分布及正态分布曲线拟合

Fig. 3 Grain size distribution and normal distribution fitting curves of Ti624x (x=2, 4, 6) alloys after different temperatures

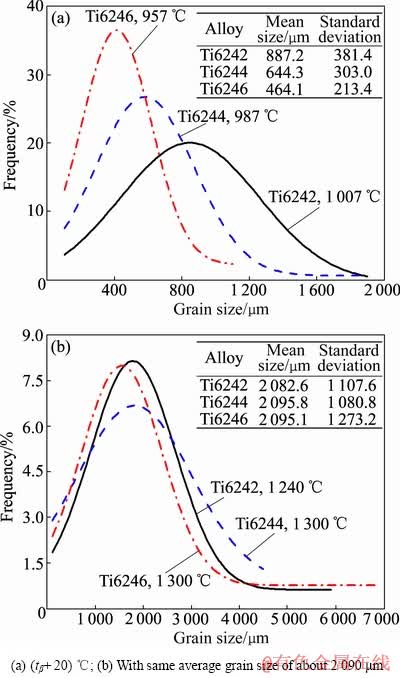

比较了Ti624x 3种合金在两组代表性状态热处理下的晶粒尺寸分布情况。如前所述,状态一为3种合金的(tβ+20) ℃处理;状态二为3种合金具有相同平均晶粒尺寸(2 090 μm)的处理。两组状态下的晶粒尺寸分布拟合曲线分别如图4(a)和(b)所示。从图4(a)可以看出,Ti6242、Ti6244、Ti6246合金经(tβ+20) ℃处理后,其平均晶粒尺寸随着Mo含量升高而依次减小,晶粒尺寸的离散程度也依次减小。而当3种合金具有相同的平均晶粒尺寸时,如图4(b)所示,其晶粒尺寸离散程度相近。这表明不同类型的钛合金,无论是近α的Ti6242还是近β的Ti6246,其晶粒长大规律是基本一致的。只是由于合金元素添加量的不同,不同类型合金的晶界迁移激活能发生变化,因此在某一热处理区间呈现出平均晶粒尺寸和晶粒尺寸分布的差异性,如图4(a)所示的tβ+20 ℃处理。

图4 Ti624x(x=2, 4, 6)合金在两组代表性状态热处理下的晶粒尺寸正态分布拟合曲线

Fig. 4 Normal fitting curves of grain size distribution of Ti624x (x=2, 4, 6) alloys under two typical conditions

2.3 Mo含量对合金显微组织的影响

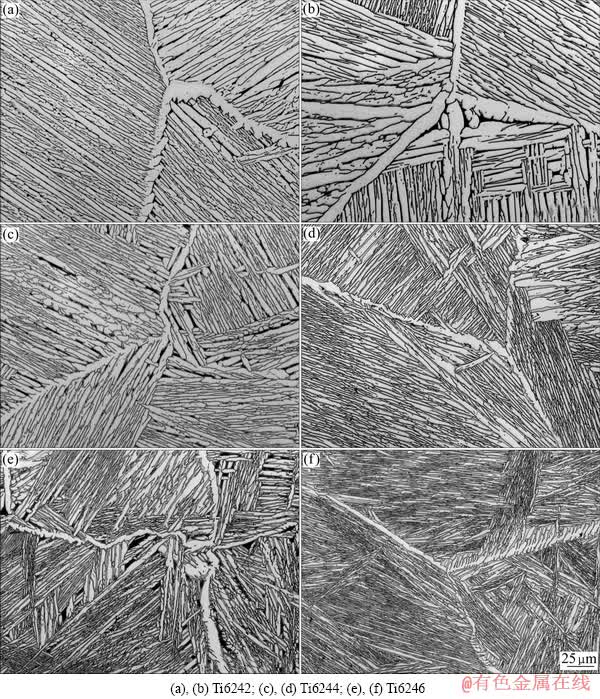

钛合金魏氏组织中α集束和α片层对合金的力学性能有重要的影响[14],影响集束和片层大小的因素主要有合金类型、原始β晶粒尺寸及β相区处理后的冷却速率。对比Ti624x 3种合金分别在(tβ+20) ℃处理和相同平均晶粒尺寸(2 090 μm)处理的高倍金相组织,如图5所示。由图5可以看出,随着Mo含量升高,无论是在(tβ+20) ℃的热处理状态下,还是相同平均β晶粒尺寸的热处理状态下,α集束和α片层都明显变小。这是因为Mo元素作为β稳定元素,其含量的升高使得β相到α相的转变温度下降,α集束的形核位置变多[15]。另外,由于相转变温度下降,在β相转变为α相的过程中原子扩散能力变弱,再加上Mo含量高的合金残留β相多,故其α片要细小。对比图5(c)和(d)、(e)和(f)还可以发现,同种合金在冷却速率相同的情况下,β晶粒尺寸大的α片层要细小。并且随着Mo含量的升高,这种β晶粒尺寸大,α片层厚度反而细小的情况变得更显著,如图5中的Ti6246合金。有人将该现象解释为晶粒尺寸对β相到α相的转变存在影响[15-16]。他们认为大β晶粒尺寸的相转变温度要低于小β晶粒尺寸的,故而大β晶粒内部形成α相的原子扩散能力变弱,因此出现了大β晶粒的α片层厚度小于小β晶粒的α片层厚度。而作者认为这种原子扩散能力变弱的更本质原因应该是来自空位浓度的影响,大晶粒内部的空位浓度低于小晶粒,进而影响β到α相这一扩散型相变的速率,因此出现大β晶粒内部α片层厚度小的现象。

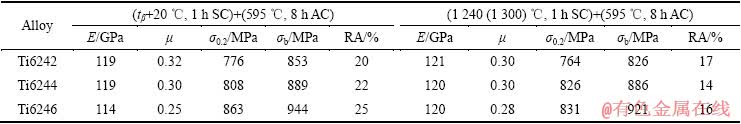

2.4 Mo含量对合金力学性能的影响

Mo元素作为β稳定元素,其含量的变化会影响合金的相比例和显微组织,同时影响合金的力学性能。表2给出了Ti624x 3种合金在两组代表性状态下的弹性模量(E)、泊松比(μ)、断面收缩率(RA)及屈服强度(σ0.2)、抗拉强度(σb)等力学性能测试结果。从表2可以看出,随着Mo含量升高,两组状态下合金的弹性模量(E)和泊松比(μ)均略有下降,而强度则明显升高。这是因为Mo含量升高,增加了合金中的β相含量,β相含量增加会降低合金的弹性模量和泊松比[5]。同时,添加Mo元素会细化α集束和片层,并起到一定的固溶强化效果,因此高Mo含量的合金断裂强度高。另外,β晶粒的大小[17](晶界的多少)也会对合金的性能产生影响。β晶粒越大,其强度和塑性都会有所下降。

图5 Ti624x(x=2, 4, 6)合金在两组代表性状态下的高倍金相组织

Fig. 5 OM microstructures of Ti624x alloys under two typical conditions of (tβ+20) ℃ ((a), (c), (e)) and with same average grain size of about 2 090 μm ((b), (d), (f))

表1 Ti624x(x=2, 4, 6)合金在两组代表性状态下的力学性能

Table 1 Mechanical properties of Ti624x (x=2, 4, 6) alloys under two typical conditions

3 结论

1) 给出了Ti624x(x=2, 4, 6)合金晶粒尺寸随着温度变化的关系,获得了Ti6242、Ti6244、Ti6246合金保温1 h的晶界迁移激活能,依次为178.9、228.8、 218.5 kJ/mol。

2) 随着Mo含量的变化,Ti624x (x=2, 4, 6)合金的β晶粒长大规律基本一致;随着温度的升高,合金的β晶粒迅速长大,晶粒尺寸的离散程度也增大。Mo含量高的合金,其晶界迁移的激活能大,晶粒长大速度慢。

3) 相同冷却速率条件下,Mo含量高的合金,其晶粒内部的α集束和α片层要细小;同种合金中β晶粒大的α片层厚度越小,该现象在Mo含量高的合金中更明显。

4) Mo作为β稳定元素,增加其含量会改变合金的相比例,从而使得合金的弹性模量和泊松比下降;另外,通过组织细化和固溶强化,Mo会增加合金的断裂强度。

REFERENCES

[1] 胡赓祥, 蔡 珣, 戎咏华. 材料科学基础[M]. 上海: 上海交通大学出版社, 2010: 206-208.

HU Geng-xiang, CAI Xun, RONG Yong-hua. Fundamentals of materials science [M]. Shanghai: Shanghai Jiao Tong University Press, 2010: 206-208.

[2] SEMIATIN S L, SOPER J C, SUKONNIK I M. Short-time beta grain growth kinetics for a conventional titanium alloy [J]. Acta Materialia, 1996, 44(5): 1979-1986.

[3] 马英杰, 刘建荣, 雷家峰, 刘羽寅, 杨 锐. 钛合金β晶粒生长规律及晶粒尺寸对损伤容限性能的影响[J]. 稀有金属材料与工程, 2009, 38(6): 976-981.

MA Ying-jie, LIU Jian-rong, LEI Jia-feng, LIU Yu-yin, YANG Rui. β-grain growth and influence of its grain size on damage-tolerance property in titanium alloy [J]. Rare Metal Materials and Engineering, 2009, 38(6): 976-981.

[4] ARI-GUR P, SEMIATIN S L. Evolution of microstructure, macrotexture and microtexture during hot rolling of Ti-6Al-4V [J]. Materials Science and Engineering A, 1998, 257(1): 118- 127.

[5] BIELER T R, SEMIATIN S L. The origins of heterogeneous deformation during primary hot working of Ti-6Al-4V [J]. International Journal of Plasticity, 2002, 18(9): 1165-1189.

[6] BANTOUNAS I, DYE D, LINDLEY T C. The effect of grain orientation on fracture morphology during high-cycle fatigue of Ti-6Al-4V [J]. Acta Materialia, 2009, 57(12): 3584-3595.

[7] BANTOUNAS I, LINDLEY T C, RUGG D, DYE D. Effect of microtexture on fatigue cracking in Ti-6Al-4V [J]. Acta Materialia, 2007, 55(16): 5655-5665.

[8] 朱绍祥. 同晶beta稳定元素对高温钛合金显微组织和抗氧化性能的影响[D]. 沈阳: 沈阳大学, 2008: 24-26.

ZHU Shao-xiang. Effect of isomorphous beta-stabilizing elements on microstructures and oxidation resistance of high temperature titanium alloy [D]. Shenyang: Shenyang University, 2008: 24-26.

[9] 张尚洲, 雷家峰, 关少轩, 刘羽寅, 李 东. 热处理对高弹高强高韧钛合金性能的影响[J]. 金属学报, 2002, 38(s1): 74-77.

ZHANG Shang-zhou, LEI Jia-feng, GUAN Shao-xuan, LIU Yu-yin, LI Dong. Influence of heat treatment on mechanical properties of high elastic modulus, high strength, high toughness and weldable titanium alloys [J]. Acta Metallurgica Sinica, 2002, 38(sl): 74-77.

[10] SEMIATIN S L, SOPER J C, SUKONNIK I M. Grain-growth in a conventional titanium-alloy during rapid, continuous heat-treatment [J]. Scripta Metallurgica et Materialia, 1994, 30(7): 951-955.

[11] GIL F J, PLANELL J A. Grain growth kinetic of the near alpha titanium alloys [J]. Journal of Materials Science Letters, 2000, 19(22): 2023-2024.

[12] WANG T, GUO H Z, TAN L J, YAO Z K, ZHAO Y, LIU P H. Beta grain growth behaviour of TG6 and Ti17 titanium alloys [J]. Materials Science and Engineering A, 2011, 528(21): 6375- 6380.

[13] 毛卫民, 赵新兵. 金属的再结晶与晶粒长大[M]. 北京: 冶金工业出版社, 1994: 242-265.

MAO Wei-min, ZHAO Xin-bing. Recrystallization and grain growth of metals [M]. Beijing: Metallurgical Industry Press, 1994: 242-265.

[14] LüTJERING G, WILLIAMS J C. Titanium [M]. Berlin: Springer, 2007: 216-226.

[15] LENAIN A, CLEMENT N, VERON M, JACQUES P J. Characterization of the alpha phase nucleation in a two-phase metastable beta titanium alloy [J]. Journal of Materials Engineering and Performance, 2005, 14(6): 722-727.

[16] GIL F J, GINEBRA M P, MANERO J M, PLANELL J A. Formation of α- structure: Effects of grain size and cooling rate on the

structure: Effects of grain size and cooling rate on the  morphologies and on the mechanical properties in Ti6Al4V alloy [J]. Journal of Alloys and Compounds, 2001, 329: 142-152.

morphologies and on the mechanical properties in Ti6Al4V alloy [J]. Journal of Alloys and Compounds, 2001, 329: 142-152.

[17] GIL F J, PLANELL J A. Behaviour of normal grain growth kinetics in single phase titanium and titanium alloys [J]. Materials Science and Engineering A, 2000, 283(1/2): 17-24.

(编辑 李向群)

基金项目:国家重点基础研究发展计划资助项目(2011CB606404);国家自然科学基金资助项目(51171195)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:雷家峰,研究员,博士;电话:024-23971958;E-mail:jflei@imr.ac.cn