攀枝花钛精矿碳热还原-真空冶炼工艺

黄润,吕学伟,张凯,宋兵,白晨光

(重庆大学 材料科学与工程学院,重庆,400044)

摘要:运用FactSage软件对攀枝花钛精矿碳热还原后在真空条件下的分离行为进行热力学计算。结果表明:在配碳量12%(质量分数),压力100 Pa,温度高于1 300 ℃时,气相中开始产生Mg,SiO和Mn蒸气;当温度为1 750 ℃时,整个体系内各物质含量趋于稳定值,钛渣品位(折算TiO2)可达94%。在同样的配碳量下,温度为1 550 ℃,压力低于1 000 Pa时,气相中也产生Mg,SiO和Mn蒸气。在碳管炉进行了预还原后钛精矿的真空冶炼实验,结果表明:金属铁已明显挥发出来;渣的主要物相为Ti2O3,TiO和少量的金属铁,钛渣品位高达93.35%(质量分数),CaO含量小于1.05%(质量分数),MgO含量小于0.42%(质量分数)。

关键词:钛精矿;真空冶炼;高钛渣;FactSage

中图分类号:TF135 文献标志码:A 文章编号:1672-7207(2014)03-0684-06

Carbothermic reduction and vacuum smelting of panzhihua ilmenite concentrate

HUANG Run, L Xuewei, ZHANG Kai, SONG Bing, BAI Chenguang

Xuewei, ZHANG Kai, SONG Bing, BAI Chenguang

(School of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: The phase relations with pressure and temperature were calculated by FactSage. The results show that Mg, SiO and Mn vapor are produced in the gas phase under the conditions of carbon addition 12%, temperature 1 300 ℃ and pressure 100 Pa. When temperature is higher than 1 750 ℃, the content of each composition in the system keeps a stable value, and the grade of titania is about 94% (convert to TiO2). When the pressure is lower than 1 000 Pa and temperature is 1 550 ℃, Mg, SiO and Mn vapor are also produced in the gas phase with the same carbon addition. On the other hand, the pre-reduced ilmenite is vacuum smelting in a carbon tube furnace. The iron vapor is volatilized. The main phases of the smelted samples are Ti2O3, TiO and little iron metal, the grade of which can reach 93.35%, CaO content is less than 1.05% and MgO content is less than 0.42%.

Key words: ilmenite; vacuum smelting; titania slag; FactSage

我国攀西地区储藏着丰富的钛资源,约占全国钛总储量的90%以上,占世界储量35%,但主要是含钒、钛和铁的复合共生矿[1]。攀枝花钛精矿是从第一次选矿后的尾矿中再次选矿而得,钛精矿含钙、镁杂质高,镁以类质同象赋存于钛铁矿中[2]。电炉工艺富集降镁难度大,必需经过后续处理才能满足生产氯化钛白和海绵钛的要求[3]。盐酸法除钙镁杂质虽然技术可行,但能耗高,设备腐蚀严重,产生的废酸量及副产品量大[4]。到目前为止,仍未开发出一条适合该资源特点和制备高品位氯化钛渣的有效途径。真空碳热还原过程中可脱除还原过程中产生的高蒸气压物质,例如MgO,SiO2和ZnO等[5-12]。基于此,本文作者采用FactSage理论计算和真空实验结合的方法研究了该工艺的可行性,以期为攀枝花钛精矿的利用提出新的工艺路线。

1 实验

1.1 原料与设备

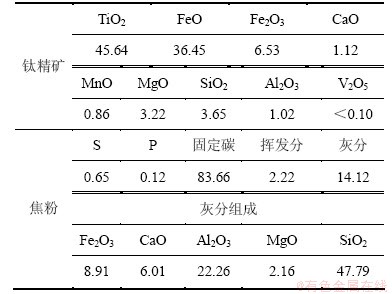

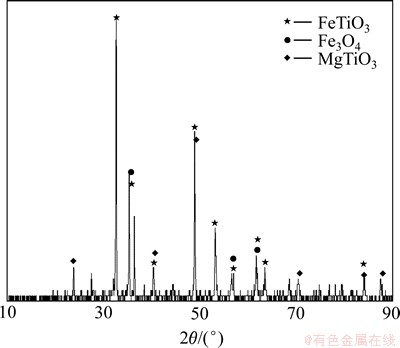

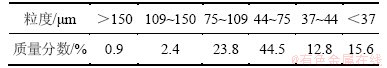

实验所用钛精矿和焦粉均取自攀枝花某企业,其化学成分如表1所示。钛精矿的主要物相为钛铁矿、磁铁矿和镁钛矿,如图1所示。通过筛分的方法所得钛精矿的粒度分布如表2所示,其表明大部分粒度是小于75 μm。真空冶炼实验采用上海晨华电炉有限公司生产的ZT-25-20真空碳管炉,额定功率为25 kW,最高工作温度为2 000 ℃和极限真空为6.67 mPa。

表1 实验原料的化学成分(质量分数)

Table 1 Chemical analysis of raw materials %

图1 攀枝花钛精矿XRD谱

Fig. 1 XRD pattern of Panzhihua ilmenite concentrate

表2 钛精矿粒度分布

Table 2 Particle size distribution of Panzhihua ilmenite concentrate

1.2 实验研究方法

1.2.1 理论计算

通过FactSage6.2软件对钛精矿真空碳热还原进行热力学计算,分析气相和渣相中的化学成分。开始反应设置为:100 g钛精矿和12 g焦粉(化学成分如表1所示),体系压力10~1 000 Pa,计算温度区间为1 200~1 800 ℃。

1.2.2 实验研究

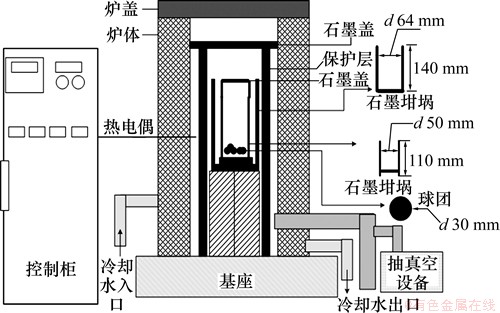

实验前,先将钛精矿和焦粉按质量比为100:12进行压块。单个球质量约为30 g,直径为30 mm,高为5 mm。然后在竖式电阻炉进行预还原,待炉温达到设定的温度后,再将球团放入刚玉坩埚里并开始计时。预还原温度为1 380 ℃,还原时间为20 min,且在整个还原过程中通氩气保护。关于预还原的更多细节请参看文献[13-14]。将预还原后的样品放入带石墨盖的刚玉坩埚中,在碳管炉中进行真空冶炼实验,其实验装置如图2所示。迅速升温到预定温度,开始计时。真空度约20 Pa,冶炼实验的温度为1 550 ℃,冶炼时间为15 min,然后停止加热,待试样冷却后取出。对获得的样品进行XRD物相和化学分析。

图2 真空碳管炉示意图

Fig. 2 Schematic diagram of vacuum carbon tube furnace

2 结果与分析

2.1 FactSage理论计算

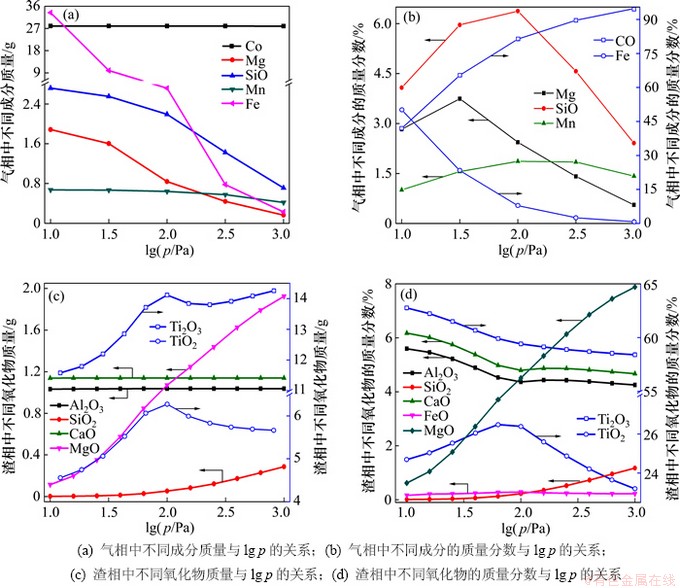

通过FactSage模拟计算,可得到气相和渣相的成分及含量。气相和渣相的成分及含量与压力的关系如图3所示。图3(a)所示为气相中各成分的质量与压力的关系,其表面在配碳量12%,温度为1 550 ℃时,压力低于1 000 Pa时,Mg,SiO和Mn渐渐挥发到气相中,而且随着压力的降低挥发的更明显[15]。气相中CO的质量几乎不变,整个气相总质量随着压力的降低而增加。气相中各成分的质量分数与压力的关系如图3(b)所示。Fe的质量分数随着压力的降低而增加,CO的质量分数则随着压力的降低而降低。由于在1 000 Pa时,各自成分挥发都较少,但随着压力的降低,Fe蒸气含量迅速增加导致其他成分的质量分数随着压力的降低而先增加后减少。在同样的条件下,渣中各成分的质量变化见图3(c):Al2O3和CaO基本不被还原,其质量保持不变;SiO2和MgO的质量随着压力的降低而降低,MgO的变化尤为明显。当压力在100~1 000 Pa之间时,Ti2O3和TiO2含量变化不大;当随着压力继续降低时,其含量均在降低,但都是以Ti2O3的含量为主。此时,会有少量的低价钛产生,但渣中杂质已明显减少,从而可获得高品位的氯化钛渣。

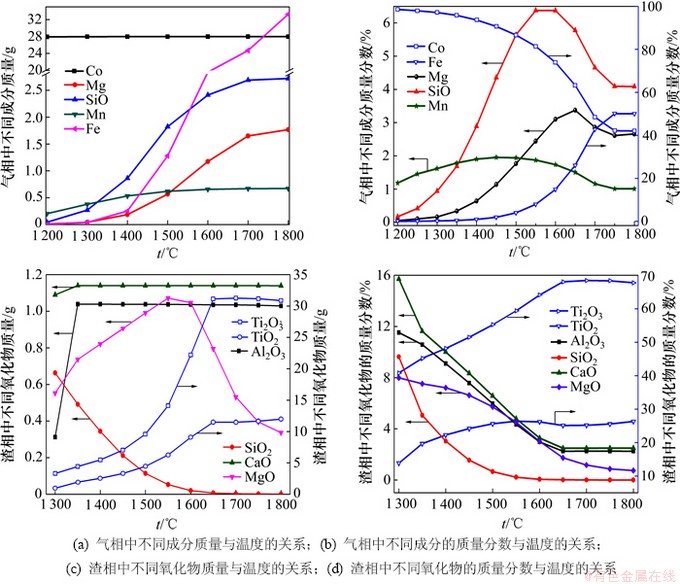

气相和渣相中不同成分含量与温度的关系如图4所示。由图4可知:当配碳量为12%,压力为100 Pa,温度高于1 200 ℃时,气相中便有少量的SiO和Mn蒸气产生;当温度高于1 300 ℃时,气相中的Mg和Fe蒸气也渐渐产生。它们都随着温度的升高而增加,其中以Fe的质量增加尤为明显;当温度高于1 750 ℃时,整个气相体系各成分的含量趋于稳定,其质量分数为:Fe 50.06%,CO 42.12%,SiO 4.09%,Mg 2.61%和Mn 1.01%(图4(b))。当温度高于1 300 ℃时,才会有渣相的形成,其中各成分的含量与温度的关系如图4(c)和(d)所示。渣相中SiO2的质量随着温度的升高而迅速下降,而Ti2O3和TiO2的质量随着温度升高而增加。当温度为1 650 ℃时,渣相中SiO2,Ti2O3和TiO2质量趋于稳定值;当温度高于1 350 ℃时,渣中Al2O3和CaO的含量基本保持不变。但渣相中SiO2,MgO,Al2O3和CaO的质量分数都是随着温度增加而降低,TiO2和Ti2O3质量分数是一直在增加;当温度达到1 750 ℃时,整个渣相各物质的含量都趋于一稳定值(图4(d))。经理论计算后,渣中主要氧化物为TiO2和Ti2O3,其含量高达94%。

图3 理论计算气相和渣相中不同成分含量与压力的关系(t=1 550 ℃, w(C)=12%)

Fig. 3 Calculated contents of different compositions in gas phase and slag phase versus pressure

图4 理论计算气相和渣相中不同成分含量与温度的关系(p=100 Pa, w(C)=12%)

Fig. 4 Calculated contents of different compositions in gas phase and slag phase versus temperature

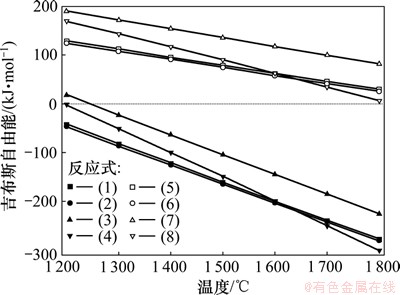

预还原后的含碳球团表现为疏松和多孔性,在真空条件下,其分压很低,CO气体很容易扩散出去。体系内可能发生以下气-固和固-固反应:

C(s)+FeO(s)→CO(g)+Fe(g) (1)

C(s)+MnO(s)→CO(g)+Mn(g) (2)

C(s)+MgO(s)→CO(g)+Mg(g) (3)

C(s)+SiO2(s)→CO(g)+SiO(g) (4)

CO(g)+FeO(s)→CO2(g)+Fe(g) (5)

CO(g)+MnO(s)→CO2(g)+Mn(g) (6)

CO(g)+MnO(s)→CO2(g)+Mg(g) (7)

CO(g)+SiO2(s)→CO2(g)+SiO(g) (8)

在系统压力为100 Pa下独立对以上8个化学反应的吉布斯自由能与温度的关系进行计算,结果如图5 所示。由图5可知:在系统压力为100 Pa 时,气-固反应的吉布斯自由能仍然为正,反应不能向右进行;固-固反应是可以进行的,其反应由易到难的顺序是:MnO,FeO,SiO2和MgO。因此,通过对攀枝花钛精矿真空碳热还原的理论计算表明,其反应机理是碳颗粒直接还原的固-固反应,这与他人研究结果相似[5]。同时表明:这种工艺将能较好地处理我国攀枝花地区含高钙、镁的钛精矿,以期为我国攀枝花钛精矿的高效清洁利用提供若干理论依据。

图5 100 Pa下吉布斯自由能和温度的关系

Fig. 5 Relationships between Gibbs free energy and temperature at 100 Pa

2.2 真空冶炼实验结果

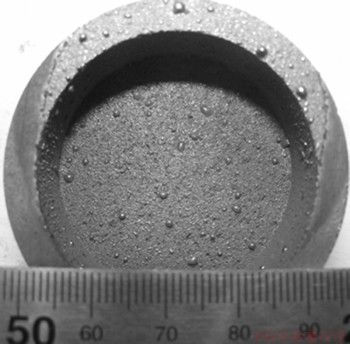

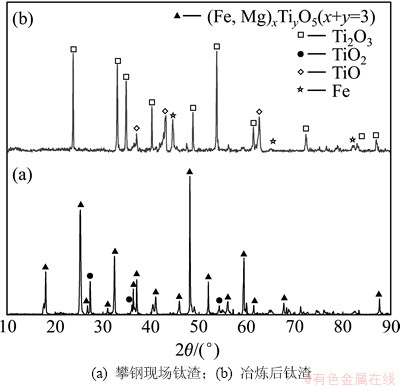

实验发现真空冶炼后的样品,其中铁已经明显挥发出来,冷凝在石墨盖上。图6所示为冷凝在石墨盖上的铁球照片。聚集在石墨盖上的铁珠清晰可见,有的铁珠直径已经大于1 mm。图7所示为真空冶炼后渣样和攀枝花某厂现场钛渣的XRD谱。由图7可知:真空冶炼后渣物相是Ti2O3,TiO和少量的金属铁;现场钛渣主要物相为:假板钛矿型((Fe, Mg)xTiyO5,x+y=3)和TiO2。真空还原后渣中主要以Ti2O3为主,这与理论计算也非常吻合(如图4(d)所示)。常规钛渣冶炼时,由于氧化镁含量高,镁与铁能相互置换形成假板钛矿型固溶体,最后稳定存在于钛渣中。其不仅降低了钛渣的品位,还阻止铁氧化物的进一步还原[16]。但真空还原时,硅、镁、锰等杂质已经通过蒸气形式挥发掉,没有假板钛矿型固溶体的形成,所以渣中的高价钛和铁氧化物更容易还原。

图6 冷凝在石墨盖上的铁珠照片

Fig. 6 Cross-sectional micrograph of iron shot in graphite cover

图7 真空还原后钛渣与攀枝花现场钛渣的XRD谱

Fig. 7 XRD pattern of reduced slag and Ti-slag from Panzhihua plant

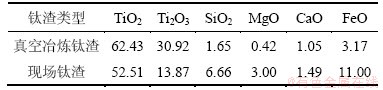

表3所示为真空冶炼后钛渣和现场钛渣的化学成分。通过化学成分对比可知:真空还原后渣中SiO2,MgO和FeO的含量比现场钛渣的含量有了显著降低。在1 550 ℃,压力约为20 Pa,还原15 min后,钛渣品位达到了93.35%。

表3 真空冶炼钛渣与现场钛渣的化学成分(质量分数)

Table 3 Chemical compositions of vacuum reduced slag and slag from Panzhihua plant %

3 结论

(1) 热力学计算表明真空还原钛精矿是可行的。在配碳量12%,温度为1 550 ℃,压力低于1 000 Pa时,气相中开始产生Mg,SiO和Mn蒸气。在配碳量12%,压力为100 Pa,温度高于1 300 ℃时,气相中开始产生Mg,SiO和Mn蒸气;当温度为1 750 ℃时,整个体系内各物质含量趋于一稳定值,钛渣品位可达94%。

(2) 在1 550 ℃,压力约为20 Pa,真空冶炼15 min后,Fe明显以蒸气形式挥发出来;渣的主要物相为Ti2O3,TiO和少量的金属铁,钛渣品位高达93.35%。

参考文献:

[1] 莫畏, 邓国珠, 罗方. 钛冶金[M]. 2版. 北京: 冶金工业出版社, 1998: 110-198.

MO Wei, DENG Guozhu, LUO Fang. Titanium metallurgy[M]. 2nd ed. Beijing: Metallurgical Industry Press, 1998: 110-198.

[2] 朱俊士. 中国钒钛磁铁矿选矿[M]. 北京: 冶金工业出版社, 1996: 21.

ZHU Junshi. Vanadium titanium magnetite benification of China[M]. Beijing: Metallurgy Industry Press, 1996: 21.

[3] Sneha S. The dissolution of iron in the hydrochloric acid leach of titania slag obtained from plasma melt separation of metalized ilmenite[J]. Chemical Engineering Research and Design, 2011, 89: 2190-2193.

[4] Mazzocchitti G I, Panias G D. Silicon and aluminum removal from ilmenite concentrates by alkaline leaching[J]. Hydrometallurgy, 2009, 96: 327-332.

[5] 罗启, 曲涛, 刘大春, 等. 红土镍矿真空碳热还原过程中镁的行为[J]. 中南大学学报(自然科学版), 2012, 43(11): 4190-4198.

LUO Qi, QU Tiao, LIU Dachun, et al. Behavior of magnesium in saprolite nickel laterite by carbothermic reduction in vacuum[J]. Journal of Central South University (Science and Technology), 2012, 43(11): 4190-4198.

[6] 罗启, 刘大春, 曲涛, 等. 真空碳热还原过程中二氧化硅的挥发行为[J]. 中南大学学报(自然科学版), 2012, 43(8): 2900-2908.

LUO Qi, LIU Dachun, QU Tiao, et al. Volatile behavior of silicon by carbothermic reduction in vacuum[J]. Journal of Central South University (Science and Technology), 2012, 43(8): 2900-2908.

[7] YANG Tian, QU Tao, YANG Bin, et al. Behavior analysis of CaF2 in magnesia carbothermic reduction process in vacuum[J]. Metallurgical and Materials Transactions B, 2012, 43(3): 657-661.

[8] 冯月斌, 杨斌, 戴永年. 真空下碳热还原氧化铝的热力学[J]. 中国有色金属学报, 2011(7): 1748-1755.

FENG Yuebin, YANG Bin, DAI Yongnian. Thermodynamics of carbothermal reduction of alumina in vacuum[J]. The Chinese Journal of Nonferrous Metals, 2011(7): 1748-1755.

[9] Jafar S, Tangstad M. Vacuum refining of molten silicon[J]. Metallurgical and Materials Transactions B, 2012, 43(6): 1427-1445.

[10] 熊利芝, 陈启元, 尹周澜, 等. 真空碳热还原氧化锌矿动力学[J]. 过程工程学报, 2010, 10(1): 133-137.

XIONG Lizhi, CHEN Qiyuan, YIN Zhuolan, et al. Vacuum carbothermal reduction kinetics of zinc oxide ore[J]. The Chinese Journal of Process Engineering, 2010, 10(1): 133-137.

[11] 刘红湘, 戴永年, 李一夫, 等. 真空碳热还原氧化镁制取金属镁的研究[J]. 真空, 2009(5): 82-86.

LIU Hongxiang, DAI Yongnian, LI Yifu, et al. Preparing magnesium by carbothermic reduction of magnesia in vacuum[J]. Vacuum, 2009(5): 82-86.

[12] KONG Lingxin, YANG Bin, LI Yifu, et al. Application of MIVM for Pb-Sn system in vacuum distillation[J]. Metallurgical and Materials Transactions B, 2012, 43(6): 1649-1656.

[13] HUANG Run, L Xuewei, BAI Chenguang, et al. Solid state and smelting reduction of Panzhihua ilmenite concentrate with coke[J]. Canadian Metallurgical Quarterly, 2012, 51: 434-439.

Xuewei, BAI Chenguang, et al. Solid state and smelting reduction of Panzhihua ilmenite concentrate with coke[J]. Canadian Metallurgical Quarterly, 2012, 51: 434-439.

[14] HUANG Run, BAI Chenguang, L Xuewei, et al. Carbothermal reduction of ilmenite concentrate at high temperature[C]// 2011TMS. San Diego, USA, 2011: 25-32.

Xuewei, et al. Carbothermal reduction of ilmenite concentrate at high temperature[C]// 2011TMS. San Diego, USA, 2011: 25-32.

[15] 戴永年, 杨斌. 有色金属真空冶金[M]. 北京: 冶金工业出版社, 2009: 158.

DAI Yongnian, YANG Bin. Nonferrous metal vacuum metallurgy[M]. Beijing: Metallurgy Industry Press, 2009: 158.

[16] 郭宇峰, 游高, 姜涛, 等. 攀枝花钛铁矿固态还原行为[J]. 中南大学学报(自然科学版), 2010, 41(5): 1639-1644.

GUO Yufeng, YOU Gao, JIANG Tao, et al. Solid-state reduction behavior of Panzhihua ilmenite[J]. Journal of Central South University (Science and Technology), 2010, 41(5): 1639-1644.

(编辑 陈爱华)

收稿日期:2013-03-10;修回日期:2013-05-10

基金项目:国家自然科学基金资助项目(51374262);中央高校基本科研业务费资助项目(CDJZR11130002)

通信作者:吕学伟(1982-),男,山东莱芜人,博士,副教授,从事金属提取与分离过程的物理化学问题、钢铁冶金新技术及工艺优化研究;电话:023-65112631;E-mail: lvxuewei@163.com