文章编号:1004-0609(2014)02-0542-05

硫酸氢铵焙烧高钛渣反应动力学

隋丽丽1, 2,翟玉春1

(1. 东北大学 材料冶金学院,沈阳 110819;

2. 沈阳医学院 基础医学院,沈阳 110034)

摘 要:研究了硫酸氢铵焙烧高钛渣的反应动力学过程,考察钛渣粒度、硫酸氢铵与钛渣质量比和焙烧温度对反应速率的影响,并对反应机理进行分析,建立了反应动力学模型。结果表明:硫酸氢铵焙烧高钛渣提取二氧化钛的动力学过程符合收缩未反应核模型,反应速率受化学反应控制,并由阿罗尼乌斯方程得到焙烧反应的表观活化能为87.95 kJ/mol。

关键词:高钛渣;硫酸氢铵;焙烧;动力学

中图分类号:TF111 文献标志码:A

Kinetics on reaction of roasting high titanium slag with ammonium bisulfate

SUI Li-li1, 2, ZHAI Yu-chun1

(1. School of Materials and Metallurgy, Northeastern University, Shenyang 110819, China;

2. School of Basic Medical Science, Shenyang Medical College, Shenyang 110034, China)

Abstract: The reaction kinetics of roasting high titanium slag with ammonium bisulfate was studied. The effects of roasting temperature, particle size and NH4HSO4-to-ore mass ratio on the roasting reaction rate were investigated. The mechanisms of the reaction were analyzed, and a model of the reaction kinetics was given. The results show that the roasting process can be modeled with the shrinking core model and the reaction rate is controlled by chemical reaction. According to the Arrhenius expression, the apparent activation energy of the roasting reaction is 87.95 kJ/mol.

Key words: high titanium slag; ammonium bisulfate; roasting; kinetics

四川攀枝花具有丰富的钒钛磁铁矿资源,在冶炼过程中堆积了大量的高钛渣,造成了资源浪费和环境污染,如何处理高钛渣成为一个亟待解决的难题[1-3]。除钛之外,高钛渣中还含有大量的硅、铝、钙和镁等有价金属,因此,实现高钛渣的综合利用具有重要的战略意义[4-5]。利用高钛渣生产二氧化钛,消除了副产物绿矾,减少了能耗和时间,不但使资源得到了合理的利用,同时解决了环境污染的问题。因此,利用高钛渣作为钛工业的基本优质原料,具有一定的经济价值。

工业生产二氧化钛的方法主要有硫酸法和氯化法,这两种方法对二氧化钛的提取率高,工艺成熟。传统的硫酸法工艺流程长,产生的三废较多,对环境污染很大[6-8],而氯化法除需使用富钛料外,还需高新技术和巨额投资,工艺难度大[9-10]。因此,有必要研究更有效、更经济的方法实现高钛渣的高值化开发和利用[4, 11]。

针对传统硫酸法生产过程中,能耗高、设备腐蚀大等特点[12-13],本文作者提出以硫酸氢铵作为焙烧剂,在硫酸氢铵焙烧工艺研究的基础上,对其反应过程的焙烧机理进行研究,分析焙烧反应的动力学模型和速度控制步骤,此研究结果为高钛渣中的钛的提取提供了理论依据,对探索生产钛白的新工艺和新技术具有重要的现实意义。

1 实验

1.1 原料和仪器

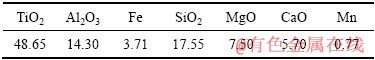

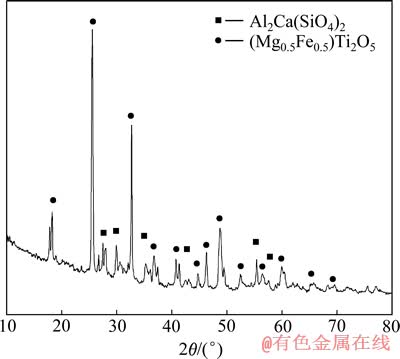

本研究采用四川攀枝花地区的高钛渣,经过破碎、球磨后用于实验,主要化学组成见表1。XRD物相分析谱如图1所示,高钛渣的主要物相为固溶镁和铁的黑钛石(Mg0.5Fe0.5)Ti2O5和复杂的硅酸盐相Al2Ca(SiO4)2[14-16]。

表1 高钛渣的主要化学组成

Table 1 Chemical compositions of high titanium slag (mass fraction, %)

图1 高钛渣的XRD谱

Fig. 1 XRD pattern of high titanium slag

实验所用试剂硫酸氢铵为工业级,硫酸高铁铵、硫氰酸钾、碳酸氢钠、重铬酸钾均为分析纯,水为去离子水。

实验所用仪器为电阻丝加热炉、FP93控温仪、DK-S24型水浴锅、W-02型搅拌器。

1.2 试验方法

将高钛渣和硫酸氢铵按比例置于坩埚中,混合均匀,将坩埚放在电阻丝加热炉中,加热至设定温度后开始计时,定时取出坩埚,迅速加入冷水,使其立即停止反应,进行浸出;浸出条件:水为浸取剂,固液质量比1:5,浸出温度70 ℃,搅拌速率 300 r/min,时间1 h。钛液中TiO2的含量采用硫酸高铁铵滴定法测定分析。

2 结果与讨论

2.1 焙烧过程动力学分析

在高温条件下,硫酸氢铵焙烧钛渣的主要反应方程式可表示如下:

NH4HSO4+TiO2=TiOSO4+NH3+H2O (1)

NH4HSO4+FeO=FeSO4+NH3+H2O (2)

NH4HSO4+CaO=CaSO4+NH3+H2O (3)

NH4HSO4+MgO=MgSO4+NH3+H2O (4)

3NH4HSO4+Al2O3=Al2(SO4)3+3NH3+3H2O (5)

TiO2、FeO、MgO、Al2O3与硫酸氢铵反应,经过浸出进入到溶液中,而不溶产物SiO2和CaSO4则残留在渣相中。图2和3所示分别为高钛渣和残留渣经过喷金处理后的SEM像。从图2和3可知,高钛渣经过硫酸氢铵焙烧、浸出后,残留渣表面凸凹不平,钛渣的形貌被破坏。残留渣经洗涤至中性,取样进行成分分析,结果如表2所列。

表2 残留渣的主要化学组成

Table 2 Chemical compositions of residue (mass fraction, %)

图2 高钛渣的SEM像

Fig. 2 SEM image of high titanium slag

图3 残留渣的SEM像

Fig. 3 SEM image of residue

硫酸氢铵焙烧高钛渣的反应属于液固多相反应,可选择“收缩未反应核模型”进行动力学研究,其控制步骤分为3种类型即扩散控制、化学反应控制和混合控制[16]。在反应过程中,温度对化学反应速率的影响远大于对扩散速率的影响,因此,改变反应温度很容易判别焙烧过程属于化学反应控制还是扩散控制。经过实验证实,高钛渣与硫酸氢铵在常温下不反应,只有在高温时才能发生发应,说明反应受温度的影响很大,故初步推断硫酸氢铵焙烧高钛渣的反应受化学反应控制;同时,反应体系均匀疏松,在反应过程中有气体生成,容易产生裂缝,加快硫酸的扩散速度,进一步判断焙烧过程受化学反应控制。并将实验数据代入其动力学方程式中,进行计算验证。

2.2 焙烧温度的影响

在硫酸氢铵与钛渣质量比为5:1,钛渣粒径为 45~53 mm的条件下,考察焙烧温度对反应速率的影响,其结果如图4所示。从图4可知,温度对焙烧反应的影响显著,二氧化钛的提取率随反应温度升高迅速增大。根据动力学原理,反应受化学反应控制时,温度升高,反应速度急剧增加;反应受扩散控制时,反应速度正比于扩散系数,而温度对扩散系数的影响相对较弱,因此,由图4可推断焙烧反应为化学反应控制。将上述实验数据代入化学反应控制的动力学方程式进行计算:

1-(1-x)1/3=Kt (6)

式中:K为表观反应速度常数;x为二氧化钛提取率;t为焙烧时间。如图5所示,1-(1-x)1/3与时间t呈现良好的线性关系,证明硫酸氢铵焙烧钛渣过程控制步骤确实为化学反应控制[17-19]。

图4 不同温度下TiO2提取率与时间t的关系

Fig. 4 Relationship between extracting rate of TiO2 and t at different temperatures

图5 不同温度下1-(1-x)1/3与时间t的关系

Fig. 5 Relationship between 1-(1-x)1/3 and t at different temperatures

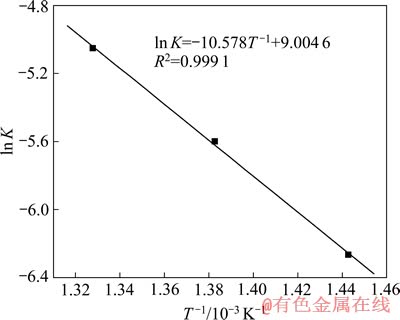

根据表观反应活化能的大小可以判断焙烧反应控制步骤,扩散控制时表观活化能一般小于20 kJ/mol;化学反应控制时表观活化能一般大于40 kJ/mol;混合控制时表观活化能介于二者之间[16]。根据 Arrhenius方程:

lnK = lnA-E/(RT) (7)

将lnK对1/T作图,结果如图6所示,为一条直线,由直线斜率,可近似求得表观活化能E=87.95 kJ/mol,进一步验证该反应过程受化学反应控制。

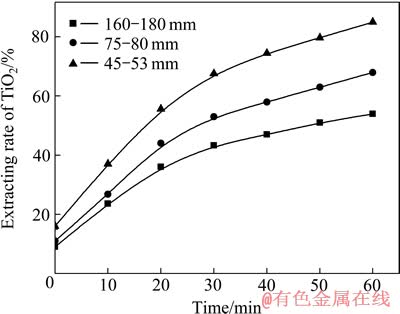

2.3 粒度的影响

在焙烧温度480 ℃,硫酸氢铵与钛渣质量比为5:1的条件下,考查了160~180 μm、75~80 μm和45~48 μm 3种不同粒度试样的动力学规律,实验结果如图7所示。从图7可以看出,随着矿物粒度的减小,二氧化钛的提取率明显提高,说明了矿物粒度对二氧化钛的反应速率有显著的影响。化学反应速度和矿物颗粒的比表面积成正比,钛渣变细后,增加了反应的接触面积,加速了分子之间的有效碰撞,提高了反应速度。将上述实验数据代入动力学方程,其结果如图8所示,1-(1-x)1/3与时间t呈现良好的线性关系,证明硫酸氢铵焙烧钛渣过程属于化学反应控制。

图6 ln k与T -1的关系

Fig. 6 Relationship between ln k and T -1

图7 不同粒径下TiO2提取率与时间t的关系

Fig.7 Relationship between extracting rate of TiO2 and t at different particle sizes

2.4 硫酸氢铵与钛渣质量比的影响

在焙烧温度为480 ℃,钛渣粒度为45~48 μm的条件下,考查了硫酸氢铵与钛渣质量比分别为3:1、4:1和5:1的动力学规律,实验结果如图9所示。从图9可以看出,随着质量比的增加,二氧化钛的提取率明显提高。在不同质量比下将1-(1-x)1/3对时间t作图,如图10所示,1-(1-x)1/3与时间t呈线性关系,表明硫酸氢铵焙烧钛渣的反应过程属于化学反应控制。

图8 不同粒径下1-(1-x)1/3与时间t的关系

Fig. 8 Relationship between 1-(1-x)1/3 and t at different particle sizes

图9 不同硫酸氢铵与钛渣质量比下TiO2提取率与时间t的关系

Fig. 9 Relationship between extracting rate of TiO2 and t at different NH4HSO4-to-ore mass ratios

图10 不同硫酸氢铵与钛渣质量比下1-(1-x)1/3与时间t的关系

Fig. 10 Relationship between 1-(1-x)1/3 and t at different NH4HSO4-to-ore mass ratios

由以上实验数据分析可知,在所有的实验条件下得到的动力学实验数据均符合1-(1-x)1/3=Kt,这进一步说明反应过程确为化学反应控制。在实验温度范围内,原矿粒径45~53 μm 的钛渣与硫酸氢铵焙烧的动力学方程可描述如下:

1-(1-x)1/3 =8.14×103exp[-87 945/(RT)]·t (8)

3 结论

1) 实验数据结果表明:采用硫酸氢铵焙烧高钛渣时,焙烧温度、高钛渣粒度以及硫酸氢铵与钛渣质量比对焙烧反应有显著的影响。

2) 硫酸氢铵焙烧高钛渣的动力学过程符合“收缩未反应核模型”,反应的表观活化能为87.95 kJ/mol,焙烧过程受化学反应控制。

REFERENCES

[1] ZHANG Wen-sheng, ZHU Zhao-wu, CHENG Chu-Yong. A literature review of titanium metallurgical processes[J]. Hydrometallurgy, 2011, 108: 177-188.

[2] AKHGAR B N, PAZOUKI M, RANIBAR M, HOSSEINNIA A, KEYANPOUR-RAD M. Preparetion of nanosized synthetic rutile from ilmenite concentrate[J]. Minerals Engineering, 2010, 23: 587-589.

[3] 刘晓华, 隋智通. 含Ti高炉渣加压酸解[J]. 中国有色金属学报, 2002, 12(6): 1281-1284.

LIU Xiao-hua, SUI Zhi-tong. Leaching of Ti bearing blast furnace slag by pressuring[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1281-1284.

[4] 路 辉, 谢 刚, 愈小花, 谢红艳. 电炉钛渣碱浸除硅、铝与碱浸渣的预氧化焙烧动力学[J]. 过程工程学报, 2010, 10(3): 513-520.

LU Hui, XIE Gang, YU Xiao-hua, XIE Hong-yan. Removel of silicon and aluminum from EAF titanium-contain slag and pre-oxidization roasting kinetics of the leached slag[J]. The Chinese Journal Process Engineering, 2010, 10(3): 513-520.

[5] KOLEN’KO Y V, BURUKHIN A A, CHURAGULOV B R, OLEYNIKOV N N. Synthesis of nanocrystalline TiO2 powders from aqueous TiOSO4 solution under hydrothermal conditions[J]. Materials Letters, 2003, 57: 1124-1129.

[6] YASIR V A, MOHANDAS P N, YUSUFF K K M. Preparetion of high surface area TiO2 (anatase) by thermal hydrolysis of titanyl sulphate solution[J]. International Journal of Inorganic Materials, 2001, 3: 593-596.

[7] BILLIK P, PLESCH G. Mechanochemical synthesis of anatase and rutile nanopowders from TiOSO4[J]. Materials Letters, 2007, 61: 1183-1186.

[8] GRZMIL B, GRELAD, KIC B, PODSIADLY M. The influence of admixtures on the course of hydrolysis of titanyl sulfate[J]. Polish Journal of Chemical Technology, 2008, 10(3): 4-12.

[9] 周忠诚, 阮建明, 邹俭鹏, 李松林, 符乃科. 四氯化钛低温水解直接制备金红石型纳米二氧化钛[J]. 稀有金属, 2006, 30(5): 653-656.

ZHOU Zhong-cheng, RUAN Jian-ming, ZOU Jian-peng, LI Song-lin, FU Nai-ke. Preparation of nanosized rutile TiO2 powders by direct hydrolysis of TiCl4[J]. Chinese Journal of Rare Metals, 2006, 30(5): 653-656.

[10] ZHANG Yong-jie, QI Tao, ZHANG Yi. A novel preparation of titanium dioxide from titanium slag[J]. Hydrometallurgy, 2009, 96: 52-56.

[11] 王 斌, 程晓哲, 韩可喜, 秦兴华, 马 勇. 酸溶性钛渣酸解性能研究[J]. 钢铁钒钛, 2009, 30(2): 6-11.

WANG Bin, CHENG Xiao-zhe, HAN Ke-xi, QIN Xing-hua, MA Yong. Research of acidolysis performance of acid soluble titanium slag[J]. Iron Steel Vanadium Itanium, 2009, 30(2): 6-11.

[12] 杨 成, 邹建新. 酸溶性钛渣制取钛白的酸解动力学[J]. 矿产综合利用, 2007, 6: 24-26.

YANG Cheng, ZOU Jian-xin. Kinetic for acidolysis of titania slag during production of titanium dioxide[J]. Multipurpose Utilization of Mineral Resources, 2007, 6: 24-26.

[13] GRZMIL B U, GRELA D, KIC B. Hydrolysis of titanium sulphate compounds[J]. Chemical Papers, 2008, 62(1): 18-25.

[14] GRZMIL B, GRELA D, KIC B. Formation of hydrated titanium dioxide from seeded titanyl sulphate solution[J]. Chemical Papers, 2009, 63(2): 217-225.

[15] 王明华, 都兴红, 隋智通. H2SO4分解富钛精矿的反应动力学[J]. 中国有色金属报, 2001, 11(1): 131-134.

WANG Ming-hua, DOU Xing-hong, SUI Zhi-tong. Kinetics of acidolysis of rich titanium concentrate by H2SO4[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 131-134.

[16] 华一新. 冶金过程动力学导论[M]. 北京: 冶金工业出版社, 2004: 188-193.

HUA Yi-xin. Introduction to kinetics of metallurgy progress[M]. Beijing: Metallurgical Industry Press, 2004: 188-193.

[17] FENG Yang, WANG Jing-gang, WANG Li-na, QI Tao, XUE Tian-yan, CHU Jing-long. Decomposition of acid dissolved titanium slag from Australia by sodium hydroxides[J]. Rare Metals, 2009, 28(6): 564-569.

[18] ZHANG Su-chun, NICOL M J. Kinetics of the dissolution of ilmenite in sulfuric acid solutions under reducing conditions[J]. Hydrometallurgy, 2010, 103: 196-204.

[19] LIU Xiao-hua, GAI Guo-sheng, YANG Yu-fen, SUI Zhi-tong, LI Li, FU Jian-xia. Kinetics of the leaching of TiO2 from Ti-bearing blast furnace slag[J]. J China Univ Mining & Technol, 2008, 18: 275-278.

(编辑 何学锋)

基金项目:国家重点基础研究发展计划项目(2007CB613603)

收稿日期:2013-03-08;修订日期:2013-06-30

通信作者:翟玉春,教授,博士;电话:024-83687731;E-mail: zhaiyc@smm.neu.edu.cn