DOI: 10.11817/j.ysxb.1004.0609.2020-39188

加碳条件下钼精矿真空冶炼过程中主要杂质元素的行为分析

王 磊1, 2,郭培民1, 2,孔令兵1, 2,赵 沛1, 2,田志凌1, 2

( 1. 钢研晟华科技股份有限公司,北京 100081;

2. 钢铁研究总院 先进钢铁流程及材料国家重点实验室,北京 100081)

摘 要:采用在钼精矿真空冶炼过程中添加碳粉的方法,进一步降低钼精矿真空冶炼过程中主要杂质SiO2、MgO、Al2O3和CaO的含量。热力学计算结果表明:SiO2、MgO、Al2O3和CaO均有可能与碳发生反应,生成气态物质被去除。试验研究结果表明,在钼精矿真空冶炼过程中加入碳粉可以明显降低其中Si、Mg、Al和Ca的含量,其中Si的脱除率约达到100%,Mg的脱除率约达到99.7%,Al的脱除率约达到78.44%,Ca的脱除率最高约为9.8%。采用品位为48%的低品位钼精矿为原料,经过真空冶炼过程,得到的金属钼产品中钼含量达到92%,S含量降至0.69%,主要杂质元素SiO2含量降至0.0021%,Cu含量小于0.005%,P含量小于0.005%,Mg含量降至0.001%,Al含量降至0.64%,Ca含量为0.51%。

关键词:钼精矿;碳;真空冶炼;杂质元素;金属钼产品

文章编号:1004-0609(2020)-02-0438-09 中图分类号:TF841.2 文献标志码:A

辉钼矿是自然界中最具有工业意义的钼矿石。在传统钼冶炼过程中,辉钼精矿氧化焙烧工序释放出的二氧化硫对环境危害极大,且冶炼流程长,工艺复杂,钼的收得率较低[1]。为了解决这些问题,钼冶金工作者提出了很多的新工艺,如加氧化钙直接氢还原[2]、石灰氧化焙烧法[3-4]、氯化焙烧[5]、水蒸气氧化法[6]、湿法分解[7-9]和生物冶金[10]等,但是这些工艺都没有得到大规模应用。

钢铁研究总院于2008年开始开发钼精矿真空分解的工艺流程[11-14],其主要思路是将钼精矿置于真空炉内加热使其分解,一步直接得到金属钼粉和硫磺两种产品。采用此工艺具有流程短、环保等优点。实验研究结果表明,钼精矿在1748 K、压力1~100 Pa范围之内实现完全分解是可行的,在此条件下,钼精矿球团逐层逐步分解[15-16]。采用此工艺得到了很好的产品,具有一定的工业应用前景。

研究发现[17],钼精矿中的SiO2、CaO、MgO、Al2O3在真空分解过程中很难被去除。当在钼精矿中加入碳后,能极大地促进真空分解反应进行,且得到的金属钼产品中的Si、Ca、Mg、Al等杂质元素的含量明显降低,但是此过程中可能发生的反应及各元素的走向分布并不清楚。因此,本文通过对钼精矿真空分解过程中的杂质元素可能的行为进行热力学分析,并采用实验进行验证,得到影响钼精矿分解过程中主要杂质元素Si、Ca、Mg、Al走向的规律,为钼精矿真空冶炼的生产过程提供理论指导。

1 钼精矿基础属性

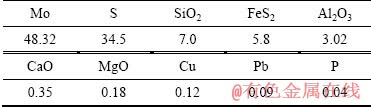

本研究中使用的钼精矿原料为某企业所生产的品位为48%的低品位钼精矿,其主要成分如表1所列。

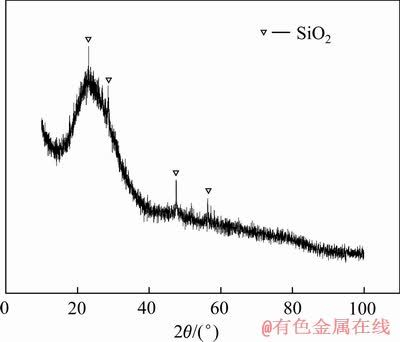

由表1中可以看出,此种钼精矿的钼品位约为48.32%,属于较低品位钼精矿,主要杂质为SiO2、FeS2、Al2O3、CaO、MgO,其物相分析如图1所示。

表1 钼精矿主要成分组成

Table 1 Chemical composition of molybdenite concentrates (mass fraction, %)

图1 钼精矿物的XRD谱

Fig. 1 XRD pattern of molybdenite concentrates

由图1可以看出,钼精矿主要物相为MoS2,含少量的SiO2。结合化学成分分析可知,钼精矿中MoS2含量可以达到80.5%,主要杂质中,SiO2含量最高,可达到7.0%。Al2O3含量为3.02%,CaO为0.35%,MgO为0.18%。因此,本文的研究对象为主要杂质SiO2、MgO、Al2O3和CaO在真空冶炼过程中的行为。

2 真空碳热还原去除杂质元素的热力学分析

鉴于钼精矿中的杂质SiO2、CaO、MgO、Al2O3较难在真空分解过程中直接去除,采用在钼精矿中加入少量还原剂碳的方法,使SiO2、CaO、MgO、Al2O3与碳发生反应,以达到去除或者降低其中Si、Ca、Mg和Al含量的目的。由于各反应在真空条件下进行,若反应物和生成物中存在气相组分且反应前后体积摩尔分数发生变化,此反应将受真空条件的影响,因此,在研究中对气相组分的平衡分压进行重点研究。当某反应的气相各组分的平衡分压总和达到压力要求值(真空度)时,此反应能顺利进行[18-19]。

2.1 SiO2与C的反应

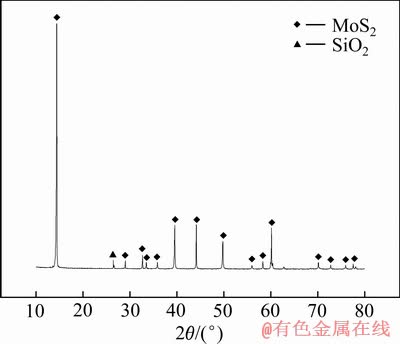

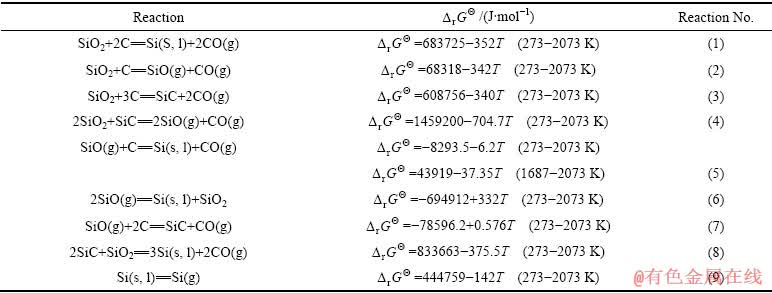

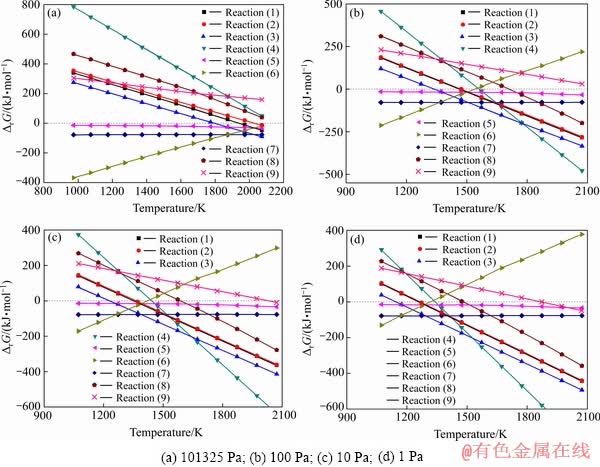

当钼精矿中加入少量碳粉后,在真空冶炼条件下,钼精矿中的SiO2可能与碳发生反应,其可能发生的反应如表2所列[20]。

SiO2的还原过程较为复杂,对其机理的解释也各不相同,但其基本的反应式是一致的。不同压力下,SiO2被还原的反应及吉布斯自由能与热力学温度(T)的关系如表2所列。

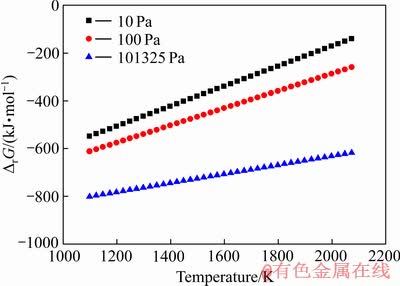

本研究中SiO2的还原反应在1~100 Pa下进行,因此分别对SiO2的还原反应的吉布斯自由能在标准大气压、100 Pa、10 Pa、1 Pa下进行计算,结果如图2所示。

在标准大气压(101325 Pa)下,在研究的温度范围内,反应(1)、(2)、(3)、(5)、(6)、(7)均可正向进行,随着压力降低,上述所列反应(1)~(9)均可正向进行。其中反应(3)最容易进行,反应(1)、(2)也较容易进行,而反应(7)也可进行,且反应(7)可看做反应(2)和反应(3)的耦合,或者反应(2)和反应(4)的耦合,反应(8)也可进行,且反应(8)可看做反应(1)和反应(3)的耦合,这样过程中所发生的的反应就较复杂。反应(5)的吉布斯自由能在研究的温度范围内恒为负,其发生的可能性也很大。反应(5)和反应(7)为气固两相反应,在低压条件下,产生的气体SiO会很快被抽走,而碳捕捉SiO气体的能力也较弱,因此反应(5)和反应(7)可能进行的限度会较小。而被抽出的SiO气体,随着温度的降低,发生歧化反应(反应(6))。而由其他还原反应生成的Si在较高的温度下,也可挥发,以气体的形式被抽走,并且随着温度的降低,再一次在真空炉低温部分凝结。这样,钼精矿中的SiO2可被还原为SiO气体被去除,或者被还原为Si,进而以气态形式去除。

表2 真空条件下SiO2与C的反应

Table 2 Possible reaction of SiO2 and C under vacuum condition

图2 不同压力下二氧化硅可能发生的反应的吉布斯自由能

Fig. 2 Gibbs free energy of possible reactions of SiO2 vs temperature under different pressures

2.2 CaO与C的反应

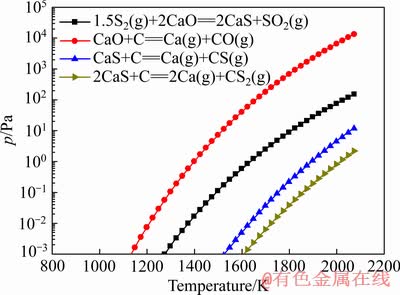

在钼精矿中加入碳之后,在真空条件下,其中的CaO可能与碳发生的反应如下[21]:

1.5S2(g)+2CaO=2CaS+SO2(g)

-168733+56T (273-2073 K) (10)

-168733+56T (273-2073 K) (10)

CaO+C=Ca(g)+CO(g)

692204-291T (273-2073 K) (11)

692204-291T (273-2073 K) (11)

2CaS+C=2Ca(g)+CS2(g)

1405312-398T (273-2073 K) (12)

1405312-398T (273-2073 K) (12)

CaS+C=Ca(g)+CS(g)

922350-285T (273-2073 K) (13)

922350-285T (273-2073 K) (13)

CaO可能发生的反应的平衡压力与温度的关系如图3所示。由图3可以看出,在钼精矿中加入碳之后,当控制压力为1~100 Pa时,CaO会与C发生反应生成Ca蒸气和CO。在此条件下,钼精矿分解得到的S2也可以与CaO发生反应生成CaS,而CaS分解较难。在存在碳的情况下,当温度更高或者压力更低时,CaS可被还原为Ca蒸气和CS气体。因此在钼精矿中加入碳,其中的CaO可以以Ca蒸气形式去除或者先转变为CaS,然后在更高的温度以及更低的压力下,再部分分解或者还原为Ca蒸气被去除。

图3 氧化钙可能发生反应的平衡压力与温度的关系

Fig. 3 Equilibrium pressures of possible reactions of CaO vs temperature

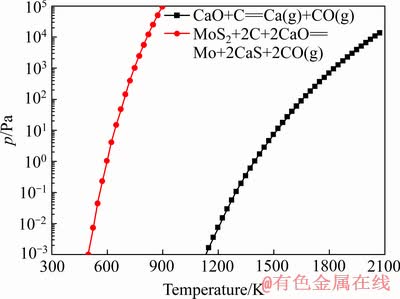

在钼精矿中,主要物相为MoS2,并不会只发生CaO与C的反应。在CaO存在的情况下,MoS2会与C、CaO发生反应,其反应开始的温度也较低。将二者进行对比,结果如图4所示。

由图4中可以看出,在压力为1~100 Pa时,MoS2会与C、CaO发生反应的温度明显低于CaO直接被碳还原的温度,因此,钼精矿中的CaO更容易在碳存在的情况下与MoS2发生反应,生成CaS、Mo和CO。而产生的CaS在较高温度1873 K(1600 ℃以上)也可与碳发生反应,生成Ca蒸气和CS。

图4 氧化钙可能发生反应的平衡压力与温度的关系

Fig. 4 Equilibrium pressures of possible reactions of CaO vs temperature

由上述分析可以知道,在CaO存在的情况下,碳更容易还原MoS2,CaO可促进MoS2的还原。这样,CaO有可能被碳直接还原或者生成CaS后再被碳还原。但是由于CaS被碳还原的温度较高,因此钼精矿中的CaO可能被碳直接还原去除或者生成CaS。

2.3 MgO与C的反应

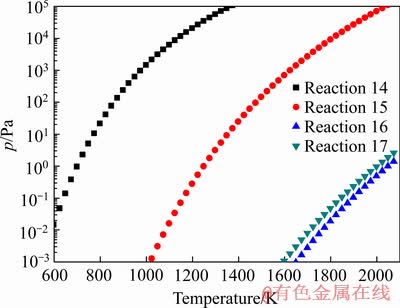

钼精矿中的Mg主要以MgO形式存在,随着钼精矿品位的不同,其中MgO含量也不同。MgO较稳定,在单纯真空分解条件下很难分解去除,而当钼精矿中加入还原剂碳之后,MgO的去除就变得可能。在真空碳存在条件下,其可能发生的反应如下[22-24]:

Mg=Mg(g)

136931+99T (273-2073 K) (14)

136931+99T (273-2073 K) (14)

MgO+C=Mg(g)+CO(g)

629567-299T (273-2073 K) (15)

629567-299T (273-2073 K) (15)

2MgO=2Mg(g)+O 2(g)

1483602-424T (273-2073 K) (16)

1483602-424T (273-2073 K) (16)

MgO+CO(g)=Mg(g)+CO2(g)

459481-125T (273-2073 K) (17)

459481-125T (273-2073 K) (17)

氧化镁可能发生反应的平衡压力与温度的关系如图5所示。由图5可以看出,Mg的挥发较容易,当压力保持在1~100 Pa时,Mg在773~860 K范围内即可变为Mg蒸气,而MgO很容易被碳还原,生成的Mg以气体形式存在,在真空炉中被抽出,随着温度的降低冷凝。MgO直接分解得到Mg和O2的反应较难进行。因此,钼精矿中的MgO很容易被碳还原成Mg,并以蒸气形式被抽出去除。

图5 氧化镁可能发生反应的平衡压力与温度的关系

Fig. 5 Equilibrium pressures of possible reactions of MgO vs temperature

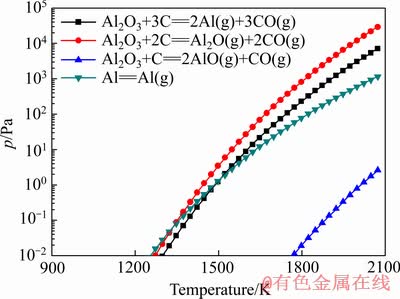

2.4 Al2O3与C的反应

钼精矿中的Al主要以Al2O3形式存在,按照钼精矿品位的不同,其Al2O3的含量也不相同。Al2O3较稳定,在单纯真空冶炼条件下很难去除,而当钼精矿中加入还原剂碳之后,Al2O3的去除也变得可能。钼精矿中加入碳粉后,在真空条件下,Al2O3可能发生的反应如下[25-27]:

Al=Al(g)

319448-119T (273-2073 K) (18)

319448-119T (273-2073 K) (18)

Al2O3+C=2AlO(g)+CO(g)

1405312-398T (273-2073 K) (19)

1405312-398T (273-2073 K) (19)

Al2O3+3C=2Al(g)+3CO(g)

125497-561T (273-2073 K) (20)

125497-561T (273-2073 K) (20)

3Al2O(g) =4Al+Al2O3

-1110913+583T (273-933 K) (21)

-1110913+583T (273-933 K) (21)

-1008089+476T (933-2073 K) (22)

-1008089+476T (933-2073 K) (22)

氧化铝可能发生反应的平衡压力与温度的关系如图6所示。由图6可知,当压力在1~100 Pa范围内时,Al2O3可被碳还原,以Al蒸气或者Al2O气体的形式被去除。

图6 氧化铝可能发生反应的平衡压力与温度的关系

Fig. 6 Equilibrium pressures of possible reactions of Al2O3 vs temperature

由Al2O歧化反应的吉布斯自由能可以知道,在0~2073 K温度范围内,其吉布斯自由能恒为负,因此其反应很容易进行。但由于Al2O的歧化反应属于体积减小的反应,因此压力降低会对歧化反应的进行产生一定影响。不同压力下Al2O歧化反应的吉布斯自由能可用式(23)计算,计算所得到的不同压力对Al2O歧化反应的影响如图7所示。

-1008089+476T-24.942

-1008089+476T-24.942 (23)

(23)

图7 不同压力下Al2O发生歧化反应的吉布斯自由能

Fig. 7 Gibbs free energy of disproportionation reactions of Al2O vs temperature under different pressure

由图7可以看出,虽然降低压力不利于Al2O歧化反应正向进行,但当控制压力为10 Pa、100 Pa、101325 Pa时,Al2O发生歧化反应的吉布斯自由能均为负。因此,控制分解压力为10~100 Pa时,Al2O的歧化反应可以发生。

因此,钼精矿中的氧化铝在碳存在的条件下,可被还原以Al气体或者Al2O气体被去除掉,而Al2O会发生歧化反应,降低温度有利于歧化反应正向进行。当控制分解压力为10~100 Pa时,Al2O会被抽出,并随着温度的降低发生歧化反应。

3 真空冶炼试验研究

3.1 实验方法

将钼精矿与活性碳粉按照一定比例混合均匀,加入适量的粘结剂造球,放入干燥箱中在423 K下干燥2 h,然后取出备用。取干燥好的球团放入真空冶炼炉中,升温至1773 K,保温2 h,整个过程中保持目标压力为30~50 Pa,当分解完成时,保持真空冶炼炉内的压力使球团随炉冷却至室温,然后取出分析。

对取出的样品以及管壁上的挥发物,进行化学成分、物相分析。

实验过程中活性碳粉的加入量按照SiO2、CaO、MgO、Al2O3与碳反应并去除的化学反应计量比加入,加入的碳与矿的质量比mC:more=5:100。

3.2 金属钼产品分析

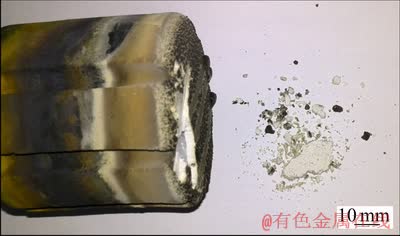

所得到的金属钼产品的形貌如图8所示。

由图8可以看出,球团之间有轻微的烧结,颜色为灰色有金属光泽,体积出现一定程度的收缩,这主要是由于其中的硫和添加的活性炭在高温真空冶炼过程中被去除所致。

图8 金属钼产品形貌

Fig. 8 Morphology of metal molybdenum product

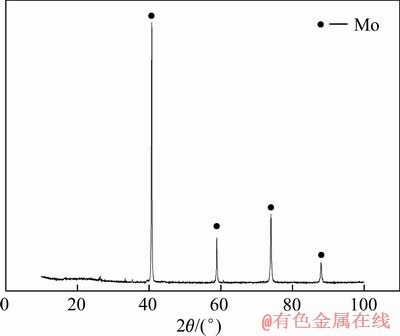

对图8中的球团进行XRD分析,结果如图9所示。由图9可以看出,所得到的产品为金属钼,说明所得到的产品的杂质已很少,金属钼含量很高。

图9 所得产品的XRD谱

Fig. 9 XRD pattern of metal molybdenum product

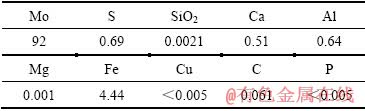

对所得到的金属钼产品进行化学分析,可得到其化学成分如表3所列。

表3 所得到金属钼的化学成分

Table 3 Chemical composition of metal molybdenum products (mass fraction, %)

由表3可以看出,金属钼中的钼含量达到了92%,S含量降至0.69%,主要杂质元素SiO2降至0.0021%,Cu<0.005%,P含量小于0.005%,添加碳后杂质元素均有所下降,铁含量为4.44%,基本没有去除。由于Al并未被完全去除,因此Al仍然以Al2O3的形式存在,Al2O3含量约为1.21%。另外,所得产品表面可能存在少量氧化[15]。

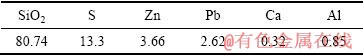

3.3 挥发物分析

在分解过程中,在真空冶炼炉管壁上除了冷凝的硫磺之外,还有很多的挥发物存在,其形貌如图10所示。由图10可以看出,挥发物粘附在真空炉管的刚玉堵头上,表面为黄黑色,内部为白色物质,分析认为是在真空还原分解过程中产生的气体在堵头上冷凝得到的。对其进行物相分析,其XRD谱如图11所示。由图11可以看出,得到的物质呈非晶态,有明显的鼓包,对比其鼓包的位置以及衍射峰的位置,可得到此挥发物主要为SiO2,而非晶态的形态有可能是由于高温下的气体在泵的作用下被抽出并在低温区快速冷却所造成的。对其进行成分分析,可得到其化学成分如表4所列。

图10 管壁上的挥发物

Fig. 10 Morphology of volatile matters

图11 管壁上挥发物的XRD谱

Fig. 11 XRD pattern of volatile matters

表4 挥发物的主要化学成分

Table 4 Chemical composition of volatile matters (mass fraction, %)

由表4中可以看出,主要成分为SiO2,其中SiO2的含量可达到80.74。其他主要成分为S、Zn、Pb、Ca、Al等。对于挥发物中的Si主要为SiO2,结合前面的热力学分析可知,这主要是由于在碳存在的情况下,SiO2与碳发生反应,生成了SiO气体被抽出,而在抽出过程中,由于温度降低,SiO气体冷凝并发生歧化反应,生成SiO2和Si,而挥发物中存在的Si与进入的少量空气反应,生成SiO2。

分析对比原料与成品中的杂质含量,其中Si的脱除率约达到100%,Mg的脱除率约达到99.7%,Al的脱除率约达到78.44%。随着碳含量的增加,其脱除率可能会进一步提高。Ca的脱除率约为9.8%,Ca 的脱除率较低,很有可能是其没有完全与碳发生反应变为钙蒸气去除,而是与钼精矿中的S发生反应生成CaS,并以CaS形式存在。CaS是一种很难去除的物质,其分解需要更高的温度和更低的压力,而对于金属钼产品中CaS的出现,也必然会使得其应用受影响,因此应尽量避免CaS的出现。

综合上述分析可以知道,在钼精矿中加入碳粉,有利于其中的杂质SiO2、CaO、MgO、Al2O3的去除。但若为了去除其中的SiO2、CaO、MgO、Al2O3,加入过量的碳粉,而在分解过程中又不能使碳全部反应完毕,必然会造成最终产品中碳含量较高,或者使分解得到的Mo金属碳化,产生Mo2C或者MoC,影响钼产品质量。

4 结论

1) 在钼精矿真空冶炼过程中加入碳粉,有利于其中的杂质SiO2、CaO、MgO、Al2O3的去除。其中Si的脱除率达到了约100%,Mg的脱除率达到了约99.7%,Al的脱除率达到约78.44%,随着碳含量的增加,其脱除率可能会进一步提高。Ca的脱除率最高约为9.8%。

2) 采用品位为48%的低品位钼精矿为原料,在加入碳粉真空冶炼的条件下,得到的金属钼中的钼含量达到了92%,S含量降至0.69%,主要杂质元素SiO2降至0.0021%,Cu<0.005%,P含量小于0.005%,Mg降至0.001%,Al降至0.64%,Ca含量为0.51%。添加碳后杂质元素均有所下降。铁含量为4.44%,基本没有被去除。

3) SiO2与碳发生反应,生成SiO气体被抽出,而在抽出过程中,由于温度降低,SiO气体冷凝并发生歧化反应,生成SiO2和Si。Al2O3可被还原以Al气体或者Al2O气体,被去除掉,而Al2O会发生歧化反应。MgO很容易被碳还原成Mg,并以蒸气形式被抽出去除。Ca很有可能没有完全与碳发生反应变为钙蒸气去除,而是大部分与钼精矿中的S发生反应生成CaS,并以CaS形式存在。

4) 对收集到的挥发物进行分析,主要成分为SiO2,其中SiO2的含量可达到80.74%。其他主要成分为S、Zn、Pb、Ca、Al等。

REFERENCES

[1] 张启修, 赵秦生. 钨钼冶金[M]. 北京: 冶金工业出版社, 2005: 163-237.

ZHANG Qi-xu, ZHAO Qin-sheng. Metallurgy of molybdenum and tungsten[M]. Beijing: Metallurgical Industry Press, 2005: 163-237.

[2] 王多刚, 郭培民, 赵 沛. 辉钼矿直接氢还原工艺的热力学研究[J]. 有色金属(冶炼部分), 2010(3): 2-4.

WANG Duo-gang, GUO Pei-min, ZHAO Pei. Thermodynamic analysis on direct reduction process of molybdenite with hydrogen[J]. Nonferrous Metals (Metallurgy Part), 2010(3): 2-4.

[3] 郭培民, 王多刚, 赵 沛. 辉钼矿非氧化焙烧工艺的热力学分析[J]. 有色金属(冶炼部分), 2010(2): 6-8.

GUO Pei-min, WANG Duo-gang, ZHAO Pei. Thermodynamic analysis on non-oxidation of molybdenite roasting process[J]. Nonferrous Metals (Metallurgy Part), 2010(2): 6-8.

[4] 肖 超, 肖连生, 夏 允, 曾 理, 高从堦. MoS2-CaO-O2系热力学分析及应用[J]. 稀有金属, 2016, 40(4): 356-362.

XIAO Chao, XIAO Lian-sheng, XIA Yun, ZENG Li, GAO Cong-kai. Thermodynamic analysis of MoS2-CaO-O2 System and its application[J]. Rare Metal, 2016, 40(4): 356-362.

[5] 王明玉, 王学文, 蒋长俊, 马艺骞, 樊烨烨, 向小艳. 镍钼矿综合利用过程及研究现状[J]. 稀有金属, 2012, 36(2): 153-160.

WANG Ming-yu, WANG Xue-wen, JIANG Chang-jun, MA Yi-qian, FAN Ye-ye, XIANG Xiao-yan. Comprehensive utilization process and research status of Ni-Mo ore[J]. Chinese Journal of Rare Metals, 2012, 36(2): 153-160.

[6] BLANCO E, SOHN H Y, HAN G, HAKOBYAN K Y. The kinetics of oxidation of molybdenite concentrate by water vapor[J]. Metallurgical and Materials Transactions B, 2007, 38(4): 689-693.

[7] AFSAHI M M, SOHRABI M, KUMAR R V, EBRAHIM H A. A study on the kinetics of hydrogen reduction of molybdenum disulfide powders[J]. Thermochimica Acta, 2008, 473(1/2): 61-67.

[8] WANG Ming-shuang, WEI Chang, FAN Gang, DENG Zhi-gan, WANG Si-fu, WU Jun. Molybdenum recovery from oxygen pressure water leaching residue of Ni-Mo ore[J]. Rare Metals, 2013, 32(2): 208-212.

[9] EBRAHIMI-KAHRIZSANGI R, ABBASI M H, SAIDI A. Molybdenite alkali fusion and leaching: Reactions and mechanism[J]. International Journal of Minerals, Metallurgy and Materials, 2010, 17(2): 127-131.

[10] 杨晓龙, 温建康, 武 彪. 铜镍多金属硫化矿生物浸出研究现状及进展[J]. 稀有金属, 2012, 36(5): 822-829.

YANG Xiao-long, WEN Jian-kang, WU Biao. Research status and process in bioleaching of Cu-Ni polymetallic sulphidedeposite[J]. Chinese Journal of Rare Metals, 2012, 36(5): 822-829.

[11] CAO Zhan-fang, ZHONG Hong, QIU Zhao-hui, LIU Guang-yi, ZHANG Wen-xuan. A novel technology for molybdenum extraction from molybdenite concentrates[J]. Hydrometallurgy, 2009, 99(1/2): 2-6.

[12] ZHOU Qiu-sheng, YUN Wei-tao, XI Jun-tao, LI Xiao-bin, QI Tian-gui, LIU Gui-hua, PENG Zhi-hong. Molybdenite- limestone oxidizing roasting followed by calcine leaching with ammonium carbonate solution[J].Transactions of Nonferrous Metals Society of China, 2017, 27(7): 1618-1626.

[13] 郭培民, 庞建明, 赵 沛. 新一代钼冶金技术与新型炼钢钼产品的开发[J]. 有色金属(冶炼部分), 2012(6): 54-57.

GUO Pei-min, PANG Jian-ming, ZHAO Pei. New technology of molybdenum metallurgy and development of new steelmaking molybdenum product[J]. Nonferrous Metals (Metallurgy Part), 2012(6): 54-57.

[14] 赵维根, 赵维保, 郭培民. 钼精矿真空分解制备高纯氧化钼的方法: 中国专利, 200810230851.X[P]. 2010-09-29.

ZHAO Wei-geng, ZHAO Wei-bao, GUO Pei-min. Preparation of high molybdenum oxide by vacuum decomposition from molybdenum concentrate: China Patent, 200810230851.X[P]. 2010-09-29.

[15] 王 磊, 郭培民, 庞建明, 赵 沛. 钼精矿真空分解过程中的物相及形貌变化[J]. 稀有金属, 2016, 40(1): 64-70.

WANG Lei, GUO Pei-min, PANG Jian-ming, ZHAO Pei. Phase and morphology evolution in vacuum decomposition process of molybdenum concentrate[J]. Chinese Journal of Rare Metals, 2016, 40(1): 64-70.

[16] WANG Lei, GUO Pei-min, PANG Jian-ming, LUO Lin-gen, ZHAO Pei. Phase change and kinetics of vacuum decomposition of molybdenite concentrate[J]. Vacuum, 2015, 116: 77-81.

[17] 王 磊, 郭培民, 庞建明, 赵 沛. 钼精矿真空分解工艺热力学分析[J]. 中国有色金属学报, 2015, 25(1): 190-196.

WANG Lei, GUO Pei-min, PANG Jian-ming, ZHAO Pei. Thermodynamic analysis of vacuum decomposition process of molybdenum concentrate[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(1): 190-196.

[18] 梁英教, 车昌荫. 无机物热力学数据手册[M]. 沈阳: 东北大学出版社, 1993: 240-241.

LIANG Ying-jiao, CHE Chang-yin. Inorganic chemical thermodynamics manual[M]. Shengyang: Northeastern University Press, 1993: 240-241.

[19] 叶大伦, 胡建华. 实用无机物热力学数据手册[M]. 北京: 冶金工业出版社, 2002: 1-30.

YE Da-lun, HU Jian-hua. Practical inorganic chemical thermodynamics data manual[M]. Beijing: Metallurgical Press, 2002: 1-30.

[20] LOUTZENHISER P G, TUERK O, STEINFELD A. Production of Si by vacuum carbothermal reduction of SiO2 using concentrated solar energy[J]. JOM, 2010, 62(9): 49-54.

[21] HU Fa-ping, PAN Jia, MA Xin, ZHANG Xi, CHEN Jie, XIE Wei-dong. Preparation of Mg and Ca metal by carbothermic reduction method–A thermodynamics approach[J]. Journal of Magnesium and Alloys, 2013, 1(3): 263-266.

[22] YANG Cheng-bo, TIAN Yang, QU Tao, YANG Bin, XU Bao-qiang, DAI Yong-nian. Analysis of the behavior of magnesium and CO vapor in the carbothermic reduction of magnesia in a vacuum[J]. Journal of Magnesium and Alloys, 2014, 2(1): 50-58.

[23] TIAN Yang, XU Bao-qiang, YANG Bin, YANG Chen-bo, QU Tao, LIU Da-chun, DAI Yong-nian. Magnesium production by carbothermic reduction in vacuum[J]. Journal of Magnesium and Alloys, 2015, 3(2): 149-154.

[24] TIAN Yang, XU Bao-qiang, YANG Cheng-Bo, YANG Bin, QU Tao, LIU Hong-xiang, DAI Yong-nian, LIU Da-chun. Analysis of magnesia carbothermic reduction process in vacuum[J]. Metallurgical and Materials Transactions B, 2014, 45(5): 1936-1941.

[25] YU Wen-zhan, YANG Bin, CHEN Xiu-min, JIANG Wen-long, YU Qing-chun, XU Bao-qiang. Thermodynamic calculation and experimental investigation on the products of carbothermal reduction of Al2O3 under vacuum[J]. Vacuum, 2012, 86(12): 2005-2009.

[26] VISHNEVETSKY I, EPSTEIN M. Solar carbothermic reduction of alumina, magnesia and boria under vacuum[J]. Solar Energy, 2015, 111: 236-251.

[27] VISHNEVETSKY I, BEN-ZVI R, EPSTEIN M, BARAK S, RUBIN R. Solar carboreduction of alumina under vacuum[J]. JOM, 2013, 65(12): 1721-1732.

Behavior analysis of main impurity elements in vacuum smelting of molybdenum concentrate with carbon

WANG Lei1, 2, GUO Pei-min1, 2, KONG Ling-bing1, 2, ZHAO Pei1, 2, TIAN Zhi-ling1, 2

(1. CISRI SUNWARD Technology Co., Ltd., Beijing 100081, China;

2. State Key Laboratory of Advanced Steel Process and Products, Central Iron and Steel Research Institute, Beijing 100081, China)

Abstract: In order to further reduce the impurities content of SiO2, MgO, Al2O3 and CaO in the vacuum smelting process of molybdenite concentrates, a method of adding carbon powder in the vacuum smelting process of molybdenite concentrates was adopted. Thermodynamic calculation results show that SiO2, MgO, Al2O3 and CaO may react with carbon to generate gaseous substances which can be removed by vacuum pump. The results show that the addition of carbon powder in the vacuum smelting of molybdenite concentrate can significantly reduce the contents of Si, Mg, Al and Ca. The removal rates of Si, Mg, Al can reach about 100%, 99.7%, and 78.44%, respectively. The max removal rate of Ca can reach about 9.8%. When 48% low-grade molybdenite concentrate are used as raw material in the vacuum smelting process, the content of Mo in the metal product can reach 92%, and the content of S decreases to 0.69%. The main impurity SiO2 decreases to 0.0021%, and the contents of Cu and P are all less than 0.005%, and the contents of Mg, Al and Ca are 0.001%, 0.64% and 0.51%, respectively.

Key words: molybdenite concentrates; carbon; vacuum smelting; main impurities; metal Mo

Foundation item: Project(U1560201) supported by the National Natural Science Foundation of China

Received date: 2018-09-20; Accepted date: 2019-07-20

Corresponding author: WANG Lei; Tel: +86-18811105273; E-mail: wangleivictory@sina.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(U1560201)

收稿日期:2018-09-20;修订日期:2019-07-20

通信作者:王 磊,工程师,博士;电话:18811105273;E-mail:wangleivictory@sina.com