文章编号:1004-0609(2013)07-2012-07

低品位复杂钼精矿的提纯工艺

杨洪英1,俞 娟2,佟琳琳1,罗文杰1

(1. 东北大学 材料与冶金学院,沈阳 110004;

2. 西安建筑科技大学 冶金工程学院,西安 710055)

摘 要:对含有大量硅酸盐类脉石矿物的低品位复杂钼精矿的提纯工艺进行研究,通过正交和单因素实验研究氢氟酸浓度、盐酸浓度、温度、处理时间和液固比对低品位复杂钼精矿提纯效果的影响。结果表明:温度、盐酸浓度和氢氟酸浓度对低品位复杂钼精矿的提纯效果影响显著,最佳条件为氢氟酸浓度10%(质量分数)、盐酸浓度20%(质量分数),温度90 ℃、时间2 h、液固比4:1。提纯后钼精矿中钼的品位达到49.94%,较提纯前钼的品位 (25.40%)有了显著的提高。

关键词:低品位复杂钼精矿;提纯;浸出

中图分类号:TF84.2 文献标志码:A

Purification process of low-grade complex molybdenite concentrate

YANG Hong-ying1, YU Juan2, TONG Lin-lin1, LUO Wen-jie1

(1. School of Materials and Metallurgy , Northeastern University , Shenyang 110004 , China;

2. School of Metallurgy Engineering, Xi’an University of Architecture and Technology, Xi’an 710055, China)

Abstract: A purification process for low-grade complex molybdenite concentrates containing plenty of silicate gangue minerals was investigated. The effects of the concentrations of hydrofluoric acid and hydrochloride, temperature, treating time, liquid-solid ratio on the refining rate of molybdenite concentrates were investigated by the orthogonal test and single factor test. The results show that temperature, hydrochloride concentration, hydrofluoric acid concentration have significant effects on the refining rate of the low-grade molybdenite concentrate, and the optimum conditions are as follows: the concentrations of hydrofluoric acid and hydrochloride are 10% (mass fraction) and 20% (mass fraction), temperature, leaching time and liquid-solid ratio are 90 ℃, 2 h and 4:1, respectively. The grade of molybdenum in molybdenite concentrate is thus up to 49.94% after the purification processes, which is evidently higher than that in the molybdenite concentrates (25.40%) before the purification processes.

Key words: low-grade molybdenite concentrate; purification; leaching

钼是一种重要的稀有金属,它在地壳中的丰度为1×10-6[1-2]。世界上50%(质量分数)的钼精矿是由单一钼矿床产出,其他主要是与铜、钨及钒伴生的矿床产出。高品位钼精矿是生产钼铁及钼合金的主要来源,但是随着钼资源的开发,钼的富矿资源大量减少,贫、细、杂等难选矿石逐渐成为提取钼的主要原料。低品位复杂钼精矿是指钼含量为20%~40%(质量分数),且含有大量脉石以及少量其他金属硫化物的钼精矿[3]。此类钼精矿由于其处理工艺步骤繁琐、回收率低、渣量大及残渣需要再处理等因素,其应用受到一定的限制[4-5]。因此,开展针对低品位复杂钼精矿的提纯研究非常必要。低品位复杂钼精矿的提纯方法分为化学法和非化学法。目前,国内外采用的化学提纯方法有微生物法[6-8]、盐酸法[9]、卤化法[10]、重铬酸盐-硫酸法[11]、硝酸-氢氟酸法[12]、氢氟酸-氯化焙烧法[13]及盐酸-氢氟酸法[4, 14];非化学法有浮选法。化学提纯方法中的微生物法、盐酸法、卤化法和重铬酸盐-硫酸法能够在一定程度上溶出硫化矿中的铜、锌、镍和铁等金属杂质,但几乎不能溶出脉石矿物。硝酸-氢氟酸法和氢氟酸-氯化焙烧法能够溶出矿石中的部分脉石,但不能溶出金属杂质。而非化学提纯的浮选柱法虽然在一定程度上能够达到提纯钼精矿的目的[15],但是对于脉石矿物嵌布粒度非常细的钼精矿,该法提纯效果非常有限。因此,开展针对钼精矿中金属杂质和脉石矿物的化学溶出研究非常必要。目前国内外对于采用化学法提纯低品位钼精矿的研究报道很少。为此,本文作者采用盐酸-氢氟酸法对低品位钼精矿进行提纯,验证提纯低品位钼精矿的可行性及有效性,为处理低品位复杂难处理钼精矿奠定基础。

1 实验

1.1 实验样品

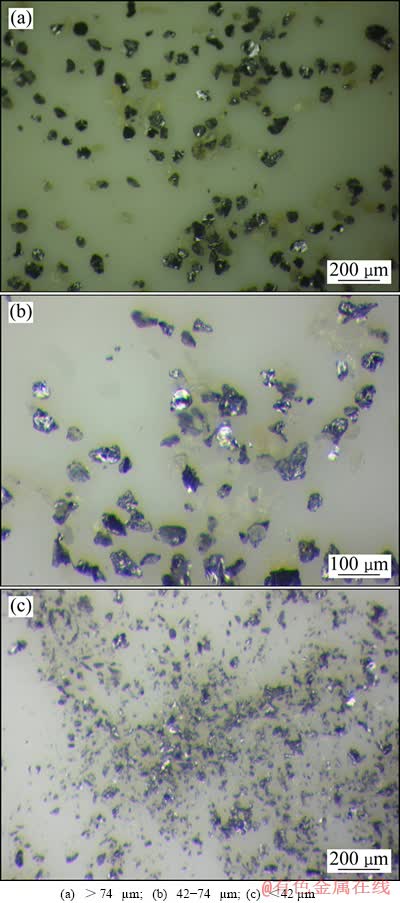

实验所采用的矿样为安徽省某低品位复杂钼精矿,主要金属矿物是黄铜矿和辉钼矿(图1)。钼精矿中钼和铜的含量(质量分数)分别为25.40%和1.33%,并含有大量的硅、镁、钙和钠(表1)。利用偏光显微镜对原矿石进行工艺矿物学研究,研究结果表明:该矿石为矽卡岩型矿石,辉钼矿粒度小,常常呈丝状、片状和束状,且与脉石矿物密切交生(图1(a)和(b)),浮选分离难度很大。矿石中含有大量的硅酸盐类和碳酸盐类脉石矿物,如石榴石、透辉石、白云石、透闪石和绿帘石(图1(c)~(f))。钼精矿中含有大量的连生体辉钼矿/石榴石、辉钼矿/透辉石、辉钼矿/白云石、辉钼矿/透闪石、辉钼矿/绿帘石和辉钼矿/黄铜矿,属于复杂的低品位钼精矿。

图1 矿石中辉钼矿、黄铜矿和脉石矿物的嵌布特征

Fig. 1 Dissemination characteristics of molybdenite, chalcopyrite and gangue minerals in ores

表1 钼精矿的化学成分

Table 1 Chemical composition of molybdenum concentrate (mass fraction, %)

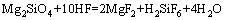

1.2 样品粒度

采用马尔文激光粒度仪对矿样进行粒度分析,结果如图2和表2所示。从表2可以看出,钼精矿粒度大于74 μm的矿物占6.87%(质量分数),粒度为42~74 μm的占22.67%(质量分数),粒度小于42 μm的占70.46%(质量分数)。利用体视显微镜对钼精矿进行形貌观察,结果表明:钼精矿中辉钼矿为片状,大部分已经解离,但在各个粒级范围内,还有部分连生体现象(图3)。

图2 钼精矿的粒度分布曲线

Fig. 2 Particle size distribution curve of molybdenum concentrates

表2 钼精矿粒度分布

Table 2 Particle size distributions of molybdenum concentrates

图3 不同粒度钼精矿的矿物特征及连生现象

Fig. 3 Mineral characteristics of molybdenum concentrates with different particle sizes and intergrowth properties of molybdenum concentrates

1.3 实验原理

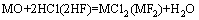

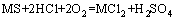

低品位复杂钼精矿含有金属元素铜、铁及大量的硅酸盐类脉石。盐酸能溶解矿石中的金属元素铜和 铁,同时脉石矿物白云石也发生溶解。氢氟酸能溶解矿石中的硅酸盐类脉石如石榴石、透辉石、白云石、透闪石和绿帘石等。辉钼矿属于惰性难溶硫化矿物,在非氧化性条件下很难被溶解。因此,采用氢氟酸-盐酸法对低品位复杂钼精矿进行提纯。提纯过程中发生的反应如式(1)~(5)所示,其中,M代表Cu和Fe。

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(4)

(5)

(5)

1.4 实验方法

将一定量的低品位复杂钼精矿与一定比例的氢氟酸和盐酸混匀后放入500 mL塑料烧杯中,在恒温水浴锅中进行搅拌,达到预定时间后停止搅拌,进行过滤、烘干和称量。钼精矿中钼含量的测定采用碱熔-钒酸铵滴定法。

2 结果与讨论

2.1 正交实验

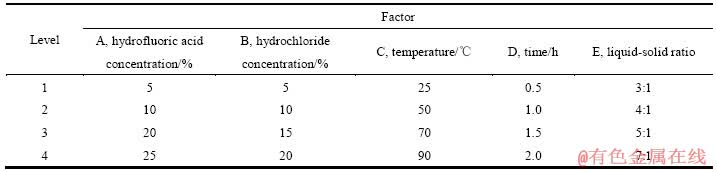

为了研究氢氟酸浓度、盐酸浓度、温度、时间以及液固比对钼提纯效果的影响,选取这5个因素为研究对象,进行正交实验,实验选用L16(45)正交表,表3所列为因素水平编码表,实验结果如表4所列。正交数据分析采用极差分析法。表4中的Ⅰ、Ⅱ、Ⅲ和Ⅳ分别为各因素第1、2、3和4水平的钼品位的加和值。K1、K2、K3和K4分别为各因素相应水平的钼品位的平均值。极差R为K1、K2、K3和K4最大平均值与最小平均值之差。因此,R值的大小反映因素的水平变化对钼精矿钼品位影响的大小。从表4中可以看出,因素A(氢氟酸浓度)、B(盐酸浓度)、C(温度)、D(时间)和E(液固比)的极差R分别为4.8、6.1、9.34、3.31和2.01。这表明5个因素对钼精矿中钼品位提高影响由大到小的顺序为温度、盐酸浓度、氢氟酸浓度、时间、液固比。

为了进行更直观的比较分析,采用各因素的不同水平和各水平下钼品位的平均值分别作为横、纵坐标,绘出各因素与钼品位的比较图(图4)。从图4可看出,5个因素在研究的水平范围内,因素A和E对钼精矿中钼品位的影响均出现峰值,即在所研究的水平范围内,因素A和E分别在A2(氢氟酸浓度10%)和E2(液固比4:1)对钼精矿钼品位的提纯效果最好。因素B、C和D在研究的水平范围内对钼精矿钼品位的提高呈直线上升趋势。这说明在所研究的水平范围内,因素B4 (盐酸浓度为20%时)最好,依据其变化规律,可以适当加大盐酸浓度,对提高钼精矿的品位仍然有利。同样,因素C和D的继续增大仍然有利于钼精矿品位的提高。因此,提高钼精矿中钼品位最佳因素水平组合为A2B4C4D4E2,即氢氟酸浓度为10%,盐酸浓度为20%,温度为90 ℃,处理时间为2 h,液固比为4:1。

2.2 单因素实验

极差R值显示,因素D和E对提高钼精矿钼品位的影响较小,而因素A、B和C对提高钼精矿钼品位的影响显著。因此,这里开展因子A、B和C的单因素研究,结果分别如图5、6和7所示。

2.2.1 氢氟酸浓度的影响

浸出条件:氢氟酸浓度5%、10%、15%、20%、25%,盐酸浓度20%,温度90 ℃,时间2 h,液固比4:1。氢氟酸浓度(因素A)对钼精矿品位提高的影响见图5。从图5可以看出,氢氟酸浓度对钼精矿品位的影响较为明显。当体系中氢氟酸浓度为5%时,钼精矿的品位为39.18%;当氢氟酸浓度提高到10%时,钼精矿的品位迅速增加到47.16%;再增大氢氟酸的浓度,钼精矿的品位不但未提高反而有所下降。在钼精矿中含有脉石镁铝榴石Mg3Al2[SiO4]3、钙铁榴石Ca3Fe2[SiO4]3、透辉石CaMg[SiO3]2和透闪石Ca2Mg5Si8O22(OH)2,当加入高浓度的氢氟酸时,加剧了氢氟酸与硅酸盐类脉石矿物的反应,并且在反应初期形成了MgF2 、CaF2和 FeF3沉淀,它们覆盖在脉石矿物表面,阻碍氢氟酸与脉石矿物的进一步反应。因此,最佳氢氟酸浓度为10%。此外,氢氟酸在一定程度上有助于钼精矿中石榴石、透辉石、透闪石和绿帘石等硅酸盐矿物的溶解。

表3 钼精矿提纯正交实验因素水平表

Table 3 Factors and levels in orthogonal experiments of purification of molybdenite concentrates

表4 钼精矿提纯正交实验结果

Table 4 Orthogonal experiment results of purification of molybdenite concentrates

图4 正交实验因素对钼品位的影响

Fig. 4 Effects of orthogonal experiment factors on Mo grade

图5 氢氟酸浓度对钼品位的影响

Fig. 5 Effect of concentration of hydrofluoric acid on Mo grade of molybdenum

2.2.2 盐酸浓度的影响

浸出条件:盐酸浓度为5%、10%、15%、20%、25%、30%,氢氟酸浓度10%,温度90 ℃,时间2 h,液固比4:1。盐酸浓度对钼精矿品位提高的影响见图6。

从图6可以看出,当体系中盐酸浓度为5%时,钼精矿的品位为38.8%。此时由于体系中盐酸浓度偏低,脉石矿物表面所覆盖的绝大部分MgF2、CaF2和 FeF3不能被溶解,它们仍然阻碍提纯反应的进一步进行;当盐酸浓度增加到10%时,钼精矿的品位有所提高(40%);之后,随着盐酸浓度的增加,钼精矿的品位迅速提高,当盐酸浓度的增大到20%时,钼精矿的品位提高到49.89%。这表明:在氢氟酸浓度为10%的提纯体系中加入浓度为20%的盐酸时,脉石矿物表面所覆盖的MgF2、CaF2和 FeF3基本被溶解,提纯反应能顺利进行。之后,再增大盐酸的浓度到25%和30%后,对提高钼精矿的品位影响不明显。因此,选择最佳盐酸浓度为20%。

图6 盐酸浓度对钼品位的影响

Fig. 6 Effect of concentration of hydrochloric acid on M grade

2.2.3 温度的影响

浸出条件:氢氟酸浓度10%,盐酸浓度20%,温度60、70、80、90和96 ℃;时间2 h,液固比4:1。温度对钼精矿品位提高的影响见图7。

从图7可以看出,提纯过程中温度的升高有利于钼精矿品位的提高。当提纯温度为60 ℃时,钼精矿的品位为40.61%;当温度升高到80 ℃时,钼精矿的品位稍有提高;当温度升高到90 ℃时,钼精矿的品位迅速提高到49.94%。这是由于温度的升高使溶液中的分子获得的能量增大,分子的运动速度加快,同时,使溶液的黏度降低,分子扩散的阻力减小,从而促进了酸与脉石矿物的提纯反应过程,提高了钼精矿的品位。之后,再升高温度至96 ℃时,温度对钼精矿品位的提高影响不明显。因此,最佳提纯温度为90 ℃。

图7 温度对钼品位的影响

Fig. 7 Effect of temperature on Mo grade

3 结论

1) 氢氟酸在一定程度上有助于钼精矿中石榴石、透辉石、透闪石和绿帘石等硅酸盐矿物的溶解。盐酸是低品位复杂钼精矿提纯的良好溶剂。

2) 在氢氟酸浓度、盐酸浓度、温度、时间和液固比这5个因素中,温度、盐酸浓度和氢氟酸浓度对钼精矿的提纯效果的影响显著。各因素对钼精矿品位提高影响由大到小的顺序为温度、盐酸浓度、氢氟酸浓度、时间、液固比。

3) 低品位复杂钼精矿提纯的最佳工艺条件如下:氢氟酸浓度10%、盐酸浓度20%、温度90 ℃、时间2 h、液固比4:1。在此最佳工艺条件下,提纯后钼精矿的品位达到49.94%。

REFERENCES

[1] 雷贵春. 德兴铜矿铜钼分离研究现状及研究方向[J]. 中国钼业, 1998, 22(4): 53-55.

LEI Gui-chun. State and direction of research of Cu-Mo separation in Dexing Copper Mining Corporation[J]. China Molybdenum Industry, 1998, 22(4): 53-55.

[2] 俞 娟, 杨洪英, 周长志, 柴 双. 某难选铜钼混合矿分离浮选试验研究[J]. 有色金属: 选矿部分, 2008(6): 6-9.

YU Juan, YANG Hong-ying, ZHOU Chang-zhi, CHAI Shuang. Experimental study on separating a refractory copper-molybdenum mixed ore[J]. Nonferrous Metals: Mineral processing Section, 2008(6): 6-9.

[3] 张文钲. 从低品位钼精矿或钼中间产品生产工业氧化钼、二钼酸铵和纯三氧化钼[J]. 中国钼业, 2004, 28(4): 33-35.

ZHANG Wen-zheng. Production of technical molybdenum oxide, ammonium dimolybdate and pure molybdenum trioxide from low grade molybdnite concentrates of molybdenum intermediate product[J]. China Molybdenum Industry, 2004, 28(4): 33-35.

[4] KUMAR M, MANKHAND T R, MURTHY D S R, MUKHOPADHYAY R, PRASAD P M. Refining of a low-grade molybdenite concentrate[J]. Hydrometallurgy, 2007, 86(2): 56-62.

[5] PRASAD P M, MANKHAND T R, PRASAD A J K. Molybdenum extraction processes: An overview[J]. National Metallurgy Laboratory Technical Journal, 1997, 39(2): 39-58.

[6] SHI Shao-yuan, FANG Zhao-heng. Bioleaching of marmatite flotation concentrate by Acidithiobacillus ferrooxidans[J]. Hydrometallurgy, 2004, 71(1): 1-10.

[7] ORQUIDEA C, FEDERICO G, HERNANDEZ I, MARRERO J, EDGARDO D. Cobalt and nickel recoveries from laterite tailings by organic and inorganic bio-acids[J]. Hydrometallurgy, 2008, 94(2): 18-22.

[8] ZHANG Yan-sheng, QIN Wen-qing, WANG Jun, ZHEN Shi-jie, YANG Cong-ren, ZHANG Jian-wen, NAI Shao-shi, QIU Guan-zhou. Bioleaching of chalcopyrite by pure and mixed culture[J]. Transactions of Nonferrous Metals Society of China, 2008, 18(6): 1491-1496.

[9] FORWARD F A, WARREN I H. Extraction of metals from sulphides by wet methods[J]. Metallurgical Reviews, 1999, 5: 137-164.

[10] JENNINGS P H, STANLEY R W, AMES H L, EVANS J I. Development of a process for purifying molybdenite concentrate[C]//Proceedings of the Second International Symposium on Hydrometallurgy. New York: AIME, 1974: 868-883.

[11] SAHA A K, SRINIVASAN S R, AKREKAR D D. Removal of copper and nickel from low-grade molybdenite concentrates[J]. National Metallurgy Laboratory Technical Journal, 1985, 27(2): 40-45.

[12] RUIZ M C, PADILLA R. Copper removal from molybdenite concentrate by sodium dichromate leaching[J]. Hydrometallurgy, 1998, 48 (3): 313-325.

[13] SAHA A K, SRINIVADAN S R, AKREKAR D D. Acid treatment for purification and enrichment of low-grade molybdenite concentrate[J]. National Metallurgy Laboratory Technical Journal, 1985, 27(4): 46-55.

[14] 李 哲, 边明文. 低品位钼精矿的化学提纯实验研究[J]. 中国钼业, 2007, 31(3): 35-37.

LI Zhe, BIAN Ming-wen. Research on chemical purifying experiment of the low-grade molybdenum ore[J]. China Molybdenum Industry, 2007, 31(3): 35-37.

[15] 石德俊. 浮选柱在钨钼浮选中的应用[J]. 中国钼业, 2009, 33(3): 9-13.

SHI De-jun. The application of flotation column in tungsten and molybdenum flotation[J]. China Molybdenum Industry, 2009, 33(3): 9-13.

(编辑 陈卫萍)

基金项目:国家自然科学基金资助项目(51174062);国家高技术研究发展计划资助项目(2012AA061502);国家科技支撑计划项目(2012BAE06B05);中央高校基本科研业务费专项基金资助项目(N110602005);西安建筑科技大学青年科技基金资助项目(QN1204)

收稿日期:2012-04-13;修订日期:2013-03-22

通信作者:杨洪英,教授,博士;电话:024-83673932;E-mail:yanghy@smm.neu.edu.cn