文章编号:1004-0609(2013)S1-s0057-05

近β钛合金时效过程中次生α相的形核机制

张 雪1,寇宏超1,赖运金2,张丰收2,李金山1,周 廉2

(1. 西北工业大学 凝固技术国家重点实验室,西安 710072;

2. 西部超导材料科技股份有限公司,西安 710016)

摘 要:系统研究了Ti-5553、Ti-55531和Ti-7333近β钛合金在β单相区固溶水冷+时效(SWA)、固溶+直接时效(SA)以及固溶缓冷+时效(SFA)等热处理制度下次生α相的形核位置、形貌和分布,探讨了近β钛合金的次生α相形核机制。结果表明:3种合金在SWA过程中,针状α相在晶界和晶内同时形核;在SFA过程中,片层状α相优先占据晶界位置析出;在SA过程中,点状α相在基体上弥散分布;此外,由于含有较多的慢扩散Mo元素,Ti-7333合金表现出较慢的时效响应,时效过程中α相形核位置分布不均匀,易于沿晶界及位错析出。EBSD结果分析显示:β晶界处α相的析出受晶界能影响,优先在大角晶界析出。

关键词:近β钛合金;热处理;次生α相;形核;EBSD

中图分类号:TG146.2+3 文献标志码:A

Nucleation mechanism of secondary α phase in near-β titanium alloy

ZHANG Xue1, KOU Hong-chao1, LAI Yun-jin2, ZHANG Feng-shou2, LI Jin-shan1, ZHOU Lian2

(1. State Key Laboratory of Solidification Processing, Northwestern Polytechnical University, Xi’an 710072, China;

2. Western Superconducting Technologies Co., Ltd, Xi’an 710016, China)

Abstract: The nucleation place, morphology and distribution of α phase in different process routes of the near-β titanium alloy (Ti-5553, Ti-55531 and Ti-7333 alloys) were investigated systematically. The results show that the needle-like secondary α precipitate morphology forms after solution treatment above β transus followed with ageng treatment (SWA). The dot α precipitation with different variants precipitate within β grains as well as along β grain boundaries during β solution follow by direct ageing (SA). In addition, the slower ageing respond and a nonuniform distribution of α precipitate are observed in Ti-7333 alloy, which results from the more slow-diffusing element Mo in Ti-7333 alloy. In the condition of β solution followed by furnace cooling and ageing (SFA), the α phase preferentially nucleates at grain boundaries. The EBSD analyses reveal that the grain boundary α precipitation is strongly influenced by β grain boundary energy which meant that grain boundary α tends to form preferentially at high energy grain boundaries (high-angle grain boundaries).

Key words: near-β titanium alloy; heat treatment; secondary α precipitation; nucleation; EBSD

随着新一代航空航天飞行器向高速化、大型化、结构复杂化以及提高燃油效率等方向的跨越式发展,具有超高强度(σb≥1 350 MPa)、高韧性、高损伤容限及综合加工性能的近β钛合金成为近年研发及应用的重点[1-3]。研究表明,Ti-6.8Mo-4.5Fe-1.5Al (TIMETALLCB)[4]、Ti-10V-2Fe-3Al(Ti-1023)[5-6]、Ti- 5Al-5Mo-5V-3Cr-0.5Fe(Ti-5553)[7-8]、Ti-3Al-5Mo-5V- 4Cr-2Zr(Ti-B19)[9]、Ti-5Al-4Mo-4V-4Cr-3Zr(Ti-1300)[10]等高强钛合金的服役性能与显微组织中α相的含量、尺寸、形貌及分布有密切关联[11-13]。通过热处理控制α相是合金获得最佳性能匹配最有效的手段。

热处理过程中的β→α相变包括α相的形核与长大两个过程。不同合金在α相形核阶段表现出不同特点。典型近β钛合金Ti-5553合金经900 ℃固溶、700 ℃时效后,α相不仅在晶界析出,而且在晶内也呈“束状”析出,α相的形核位置与位错线一致[14]。而Ti-LCB合金中,α相的形核与时效温度有关,在较高温度时效时,α相优先在晶界形核,而在较低温度时,在晶界和晶内都有α相形核,另外,间接时效更有利于晶内α相的形成[15]。对Ti-LCB合金中晶界α相进一步的研究中,BOHEMEN等[16]发现,晶界α相的数量随着β晶界取向差的增加而增加,其中约70%的晶界α相是在两侧晶粒的{110}面具有一致取向的β晶界处析出。钛合金中次生α相的形核与合金成分、温度等因素密切相关。为此,本文作者研究了Ti-5553、Ti-55531和Ti-7333近β钛合金在β单相区固溶水冷+时效(SWA)、固溶+直接时效(SA)以及固溶缓冷+时效(SFA)等热处理制度下次生α相的形核位置、形貌和分布,探讨了近β钛合金次生α相形核机制。

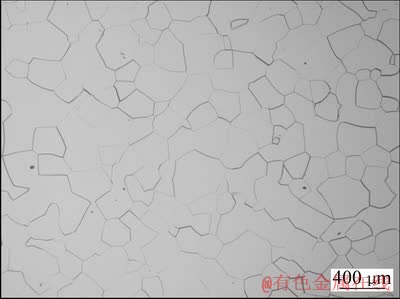

1 实验

实验用Ti-5553、Ti-55531和Ti-7333合金经真空自耗电弧熔炼后,开坯锻造成棒材,3种合金的棒材均为等轴组织,初生α相呈短棒状均匀分布在β基体上,体积分数约为40%。通过金相法测定Ti-7333合金和Ti-55531合金的相变点温度为850 ℃,Ti-5553合金的相变点为870 ℃。通过线切割的方法从棒材上切取尺寸为10 mm×10 mm×10 mm 的试样随炉进行β单相区固溶水冷+时效(SWA)、固溶+直接时效(SA)以及固溶缓冷+时效(SFA)3种热处理实验。3种合金经相变点以上(900 ℃)固溶处理后,水淬的组织为β单相组织,如图1所示。Ti-5553合金晶粒大小约为300 μm,Ti-55531合金和Ti-7333合金晶粒大小约为200 μm。利用OLYMPUS PMG3光学显微镜和JSM-6700F FEG扫描电镜进行组织观察,EBSD测试在装有电子背散射衍射探头的场发射型扫描电镜上进行。EBSD实验数据采集及结果分析采用Oxford instrument的HKL channel 5 软件。

图1 Ti-7333合金经900 ℃固溶处理30 min后的水淬组织照片

Fig. 1 Optical micrograph of Ti-7333 alloy after treatment at 900 ℃ for 30 min followed by WQ

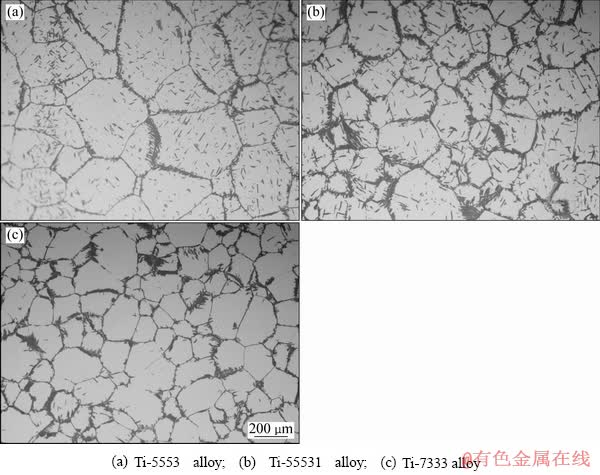

图2 合金经(900 ℃,45 min)+WQ+ (700℃,5 min)处理后的显微组织

Fig. 2 Microstructures of samples after (900 ℃,45 min), WQ and (700 ℃, 5 min)

2 结果与讨论

2.1 β相区固溶水冷再时效(SWA)

图2所示为3种近β钛合金经900 ℃固溶处理45 min后水淬至室温,再在700 ℃时效处理5 min后的显微组织。由图2可以看出,在水冷至室温过程中形成的ω相为次生α相形核提供条件,Ti-5553合金和Ti-55531合金中α相析出较均匀,以点状或星状析出为主;而在Ti-7333合金中,α相析出数量较少且不均匀,部分区域细小α相大量聚集呈“黑斑”状,其他区域α相析出连点成线现象明显。出现这种差别的原因可能与Ti-7333合金中Mo当量较高,淬火条件下β相分解不完全,形成ω相不稳定且含量较少,从而导致α相易于在晶界等缺陷处形核有关[17]。

2.2 β相区固溶后直接时效(SA)

Ti-5553合金和Ti-7333合金经(900 ℃,30 min)固溶处理后以100 ℃/min速率冷却至700 ℃再时效5 min后的显微组织如图3所示。由图3可以看出,两种合金的β晶界处均有连续或不连续α薄膜析出,晶内有点状α相弥散析出。但在Ti-5553合金晶内点状α相分布较均匀,尺度较大;在Ti-7333合金中晶界α相占大多数,晶内α相析出不均匀且尺寸较小,表现为部分晶粒内α相析出较多,而部分晶粒内析出较少。SA热处理状态下合金中次生α相的形核数量明显少于固溶处理水冷后再时效的组织。这说明从900 ℃快冷至700 ℃的过程由于没有ω相的存在,在时效过程中α相只能在缺陷处形核,从而导致形核数量较少。

图3 合金经(900 ℃,30 min)+100 ℃/min+(700 ℃,5 min)处理后的显微组织

Fig. 3 Microstructures of samples after (900 ℃, 30 min) followed by fast cooling 100 ℃/min to (700 ℃, 5 min)

图4 合金经(900 ℃,45 min)+FC+(700 ℃,5 min)处理后的显微组织

Fig. 4 Microstructures of samples after (900 ℃,45 min)+FC+(700 ℃,5 min)

2.3 β相区固溶缓冷后时效(SFA)

3种合金经900 ℃固溶处理45 min后缓慢冷却至700 ℃再保温5 min,获得如图4所示的显微组织。在Ti-5553合金和Ti-55531合金中α相在晶界处和晶粒内均有析出,α集束在晶粒内平行或交错分布, 而在Ti-7333合金中α相只在晶界处析出,且晶界形貌各有不同。

2.4 晶界取向差对晶界α相的影响

有学者认为,上述组织中晶界形貌的差别与相邻β晶粒取向差有关。为此,本文作者采用EBSD对Ti-7333合金经β相区固溶后缓冷至700 ℃保温5 min的试样组织进行分析,得到晶界取向对晶界α相析出行为的影响以及晶界α相特征。图5所示为Ti-7333合金的EBSD图像以及对应区域晶界取向差分布图,不同颜色代表不同位向的晶粒。对大约100条晶界的取向差进行了统计,发现有α相析出的晶界取向差均大于15°,即为大角晶界,总会优先在{110}面具有一致取向的大角晶界上析出(如黑色字体),而在小角晶界上不析出(红色字体)。这种差异主要是来源于晶界能。对于小角晶界,由于界面上的原子相对有序地整齐排布,使得小角晶界相对于大角晶界有着很低的界面能和扩散系数,这就使得α相在小角度晶界上的形核和生长都更加困难。

图5 Ti-7333合金在900 ℃固溶45 min后以2 ℃/min冷却速度降温至650 ℃的EBSD谱及其相应区域的显微组织以及典型晶界处的β相{110}面极图

Fig. 5 Microstructure of Ti-7333 alloy and corresponding EBSD map, {110} β poles of typical grain boundaries

3 结论

1) 近β钛合金中次生α相均优先在晶界等位错处形核。晶界处存在α相变体选择,在相邻晶粒的{110}面具有一致取向的晶界处析出较多。

2) 由于β相区固溶后水冷再时效过程中ω相的形成以及空位聚集,比直接时效时更有利于α相形核。从β单相区缓慢冷却过程为合金元素充分扩散提供条件,有利于α相的均匀形核及长大。

3) Ti-7333合金由于含有较多的慢扩散Mo元素,表现出较慢的时效响应,时效过程中α相形核位置分布不均匀,易于沿晶界及位错析出。

REFERENCES

[1] RODNEY R B, BRIGGS R D. The use of β titanium alloys in the aerospace industry[J]. Journal of Materials Engineering and Performance, 2005, 14(6): 681-685.

[2] 王鼎春. 高强钛合金的发展与应用[J]. 中国有色金属学报, 2010, 20(S1): s958-s963.

WANG Ding-chun. Development and application of high-strength titanium alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s958-s963.

[3] 商国强, 朱知寿, 常 辉, 王新南, 寇宏超, 李金山. 超高强度钛合金研究进展[J]. 稀有金属, 2011, 35(2): 286-291.

SHANG Guo-qiang, ZHU Zhi-shou, CHANG Hui, WANG Xin-nan, KOU Hong-chao, LI Jin-shan. Development of ultra-High strength titanium alloy[J]. Chinese Journal of Rare Metals, 2011, 35(2): 286-291.

[4] GUNAWARMAN B, NIINOMI M, AKAHORI T, SOUMA T, IKEDA M, TODA H. Mechanical properties and microstructures of low cost β titanium alloys for healthcare applications[J]. Materials Science and Engineering C, 2005, 25(3): 304-311.

[5] JACKSON M, DASHWOOD R, CHRISTODOULOU L, FLOWER H. The microstructural evolution of near beta alloy Ti-10V-2Fe-3Al during subtransus forging[J]. Metallurgical and Materials Transactions A, 2005, 36(5): 1317-1327.

[6] RAGHUNATHAN S L, STAPLETO, A M, DASHWOOD R J, JACKSON M, DYE D. Micromechanics of Ti-10V-2Fe-3Al: In situ synchrotron characterisation and modeling[J]. Acta Materialia, 2007, 55(20): 6861-6872.

[7] NICHOLAS G J, DASHWOOD R G, DAVID D, JACKSON M. Thermomechanical processing of Ti-5Al-5Mo-5V-3Cr[J]. Materials Science and Engineering A, 2008, 490(1): 369-377.

[8] 徐 峰, 计 波, 朱益藩, 罗月新, 庞克昌. 加工工艺对Ti5553合金等温锻件力学性能和显微组织的影响[J]. 中国有色金属学报, 2010, 20(S1): s100-s103.

XU Feng, JI Bo, ZHU Yi-fan, LUO Yue-xin, PANG Ke-chang. Effect of process on mechanical properties and microstructure of Ti5553 isothermal forgings[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s100-s103.

[9] 常 辉. Ti-B19合金的固态相变动力学及其组织演变规律[D]. 西安: 西北工业大学, 2006.

CHANG Hui. Solid phase transformation kinetics and microstructure evolutions of Ti-B19 alloy[D]. Xi’an: Northwestern Polytechnical University, 2006.

[10] 葛 鹏, 周 伟, 赵永庆. 热处理制度对Ti -1300合金组织和力学性能的影响[J]. 中国有色金属学报, 2010, 20(S1): s1068-s1072.

GE Peng, ZHOU Wei, ZHAO Yong-qing. Influence of heat treatment on microstructure and mechanical properties of Ti-1300 alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(S1): s1068-s1072.

[11] IVASISHIN O M, MARKOVSKY P E, SEMIATIN S L, WARD C H. Aging response of coarse- and fine-grained β titanium alloys[J]. Materials Science and Engineering A, 2005, 405(1): 296-305.

[12] CLEMENT N, LENAIN A, JACQUES P J. Mechanical property optimization via microstructural control of new metastable beta titanium alloys[J]. JOM Journal of the Minerals, Metals and Materials Society, 2007, 59(1): 50-53.

[13] 赵永庆, 常 辉, 李佐臣, 陈 军. 西北有色院创新研制的船用钛合金[J]. 钛工业进展, 2004, 21(6): 12-16.

ZHAO Yong-qing, CHANG Hui, LI Zuo-chen, CHEN Jun. Titanium alloys for shipbuilding developed by northwest Institute for nonferrous metal research[J]. Titanium Industry Progress, 2004, 21(6): 12-16.

[14] DAVID D, NICHOLAS G J. Microstructure formation in alpha-beta titanium alloys[C]//Proceedings of the 12th world Conference on Titanium VolumeⅡ. Beijing: Science Press, 2011: 404-409.

[15] LENAIN A,  N, JACQUES P J. Characterization of the α phase nucleation in a two-phase metastable β titanium alloy[J]. Journal of Materials Engineering and Performance, 2005, 14(6): 722-727.

N, JACQUES P J. Characterization of the α phase nucleation in a two-phase metastable β titanium alloy[J]. Journal of Materials Engineering and Performance, 2005, 14(6): 722-727.

[16] van BOHEMEN S M C, KAMP A, PETROV R H, KESTENS L A I, SIETSMA J. Nucleation and variant selection of secondary α plates in a β Ti alloy[J]. Acta Materialia, 2008, 56(20): 5907-5914.

[17]  G, WILLIAMS J C. Titanium[M]. 2nd ed. Harburg: Springer Berlin Heidelberg, 2007: 28-42.

G, WILLIAMS J C. Titanium[M]. 2nd ed. Harburg: Springer Berlin Heidelberg, 2007: 28-42.

(编辑 杨 华)

基金项目:国家自然科学基金资助项目(51371143)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:寇宏超,副教授,博士;电话:029-88460568;传真:029-88460294;E-mail:hchkou@nwpu.edu.cn