低成本β钛合金热处理后的显微组织变化和力学性能

来源期刊:中国有色金属学报(英文版)2012年第11期

论文作者:Khaled M. IBRAHIM Mansour MHAEDE Lothar WAGNER

文章页码:2609 - 2615

关键词:β钛合金;Ti-6.6Mo-4.5Fe-1.5Al合金;疲劳断裂;时效;二次α相;初始 α相;β晶粒;拉伸强度;疲劳极限

Key words:beta Ti alloy; Ti-6.6Mo-4.5Fe-1.5Al alloy; fatigue crack; ageing; secondary α; primary α; β-grain; tensile strength; fatigue limit

摘 要:研究了时效时间对低成本β(LCB) Ti-6.6Mo-4.5Fe-1.5Al钛合金的显微组织和力学性能的影响,以及显微组织与疲劳断裂裂纹的产生、延伸的联系。延长时效时间有助于二次α相和β晶粒体积分数的增多以及初始 α相的部分球化。在500 °C下热处理0.5 h的合金得到的拉伸强度最大(1565 MPa),疲劳极限最高(750 MPa);而在500 °C下热处理4 h的合金得到的拉伸强度最小(1515 MPa),疲劳极限最低(625 MPa)。在500 °C下热处理4 h的合金的断裂模式为穿晶断裂, 而在500 °C下热处理0.5 h的合金的断裂模式为穿晶断裂和沿晶断裂的混合。 在疲劳样品的外表面形成的裂纹沿β晶界上初始 α相延伸。

Abstract: The influence of ageing time on microstructure and mechanical properties of low-cost beta (LCB) titanium alloy with a chemical composition of Ti-6.6Mo-4.5Fe-1.5Al was investigated. The correlation between microstructure and fatigue crack initiation and growth was also studied. Increasing ageing time tended to increase the volume fraction of the secondary α-precipitates, β-grain size and partial spheroidization of primary α-phase. The maximum tensile strength (1565 MPa) and fatigue limit (750 MPa) were obtained for the samples aged at 500 °C for 0.5 h, while the minimum ones of 1515 MPa and 625 MPa, respectively, were reported for the samples aged at 500 °C for 4 h. The samples aged at 500 °C for 4 h showed a transgranular fracture mode. However, the samples aged at 500 °C for 0.5 h revealed a mixture fracture mode of transgranular and intergranular. The formed cracks on the outer surface of the fatigue samples were found to propagate through the β-grains connecting the primary α-particles existing at the β-grain boundaries.

Trans. Nonferrous Met. Soc. China 22(2012) 2609-2615

Khaled M. IBRAHIM1, Mansour MHAEDE2, Lothar WAGNER2

1. Central Metallurgical R&D Institute-CMRDI, P.O. Box 87 Helwan, Cairo, Egypt;

2. TU-Clausthal, IWW, Agricolastr. 6, Clausthal-Zellerfeld, Germany

Received 9 December 2011; accepted 13 March 2012

Abstract: The influence of ageing time on microstructure and mechanical properties of low-cost beta (LCB) titanium alloy with a chemical composition of Ti-6.6Mo-4.5Fe-1.5Al was investigated. The correlation between microstructure and fatigue crack initiation and growth was also studied. Increasing ageing time tended to increase the volume fraction of the secondary α-precipitates, β-grain size and partial spheroidization of primary α-phase. The maximum tensile strength (1565 MPa) and fatigue limit (750 MPa) were obtained for the samples aged at 500 °C for 0.5 h, while the minimum ones of 1515 MPa and 625 MPa, respectively, were reported for the samples aged at 500 °C for 4 h. The samples aged at 500 °C for 4 h showed a transgranular fracture mode. However, the samples aged at 500 °C for 0.5 h revealed a mixture fracture mode of transgranular and intergranular. The formed cracks on the outer surface of the fatigue samples were found to propagate through the β-grains connecting the primary α-particles existing at the β-grain boundaries.

Key words: beta Ti alloy; Ti-6.6Mo-4.5Fe-1.5Al alloy; fatigue crack; ageing; secondary α; primary α; β-grain; tensile strength; fatigue limit

1 Introduction

Low cost beta (LCB) titanium alloys are being developed in which they can be processed to have high strength, low modulus and potential applications including springs and fasteners in aerospace and automotive industries as well as armour components [1,2]. Elevated specific strength is the primary incentive for selection and design into aerospace applications including engine and airframe components. The expansion of titanium applications to non-aerospace industries (e.g., automotive, chemical, energy, marine, biomedical, sports and architecture) entails improvements in the understanding of titanium metallurgy, advances in processing methods, ability to manufacture components without defects, and developing of low-cost Ti alloys [3-5]. One of the developed titanium alloys is the low-cost beta titanium alloy (LCB) which has a chemical composition of Ti-1.5Al-4.5Fe-6.8Mo (mass fraction, %). LCB Ti alloy is heat treated to obtain 1400 MPa ultimate strength with 13% elongation [6-8]. LCB is considered a metastable β titanium alloy which is primarily strengthened by precipitating of the secondary phases, e.g., α and ω. The mechanical properties of LCB Ti alloy are strongly dependent on the type, morphology, size, coherency and volume fraction of these precipitates resulting from β phase decomposition [9,10]. Understanding the fatigue crack initiation and growth in titanium alloys, however, is complicated due to the changes in their microstructure with a small change in the heat treatment process [11,12]. In order to avoid any catastrophic failure during service, the first defects and small cracks must be investigated at the scale of microstructure. It is well documented that fatigue crack initiation is strongly influenced by microstructure features such as grain size, grain orientation and misorientation of the grains [13]. Therefore, the present work aims at studying the correlation between microstructure features, heat treatment process and fatigue crack initiation and its propagation in the heat treated LCB titanium alloy.

2 Experimental

LCB titanium alloy was first cast using a vacuum induction furnace as rods of 30 mm in diameter. Hot swaging was applied at 760 °C to reduce the cross-section diameter to 10 mm in 11 steps. The chemical composition of the investigated LCB titanium alloy is given in Table 1. The schematic drawing of the thermal treatment used in this study is shown in Fig. 1. The swaged rods were solution treated at 760 °C for 0.5 h followed by water quenching (denoted as RX). Ageing processes were applied at 500 °C for 0.25, 0.5, 4 and 16 h, respectively. Microstructure investigation was carried out using an optical microscope and volume fraction of α-phase was estimated by using an image analyser software. Mechanical properties were determined for the solution treated samples as well as the aged ones at 0.5 for 4 h. Tensile test was performed on threaded cylinderical specimens having a gage length and diameter of 20 and 4 mm, respectively. Rotary fatigue test was carried out in a high cycle fatigue regime (HCF) using a stress ratio of R=-1 and frequency of 50 Hz. The fatigue samples were electropolished to provide a mirror-like surface to facilitate optical crack-length measurements. Fatigue crack nucleation sites and fracture surface of the broken fatigue samples were examined using an optical and a scanning electron microscopes, respectively.

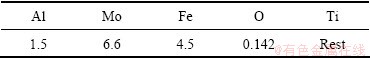

Table 1 Chemical composition of the investigated LCB Ti alloy (mass fraction, %)

Fig. 1 Thermomechanical process for producing LCB titanium samples

3 Results and discussion

3.1 Microstructure

The microstructure of the investigated LCB Ti alloy under different conditions are shown in Fig. 2. Because of the swaging process was carried out at a temperature below the beta-transus or in the α+β zone (760 °C), the swaged samples obtained a structure consisting of primary α-phase imbedded in a β-matrix [14] (see Fig. 2(a)). It is well known that the evolution of microstructure during hot deformation is very sensitive to the process parameters such as temperature, strain rate and history of the material (chemistry and starting microstructural condition). In recent years, the processing map approach has been established as a useful tool to control the deformation process such as forging, rolling, swaging and extrusion. Generally, LCB alloy exhibits a wide safe processing window of dynamic recrystallization with excellent ductility [15]. It is also recommended to apply solution treatment process below the β-transus, as stated in this study, to maintain fine grain structure that resulted in a desirable combination of strength and ductility as well as fatigue property [7]. Therefore, the solution treated samples showed fine equiaxed β-grain structure with almost complete spheroidization of 15% primary α-phase (see Fig. 2(b)). The primary α-phase lies at boundaries of β-grains and located also at the triple points of the β-grains. The β-grain size is approximately 3 to 5 μm. Meanwhile, the structure of the aged samples showed a different feature from the solution treated one. As shown in Figs. 2(c)-(f), the microstructure of the aged samples consists mainly of primary α-phase and fine secondary α-phase precipitated at/or inside the β-grains. The amount of precipitated fine secondary α-phase increased with increasing the ageing time [16,17]. It is also noticed that increasing ageing time had a minor effect on the volume fraction of primary α-phase and grain size of the β-matrix [12]. For example, the aged samples at 500 °C for 0.25 h showed a structure consisting of primary α-phase (globular white shape) distributed at the β-grain boundaries and fine secondary α-precipitates (black shape) distributed at/inside the grain boundaries (see Fig. 2(c)). However, a longer ageing time resulted in thickening and growth of the primary α-phase that distributed heterogeneously at the β-grain boundaries [2,16]. In addition, a larger number of fine secondary α-precipitates were found inside the β-matrix (see Figs. 2(d)-(f).

3.2 Mechanical properties

It was previously reported [7] that the peak age for LCB Ti alloy can be obtained after 1-4 h. Therefore, in this study three selected conditions (up to 4 h ageing time) were chosen to evaluate the mechanical properties. These selected conditions were solution treatment (RX), ageing for 0.5 h (RX+A) and ageing for 4 h (RX+B). The tensile properties of the selected conditions are given in Table 2. The effect of β strengthening with the secondary α-phase is clearly shown in the aged conditions, where the modules of elasticity increased from 81 GPa to 106 GPa with increasing ageing time.

Fig. 2 Microstructures of investigated LCB Ti-alloy in different conditions

Table 2 Mechanical properties of LCB at room temperature

Both yield and ultimate strengths are also increased with ageing time on the account of ductility. The maximum ultimate strength of 1565 MPa was obtained for the ageing condition of 500 °C for 0.5 h, while with increasing the aging time to 4 h, the ultimate strength decreases to 1515 MPa. It is suggested that ageing at 500 °C for 0.5 h gave good distribution of secondary α-phase inside or/at the β-grain boundaries. However, with increasing ageing time to 4 h, the structure showed massive quantities of secondary α-phase distributed heterogeneously inside the β-grain boundaries which will in turn weaken these boundaries [4,16]. Therefore, it could be said that the decrease in strength by increasing the ageing time to 4 h is attributed to the coarsening of structure and existing of massive number of secondary α particles at β-grain boundaries.

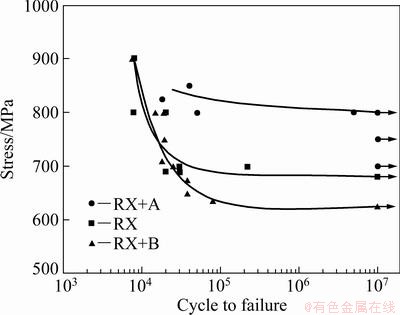

Figure 3 shows the fatigue behaviour of the studied LCB Ti alloy. The maximum fatigue strength of 750 MPa was obtained for the sample aged at 500 °C for 0.5 h, and the minimum one (625 MPa) was reported for the sample aged at 500 °C for 4 h. It could be suggested that the amount of secondary α-particles precipitated at or inside β-grain boundaries as well as their distribution play an important role in controlling the mechanical properties and fatigue performance [7]. Therefore, optimum tensile properties as well as fatigue strength were obtained at 0.5 h ageing time due to the good distribution of secondary α-particles at/or inside the β-grain boundaries. Moreover, fatigue crack initiation is favored in coarse-grained material compared to fine-grained ones, assuming everything else equal. It is also documented [18,19] that crack initiation life increases and the crack propagation life decreases with decreasing the grain size. This can explain why an optimum fatigue life was obtained for the aged sample for 0.5 h compared with the other aged for 4 h.

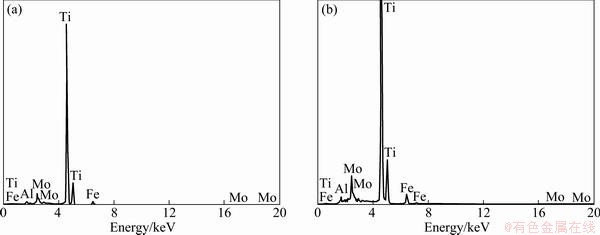

Fig. 3 Smooth rotating bending fatigue strength of investigated LCB titanium alloy

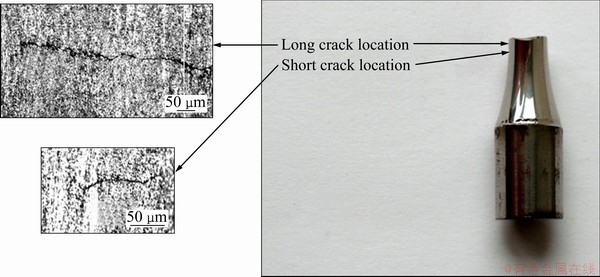

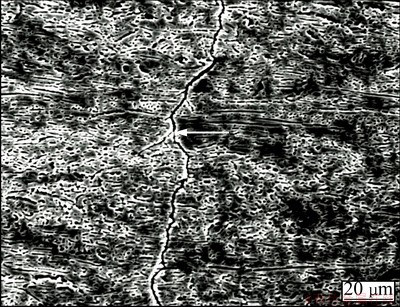

The resistance to crack initiation in LCB titanium alloy under cyclic loading is one of the critical design parameter for several applications in automotive and aerospace industries. Therefore, it is important to study the correlation between microstructure feature and crack initiation site. It is also documented in Ref. [20] that fatigue crack initiation sites could be due to 1) texture or preferred grain orientation, 2) planar slip and uniform slip with dislocation cell formation, 3) soft and hard phases, and 4) surface grains versus interior grains. It is well known that fatigue crack initiation period is a material surface phenomenon, where slip bands and grain boundaries are the preferential sites of fatigue crack initiation in LCB Ti alloy under stress-controlled cyclic loading condition [21,22]. Also, slip band cracking is more significant in the early stage of fatigue damage than grain boundary cracking. These slip band cracks may be related to the overall plastic deformation taking place individually in a grain, in which the local stress is sufficiently high to result in a plastic flow although the nominal applied stress is much lower than macroscopic yield stress[23]. In order to verify that with the LCB titanium alloy under investigation, the outer surfaces of the broken fatigue samples were etched and examined under the optical microscope to identify the crack location sites. Two types of cracks were found on the outer surfaces. Long cracks were found very near to the fracture surface, while short ones were located at a certain distance from fracture surface (about 3 mm measured out of the fracture surface), as shown in Fig. 4. It is well recognized that under the same crack driving force, the crack growth rates usually exceed those of long cracks, and the short cracks grow at stress intensities below the long crack threshold [24]. In this work, the short cracks were thoroughly investigated using a scanning electron microscope to find the locations of initiation sites and the propagation pass of those short cracks. It is noticed that these short cracks were propagated through the β-grain boundaries, trying to follow the same pass of the grain boundaries [25], as shown by the arrows in Fig. 5. According to the work proposed by NAVARRO and RIOS [26,27], the condition for crack propagation into the next grain is governed by the stress concentration ahead of the crack tip, and a crack advancing the stress must be high enough to simulate dislocation sources in the adjacent grain. The critical value of stress concentration for operating dislocation sources is dependent on the misorientation relationship among the grains involved. It could be suggested that the slip deformation in the LCB titanium alloy was induced by the incompatibility stresses due to swaging process. In this sense, the elastic-plastic incompatibility inside the grains can be considered the original cause of slip band crack initiation [18]. Of course, crack initiation is a complex process that can lead to a crack which is extremely small (≈1 μm or less) or one that appears to “pop in” (initiates and rapidly grows) at up to 100 μm in length [18,19]. In this study, the short cracks seem to be initiated and propagated suddenly up to 100 μm in length, as seen in Fig. 4 where the length of the existing short crack is approximately 90 μm. These short cracks were branched into small ones that propagated around the grain boundary, as shown in Fig. 6(a), and can be seen more clearly at higher magnification in Fig. 6(b). It is observed that these short cracks started branching from the primary alpha existing at the grain boundaries and trying to connect each α-particle simultaneously until reaching the end of the grain, as shown by the arrows in Fig. 6(b). Those short cracks were found to stop also at α-particle, in which the α-particle is considered a crack initiation site and sometimes crack arrest [28], as seen in Fig. 6(c). In order to verify this observation, an EDX was performed on both α and β phases, as shown in Fig. 7. This observation was in agreement with the work done by GUILLEMOT et al [29], where Fe and Mo are more located in the β-phase and the less amount of Fe and Mo is existing in α-phase. Therefore, it is evidence now that α-particles are considered crack initiation and arrest sites, while crack propagates in the β matrix [29]. This result is in agreement with that reported recently by CHAN [18] and HERASYMCHUK [19].

Fig. 4 Long and short cracks existing on outer surface of fatigue sample

Fig. 5 Fatigue crack propagation through β-phase grain boundaries

The fracture surfaces of some selected fatigue samples were examined to study the fatigue fracture modes, as shown in Figs. 8(a)-(c). The fracture surface of the sample aged at 500 °C for 0.5 h exhibited a typical fine microvoid fracture surface and a mixture of intergranular and transgranular modes, as seen in Fig. 8(a). However, the sample aged at 500 °C for 4 h showed a relatively flat fracture surface with microvoids inside (see Fig. 8(b)). This fracture mode is considered a transgranular fracture where the fracture goes around the β-grains that contain a large amount of alpha phase. The solution treated samples showed a fracture surface with a large amount of dimples due to the high ductility compared to the other aged ones. In addition, the fracture surface showed a mixture of intergranular and transgranular fracture modes. It is obvious that the fracture surface in each case (solution treated and aged conditions) was in agreement with the fatigue result that was obtained in this study.

Fig. 6 Fatigue crack propagation at grain boundaries

Fig. 7 EDX analyses of α (a) and β (b) phases

Fig. 8 Fatigue fracture surfaces of investigated LCB titanium alloy

4 Conclusions

1) Solution treated LCB Ti-samples showed a microstructure consisting of fine equiaxed β-grains with about 15% primary α.

2) The volume fraction of secondary α-precipitates increased with increasing the ageing time.

3) The maximum tensile and fatigue strength values were obtained by applying 0.5 h ageing time.

4) The fatigue cracks were propagated through the β-grains connecting the α-particles existing at the β-grain boundaries.

5) Samples aged for 4 h obtained a transgranular fracture mode, while both solution treated and aged samples for 0.5 h showed a mixture of transgranular and intergranular fracture modes.

References

[1] TAMIRISAKANDALA S, VEDAM B V, BHAT R B. Recent advanced in the deformation processing of titanium alloys [J]. Journal of Materials Engineering and Performance, 2003, 12: 661-673.

[2] CLEMENT N, LENAIN A, JACQUES P J. Mechanical property optimization via microstructural control of new metastable beta titanium alloys [J]. JOM, 2007, 59: 50-53.

[3] WILLIAMS J. Thermomechanical processing of high performance Ti alloys: Recent progress and future needs [J]. Journal of Materials Processing Technology, 2001, 117: 370-373.

[4] IVASISHIN O M, MARKOVSKY P E, SEMIATIN S L, WARD C H. Aging response of coarse and fine grained beta titanium alloys [J]. Materials Science and Engineering A, 2005, 405: 296-305.

[5] PRIMA F, VERMAUT P, TEXIER G, ANSEL D, GLORIANT T. Evidence of α-nanophase heterogeneous nucleation from ω particles in a β-metastable Ti-based alloy by high-resolution electron microscopy [J]. Scripta Materialia, 2006, 54: 645-648.

[6] NYAKANA S L, FANNING J C, BOYER R R. Quick reference guide for β titanium alloys in the 00S [J]. Journal of Materials Engineering and Performance, 2005, 14: 799-811.

[7] KOSAKA Y, FOX S P, FALLER K, REICHMAN S H. Properties and processing of TIMETAL LCB [J]. Journal of Materials Engineering and Performance, 2005, 14: 792-798.

[8] IVASISHIN O M, MARKOVSKY P E, MATVIYCHUK Y V, SEMIATIN S, WARD C H. A comparative study of the mechanical properties of high-strength β-titanium alloys [J]. Journal of Alloys and Compound, 2008, 457: 296-309.

[9] PRIMA F, DEBUIGNE J, BOLIVEAU M, ANSEL D. Control of omega volume fraction precipitated in a beta titanium alloy: Development of an experimental method [J]. Journal of Materials Science Letters, 2000, 19: 2219-2221.

[10] BOYER R R, RACK H J, VENTATESH V. The influence of thermomechanical processing on the smooth fatigue properties of Ti–15V–3Cr–3Al–3Sn [J]. Journal of Materials Science and Engineering A, 1998, 243: 97-102.

[11] LENAIN A, CLEMENT N, VERON M, JACQES P J. Characterization of the phase transformations in a metastable β-titanium alloys [J]. Materials Science Forum, 2007, 539-543: 3712-3717.

[12] KOKUOZ B Y, KOSAKA Y, RACK J H. High-cycle fatigue crack initiation and growth in TIMETAL LCB [J]. Journal of Materials Engineering and Performance, 2005, 14: 773-777.

[13] IBRAHIM K I, MHAEDE M, WAGNER L. Mechanical properties of titanium alloys produced in Egypt [C]//12th International Conference of Titanium. Beijing, 2011-06-17-24.

[14] MA F, LU W, QIN J, ZHANG D. Microstructure evolution of near-α titanium alloys during thermomechanical processing [J]. Materials Science and Engineering A, 2006, 416: 59-65.

[15] TAMIRISAKANDALA S, VEDAM B V, BHAT R B. Recent advances in the deformation processing of titanium alloys [J]. Journal of Materials Engineering and Performance, 2006, 12: 661-673.

[16] AZIMADEH S, RACK H J. Phase transformations in Ti-6.8Mo-4.5Fe-1.5Al [J]. Metallurgical and Materials Transactions A, 1998, 29: 2455-2467.

[17] NAG S, BANERJEE R, SRINIVASAN R, HWANG J Y, HARPER M, FRASER H L. ω-assisted nucleation and growth of the α precipitates in the Ti-5Al-5Mo-5V-3Cr-0.5Fe β titanium alloy [J]. Acta Materialia, 2009, 57: 2136-2147.

[18] CHAN K S. Roles of microstructure in fatigue crack initiation [J]. International Journal of Fatigue, 2010, 32: 1428-1447.

[19] HERASYMCHUK O M. Nonlinear relationship between the fatigue limit and quantitative parameters of material microstructure [J]. International Journal of Fatigue, 2011, 33: 649-659.

[20] CHAN K S. Changes in fatigue life mechanism due to soft grains and hard particles [J]. International Journal of Fatigue, 2010, 32: 526-534.

[21] LUTJERING G, WILLIAMS J C. Titanium [M]. Germany: Springer-Verlag, 2003.

[22] KRUPP U, FLOER W, LEI J, HU Y, CHRIST H J, SCHICK A, FRITZEN C P. Mechanisms of short fatigue crack initiation and propagation in a β-Ti alloy [J]. Philosophical Magazine A, 2002, 82(17-18): 3321-3332.

[23] HU Y M, FLOER W, KRUPP U, CHRIST H J. Microstructurally short fatigue crack initiation and growth in Ti-6.8Mo-4.5Fe-1.5Al [J]. Materials Science and Engineering A, 2000, 278: 170-180.

[24] NARASAIAH N, RAY K K. Initiation and growth of micro-cracks under cyclic loading [J]. Materials Science and Engineering A, 2008, 474: 48-59.

[25] AKAHORI T, NINOMI M, FUKUNAGA K, INAGAKI I. Effects of microstructure on the short fatigue crack initiation and propagation characteristics of biomedical α/β titanium alloys [J]. Metallurgical and Materials Transactions A, 2000, 31: 1949-1958.

[26] NAVARRO A, RIOS E R. A model for short fatigue crack propagation with an interpretation of the short-long crack transition [J]. Fatigue & Fracture of Engineering Materials & Structures, 1986, 9: 169-186.

[27] NAVARRO A, RIOS E R. A microstructurally short fatigue crack growth equation [J]. Fatigue & Fracture of Engineering Materials & Structures, 1988, 11: 383-396.

[28] McBAGONLURI F, AKPAN E, MERCER C, SHEN W, SOBOYEJO W O. An investigation of the effects of microstructure on dwell fatigue crack growth in Ti-6242 [J]. Materials Science and Engineering A, 2005, 405: 111-134.

[29] GUILLEMOT F, PRIMA F, TOKAREV V N, BELIN C, LAZARE S. Single-pulse KrF laser ablation and nanopatterning in vacuum of β-titanium alloys used in biomedical applications [J]. Applied Physics A, 2004, 79: 811-813.

Khaled M. IBRAHIM1, Mansour MHAEDE2, Lothar WAGNER2

1. Central Metallurgical R&D Institute-CMRDI, P.O. Box 87 Helwan, Cairo, Egypt;

2. TU-Clausthal, IWW, Agricolastr. 6, Clausthal-Zellerfeld, Germany

摘 要:研究了时效时间对低成本β(LCB) Ti-6.6Mo-4.5Fe-1.5Al钛合金的显微组织和力学性能的影响,以及显微组织与疲劳断裂裂纹的产生、延伸的联系。延长时效时间有助于二次α相和β晶粒体积分数的增多以及初始 α相的部分球化。在500 °C下热处理0.5 h的合金得到的拉伸强度最大(1565 MPa),疲劳极限最高(750 MPa);而在500 °C下热处理4 h的合金得到的拉伸强度最小(1515 MPa),疲劳极限最低(625 MPa)。在500 °C下热处理4 h的合金的断裂模式为穿晶断裂, 而在500 °C下热处理0.5 h的合金的断裂模式为穿晶断裂和沿晶断裂的混合。 在疲劳样品的外表面形成的裂纹沿β晶界上初始 α相延伸。

关键词:β钛合金;Ti-6.6Mo-4.5Fe-1.5Al合金;疲劳断裂;时效;二次α相;初始 α相;β晶粒;拉伸强度;疲劳极限

(Edited by YANG Hua)

Corresponding author: Khaled M. IBRAHIM; E-mail: khaledabouelela@yahoo.com

DOI: 10.1016/S1003-6326(11)61507-0