文章编号:1004-0609(2014)05-1251-08

热处理对超细晶Ti-55511近β钛合金显微组织和力学性能的影响

李 超,张晓泳,李志友,周科朝

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用热轧制备晶粒尺寸为0.1~0.5 μm的超细晶Ti-55511近β钛合金,利用SEM和TEM等研究热处理工艺对超细晶合金显微组织和力学性能的影响。结果表明,在350~650 ℃的温度条件下,合金强度和硬度随温度的升高呈现先增高后降低的趋势,在450 ℃时达到峰值强度1486.09 MPa;在450 ℃退火时,随着退火时间的延长,合金强度首先急剧上升至1536 MPa后趋于稳定,伸长率呈现先增加后下降的趋势;合金在退火过程中主要经历动态回复过程,未发生明显的粗化长大现象,晶粒尺寸均小于1 μm。动态回复过程在消除加工硬化的同时促进了晶界/相界的稳定化,增强细晶强化作用;退火过程中发生α→α2和β→ω→α相变过程,第二相粒子弥散强化效应增强。但是当第二相粒子尺寸增大至一定程度时,会显著降低合金的塑性。退火过程中合金力学性能的变化与强化机制的作用有关。

关键词:Ti-55511合金;超细晶;热处理;显微组织;力学性能

中图分类号:TG113 文献标志码:A

Effect of heat treatment on microstructure and mechanical properties of ultra-fine grained Ti-55511 near β titanium alloy

LI Chao, ZHANG Xiao-yong, LI Zhi-you, ZHOU Ke-chao

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The ultra-fine grained (UFG) Ti-55511 near β titanium alloy with grain size of 0.1-0.5 μm was prepared by hot rolling. The effects of heat treatment on the microstructure and mechanical properties were investigated by SEM and TEM. The results indicate that both the strength and hardness of the alloy increase firstly and then reduce with increasing the heat treatment temperature from 350 ℃ to 650 ℃. The peak strength of 1486.09 MPa appears at 450℃. The strength dramatically reaches 1536 MPa and then becomes stable with prolonging the holding time when heat-treated at 450 ℃. While the maximum elongation increases firstly and then decreases. During the annealing process the dynamic recovery occurs in the alloy and the grain size remains smaller than 1 μm. The dynamic recovery stimulates the grain refinement effect by eliminating the hardening process and improves the stability of the grain boundary/phase boundary. The phase transitions of α→α2 and β→ω→α enhance the second phase particle dispersion effect during the annealing process. However, the ductility of alloy significantly decreases when the second phase particles grow up to a certain size. The mechanical property evolution during annealing process is mainly related to the effect of strengthening mechanisms.

Key words: Ti-55511 alloy; ultra-fine grain; heat treatment; microstructure; mechanical property

以Ti-55511(Ti-5Al-5Mo-5V-1Cr-1Fe)、Ti-1023 (Ti-10V-2Fe-3Al)等为典型代表的高强韧近β钛合金具有β相线低、加工变形性好、整体近净成形容易等优点,并且容易实现不同强度和韧性等指标的匹配性调控,获得优异的综合力学性能[1-5]。因此,作为一类高性能轻质高强结构材料,近β钛合金不但在航空领域受到重视,如已大量用于制作美国波音B787、欧洲空客A380先进客机的起落架、机翼等关键部位承力构件[6-7],而且在汽车、船舰以及体育休闲等领域也有广阔的应用前景。

晶粒细化是提高钛合金性能的重要手段之一[8]。具有0.2~0.5 μm晶粒尺寸的超细晶Ti-6Al-4V合金的室温抗拉强度达到约1300 MPa, 较2~8 μm晶粒尺寸的合金提高约30%[9]。等径角挤压(ECAP)[10]、高速扭转(HTP)[11]、轧制[12]和换向锻造[13]等大塑性变形(SPD)技术是制备超细晶钛合金的重要手段。SPD实现钛合金细晶化对变形条件要求十分苛刻,往往需要在高应变量(真应变≥2)和较低变形温度(≤550 ℃)下进行[13]。这对合金的低温成型性能提出了较高的要求,即使冷成型性较好的纯Ti也需要在400~600 ℃的温度条件下才可实现SPD晶粒超细化[14]。由于近β钛合金含有临界于α+β两相钛合金和亚稳定β钛合金之间的合金元素浓度[15],在250~500 ℃区间内会发生β→ω→α和β→α等复杂相变[16],因此,在低于550 ℃条件下变形时合金抗力高(≥1000 MPa),难以通过SPD方法实现晶粒超细化。然而,针对近β钛合金在变形过程中的组织演变特性,有可能借助变形前组织状态的调控,降低SPD方法的苛刻要求,实现近β钛合金的晶粒超细化。LI等[17]在研究Ti-55511近β钛合金热变形行为时,初始坯料中预置体积分数约50%、长2.5 μm、宽0.2 μm的针片状α相,然后借助于热压缩手段,在700~750 ℃获得了晶粒尺寸0.2~0.8 μm的超细晶。但是,围绕这种近β合金超细晶热处理过程中组织演变与力学性能相关性领域的研究尚属空白。

国内外针对近β钛合金的热处理主要集中在采用近β锻造或α+β两相区锻造制备的晶粒尺寸3~20 μm的显微组织。以Ti-55511合金为例[18],其典型的热处理工艺如下:Tβ-(20~50)固溶、1~1.5 h+炉冷至Tβ-(80~120)、1~3 h+空冷至室温+300~650 ℃、2~6 h。经过热处理调控获得的显微组织中包含体积分数 约30%~40%的球状α相、约10%粗片状α相和约10%细针状α相。其中,球状α相提高合金强度和塑性、粗片状α相提高合金的断裂韧性、细针状α相进一步提高合金强度。经热处理调控后,Ti-55511近β钛合金抗拉强度可达1080~1280 MPa,KIC达55~75 (MPa·m1/2),合金强度和韧性的综合匹配性较好[19]。

然而,在采用SPD方式制备的超细晶组织中,存在较高的残余应力和畸变能,采用上述常规热处理条件会显著增大晶粒尺寸、降低细晶化效果。因此,必须在保证合金超细晶特征的前提下设计一种新的强韧化热处理工艺。大量研究表明,超细晶钛合金的热处理多采用200~600 ℃低温单级退火工艺进行。LI等[17]对Ti-25Nb-3Zr-3Mo-2Sn亚稳定性β钛合金超细晶热稳定性的研究发现,采用400~600 ℃的单级退火时,利用回复和第二相弥散析出作用,在不改变合金超细晶特征的前提下,降低位错/缺陷密度、提高亚晶/晶粒稳定性,提高合金热稳定性和力学性能。另外,受较高残余应力和高畸变能的影响,超细晶钛合金在低温退火过程中还可能出现一系列特殊的相变过程。XU等[10]对Ti67.4Nb24.6Zr5Sn3(TNZS,摩尔分数,%)β型钛合金超细晶的研究中发现,在ECAP过程中出现了β→α″应力诱导马氏体相变,在后续受热时效的过程中会进一步发生α″→β的逆向转变。然而,针对Ti-55511等高强韧近β钛合金体系超细晶组织热处理组织演变和相变领域,国内外报道很少。因此,开展近β钛合金超细晶组织的热处理研究具有重要的理论价值。

综上所述,本文作者采用与压缩变形受力状态最接近的SPD轧制变形手段,通过调控变形前初始组织特征制备Ti-55511超细晶板材。在获得超细晶板材的基础上,采用SEM和TEM显微分析方法,研究热处理过程中超细晶板材相变和显微形貌演变。通过对组织演变与力学性能相关性的分析,揭示超细晶的热处理强韧化机理,为超细晶板材显微组织和力学性能的调控提供技术指导。

1 实验

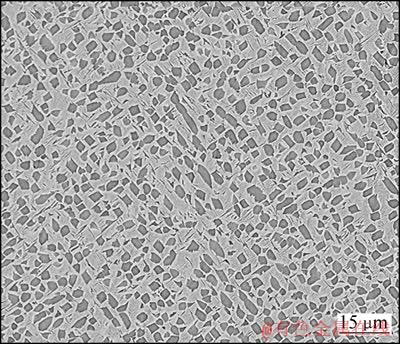

图1 Ti-55511合金原始锻棒的SEM像

Fig. 1 SEM image of received Ti-55511 billet

本研究采用由湖南湘投金天钛业科技有限公司提供的Ti-5Al-5Mo-5V-1Cr-1Fe合金锻棒(见图1),化学成分(质量分数,%)为5.75Al、5.42Mo、4.48V、0.75Cr、1.2Fe,杂质总含量小于0.3,其余为Ti,β转变温度为(875±5) ℃。合金抗拉强度为1080 MPa,伸长率为11%。

LI等[17]研究表明,含体积分数为50%~60%的细针α相(宽度0.1~0.5 μm、长度1~5 μm)的Ti合金经真应变0.7的热压缩变形后,得到晶粒尺寸小于1 μm的超细晶组织。本研究中,采用920 ℃、1 h固溶处理+水冷至室温+700 ℃时效的热处理制度,获得上述类似的初始组织,进而进行超细晶的热轧制备。在LO500轧机上进行热轧,经2道次轧制成3 mm薄板,其中第1道次变形量为50%、第2道次变形量为40%。轧制完成后直接水冷至室温以保留变形组织,沿板材轧制方向取样,在氩气氛保护管式电阻炉中进行热处理实验,热处理温度为350~650 ℃,保温时间为0.5~32 h。

拉伸实验在Instron8802型力学试验机上进行。HRC硬度测试在华银200HRS-150型数显洛氏硬度计上进行,载荷为1470 N,保压时间为5 s。显微组织观察在NOVATM Nano SEM 230型扫描电子显微镜观上进行,腐蚀液配方如下:1.5 mL HF,3 mL HNO3,100 mL H2O。TEM分析在JEM-2100F型投射电子显微镜上进行,加速电压为200 kV。TEM样品制备方法如下:用钼线切割机切取厚度为0.3 mm 的薄片,经金相砂纸减薄至80 μm 后冲成d 3 mm 的小圆片,然后用TENUPOL-5 型双喷电解减薄仪减薄至穿孔。双喷减薄液配方为600 mL CH3OH、350 mL CH3(CH2)3OH、50 mL HClO4。双喷减薄时仪器电压为22 V,电流为60~80 mA,温度为-30~ -35 ℃。

2 结果与讨论

2.1 轧制前后合金的显微形貌

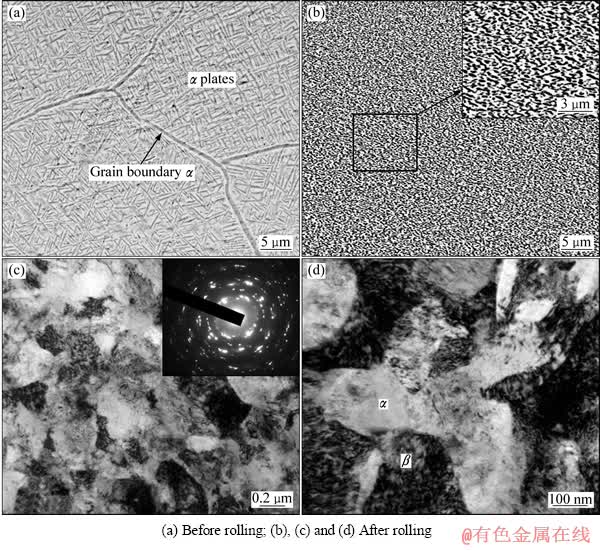

图2 轧制前后Ti-55511钛合金的SEM和TEM像

Fig. 2 SEM images and TEM images of Ti-55511 alloy

图2所示为轧制变形前后Ti-55511合金的显微形貌。从图2(a)轧制变形前显微形貌可以看出,通过920 ℃、1 h固溶处理+水冷至室温+700 ℃时效处理,β相晶界和晶内析出了体积分数约为50%的针状α相。其中,晶界α相宽度为0.2~0.4 μm;晶内α相呈针片状分分布,宽度为0.1~0.3 μm,长度为1~5 μm。β基体被针片α相分割成尺寸为0.2~0.8 μm的小块区域。从图2(b)轧制变形后Ti-55511合金的显微形貌可以发现,原始连续晶界和针状α相均被破碎/球化成等轴状,尺寸为0.1~0.4 μm。由图2(c)进一步发现,β相也发生了破碎,尺寸为0.3~0.5 μm。从高倍照片中可以看出(见2(d)),破碎的α相和β相中均缠结了大量的位错,且α/β相界面曲折。

2.2 合金的退火显微组织

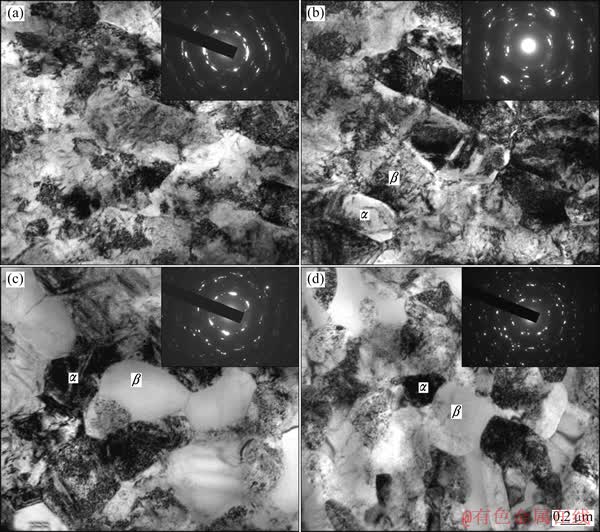

图3所示为超细晶Ti-55511合金在不同退火温度下保温4 h后形成的显微组织。在350~650 ℃的退火温度范围内,合金未发生明显的晶粒长大现象。与退火前的显微形貌相比(见图2(c)),经350 ℃退火后,合金中仍残存大量位错,且α/β界面模糊(见图3(a));当温度升高至450 ℃,合金中位错密度逐渐降低,但α/β界面仍较模糊(见图3(b));温度升高至550 ℃后,α/β、β/β界面逐渐清晰,且多边化明显,晶粒尺寸为0.2~0.8 μm(见图3(c));温度进一步升高至650 ℃后(见图3(d)),α和β相晶粒尺寸略有长大,α/α和β/β亚晶界面消失。上述现象产生的主要原因如下:在350~650 ℃的退火温度范围内,超细晶合金主要经历动态回复过程,随温度的升高合金且回复程度而加剧。回复过程中,位错通过滑移和攀移运动至晶界或相界附近,从而将α相和β相分割成为亚晶,在350~550 ℃条件下亚晶界随温度的升高逐渐清晰,而α/β相界的阻碍作用抑制了β晶粒的长大。当温度进一步升高至650 ℃时,出现α和β亚晶合并长大的现象,因此亚晶界面消失。此外,对比图2(c)和图3(a)~(d)中的衍射花样可以看出,轧制变形后未退火的衍射斑点呈连续分布,环状特征明显,晶粒取向差较大;随着后续退火温度的增加衍射斑连续性降低,晶粒取向度降低。

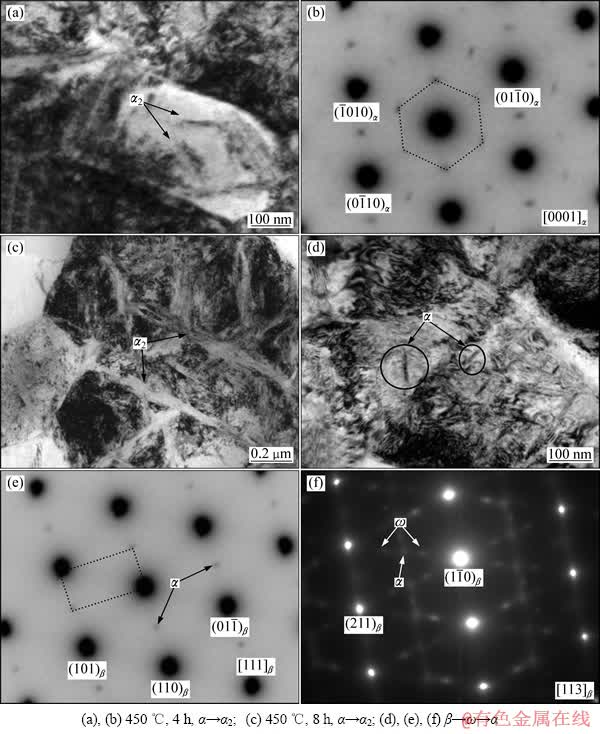

由于Ti-55511近β钛合金在250~500 ℃条件下保温时会发生β→ω→α和β→α等复杂相变,因此,实验中对超细晶退火过程中的相变进行分析。图4所示为450 ℃保温4 h后合金相变形貌。由图4(a)可以看出,退火后α相内析出长度小于100 nm、宽度为5~20 nm的针状析出相。通过对α相(0001)面电子衍射花样(见图4(b))的分析发现,在[h/2,k/2,l]位置出现了清晰的超点阵斑点。在钛合金中,这种超点阵斑点是由α相长程有序转变为α2相引起的。α2相是一种以Ti3Al为基体的长程有序相,为D019结构,其空间群为P63/mmc。α2相主要是从初生α相中以相对均匀的共格方式析出,Al原子在α的(0001)面上有序分布,形成2倍于α相a轴的晶格常数,使得超点阵衍射斑出现[20]。α2相的析出满足 、

、 的位相关系[21]。在Ti-55511超细晶合金退火过程中,随着温度从450 ℃提高至550 ℃(见图3(c))和时间从4 h延长至8 h(见图4(c)),合金中的针状α2相逐渐长大;当退火温度升高至650 ℃时,α相中并未析出α2相。钛合金中的α2相主要在α型、近α型及α稳定元素含量较高的(α+β)两相钛合金中发现,然而本研究中在超细晶近β钛合金中首次发现这种现象,其主要原因可能与超细晶组织中高畸变能的作用有关。

的位相关系[21]。在Ti-55511超细晶合金退火过程中,随着温度从450 ℃提高至550 ℃(见图3(c))和时间从4 h延长至8 h(见图4(c)),合金中的针状α2相逐渐长大;当退火温度升高至650 ℃时,α相中并未析出α2相。钛合金中的α2相主要在α型、近α型及α稳定元素含量较高的(α+β)两相钛合金中发现,然而本研究中在超细晶近β钛合金中首次发现这种现象,其主要原因可能与超细晶组织中高畸变能的作用有关。

图3 350、450、550和650 ℃下保温4 h后Ti-55511合金的TEM显微组织

Fig. 3 Microstructure characteristics (TEM) of Ti-55511 alloy after holding at 350 ℃ (a), 450 ℃(b), 550 ℃(c) and 650 ℃(d) for 4 h

图4 退火过程中Ti-55511合金的相变形貌及SAD谱

Fig. 4 TEM imags and SAD patterns showing phase transformation of Ti-55511 alloy during annealing

由图4(d)可以看出,β相中析出长度小于100 nm、宽度为5~15 nm的针状析出相。通过对β[111]和[113](见图4 (e)和(f))晶带轴的衍射斑花样进行分析,发现β基体中同时含有ω和α相。JONES等[22]研究认为,在350~500 ℃温度范围保温时,近β钛合金中β相会发生β→ω的相变过程。随着保温时间的延长,ω相会促进α相在ω/β界面或界面一定距离处形核长大,从而使细针状α相细小弥散析出。超细晶Ti-55511合金在450 ℃时效时可观察到ω和α相同时存在的现象,可以认为此时也发生了β→ω和β→ω→α相变过程。然而,当退火温度从450 ℃升高至550 ℃和650 ℃时(见图3(c)和(d)),在β基体中并未观察到析出细针状α相的现象。产生这一现象的主要原因如下:550 ℃已经高于β→ω和β→ω→α的相变区间,此时主要发生了β直接转变为α相的相变过程。在β直接转变为α相的过程中,α相在缺陷密度较高的α/β界面附近形核,并依附于α相长大。受α在α/β界面附近形核并依附于相界长大的影响,超细晶退火前模糊、曲折的相界面(见图2(d))逐渐趋于清晰、圆滑(见图3(c)和(d))。

2.3 合金的力学性能

为了进一步评价具有超细晶组织特征Ti-55511合金的力学性能,对合金进行了抗拉强度和硬度测试。其中,轧制变形后超细晶Ti-55511合金的抗拉强度高达1304.7 MPa,高于锻造态试样的1080 MPa。通过对显微组织的分析可以认为,其强化机理主要有细晶强化和形变强化2种:一方面超细晶的晶粒经过强变形已细化至0.1~0.5 μm,导致晶界/相界含量增加,对位错滑移产生强烈的阻滞效应,细晶强化效果明显;另一方面经过大塑性变形的合金,位错密度高,从而使弹性应力场不断增加,位错间的交互作用不断增强,位错的运动越来越困难,加工硬化效果显著。

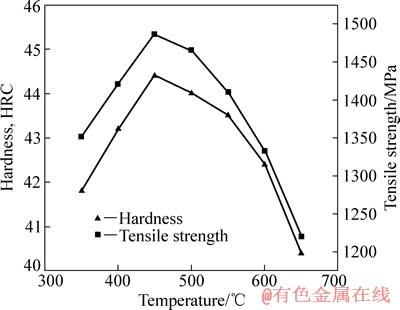

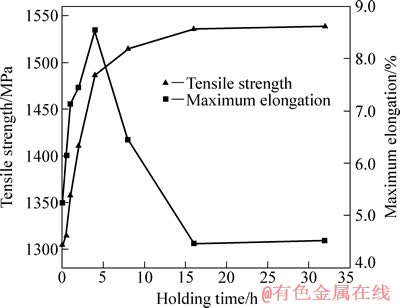

图5所示为保温时间为4 h时Ti-55511合金退火温度与硬度和抗拉强度的关系。可以看出,随着退火温度从350 ℃增加至650 ℃,合金的强度和硬度呈现出先增加后降低的趋势,峰值硬度(45.4HRC)和强度(1486.09 MPa)均出现在450 ℃。图6所示为450 ℃处理时Ti-55511合金保温时间与抗拉强度和伸长率的关系。可以看出,随着退火时间的延长,合金的抗拉强度逐渐升高,在16 h时强度高达1536 MPa,随后趋于稳定;合金的伸长率呈现出先升高后降低的趋势,在4 h时伸长率达到8.54%,随后急剧下降,在16 h时降低至4.47%。产生这种现象的主要原因与显微组织演变密切相关。

图5 保温时间为4 h时退火温度与超细晶Ti-55511合金力学性能的关系

Fig. 5 Relationships among annealing temperature and mechanical properties of ultra-fine grained Ti-55511 alloy held for 4 h

图6 450 ℃退火时保温时间与超细晶Ti-55511合金力学性能的关系

Fig. 6 Relationships among holding time and mechanical properties of ultra-fine grained Ti-55511 alloy annealed at 450 ℃

2.4 合金力学性能与显微组织的相关性

经过350~650 ℃、4 h的退火处理后,合金强度在350~450 ℃范围内显著增加,当温度进一步升高时合金强度逐渐降低。在各热处理条件下,合金中位错密度均大幅度下降,此时合金中残余应力、缺陷密度和畸变能降低,加工硬化效果降低;然而,退火后合金中α/α、α/β和β/β的晶界/相界逐渐趋于稳定,轧制变形后位错缠结逐步转变为亚晶,从而使晶界/相界对位错的阻滞效应增强,细晶强化作用明显;与此同时,在350~450 ℃温度区间,退火过程中发生了α→α2和β→ω→α的相变过程,由于α和β相分别析出了α2和α两类呈细针状第二相,合金第二相粒子弥散强化效应增加。随着细晶强化效应与第二相粒子弥散强化效应的双重作用的增加,合金强度和硬度逐渐升高。当温度高于500 ℃时,由于退火温度高于ω相析出区间,因而直接发生了β→α的相变过程,由于此时α相在缺陷密度较高的α/β界面附近形核,并依附于破碎的α相长大,未出现弥散针状α相的析出,因此第二相强化作用降低,合金强度逐渐降低。当温度高于550 ℃时,由于退火温度高于ω和α2相的析出区间,因而合金的第二相弥散强化效应进一步降低,合金强度进一步下降。当温度进一步升高至650 ℃时,由于出现了β相回复引起的β亚晶的合并长大现象,晶界/相界强化作用降低,合金强度降低至最低。450 ℃保温4 h时,由于细晶强化效应和第二相粒子弥散强化效应的作用最强,因此合金强度/硬度达到峰值。

在450 ℃时,随着保温时间的延长,合金强度和伸长率在0~4 h呈现出急剧上升的趋势;4~32 h时,合金强度缓慢增加后趋于平缓,硬度则显著降低。产生这种现象的主要原因如下:当退火时间在0~4 h时,合金中α→α2和β→ω→α的相变过程迅速发生,且随着退火时间的延长α2和α相尺寸显著增大,合金强度急剧增加;受退火初期合金中位错、缺陷密度和畸变能的大幅度降低,加工硬化逐步消除,合金伸长率显著提高。随着退火时间的延长,合金中α→α2和β→ω→α的相变过程已转变完全,强度缓慢增加并最后趋于稳定;随退火时间的延长针状α2和α相逐渐长大,当长大至临界尺寸时,对位错的滑移/攀移运动阻碍作用显著增强,因此,合金伸长率却呈现出显著降低的趋势。

由上述分析可知,超细晶Ti-55511合金退火过程的主要强化机制为细晶强化和第二相粒子弥散强化。其中,回复过程在消除加工硬化的同时促进了晶界/相界的稳定化,提高细晶强化作用;退火过程中发生的α→α2和β→ω→α相变过程,α和β相分别析出了α2和α两类呈细针状第二相,第二相粒子弥散强化效应增强。尽管第二相强化效果明显,但是当第二相粒子尺寸增大至一定尺寸时,会显著降低合金的塑性。

3 结论

1) 轧制制备的Ti-55511近β钛合金中存在包含大量位错的超细晶组织,α/β晶粒细化,尺寸在0.1~0.5 μm之间,其抗拉强度达1304.7 MPa,伸长率为5.24%。在350~650 ℃的退火温度范围内,合金主要经历动态回复过程,未发生明显的粗化长大现象,晶粒尺寸均小于1 μm。在退火过程中发生了α→α2和β→ω→α的相变过程。

2) 随着退火温度从300 ℃升高至650 ℃,合金的强度和硬度呈现出先增加后降低的趋势,峰值硬度(45.4HRC)和强度(1486.09 MPa)均出现在450 ℃;当退火温度恒定为450 ℃时,随着退火时间的延长,合金的抗拉强度逐渐增大,在16 h时强度高达1536 MPa,随后趋于稳定;合金的伸长率呈现出先升高后降低的趋势,在4 h时伸长率达到8.54%,随后急剧下降,在16 h时降低至4.47%。

3) 超细晶Ti-55511合金退火过程的主要强化机制为细晶强化和第二相粒子弥散强化。其中,动态回复过程在消除加工硬化的同时促进了晶界/相界的稳定化,提高细晶强化作用;退火过程中发生α→α2和β→ω→α的相变过程,α和β相分别析出了α2和α两类呈细针状的第二相,第二相粒子弥散强化效应增强。但是当第二相粒子尺寸增加至一定尺寸时,会显著降低合金的塑性。

REFERENCES

[1] 韩 栋, 张鹏省, 毛小南, 卢亚锋, 奚正平, 杨建朝. BT22钛合金及其大型锻件的研究进展[J]. 材料导报, 2010, 24(2): 46-50.

HAN Dong, ZHANG Peng-sheng, MAO Xiao-nan, LU Ya-feng, XI Zheng-ping, YANG Jian-chao. Research progress of BT22 titanium alloy and its large forgings[J]. Materials Review, 2010, 24(2): 46-50.

[2] 沙爱学, 王庆如, 李兴无. 航空用高强度结构钛合金的研究及应用[J]. 稀有金属, 2004, 28(1): 239-242.

SHA Ai-xue, WANG Qing-ru, LI Xing-wu. Research and application of high-strength titanium alloys used in airplane structure[J]. Chinese Journal of Rare Metals, 2004, 28(1): 239-242.

[3] BOYER R. R. An overview on the use of titanium in the aerospace industry[J]. Materials Science and Engineering A, 1996, 213(1/2): 103-114.

[4] DEHGHAN-MANSHADI A, DIPPENAAR R J. Development of α-phase morphologies during low temperature isothermal heat treatment of a Ti-5Al-5Mo-5V-3Cr alloy[J]. Material Sciences and Engineering A, 2011, 528(3): 1833-1839.

[5] 王清瑞,沙爱学,黄 旭,刘 宇. 热处理制度对TC18A 钛合金丝材组织和性能的影响[J]. 中国有色金属学报, 2010, 20(专辑1): s634-s637.

WANG Qing-rui, SHA Ai-xue, HUANG Xu, LIU Yu. Influence of heat treatment process on microstructure and mechanical property of TC18A alloy wire[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(Special 1): s634-s637.

[6] JACKSON M, JONES N G, DYE D, DASHWOOD R J. Effect of initial microstructure on plastic flow behavior during isothermal forging of Ti-10V-2Fe-3Al[J]. Materials Science and Engineering A, 2009, 50(1/2): 248-254.

[7] LI Chao, ZHANG Xiao-yong, ZHOU Ke-chao, PENG Chao-qun. Relationship between lamellar α evolution and flow behavior during isothermal deformation of Ti-5Al-5Mo-5V-1Cr-1Fe near β titanium alloy[J]. Materials Science and Engineering A, 2012, 558: 668-674.

[8] SERGUEEVA A V, STOLYAROV V V, VALIEV R Z, MUKHERJEE A K. Advanced mechanical properties of pure titanium with ultrafine grained structure[J]. Scripta Materialia, 2001, 45(7): 747-752.

[9] ZHEREBTSOV S, KUDRYAVTSEV E, KOSTJUCHENKO S, MALYSHEVA S, SALISHCHEV G. Strength and ductility-related properties of ultrafine grained two-phase titanium alloy produced by warm multiaxial forging[J]. Materials Science and Engineering A, 2012, 536: 190-196.

[10] XU W, WU X, CALIN M, STOICA M, ECKERT J, XIA K. Formation of an ultrafine-grained structure during equal-channel angular pressing of a β-titanium alloy with low phase stability[J]. Scripta Materialia, 2009, 60(11): 1012-1015.

[11] ESTRIN Y, VINOGRADOV A. Fatigue behaviour of light alloys with ultrafine grain structure produced by severe plastic deformation: An overview[J]. International Journal of Fatigue, 2010, 32(6): 898-907.

[12] GUO Qiang, WANG Qing, SUN Dong-li, HAN Xiu-li, WU Gao-hui. Formation of nanostructure and mechanical properties of cold-rolled Ti-15V-3Sn-3Al-3Cr alloy[J]. Materials Science and Engineering A, 2010, 527: 4229-4232.

[13] ZHERBTSOV S, MURZINOVA M, SALISHCHEV G, SEMIATIN S L. Spheroidization of the lamellar microstructure in Ti-6Al-4V alloy during warm deformation and annealing[J]. Acta Materialia, 2011, 59(10): 4138-4150.

[14] LA Pei-qing, MA Ji-qiang, ZHU Yun-tian, YANG Jun, LIU Wei-min, XUE Qun-ji, VALIEV R Z. Dry-sliding tribological properties of ultrafine-grained Ti prepared by severe plastic deformation[J]. Acta Materialia, 2005, 53(19): 5167-5173.

[15] WEISS I, SEMIATIN S. L. Thermomechanical processing of beta titanium alloys—An overview[J]. Materials Science and Engineering A, 1998, 243 (1/2): 46-65.

[16] JONES N G, DASHWOOD R J, JACKSON M, DYE D. β phase decomposition in Ti-5Al-5Mo-5V-3Cr[J]. Acta Materialia, 2009, 57(13): 3830-3839.

[17] LI Chao, ZHANG Xiao-yong, LI Zhi-you, ZHOU Ke-chao. Hot deformation of Ti-5Al-5Mo-5V-1Cr-1Fe near β titanium alloys containing thin and thick lamellar α phase[J]. Materials Science and Engineering A, 2013, 573: 75-83.

[18] 官 杰, 刘建荣, 雷家峰, 刘羽寅. TC18钛合金的组织和性能与热处理制度的关系[J]. 材料研究学报, 2009, 23(1): 77-82.

GUAN Jie, LIU Jian-rong, LEI Jia-feng, LIU Yu-yin. The relationship of heat treatment-microstructures-mechanical properties of the TC18 titanium alloy[J]. Chinese Journal of Material Research, 2009, 23(1): 77-82.

[19] 沙爱学, 李兴无, 王庆如, 鲍如强. 热变形温度对TC18钛合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2005, 15(8): 1167-1172.

SHA AI-xue, LI Xing-wu, WANG Qing-ru, PAO Ru-qiang. Influence of hot deformation temperature on microstructure and mechanical properties of TC18 alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(8): 1167-1172.

[20] AZAD S, MANDAL R.K, SINGH A K. Effect of Mo addition on transformation behavior of (α2+γ) based Ti-Al alloys[J]. Materials Science and Engineering A, 2006, 429(1/2) 219-224.

[21] HUANG A J, LI G P, HAO Y L, YANG R. Acicular α2 precipitation induced by capillarity at α/β phase boundaries in Ti-14Al-2Zr-3Sn-3Mo-0.5Si titanium alloy[J]. Acta Materialia, 2003, 51(16): 4939-4952.

[22] JONES N G, DASHWOOD R J, JACKSON M, DYE D. Development of chevron-shaped a precipitates in Ti-5Al-5Mo-5V-3Cr[J]. Scripta Materialia, 2009, 60(7): 571-583.

(编辑 龙怀中)

基金项目:国家自然科学基金委员会创新研究群体科学基金资助项目(51021063);中央高校基本科研业务费前沿研究计划(2009QZZD007);湖南省研究生科研创新项目(CX2012B044)

收稿日期:2013-06-20;修订日期:2013-11-27

通信作者:张晓泳,副研究员,博士;电话:0731-88836264;E-mail:zhangxiaoyong@csu.edu.cn