DOI:10.19476/j.ysxb.1004.0609.2019.08.16

铜渣组分含量对渣锍高温沉降分离效果的影响

张家靓1, 2,杨 旭1, 3,张建坤1,陈永强1, 2,张立峰1, 2,王成彦1, 2

(1. 北京科技大学 冶金与生态工程学院,北京100083;

2. 稀贵金属绿色回收与提取北京市重点实验室,北京100083;

3. 中国恩菲工程技术有限公司,北京 100038)

摘 要:本文利用高温沉降实验对FeO-SiO2-Fe3O4-CaO-Al2O3-MgO系中不同组分含量以及温度对铜渣、铜锍分离效果的影响进行研究,同时利用热力学计算软件FactSage结合含固相熔渣的黏度、密度计算公式,对不同渣型炉渣的黏度和密度进行计算,进而研究其对渣锍分离效果的影响。结果表明,当炉渣黏度大于0.5 Pa·s时,黏度升高对渣锍分离有着十分不利的影响。当炉渣各组分控制在SiO2/Fe比(w(SiO2)/w(Fe))0.82%~0.97%、w(CaO) 0~6.2%、w(Al2O3) 2%~7%、w(MgO) 0~1.25%和w(Fe3O4) 0~10%,且沉降温度在1230 ℃以上时,熔渣具有良好的流动性,其密度也在理想的范围内,沉降后渣中的含铜量低于1%。由沉降后渣的矿相分析表明,难以沉降的铜物相主要为呈点状分布的微米级黄铜矿和少量大粒径的辉铜矿。

关键词:铜冶炼;渣锍分离;FactSage;黏度;密度;渣型优化

文章编号:1004-0609(2019)-08-1712-09 中图分类号:TF811 文献标志码:A

铜富氧熔池熔炼包括诺兰达法、富氧底吹法、瓦纽科夫法和奥斯麦特/艾萨法等,目前广泛地应用于当今世界的铜冶炼生产中[1]。铜富氧熔池熔炼通过炉顶喷枪或设置于熔池内的喷嘴将富氧空气鼓入熔池中。在强烈的气体搅动下,精矿中的铁和硫剧烈氧化放出大量的热,同时产出高品位的铜锍和大量炉渣。根据冶炼工艺的不同,造锍熔炼产生的炉渣和铜锍的混合物直接在冶炼炉内分离后分别排出(诺兰达法、富氧底吹法、瓦纽科夫法等),或通过沉降电炉进行分离(奥斯麦特/艾萨法等)[1-2]。炉渣和铜锍分离效果的好坏,直接影响铜的直收率,对企业的经济效益产生巨大的影响。

炉渣含铜是冶金过程中铜损失的主要方式,其在渣中的损失形式主要分为溶解损失和机械损失。溶解损失主要是铜的氧化物或铜锍粒子溶解在炉渣中;机械损失主要为细小颗粒的铜锍粒子机械夹杂在炉渣中[3]。由于熔炼生成的金属和熔体液滴分散在熔渣中,他们的汇合长大、沉降分离都是在炉渣介质中进行的[4]。因此,熔渣的物理性质对金属、熔锍与渣的分离起着重要的作用。黏度、密度是铜冶炼渣的重要物理性质,主要取决于炉渣的组成成分和温度[5]。对于铜的冶炼来说,炉渣中的主要成分为SiO2和FeO,其次还有Fe3O4、Al2O3、CaO和MgO等。许多学者曾对硅铁渣系的黏度进行过卓有成效的研究[6-10]。其中,盛力等[11]针对基于铜冶炼渣的FeO-SiO2-Fe3O4-CaO-Al2O3- MgO系,采用FactSage热力学软件结合Roscoe方程对该渣系在一定温度下的含固相黏度进行计算。结果表明,黏度计算值和实验值误差在30%以内,该计算方法可较为准确地预测含固相铜冶炼渣的黏度。密度对于炉渣与金属的反应、质量传递同样具有重要的意义。炉渣密度越小,密度更大的铜锍更容易在重力作用下沉降而与炉渣分离。国内外的学者对于铜冶炼渣的密度,提出了各种密度计算模型和经验公式[12-13]。这些模型和公式对于定性或定量研究炉渣密度的变化规律,进而指导实际的生产过程有着重要的作用。

另外,一些学者曾对不同组分渣型对渣中铜损失的影响进行过研究[14-16]。ELLIOT[17]通过向饱和硅铁渣中加入铜-金合金的方式,测量了渣中不同MgO、Al2O3和CaO含量条件下铜的溶解度。KIM等[18]通过将金属铜与饱和硅铁渣进行混合,在1250 ℃条件下,研究了不同Al2O3、MgO和CaO含量下渣中铜溶解度的变化规律。研究发现,CaO、MgO和Al2O3的加入有利于降低渣中的铜含量。CaO对渣中铜含量的影响最大,其次为MgO和Al2O3。基于同样的方法,ZIVKOVIC等[19]对Cu在SiO2-FeO-Fe3O4-CaO-Al2O3渣系中的溶解度进行了探究。结果发现,随着渣中SiO2、CaO和Al2O3含量的增加,渣中铜的溶解度降低,而FeO和Fe3O4含量的升高对降低渣中铜的溶解度有不利影响。

通过文献总结发现,前人主要对铜在渣中的化学溶解损失进行研究。而对于实际铜熔炼过程的渣、锍分离来说,铜主要以硫化物形式存在,而机械损失是渣中铜损失的主要形式[3]。另外,前人所研究的这些渣系并未涵盖实际铜冶炼炉渣的所有组分,迄今为止,对于FeO-SiO2-Fe3O4-CaO-Al2O3-MgO六元渣系中不同成分对渣锍分离效果的影响未有系统研究。因此,为了提高铜冶炼中渣锍分离效果,降低渣含铜,亟需通过研究探明铜渣不同组分对渣锍分离效果的影响规律,为实际铜渣沉降分离过程的优化提供理论支撑。

本文首先利用高温沉降实验对FeO-SiO2-Fe3O4- CaO-Al2O3-MgO体系中不同组分含量、温度下的渣锍分离效果进行研究。同时利用FactSage软件的多元多相平衡计算和纯液相炉渣黏度计算功能,结合含固相熔渣的黏度和密度计算公式,计算不同渣型下熔渣黏度、密度的变化规律,进而研究这些物性参数对沉降分离后渣中铜含量的影响。并通过上述研究,对铜冶炼过程的渣锍分离提出了优化的渣型组成。

1 实验和计算方法

1.1 渣锍高温沉降实验

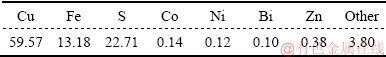

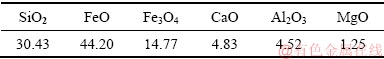

渣锍高温沉降实验以某艾萨铜冶炼厂提供的纯铜锍为原料,其元素组成如表1所示。炉渣则采用草酸亚铁、Fe3O4、SiO2、CaO、Al2O3和MgO分析纯试剂分两步合成。第一步先将一定配比的草酸亚铁和SiO2试剂充分混匀,然后利用电阻炉以10 ℃/min的速率在流动的高纯氩气保护下加热到1300 ℃,所用坩埚为钼坩埚,保护气流量为800 mL/min,保温时间为2 h。随后将坩埚取出经水淬、破碎、磨细后得到FeO-SiO2渣;第二步将FeO-SiO2渣与Fe3O4、CaO、Al2O3和MgO试剂按照配比充分混合,混合物料同样在1300 ℃高温下在氩气保护下合成,得到符合成分要求的六元系炉渣。炉渣的初始组成如表2所示,当考察某一组分的含量变化对渣中铜含量以及熔渣物性的影响时,只变化该组分的加入量,其余组分之间的比例固定不变。细磨后的合成炉渣与纯铜锍按照100 g:120 g的质量比进行充分混合。将配制好的渣锍混合物倒入坩埚,待电阻炉温度升至所需温度,将坩埚放入其中反应,反应3 h后,停止加热并将坩埚取出在室温下冷却。随后将坩埚敲碎,将铜锍和渣尽可能完全剥离,得到的沉降渣溶解后,利用电感耦合等离子发射光谱仪(ICP-OES, Optima 7000 DV, Perkin Elmer instruments, US)分析其中的铜含量。铜锍原料和沉降渣利用X射线衍射仪(XRD, Ultima IV, Rigaku, Japan)、光学显微镜(Axiovision, Car Zeiss, Germany)、扫描电镜背散射电子成像(SEM, MLA250, FEI, US)和X射线能谱(EDS, MLA250, FEI, US)来分析其成分和矿物组成。

表1 铜锍的化学成分

Table 1 Chemical composition of matte (mass fraction, %)

表2 六元渣系各组分的初始含量

Table 2 Initial mass fraction of various components in slag system (mass fraction, %)

1.2 含固相熔渣黏度、密度的计算方法

热力学软件FactSage是由F*A*C*T/Fact-Win和ChemSage两个热化学软件包整合而成,由于其丰富的数据库和强大的数值计算处理能力,已广泛应用于冶金、材料、地质等领域的各个方面[20]。利用FactSage中的Equilib模块,选择纯物质FactPS和氧化物FToxide数据库,设定初始熔渣组成成分及平衡温度后,即可得到该温度下固、液相的平衡组成。

根据文献[11]中的方法,含固相熔渣的黏度( )由式(1)得到,其中a和n值通过实验值拟合得出,分别为2.0和3.95;固相体积分数ΦS由式(2)~(4)计算得到

)由式(1)得到,其中a和n值通过实验值拟合得出,分别为2.0和3.95;固相体积分数ΦS由式(2)~(4)计算得到

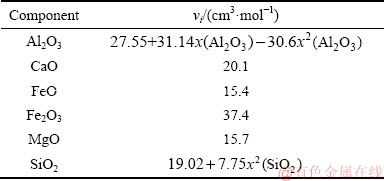

式中:VS和VL分别为熔渣中固相和剩余液相的体积;mj和 分别为每种固相的质量和密度;vi、mi和Mi为液相中每种物质的偏摩尔体积、质量与摩尔质量。其中

分别为每种固相的质量和密度;vi、mi和Mi为液相中每种物质的偏摩尔体积、质量与摩尔质量。其中 直接由FactSage中的FactPS数据库得到,mj和mi由FactSage中的Equilib模块计算所得,1230 ℃下每种物质的偏摩尔体积vi如表3所示[11, 21]。该偏摩尔体积值是由炉渣实际密度测试结果推算得到的。

直接由FactSage中的FactPS数据库得到,mj和mi由FactSage中的Equilib模块计算所得,1230 ℃下每种物质的偏摩尔体积vi如表3所示[11, 21]。该偏摩尔体积值是由炉渣实际密度测试结果推算得到的。

表3 1230 ℃下炉渣中各组分的偏摩尔体积值

Table 3 Recommend values for partial molar volume of various slag components at 1230 ℃

根据由FactSage计算出的1230 ℃熔渣的固相、液相平衡成分,含固相熔渣的密度( )由式(5)计算得出。在研究温度变化对渣锍分离效果的影响时,由于炉渣中各组分的偏摩尔体积值改变,故不同温度下熔渣的密度值没有计算。

)由式(5)计算得出。在研究温度变化对渣锍分离效果的影响时,由于炉渣中各组分的偏摩尔体积值改变,故不同温度下熔渣的密度值没有计算。

2 结果与讨论

2.1 铜锍的矿物学特征

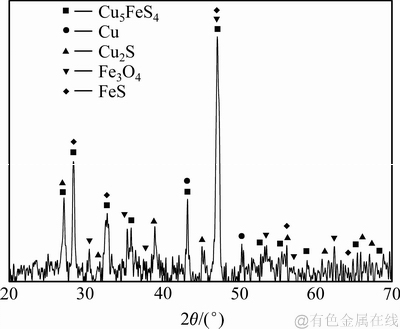

铜锍原料的XRD谱如图1所示。由图1可知,铜锍中的物相主要为斑铜矿(Cu5FeS4),其次为辉铜矿(Cu2S)和金属铜。此外还有硫化亚铁和磁铁矿。

图1 铜锍的XRD谱

Fig. 1 XRD pattern of matte

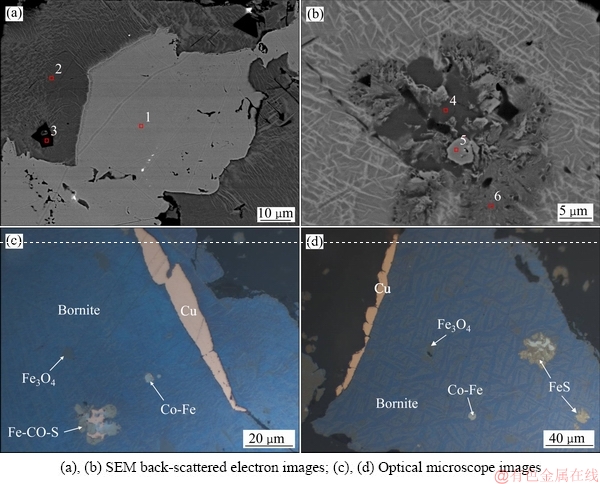

图2 铜锍的矿相显微图像

Fig. 2 Mineral micrographs of matte

图2(a)和(b)所示为铜锍的背散射扫描电镜图像,其光镜图像如图2(c)和(d)所示。为了确定铜锍中各物相的成分,利用EDS能谱仪对图2(a)和(b)中的各物相微区进行元素成分测定,结果如表4所示。铜锍中铜的物相主要为少量金属铜(见图2(a)中区域1)和大量由斑铜矿与辉铜矿以固溶体结构形成的格状共晶集合体(见图2(a)中区域2),这种集合体在光镜下表现为斑铜矿的晶型(Bornite)。在高温沉降过程中,铜的金属粒子和硫化物形成铜锍微滴悬浮于熔渣中,在重力的作用下经过汇聚、沉降与炉渣分离。铜锍中其他相如磁铁矿(见图2(a)中区域3)多呈自形-半自行晶细粒较均匀地分布于斑铜矿相中,而硫化亚铁相、钴铁合金、钴铁硫化物相(分别见图2(b)中区域4、5、6)多呈紧密共生的集合体形式存在。

表4 铜锍EDS能谱分析结果

Fig. 4 EDS elemental analysis of matte

2.2 炉渣组分的含量和沉降温度对铜渣分离效果的影响

在沉降温度为1230 ℃、沉降时间3 h的条件下,考察FeO-SiO2-Fe3O4-CaO-Al2O3-MgO系不同组分的含量对沉降分离渣中铜含量、熔渣黏度和密度的影响。

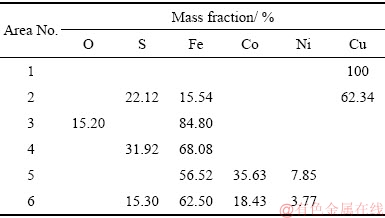

图3(a)和(b)所示分别为炉渣Fe3O4的含量变化对沉降渣中铜含量和熔渣黏度、密度的影响。由图3中可以看出,当Fe3O4含量较低时(小于10%),随着渣中Fe3O4含量升高,沉降渣中的铜含量变化不大,熔渣密度缓慢下降,黏度几乎保持不变。但当Fe3O4含量大于10%时,沉降渣中含铜量迅速上升,此时熔渣中有大量固相尖晶石析出,导致熔渣黏度大幅升高,流动性大幅下降,同时熔渣密度也逐渐增大。这使得铜锍的聚集和沉降更加困难,铜锍在渣中的机械夹杂增多。由此可见,渣中Fe3O4含量对于炉渣中铜的损失有着关键的影响,在实际生产中必须严格控Fe3O4的含量。

图3 Fe3O4含量对沉降渣铜含量和熔渣黏度、密度的影响

Fig. 3 Effects of Fe3O4 content on copper content of sedimentation slag(a) and viscosity, density of molten slag(b)

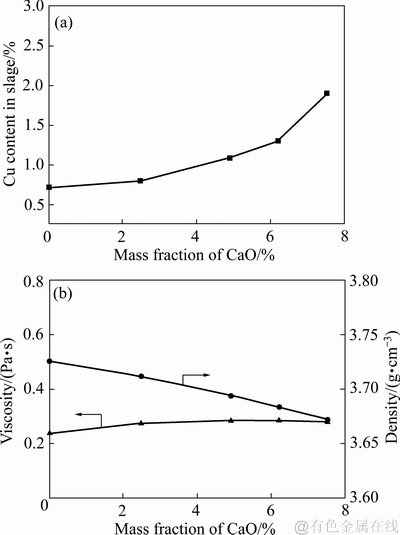

炉渣的CaO含量变化对沉降渣中含铜量和熔渣黏度、密度的影响分别如图4(a)和(b)所示。当CaO含量小于6.2%时,随着CaO含量的增加,沉降渣中铜含量变化不大,熔渣黏度的变化也较小。这与通常认为的CaO在含量较低时会促进聚合硅酸盐的结构解聚,降低炉渣黏度从而有利于铜渣分离有所相悖。这主要是因为本研究所使用的渣为碱性渣,硅的聚合程度不高,因此CaO作为碱性氧化物所能发挥的作用不大。对于熔渣密度来说,CaO的加入使得熔渣中非桥键氧增多,有利于降低熔渣体系的膨胀系数,减小炉渣密度[5]。但计算时发现,随着CaO的含量继续增加,熔渣中难熔固相铁氧化物含量增多,这给炉渣和铜锍的分离造成了困难。同时,ELLIOTT等[22]通过研究发现,随着硅铁渣中的CaO含量大于3%,渣-锍间的界面张力不断减小,不利于炉渣和铜锍的分离。因此,当CaO含量大于6.2%时,渣中铜含量有明显的升高。

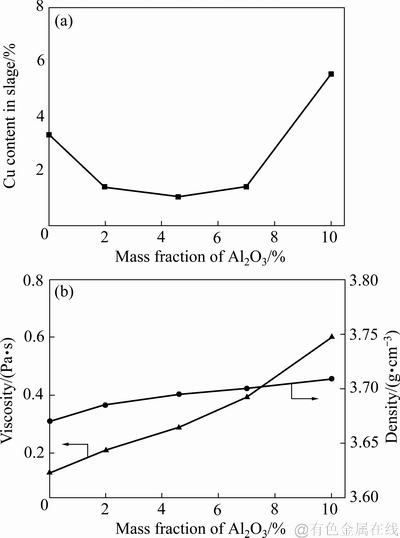

图5(a)和(b)分别为炉渣的Al2O3含量变化对沉降渣中铜含量和熔渣黏度、密度的影响。从图5(a)中可以看出,当Al2O3含量低于4.6%时,沉降渣中铜含量随着Al2O3含量的升高而降低。这与MACKEY等[5]的研究结果是一致的,该研究发现当Al2O3含量较低时,铜在渣中的损失随着Al2O3含量的增加而降低。虽然在图5(b)中可以看到,此时熔渣黏度有所增加,但仍保持在较低的范围。当Al2O3含量继续增加,渣的黏度迅速升高,熔渣流动性减弱,不利于渣、锍相的分离,所以沉降渣中铜含量急剧上升。

图4 CaO含量对沉降渣铜含量和熔渣黏度、密度的影响

Fig. 4 Effects of CaO content on copper content of sedimentation slag(a) and viscosity, density of molten slag(b)

图5 Al2O3含量对沉降渣含铜量和熔渣黏度、密度的影响

Fig. 5 Effects of Al2O3 content on copper content of sedimentation slag(a) and viscosity, density of molten slag(b)

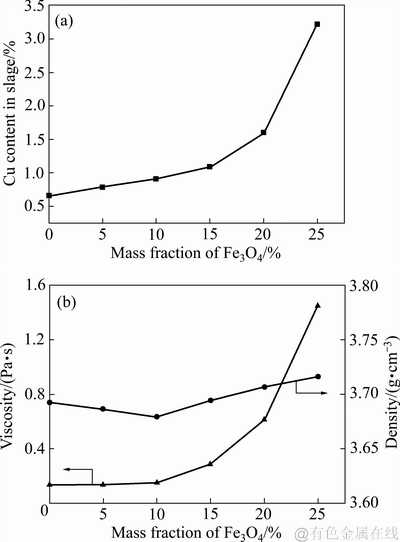

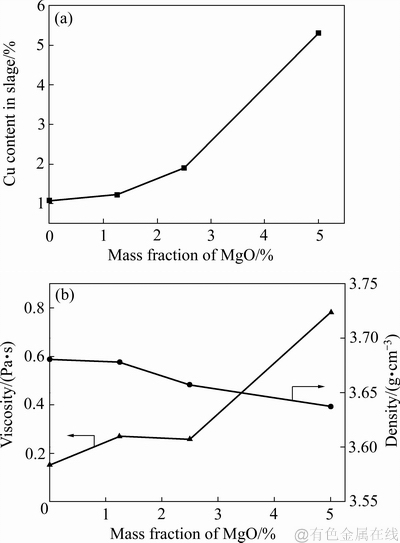

炉渣的MgO含量变化对沉降渣中铜含量和熔渣黏度、密度的影响如图6(a)和(b)所示。当渣中MgO含量较低时(小于1.25%),由于熔渣中成分变化不大,沉降渣中铜含量、熔渣黏度和密度变化也不明显。当MgO含量高于2.5%时,沉降渣中铜含量急剧升高。从图6(b)可以看出,熔渣黏度同样急剧上升。这是由于当MgO含量偏高时,大量橄榄石和尖晶石固相从熔渣中析出,导致熔渣流动性大幅下降。虽然MgO的加入有利于降低熔渣的密度,但黏度急剧升高带来的不利影响仍占主要因素。在实际生产中,应控制MgO含量在1.25%以下。

图6 MgO含量对沉降渣铜含量和熔渣黏度、密度的影响

Fig. 6 Effects of MgO content on copper content of sedimentation slag(a) and viscosity, density of molten slag(b)

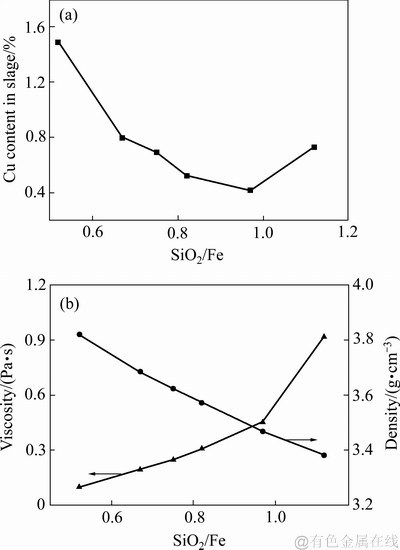

图7(a)和(b)所示分别为炉渣SiO2/Fe比(w(SiO2)/ w(Fe))的变化对沉降渣中铜含量和熔渣黏度、密度的影响。由图7可以看到,当炉渣SiO2/Fe比从0.52上升至0.97时,沉降渣中铜含量逐渐降低。虽然此时熔渣黏度有所上升,但黏度基本在0.5 Pa·s范围内变化,熔渣仍可以保持较好的流动性。而由密度的变化可以看出(见图7(b)),当炉渣中的SiO2/Fe比升高时,熔渣的密度大幅降低。同时锍-渣界面张力也随之增大,促进了锍滴的聚合、沉降[1]。因此,此时SiO2/Fe比的升高更有利于降低渣中铜的物理损失。但当SiO2/Fe比从0.97继续增大至1.12的过程中,由于体系中的SiO2达到饱和后从液相中析出,导致此时炉渣黏度从0.45 Pa·s激增至0.91 Pa·s,炉渣的流动性大幅降低,从而沉降渣含铜量上升。由于当SiO2/Fe比在0.82~0.97之间时,炉渣的黏度和沉降渣铜含量均较低。因此,生产中建议将炉渣SiO2/Fe比控制在0.82~0.97之间。

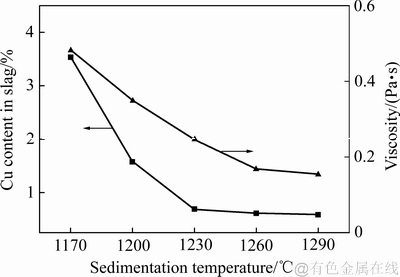

沉降温度对沉降渣铜含量和熔渣黏度的影响如图8所示。由图8可以看到,当温度小于1230 ℃时,随着温度的升高,由于熔渣中的质点热运动更加强烈,熔渣黏度逐渐降低,沉降渣中铜含量迅速降低。此温度范围内沉降温度的变化对铜渣分离有着较大的影响。当温度高于1230 ℃时,熔渣流动性已经达到一个较高的水平,随着温度继续升高,沉降渣中铜含量下降的趋势变缓。考虑到实际生产中,采用尽可能低的沉降温度对降低生产能耗有利,因此沉降温度应保持在1230 ℃左右。

图7 SiO2/Fe比对沉降渣含铜量和熔渣黏度、密度的影响

Fig. 7 Effects of SiO2/Fe ratio on copper content of sedimentation slag(a) and viscosity, density of molten slag(b)

图8 沉降温度对沉降渣铜含量和熔渣黏度的影响

Fig. 8 Effects of sedimentation temperature on copper content of sedimentation slag and viscosity of molten slag

2.3 沉降炉渣的物相分析

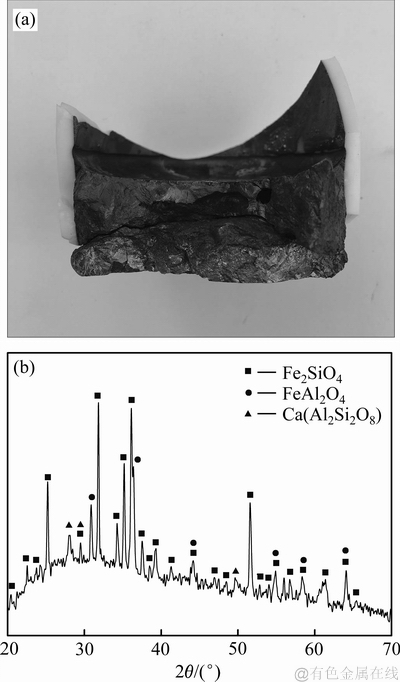

在沉降温度为1230 ℃,炉渣成分为w(Fe3O4) 10%、w(CaO) 4.9%、w(Al2O3) 4.6%、w(MgO) 1.25%、SiO2/Fe比为0.95的条件下,得到如图9(a)所示的沉降分离产物,可以看出,炉渣和铜锍的分层非常清晰。取上层渣样进行XRD分析,结果如图9(b)所示,由XRD结果可知,沉降渣中的主要物相为铁橄榄石(Fe2SiO4)、铁铝尖晶石(FeAl2O4)、钙长石(CaAl2Si2O8)以及无定形的玻璃相。XRD谱中并没有明显的铜物相特征峰,说明其在沉降渣中铜含量较低。

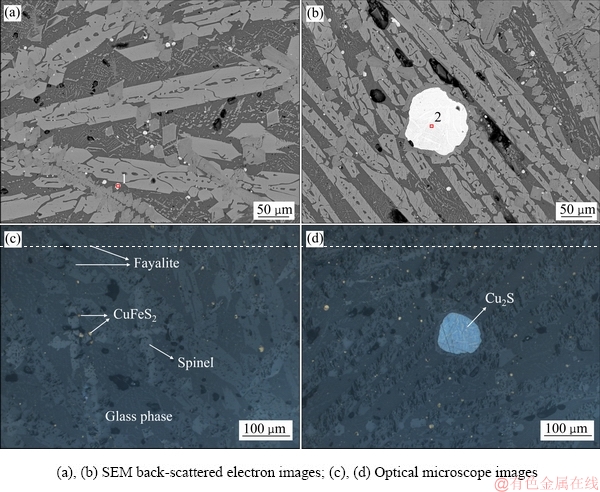

沉降渣的背散射扫描电镜图像如图10(a)和(b)所示。通过EDS能谱分析,沉降渣中铜的矿相主要为黄铜矿(CuFeS2,图10(a)中区域1)和辉铜矿(Cu2S,图10(b)中区域2)。沉降渣的光镜图像如图10(c)和(d)所示。

图9 产物的分层形貌和沉降渣的XRD谱

Fig. 9 Stratified morphology(a) of sedimentation products and XRD pattern(b) of slag

图10 沉降渣的矿相显微图像

Fig. 10 Mineral micrographs of slag

通过镜下观察,黄铜矿在沉降渣中的结晶粒度细小而分散,绝大多数粒径在10 μm以下。在高温沉降过程中,铜锍微滴粒度越小,沉降速度越慢,受熔渣干扰越大,稳定分散能力越强,从而沉降分离难度越大[23]。对于这些微米级的铜锍粒子,仅仅依靠重力已经难以实现与渣的分离,必须促进其聚合长大。除了这些细小的铜锍颗粒,还有极少的大粒径的辉铜矿夹杂在炉渣中。

3 结论

1) 在1230 ℃条件下,铜冶炼渣黏度随着Fe3O4、Al2O3、MgO和SiO2/Fe比的升高而明显升高。当熔渣黏度大于0.5 Pa·s时,熔渣的黏度升高对渣锍分离有着十分不利的影响。在所研究的渣型变化范围内,熔渣密度变化较小,总体来说,熔渣密度受渣中成分变化的影响从大到小依次为SiO2/Fe比、CaO、MgO和Al2O3。

2) 升高温度有利于大幅降低沉降渣中的铜含量,但当温度超过1230 ℃时,沉降渣中铜含量变化不大。综合考虑渣锍分离效果和能耗,最优的沉降温度为1230 ℃。

3) 在实际的渣锍沉降分离过程中,理想的炉渣组成为SiO2/Fe比0.82~0.97,w(CaO) 0~6.2%、w(Al2O3) 2%~7%、w(MgO) 0~1.25%和w(Fe3O4) 0~10%。此时熔渣具有良好的流动性和理想的密度,渣锍分离后渣中铜含量低于1%。

4) 沉降后渣的矿相分析表明,渣中难以沉降的铜物相主要为呈点状分布的微米级黄铜矿和少量辉铜矿。

REFERENCES

[1] 朱祖泽, 贺家齐. 现代铜冶金学[M]. 北京: 科学出版社, 2003: 37-38.

ZHU Zu-ze, HE Jia-qi. Modern copper metallurgy[M]. Beijing: Science Press, 2003: 37-38.

[2] 衷水平, 陈 杭, 林泓富, 吴建辉, 刘 闯, 郭先建. 我国铜熔炼工艺简析[J]. 有色金属(冶炼部分), 2017(11): 1-8.

ZHONG Shui-ping, CHEN Hang, LIN Hong-fu, WU Jian-hui, LIU Chuang, GUO Xian-jian. Brief analysis on copper smelting process in China[J]. Nonferrous Metals (Extractive Metallurgy), 2017(11): 1-8.

[3] GORAI B, JANA R K. Characteristics and utilisation of copper slag—A review[J]. Resources, Conservation and Recycling, 2003, 39(4): 299-313.

[4] 彭容秋. 铜冶金[M]. 长沙: 中南大学出版社, 2004: 12.

PENG Rong-qiu. Copper metallurgy[M]. Changsha: Central South University Press, 2004: 12.

[5] MACKEY P J. The physical chemistry of copper smelting slags—A review[J]. Canadian Metallurgical Quarterly, 1982, 21(3): 221-260.

[6] DUCRET A C, RANKIN W J. Liquidus temperatures and viscosities of FeO-Fe2O3-SiO2-CaO-MgO slags at compositions relevant to nickel matte smelting[J]. Scandinavian Journal of Metallurgy, 2002, 31(1): 59-67.

[7] SEKI K, OETERS F. Viscosity measurements on liquid slags in the system CaO-FeO-Fe2O3-SiO2[J]. Transactions of the Iron and Steel Institute of Japan, 1984, 24(6): 445-454.

[8] JI F Z, DU Si-chen, SEETHARAMAN S. Experimental studies of the viscosities in the CaO-FenO-SiO2 slags[J]. Metallurgical and Materials Transactions B, 1997, 28(5): 827-834.

[9] KUCHARSKI M, STUBINA N, TOGURI J. Viscosity measurements of molten Fe-O-SiO2, Fe-O-CaO-SiO2, and Fe-O-MgO-SiO2 slags[J]. Canadian Metallurgical Quarterly, 1989, 28(1): 7-11.

[10] 侯朋涛, 王丽君, 刘仕元, 张建坤, 周国治. K2O含量对CaO-Al2O3-MgO-FexO-SiO2系熔体黏度及析出相的影响[J]. 中国有色金属学报, 2017, 27(9): 1929-1935.

HOU Peng-tao, WANG Li-jun, LIU Shi-yuan, ZHANG Jian-kun, ZHOU Guo-zhi. Influence of K2O on viscosities and precipitated phase of CaO-Al2O3-MgO-FexO-SiO2 slags[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(9): 1929-1935.

[11] 盛 力, 李江涛, 张建坤, 张家靓, 张立峰, 侯新梅. 含固相铜冶炼渣的黏度计算及其应用[J]. 工程科学学报, 2017, 39(1): 48-53.

SHENG Li, LI Jiang-tao, ZHANG Jian-kun, ZHANG Jia-liang, ZHANG Li-feng, HOU Xin-mei. Viscosity calculation and its application of the copper smelting slag containing solid phase[J]. Chinese Journal of Engineering, 2017, 39(1): 48-53.

[12] UTIGARD T A, WARCZOK A. Density and viscosity of copper/nickel sulphide smelting and converting slags[C]// Proceedings of COPPER 95-COBRE 95 International Conference. Chile, 1995: 423-437.

[13] SHU Qi-feng. A density estimation model for molten silicate slags[J]. High Temperature Materials and Processes, 2007, 26(5/6): 341-348.

[14] NAGAMORI M. Metal loss to slag: Part I. Sulfidic and oxidic dissolution of copper in fayalite slag from low grade matte[J]. Metallurgical Transactions, 1974, 5(3): 531-538.

[15] HENAO H M, PIZARRO C, FONT J, MOYANO A, HAYES P C, JAK E. Phase equilibria of “Cu2O”-“FeO”-CaO-MgO- Al2O3 slags at PO2 of 10-8.5 atm in equilibrium with metallic copper for a copper slag cleaning production[J]. Metallurgical and Materials Transactions B, 2010, 41(6): 1186-1193.

[16] RUSEN A, GEVECI A, TOPKAYA Y A, DERIN B. Effects of some additives on copper losses to matte smelting slag[J]. JOM, 2016, 68(9): 2323-2331.

[17] ELLIOT B J. The effect of slag composition on copper losses to silica-saturated iron silicate slags[D]. Johannesburg: University of the Witwatersrand, 1978: 204-211.

[18] KIM H G, SOHN H Y. Effects of CaO, Al2O3, and MgO additions on the copper solubility, ferric/ferrous ratio, and minor-element behavior of iron-silicate slags[J]. Metallurgical and Materials transactions B, 1998, 29(3): 583-590.

[19] ZivkoviC Z, Mitevska N, Mihajlovic I, Nikolic D. The influence of the silicate slag composition on copper losses during smelting of the sulfide concentrates[J]. Journal of Mining and Metallurgy B, 2009, 45(1): 23-24

[20] 曹战民, 宋晓艳, 乔芝郁. 热力学模拟计算软件FactSage及其应用[J]. 稀有金属, 2008, 32(2): 216-219.

CAO Zhan-min, SONG Xiao-yan, QIAO Zhi-yu. Thermodynamic modeling software FactSage and its application[J]. Chinese Journal of Rare Metals, 2008, 32(2): 216-219.

[21] KEENE B J, MILLS K C. Densities of molten slags (Chapter 8)[M]. Dusseldorf: Verlag Stahleisen GmbH, 1995: 313-348.

[22] ELLIOTT J F, MOUNIER M. Surface and interfacial tensions in copper matte-slag systems, 1200 ℃[J]. Canadian Metallurgical Quarterly, 1982, 21(4): 415-428.

[23] 孙铭良, 黄克雄, 李新海, 张祥远, 马丹文. 炼铜炉渣的显微分析与渣含铜[J]. 中国有色金属学报, 1998, 8(1): 109-115.

SUN Ming-liang, HUANG Ke-xiong, LI Xin-hai, ZHANG Xiang-yuan, MA Dan-wen. Microanalysis for slag of copper matte smelting and loss of copper in slag[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(1): 109-115.

Influence of slag contents on sedimentation separation of slag and matte at high temperature

ZHANG Jia-liang1, 2, YANG Xu1, 3, ZHANG Jian-kun1, CHEN Yong-qiang1, 2, ZHANG Li-feng1, 2, WANG Cheng-yan1, 2

(1. School of Metallurgical and Ecological Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Beijing Key Laboratory of Green Recycling and Extraction of Metals, Beijing 100083, China;

3 China ENFI Engineering Corporation, Beijing 100038, China)

Abstract: In this work, the influences of contents of slag component and smelting temperature on the slag/matte separation efficiency were studied in FeO-SiO2-Fe3O4-CaO-Al2O3-MgO system, using high temperature sedimentation experiments. The viscosity and density at different contents of slag component were calculated using FactSage thermodynamic software, cooperated with the formula for the viscosity and density of solid-containing slag, to investigate their effects on the slag/matte separation. The results show that when the viscosity of slag is higher than 0.5 Pa·s, the further increase of viscosity has an extremely adverse effect on the slag/matte separation. When the compositions of slag are SiO2/Fe ratio of 0.82%-0.97, w(CaO) of 0-6.2%, w(Al2O3) of 2%-7%, w(MgO) of 0-1.25%, w(Fe3O4) of 0-10%, and sedimentation temperature is above 1230 ℃, the molten slag shows good liquidity and its density is also in the ideal range, and the content of copper in the sedimentation slag can be lower than 1%. The mineralogical analysis for the sedimentation slag indicates that the copper loss in slag is primarily the punctiform chalcopyrite at micron scale and small amounts of larger-particle chalcocite.

Key words: copper smelting; slag/matte separation; FactSage; viscosity; density; optimization of slag type

Foundation item: Project (AA18242042-1)supported by the Innovation-Driven Development Project of Guangxi, China

Received date: 2018-08-14; Accepted date: 2018-12-25

Corresponding author: CHEN Yong-qiang; Tel: +86-18500152290; E-mail: chyq0707@sina.com

(编辑 何学锋)

基金项目:广西创新驱动发展专项资金项目(AA18242042-1)

收稿日期:2018-08-14;修订日期:2018-12-25

通信作者:陈永强,教授,博士;电话:18500152290;E-mail:chyq0707@sina.com