文章编号:1004-0609(2014)12-3115-08

低品位钼精矿氧化焙烧过程的反应行为

甘 敏1, 2,范晓慧1,张 麟2,姜 涛1,邱冠周1,王 勇2,邓 琼1,陈许玲1

(1. 中南大学 资源加工与生物工程学院,长沙 410083;

2. 大冶有色金属集团控股有限公司,黄石 435100)

摘 要:研究品位为39.27%的低品位钼精矿的氧化焙烧热力学、物相演变规律及焙烧特征。热力学分析表明:MoS2氧化的趋势仅次于FeS2氧化趋势,能生成多种价态的氧化物,且生成的MoO3可与多种金属氧化物反应生成钼酸盐,其中生成钼酸钙的趋势最大。焙烧过程包括MoS2氧化不充分、MoO3稳定存在和钼酸盐生成3个阶段,温度过高或时间过长易生成不利于后续钼溶出的钼酸盐和低价氧化钼,适宜的焙烧温度为650~675 ℃、焙烧时间为2 h左右。氧化焙烧后,氨浸的钼溶出率仅为84.02%,浸出渣中钼含量高达13.93%,XRD分析表明浸出渣的组成以钼酸钙为主。采用Na2CO3为浸出剂对氨浸渣进行二次浸出,可将氨浸渣中的钼酸钙溶出,最终钼的总回收率可达90.82%。

关键词:低品位钼精矿;热力学;氧化焙烧;物相变化

中图分类号:TD982

Reaction behavior of low grade molybdenum concentrates in oxidation roasting process

GAN Min1, 2, FAN Xiao-hui1, ZHANG Lin2, JIANG Tao1, QIU Guan-zhou1, WANG Yong2,

DENG Qiong1, CHEN Xu-ling1

(1. School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China;

2. Daye Nonferrous Metals Group Co., Ltd., Huangshi 435100, China)

Abstract: Thermodynamics of oxidation roasting, phase evolution rules and roasting characteristics of low grade molybdenum concentrate with grade of 39.27% were studied. Thermodynamics analyses show that the oxidation tendency of MoS2 is second to that of FeS2, so it is easily oxidized and generates several oxide products. Furthermore, MoO3 could react with various metal oxides to generate molybdate in which calcium molybdate generates most easily. Roasting process contains three stages of incomplete oxidization of MoS2, stable existence of MoO3 and generation of molybdate. Molybdate and low valence molybdenum oxide, which go against subsequent leaching, will easily generate at over high temperature or for long time. The suitable temperature is 650-675 ℃ and the roasting time is 2 h. After roasting, ammonia leaching rate of molybdenum is only about 84.02%, residue of Mo in leaching residue reaches 13.93%. XRD analysis shows that calcium molybdate is the main component in leaching residue. When Na2CO3 is used as the leaching reagent, calcium molybdate can be extracted during leaching residue, and the ultimate recovery rate of Mo can reach 90.82%.

Key words: low grade molybdenum; thermodynamics; oxidation roasting; phase evolution

钼是一种稀有难熔金属,具有广泛的用途,近年来在航天航空和光电材料等高科技领域中的应用不断扩大,使得其成为战略性金属资源[1-3]。我国钼储量丰富,钼金属储量仅次于美国居世界第2位,资源储量占全球钼资源的25%左右[4]。钼矿床类型复杂,其中单一矿石的钼储量仅占全国总储量的 29.7%,其余则为铜钼型、钼钨型、钼铁型等共生矿床[5-6]。由于我国钼矿床以低品位为主,且多为难选的共生矿,导致我国众多矿山产出的钼精矿品位低。

国内外研究者一般采用氧化分解-氨浸工艺处理钼精矿[7]。氧化分解是钼提取分离过程的重要工序,其工艺主要有氧化焙烧分解工艺和湿法分解工艺两大类,氧化焙烧分解工艺主要是通过空气将辉钼矿进行氧化,而湿法分解工艺主要利用强氧化剂在水相中将其氧化成高价钼。湿法工艺虽然解决了SO2的污染问题,但具有对设备要求苛刻、投资大和成本高等特点[7-12]。而焙烧分解工艺不用消耗额外的氧气或氧化剂,且自身氧化放热即可达到分解温度,具有工艺简单、消耗小和成本低的特点,是当前处理标准钼精矿(Mo含量大于45%)的主要工艺[5, 13-17]。

低品位钼精矿尚无成熟的加工工艺和技术,当前其研究以湿法为主,有研究者采用常规酸浸和加压氧化等工艺对低品位钼精矿进行处理[18-19]。但在湿法氧化过程中大量处理剂的加入导致钼的含量更趋贫化,且众多杂质金属离子被同步溶出,带来处理工艺流程复杂及设备增多等问题,延长了富集周期并增加了生产成本。而焙烧法氧化低品位钼精矿,由于其脉石矿物含量高,导致其焙烧的难度大。因此,本文作者通过分析低品位钼精矿氧化焙烧过程反应热力学,结合物相变化以及低品位钼精矿的焙烧特征的研究,揭示低品位钼精矿氧化焙烧过程的反应行为,为低品位钼精矿高效氧化-溶出的过程提供理论依据。

1 实验

1.1 钼精矿工艺矿物学

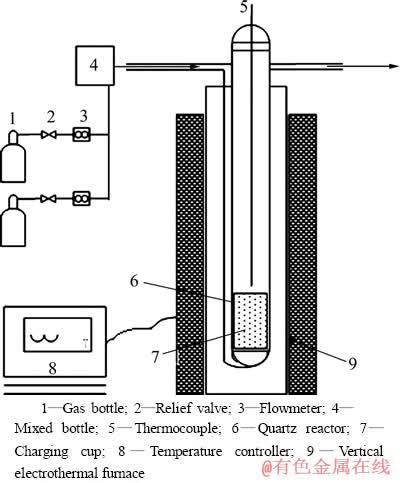

采用铜选别过程回收得到的低品位钼精矿,其化学成分如表1所列。该钼精矿品位较低,钼含量为39.27%,未能达到标准钼精矿的品位(>45%)。钼精矿中脉石成分主要为SiO2、CaO和MgO,含量分别为9.77%、5.23%和4.29%;由于该钼精矿为硫化矿选铜过程回收的产品,因此钼精矿中还残留一定量的含铜矿物和含铁矿物。

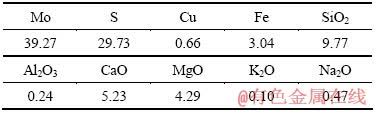

表1 低品位钼精矿的化学成分

Table 1 Chemical compositions of low grade molybdenum concentrate(mass fraction, %)

钼精矿矿物组成如表2所列。钼精矿中主要矿物为辉钼矿,含量为65.4%;其次为硫化物,包括黄铜矿、斑铜矿、黄铁矿等;还含有赤铁矿和褐铁矿等铁氧化物,铝硅酸盐、镁硅酸盐和石英等含硅脉石矿物,以及方解石和白云石等碳酸盐。

表2 钼精矿中主要矿物组成及其相对含量

Table 2 Main mineral compositions and relative contents of molybdenum concentrate

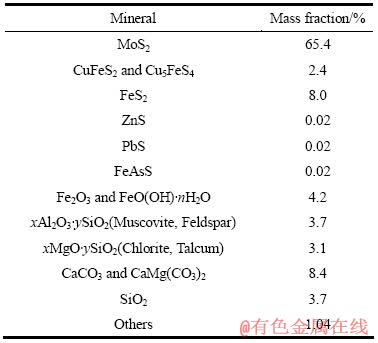

采用光学显微镜研究了矿物的嵌布特征,结果如图1所示。结果表明:辉钼矿多以单体矿物形式产出,形状和粒径不一,有鳞片状、板状和条状,更多的是不规则粒状,粒径一般在0.02~0.20 mm之间。辉钼矿与其他金属硫化矿关系密切,约有15%的辉钼矿以连生体形式产出,较常见的情况有:与黄铜矿或黄铁矿连生;被大颗粒黄铜矿包裹;大颗粒辉钼矿包裹细粒黄铜矿;与斑铜矿连生。

1.2 实验方法

图1 辉钼矿的嵌布特征

Fig. 1 Dissemination characteristics of molybdenite

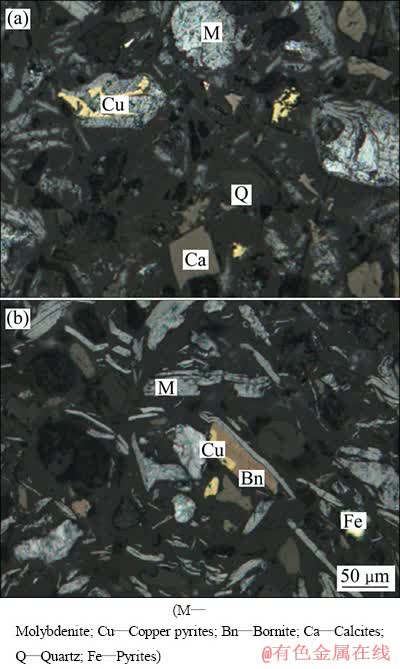

图2 氧化焙烧试验装置示意图

Fig. 2 Schematic diagram experimental devices of oxidation roasting

本实验主要模拟气固对流传热和传质的氧化焙烧过程。先将钼精矿制备成具有一定粒度的小球,在焙烧过程中向钼精矿小球构成的料层中通入空气,使钼精矿与空气充分接触。钼精矿成球方法如下:在钼精矿中配加1%(质量分数)膨润土,充分混合后,在圆盘造球机中将其制备成粒径为5 mm的小球,球团经干燥后供后续焙烧实验使用。钼精矿氧化焙烧实验装置如图2所示,焙烧实验在竖式电热炉中进行。首先将25 g粒径为5 mm的钼精矿球团装入料杯中,料杯底部开有小孔供反应气体通过,然后将盛有钼精矿球团的料杯装入规格为d 38 mm×550 mm熔融石英玻璃反应罐,将反应罐放入电热炉的加热区,在实验开始前,向反应罐中通入流量为5 L/min的氮气,直至反应罐内温度达到预设温度,然后向反应罐中通入空气进行氧化。焙烧一定时间后,将焙烧好的钼焙砂取出并取样供后续检测分析。

采用钼焙砂中可溶钼(溶于氨水)的含量以及焙烧过程钼精矿中硫的脱除率以评价氧化焙烧的效果。可溶钼含量是指钼焙砂中溶入氨水的钼占钼焙砂中钼总量的百分比,其检测是将钼焙砂磨细至粒径在0.074 mm以下,取5 g磨细的矿样置于50 mL烧杯中,为保证钼焙砂中钼充分浸出,采用过量的氨水在液固比为1:1的条件下充分混匀,在70 ℃恒温箱内进行浸出实验,过滤烘干后取样检测浸出渣中钼的含量。可溶钼含量的计算公式如下所示:

(1)

(1)

式中: 为可溶钼含量;m1为用于浸出的钼焙砂质量;

为可溶钼含量;m1为用于浸出的钼焙砂质量; 为钼焙砂中钼含量;m2为浸出渣质量;

为钼焙砂中钼含量;m2为浸出渣质量; 为浸出渣中钼含量。

为浸出渣中钼含量。

硫的脱除率是指焙烧过程挥发脱除的硫占钼精矿中硫总量的百分比,其计算公式如下所示:

(2)

(2)

式中: 为硫的脱除率;m0为用于氧化焙烧的钼精矿质量;

为硫的脱除率;m0为用于氧化焙烧的钼精矿质量; 为钼精矿中硫的含量;m1为焙烧后钼焙砂的质量;

为钼精矿中硫的含量;m1为焙烧后钼焙砂的质量; 为焙烧后钼焙砂中残余硫的含量。

为焙烧后钼焙砂中残余硫的含量。

2 结果和讨论

2.1 钼精矿氧化焙烧热力学

低品位钼精矿焙烧过程是一个复杂的物理化学过程,可能发生的反应主要有3类:硫化物氧化体系、含钼矿物的氧化体系及生成的MoO3与金属氧化物生成钼酸盐的体系。通过公式 进行热力学计算,其中,

进行热力学计算,其中, 为反应的标准吉布斯自由能,J·mol-1;

为反应的标准吉布斯自由能,J·mol-1; 为反应的标准标准摩尔生成热,J·mol-1;

为反应的标准标准摩尔生成热,J·mol-1; 为物质吉布斯自由能,J·mol-1·K-1;T为热力学温标,K。得到钼精矿焙烧过程中固相反应的

为物质吉布斯自由能,J·mol-1·K-1;T为热力学温标,K。得到钼精矿焙烧过程中固相反应的 与T的关系。

与T的关系。

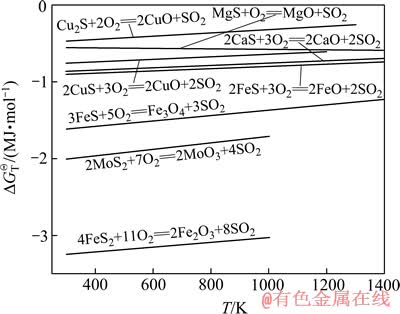

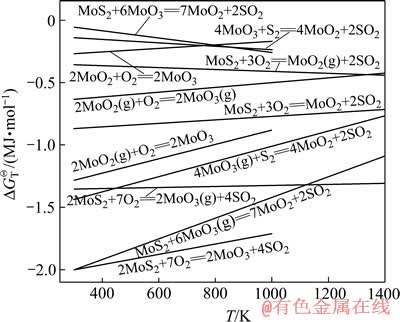

钼精矿在氧化焙烧过程中,辉钼矿、黄铁矿和黄铁矿等硫化物发生氧化反应生成各种氧化物,反应式如下所示:

MeS+O2=MeO+SO2(g)(Me为Mo、Fe、Cu、Mg、Ca等) (3)

硫化物氧化的热力学分析如图3所示,在相同的氧化焙烧条件下,钼精矿中硫化物发生氧化反应的趋势大小依次为FeS2、MoS2、FeS、CaS、CuS、MgS、Cu2S,在1400 K以下温度均可自发进行。因此,在钼精矿焙烧过程,FeS2被氧化的趋势最大,而MoS2也较容易被氧化。

图3 钼精矿中硫化矿氧化反应 关系

关系

Fig. 3 Relationship between  and T about sulfide oxidation reaction in molybdenum concentrate

and T about sulfide oxidation reaction in molybdenum concentrate

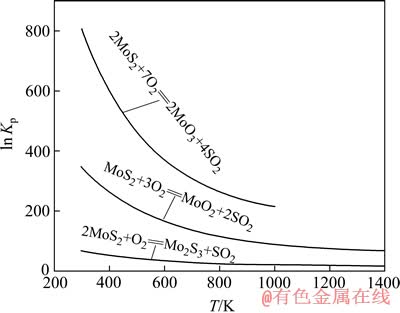

钼精矿氧化为强放热过程,由于钼有多种价态,其在氧化过程中可生成多种氧化物,是一个复杂的气固多相化学反应。辉钼矿的氧化反应式如下所示:

xMoS2+(2x+y/2)O2=MoxOy+2xSO2↑(MoxOy为MoO3、MoO2等) (4)

在Mo-S-O体系中,其热力学分析如图4和5所示。可知,在298~1400 K的温度范围内,钼精矿氧化过程生成MoO3和MoO2的固相反应均能自发发生,但生成MoO3的吉布斯自由能比生成MoO2的低。由图4可知,在正常的焙烧条件下,MoS2氧化生成MoO3实际上是一个不可逆的强放热反应,反应趋势大。由图5中ln Kp与T的关系可知,在正常的焙烧温度范围内,MoS2氧化生成MoO3的平衡常数Kp很大,反应极易进行,即使在较低的O2分压下,也能进行反应。但MoO3(s)熔点较低(795 ℃),若焙烧温度高于MoO3熔点,MoO3将开始熔化从而导致精矿烧结,恶化矿物粒子内部的氧化反应条件。在矿物粒子内部氧含量较低时,由于MoS2和MoO3(g)的反应在正常焙烧温度下可自发进行,易生成低价的氧化钼。因此,钼精矿焙烧过程生成的钼矿物应该是MoO3、MoO2和Mo2S3等的混合钼化合物,以MoO3为主。

图4 含钼矿物氧化反应中 关系

关系

Fig. 4 Relationship between  and T about molybdenum bearing minerals oxidation reaction

and T about molybdenum bearing minerals oxidation reaction

图5 含钼矿物氧化反应中ln K p-T关系

Fig. 5 Relationship between ln K p and T about molybdenum bearing minerals oxidation reaction

在氧化焙烧的环境下,MoO3将与一些伴生元素的金属氧化物或硫化物氧化生成的金属氧化物相互作用生成钼酸盐,其反应式如下所示:

MeO+MoO3=MeMoO4(Me为Mg、Fe、Cu、Ca等) (5)

焙烧过程钼酸盐生成的热力学分析如图6所示。在298~1400 K的温度范围内,金属氧化物与MoO3的反应均能自发进行。金属氧化物与固态MoO3生成钼酸盐的反应趋势由大到小的顺序为:CaO、CuO、MgO、FeO;金属氧化物与气态的MoO3生成钼酸盐的反应趋势由大到小的顺序为:CaO、MgO、FeO。因此,焙烧过程中生成钼酸钙的趋势最大,而钼酸钙为难溶盐,会影响钼的浸出效率。

图6 钼精矿氧化过程钼酸盐生成中 关系

关系

Fig. 6 Relationship between  and T about molybdate generation in molybdenum concentrate oxidation process

and T about molybdate generation in molybdenum concentrate oxidation process

2.2 钼精矿氧化过程物相演变规律

图7 焙烧2 h后不同焙烧温度下钼焙砂的物相变化

Fig. 7 Phase evolution of molybdenum calcine roasted for 2 h at different roasting temperatures

研究不同焙烧温度下氧化焙烧产物的物相变化规律,如图7所示。随着焙烧温度的变化,低品位钼精矿氧化焙烧过程中物相组成也发生变化。当焙烧温度为600 ℃时,由于钼精矿中FeS2发生氧化反应的趋势最大,因此FeS2已开始氧化生成Fe2O3;而辉钼矿虽然开始反应,但MoO3衍射峰强度较弱,钼焙砂的物相仍以辉钼矿为主,主要是由于在600 ℃温度下辉钼矿的氧化反应速度较慢。随着温度从600 ℃升高到 675 ℃,矿物中的钼与氧的反应更充分,MoS2的衍射峰强度减弱,而MoO3的衍射峰强度显著增强,表明辉钼矿(MoS2)的氧化占据主导地位,且MoS2及硫的大量消耗使其与MoO3的交互反应减少,体系中MoO3稳定存在,焙烧产物以MoO3为主。同时,Fe2O3衍射峰强度增强,黄铁矿进一步被氧化,当温度达到650 ℃时,开始有CaMoO4生成,矿物中的Mg和Si等矿物也开始生成透辉石Mg2SiO6。随着反应温度继续升高到700 ℃,钼焙砂中MoO3的衍射峰强度增幅减小,辉钼矿的氧化较为完全。此时Ca和Fe等金属氧化物与MoO3显著发生反应,因此,CaMoO4和FeMoO4衍射峰强度增强。CaMoO4难溶于碱性溶液,CaMoO4生成不仅影响浸出的效果,且由于CaMoO4与MoO3共晶温度低,使焙砂在低于MoO3熔点温度立即发生烧结,使块料难以彻底氧化脱硫。因此,对于低品位钼精矿,其适宜的焙烧温度范围为650~675 ℃。

研究了不同焙烧时间下低品位钼精矿氧化焙烧产物的物相变化规律,如图8所示。当焙烧时间为1 h时,钼精矿中的部分钼元素经氧化得到MoO3,由于氧化时间太短,钼元素不能充分氧化,故部分钼仍以辉钼矿(MoS2)的形式存在于钼焙砂中,而黄铁矿由于反应热力学优势已被氧化成Fe2O3。当焙烧时间延长至2 h,反应体系中辉钼矿氧化占据反应优势,MoO3衍射峰强度明显增强,辉钼矿衍射峰强度急剧减弱,钼焙砂中的Mo大部分以MoO3的形式存在。同时,出现强度较弱的钼酸钙衍射峰,有少量的钼酸盐生成。当焙烧时间延长至2.5 h,MoO3衍射峰强度反而降低,而钼酸盐等杂质衍射峰强度增强,表明辉钼矿完全氧化后,继续延长焙烧时间将增加钼酸盐形成的反应时间,对钼精矿焙烧产品质量不利。因此,在焙烧温度为675 ℃条件下,钼精矿氧化的适宜焙烧时间为2 h。

图8 焙烧温度675 ℃下焙烧不同时间钼焙砂的物相变化

Fig. 8 Phase evolution of molybdenum calcine roasted at 675 ℃ for different roasting times

2.3 低品位钼精矿氧化焙烧特征

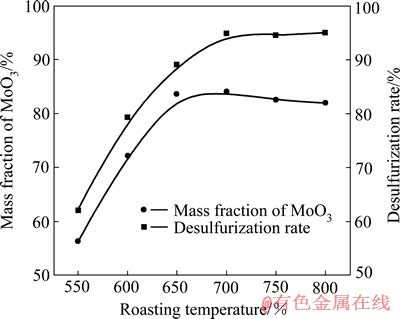

研究了焙烧温度对钼精矿中硫脱除率的影响,以及焙烧温度对钼焙砂中可溶钼(MoO3)比例的影响,结果如图9所示。随着温度的升高,钼精矿脱硫率呈升高趋势,焙砂中可溶钼的比例逐渐增加,当温度增至650 ℃时,钼精矿脱硫率达到90%以上;而当温度为675 ℃时,钼焙砂中可溶钼比例达到最高值(84.02%);当温度继续升高时,由于钼酸钙等钼酸盐的生成,钼焙砂中可溶钼含量反而降低,将影响后续钼的溶出。

图9 焙烧2 h后不同焙烧温度对钼精矿氧化焙烧的影响

Fig. 9 Effect of different roasting temperatures on oxidation roasting of molybdenum concentrate after roasting for 2 h

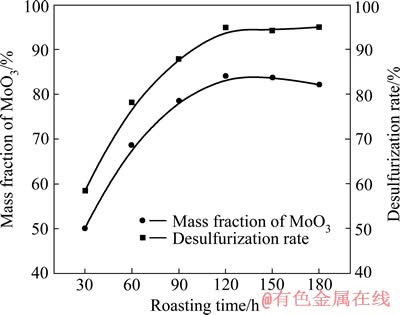

图10 焙烧温度为675 ℃时不同焙烧时间对钼精矿氧化焙烧的影响

Fig. 10 Effect of roasting time on oxidation roasting of molybdenum concentrate at 675 ℃

研究了焙烧时间对钼氧化和硫脱除的影响,如图10所示。当焙烧时间为0.5~2 h,随时间延长辉钼矿氧化越来越充分,钼精矿脱硫率逐步提高,钼焙砂中可溶钼比例增加,脱硫率也从58.58%增至90%以上,可溶钼比例从50.16%增至84.02%;当焙烧时间超过2 h,脱硫率增长均趋于平缓,钼焙砂中可溶钼比例有所降低。

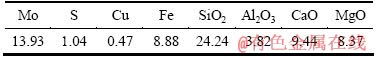

在焙烧温度675 ℃、焙烧时间2 h,以及在氨水充分过量的条件下,低品位钼精矿焙烧后,钼的浸出率仅为84.02%左右,明显低于高品位钼精矿钼的浸出率(>90%)。分析了低品位钼精矿焙烧-氨浸后的浸出渣中化学成分,如表3所列。氧化焙烧后所得可溶钼溶解于氨水而被浸出,因此Mo含量大幅下降,但浸出渣中Mo的残存量仍比较高,达到13.93%。

表3 浸出渣化学分析

Table 3 Chemical compositions of residue from ammonia leaching (mass fraction, %)

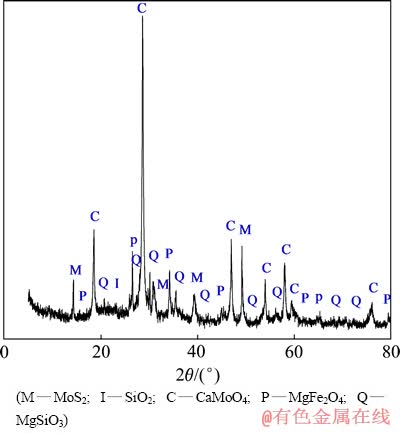

采用XRD分析了浸出渣的矿物组成,如图11所示。钼焙砂氨浸后所得浸出渣中,MoO3的衍射峰完全消失,表明该部分钼已完全溶解于氨水而被浸出。而钼酸钙的衍射峰强度非常强,浸出渣中主要的含钼矿物为钼酸钙,同时辉钼矿衍射峰强度也较强,表明少量辉钼矿因低品位钼精矿焙烧过程易烧结而没有被氧化。浸出渣中含有不少难溶的镁铁尖晶石(MgFe2O4)、镁橄榄石(MgSiO3)以及石英等。

图11 浸出渣的XRD谱

Fig. 11 XRD analysis of residue from ammonia leaching

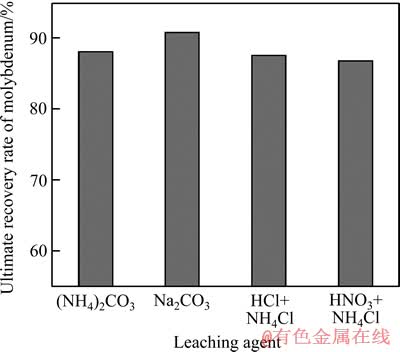

单采用氨水浸出钼焙砂,浸出率低,难溶于氨水的钼酸钙难以被浸出。因此,需对氨浸渣进行进一步处理,以提高钼的回收率。在浸出温度90 ℃、浸出时间2 h、液固比3:1和搅拌机转速250 r/min的条件下,研究了不同浸出剂对氨浸渣进行再处理的浸出效果,其结果如图12所示。浸出效果最好的为Na2CO3,其次为 (NH4)2CO3,再次为HCl(40 g/L)+NH4Cl和HNO3(40 g/L)+NH4Cl。当采用Na2CO3对氨浸渣进行二次浸出时,钼的总浸出率可达90.82%,主要是由于钼酸钙与Na2CO3反应生成可溶的钼酸钠而被浸出。

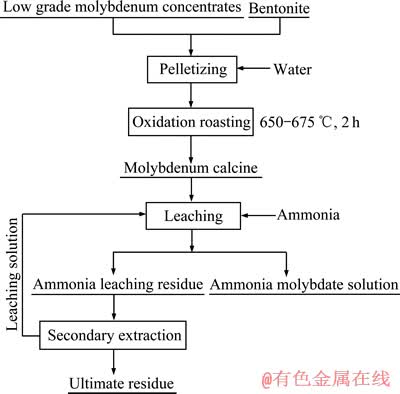

综上可知,针对氧化低品位钼精矿,为钼回收率高的提取效果,其加工的合理工艺路线如图13所示。

图12 氨浸渣二次浸出对钼总溶出率的影响

Fig. 12 Effect of secondary extraction of leaching residue on ultimate recovery rate of molybdenum

图13 低品位钼精矿处理的工艺流程

Fig. 13 Technological process of treatment on molybdenum concentrate

3 结论

1) 低品位钼精矿焙烧过程是一个复杂的物理化学过程,发生硫化物氧化、含钼矿物氧化和钼酸盐生成等多种反应。热力学分析表明:钼精矿中硫化物的氧化顺序为FeS2、MoS2、FeS、CaS、CuS、MgS、Cu2S,其中MoS2较易氧化;辉钼矿氧化可生成多种价态的产物,故钼矿物经焙烧后可能是MoO3、MoO2和Mo2S3等的混合物;氧化生成的MoO3可与金属氧化物自发生成钼酸盐,其中钼酸钙最易生成。

2) 随着焙烧温度升高以及焙烧时间延长,体系中FeS2最先氧化生成Fe2O3,而后辉钼矿(MoS2)的氧化占据主导地位,焙砂中MoS2含量减少,MoO3含量显著增加;但当温度太高或焙烧时间太长,体系中易生成难溶的钼酸盐,不利于钼的后续溶出。适宜的焙烧温度为650~675 ℃,焙烧时间为2 h左右。

3) 低品位钼精矿氨浸的溶出率仅为84.02%,可溶钼(MoO3)虽然完全溶解,但难溶的钼酸盐和少量未彻底氧化辉钼矿仍残留在浸出渣中。将氨浸渣进行二次浸出,当以Na2CO3为浸出剂时,可将氨浸渣中的钼酸钙浸出,最终钼的总溶出率可达90.82%。

REFERENCES

[1] 罗振中. 钼的应用及其发展[J]. 中国钼业, 1998, 27(2): 7-10.

LUO Zheng-zhong. Application and development of molybdenum[J]. China Molybdenum Industry, 1998, 27(2): 7-10.

[2] ZHANG Jiu-xing. The mechanism of strengthening and toughening of rare earth molybdenum alloy[C]// Proceeding of the l3th International Plansee Seminar. Bildstein: Metallwerk, 1993.

[3] LINDSTROM R E, SCHEINER B J. Extraetion of molybdenum from ores by electro-oxidation[J]. Bureau of Mines Metals Reeovery Program USBM Tech Progress Rep, 1972, 10(5): 4-7.

[4] 张文朴. 我国钼资源中稀贵金属的综合利用与再生回收研发进展[J]. 稀有金属与硬质合金,2007, 35(2): 35-40.

ZHANG Wen-pu. Progress of research and development of utilization and reproduction reclamation of china rare and noble metals in molybdenum resources[J]. Rare Metals and Cemented Carbides, 2007, 35(2): 35-40.

[5] 向铁根. 钼冶金[M]. 长沙: 中南大学出版社, 2002: 1-20.

XIANG Tie-gen. Molybdenum metallurgy[M]. Changsha: Central South University Press, 2002: 1-20.

[6] 吴爱祥. 我国钼资源的分布与特征[J]. 中国钼业, 1994, 53(4): 5-6.

WU Ai-xiang. Distribution and characteristic of china molybdenum resources[J]. China Molybdenum Industry, 1994, 53(4): 5-6.

[7] 张启修, 赵秦生. 钨钼冶金[M]. 北京: 冶金工业出版社, 2005.

ZHANG Qi-xiu, ZHAO Qin-sheng. Tungsten-molybdenum metallurgy[M]. Beijing: MetallurgicalIndustryPress, 2005.

[8] WARREN I H, MOUNSEY D M. Factors influencing the selective leaching of molybdenum with sodium hypochlorite from copper/molybdenum sulphide minerals[J]. Hydrometallurgy, 1983, 10(3): 343-357.

[9] BHAPPU R R, REYNOLDS E H, STAHMENNW S. Studies on hypochlorite leaching of molybdenum[J]. Unit Processes in Hydrometallurgy, 1963: 95-113.

[10] 彭建蓉, 杨大锦, 陈加希, 阎江峰. 原生钼矿加压碱浸试验研究[J]. 稀有金属, 2007, 31: 110-113.

PENG Jian-rong, YANG Da-jin, CHEN Jia-xi, YAN Jiang-feng. Study on pressure alkaline leaching original molybdenum[J]. Chinese Journal of Rare Metals, 2007, 31: 110-113.

[11] CAO Zhan-fang, ZHONG Hong, LIU Guang-yi. Electric- oxidation kinetics of molybdenite concentrate in acidic NaCl solution[J]. The Canadian Journal of Chemical Engineering, 2009, 87(6): 93-94.

[12] 符剑刚, 钟 宏, 彭 斌. 超声强化电氧化法湿法分解辉相矿[J]. 过程工程学报, 2005, 5(4): 389-392.

FU Jian-gang, ZHONG Hong, PENG Bin. Study on ultrasonic strengthening wet digestion of molybdnite by electro oxidation method[J]. The Chinese Journal of Process Engineering, 2005, 5(4): 389-392.

[13] SHARMA T. Physico-chemical processing of low grade manganese ore[J]. International Journal of Mineral Processing, 1992, 35(3/4): 191-203.

[14] 任宝江. 回转窑焙烧钼精矿的生产实践[J]. 有色金属: 冶炼部分, 1999(2): 18-20.

REN Bao-jiang. Production practice of molybdenum concentrate roasting by rotary kiln[J]. Nonferrous Metals: Extractive Metallurgy, 1999(2): 18-20.

[15] MEHUGH L F, BARCHERS D E. Roasting of molybdenite on centrates containing flotation oils. US, 4523948[P]. 1985-06-18.

[16] MEHUGH L F, GODSSEHALK J, KUZIOR M. Climax conversionⅢ[C]// Vancouver: The X Ⅵ Canadian Institute of Mining and Metallurgy Annu Meeting, 1977: 8.

[17] MAHESHC J, MAY W A. Fluidized-bed roasting of molybdenites concentrates. US, 6190625[P]. 2001-02-20.

[18] 杨洪英, 俞 娟, 佟琳琳, 罗文杰. 低品位复杂钼精矿的提纯工艺[J]. 中国有色金属学报, 2013, 23(7): 2016-2018.

YANG Hong-ying, YU Juan, TONG Lin-lin, LUO Wen-jie. Purification process of low grade complex molybdenum concentrates[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 2016-2018.

[19] WANG Si-fu, WEI Chang, DENG Zhi-gan, LI Cun-xiong, LI Xin-bing, WU Jun, WANG Ming-shuang, ZHANG Fan. Extracion of molybdenum and nickel from Ni-Mo ore by pressure acid leaching[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(10): 3083-3088.

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51304245,51174253);中国博士后科学一等资助基金项目(2013M540639);中国有色矿业集团总公司科技项目(2013KJJH06)

收稿日期:2014-04-22;修订日期:2014-07-18

通信作者:范晓慧,教授,博士;电话:0731-88830542;E-mail: csufanxiaohui@126.com