TiC颗粒增强镍基合金复合涂层的摩擦学性能

来源期刊:中国有色金属学报(英文版)2013年第6期

论文作者:蔡 滨 谭业发 何 龙 谭 华 高 立

文章页码:1681 - 1688

关键词:等离子喷涂;复合涂层;TiC颗粒;镍基合金;摩擦与磨损

Key words:plasma spray; composite coatings; TiC particle; Ni-based alloy; friction and wear

摘 要:运用等离子喷涂技术制备了TiC颗粒增强镍基合金复合涂层,分析了TiC颗粒增强镍基合金复合涂层的微观结构,研究了其摩擦磨损行为与机理。结果表明:TiC颗粒增强镍基合金复合涂层主要由γ-Ni,CrB,Cr7C3和TiC构成;复合涂层与基底材料间形成了厚度为9.4 μm的过渡层,达到了冶金结合。当TiC颗粒含量为30%(体积分数)时,复合涂层的摩擦系数和磨损率均最低,即其摩擦系数为0.33,较纯镍基合金涂层降低了30%;其磨损率为0.3×10-3mm3/m,是纯镍基合金涂层的1/3。当载荷在6~10 N的范围内时,复合涂层呈轻微磨损,其磨损机理主要为粘着磨损;当载荷达到12 N时,复合涂层产生严重磨损,其磨损机制转变为硬质相的脱落和转移层的层脱剥落。

Abstract: The TiC particles reinforced Ni-based alloy composite coatings were prepared by plasma spray. The microstructure and tribological properties of the composite coatings were investigated. The results show that the composite coatings are mainly composed of γ-Ni, CrB, Cr7C3 and TiC. A transition layer of 9.4 μm in thickness forms at the interface, indicating the metallurgy bond between the composite coating and the substrate. When the content of TiC particles is 30% in volume fraction, both of the friction coefficient and wear rate of the composite coatings reach the lowest values. The friction coefficient is 0.33 which is reduced by 30% compared with the pure Ni-based alloy coating; the wear rate is 0.3×10-3 mm3/m which is about 1/3 that of latter. Under the load of 6-10 N, the composite coatings are in a slight wear stage and their wear mechanisms are mainly adhesive wear. Under the high load of 12 N, the composite coatings suffer from severe wear, and the wear mechanisms change into the desquamation of the hard phases and the delamination of the transferred layer.

Trans. Nonferrous Met. Soc. China 23(2013) 1681-1688

Bin CAI, Ye-fa TAN, Long HE, Hua TAN, Li GAO

Institute of Field Engineering, PLA University of Science and Technology, Nanjing 210007, China

Received 11 May 2012; accepted 10 October 2012

Abstract: The TiC particles reinforced Ni-based alloy composite coatings were prepared by plasma spray. The microstructure and tribological properties of the composite coatings were investigated. The results show that the composite coatings are mainly composed of γ-Ni, CrB, Cr7C3 and TiC. A transition layer of 9.4 μm in thickness forms at the interface, indicating the metallurgy bond between the composite coating and the substrate. When the content of TiC particles is 30% in volume fraction, both of the friction coefficient and wear rate of the composite coatings reach the lowest values. The friction coefficient is 0.33 which is reduced by 30% compared with the pure Ni-based alloy coating; the wear rate is 0.3×10-3 mm3/m which is about 1/3 that of latter. Under the load of 6-10 N, the composite coatings are in a slight wear stage and their wear mechanisms are mainly adhesive wear. Under the high load of 12 N, the composite coatings suffer from severe wear, and the wear mechanisms change into the desquamation of the hard phases and the delamination of the transferred layer.

Key words: plasma spray; composite coatings; TiC particle; Ni-based alloy; friction and wear

1 Introduction

The requirements on long service life and high reliability of machine parts become increasingly urgent with the rapid development of mechanical equipments. The preparation of anti-wear alloy coatings on the surfaces of machine parts by surface engineering technology is an effective approach to improve their service lives.

The mechanical properties and the wear resistance of the alloy coatings reinforced by hard phase particles can be greatly improved [1]. As is known, the hard phase particles, such as SiC, Al2O3, WC and TiB2, are widely used to reinforce the anti-wear alloy coatings. For example, the SiC particles reinforced Ni-based alloy coatings prepared by laser cladding presented a higher microhardness than the Ni-based alloy coatings, and the wear resistance of the former was increased by 1 times compared with the latter [2]. JU et al [3] prepared the Ni-clad Al2O3 particles reinforced composite coatings with 70% Al2O3. The microhardness of the coating was HV0.2810 and its wear resistance was 2.7 times that of the substrate material (45 carbon steel). The wear resistance of the thermal sprayed Co-based alloy coatings with addition of WC particles was improved by 4-9 times, and it would be better at high loads than at low loads [4]. LOTFI et al [5] prepared the TiB2 reinforced NiCr alloy composite coatings by HVOF spraying. It was found that the Ni(Cr)-65%TiB2 exhibited the greatest resistance to abrasive wear with alumina (more than twice that of the Ni(Cr)-40%TiB2 coating). CHEN et al [6] researched the plasma sprayed TiB2 reinforced 316L stainless steel composite coatings. It was found that the wear resistance of the composite coatings was increased by 35% compared with the stainless steel coatings. Though the above hard phase particles have played a significant role in reinforcing alloy coatings and improving their wear resistance, there are some shortages of these hard phase materials. For example, Al2O3 particles may cause low fracture toughness of the composite coatings because of their high brittleness [7]. SiC will be discomposed at the temperature of (2830±40) °C, which can result in the deterioration of mechanical properties for the composite coatings [8]. WC will be decarbonized and/or react with the alloy elements to produce brittle phases such as W2C, M6C and M12C [9], which will lead to the increase of coating brittleness. TiC particles have demonstrated the great potential as the reinforced phase of composite materials because of the properties of high hardness, high modulus, low density and high thermal stability [10]. For example, WANG et al [11] researched the laser clad TiC/FeCrBSi composite coating, the wear volume of which was significantly reduced compared with the FeCrBSi coating.

Plasma spray is an effective technology with convenient operation procedure and low cost in surface engineering. It can deposit almost all metal and ceramic materials. Co-based alloy, Ni-based alloy and Fe-based alloy are the common materials in plasma spray and are widely used as the matrix of the composite coatings. In general, the Co-based alloy has the excellent properties of thermal stability, wear resistance and anti-oxidation, but it is expensive. Although the Fe-based alloy presents some good wear resistance, it usually has the poor technological characteristic in thermal spray compared with the Co-based and Ni-based alloys. By now, Ni-based alloy has been widly applied as the matrix material of the anti-wear composite coatings for its comprehensive properties of wear resistance, anti- corrosion and low cost [12-14]. However, the researches on plasma spray TiC particles reinforced Ni-based alloy composite coatings are not sufficient to meet with the increasing applications in engineering fields. In this work, the TiC particles reinforced Ni-based alloy composite coatings were prepared by plasma spray technology. The microstructure of the composite coatings was analyzed and the tribological behavior and mechanisms were studied in detail.

2 Experimental

2.1 Specimen preparation

The TiC particles reinforced Ni-based alloy composite materials were composed of Ni-based alloy powders and TiC powders. The chemical composition of the Ni-based alloy powders was 15.5Cr, 3B, 4Si, 14Fe, 0.75C and balance Ni (mass fraction, %) and its particle size was in the range of 55-128 μm. The purity of TiC particles with the size of 2.0-2.4 μm was 99.9%. The spray powders were made by the mixture of the Ni-based alloy powders and the TiC particles in the ball mill equipment for 1 h.

The 45 carbon steel was chosen as the substrate, which was previously treated by surface degrease and sand spraying. The composite powders were respectively sprayed on the surface of 45 carbon steel by the plasma spray equipment of DH1080. The spray technological parameters were electric current of 600 A, voltage of 40 V and spray distance of 80 mm. The thickness of the spray coating was 400 μm with surface roughness of 0.5 μm after being ground with diamond wheel.

2.2 Test and analysis method

The X-ray diffraction (XRD) analysis of the composite coatings was performed on a D/max 2500 X-ray diffractometer. The microstructure and the worn surface of the composite coatings were observed with a optical microscope (OM) of DMM-330C and a scanning electron microscope (SEM) of QUANTA 200. Porosity of the coatings was tested by the DM-3000 metallography analysis software. Chemical composition of the composite coatings was analyzed with the energy-dispersive analysis of X-ray (EDAX).

The microhardnesses of the coatings were measured with a DHV-1000 sclerometer under the load of 4.92 N with a dwell time of 15 s. Fracture toughness of the coatings (K1C) was computed by the following equation according to the indentation method [15]:

KC=0.029H0.6E0.4a1.04l-0.54 (1)

where H is the Vickers microhardness; E is the elasticity modulus; a is the dimension of the diagonals after elastic recovery; l is the crack length ahead of the indentation diagonal.

The tribological tests were carried out in a ball-on-disc tribometer of HT-500. The upper specimens were GCr15 steel ball with the diameter of 4 mm and surface roughness of 0.05 μm. The down ones were the composite coatings. Tribological tests were conducted under conditions of the speed of 0.1 m/s at room temperature, normal load of 6-12 N and sliding distance of 720 m. The volume wear rate v of the tested specimen was calculated by

(2)

(2)

where Δm is the mass loss of the coating which was measured by the balance of TG328A; ρ is the intensity of the coating; L is the sliding distance.

3 Results and discussion

3.1 Microstructure and microhardness

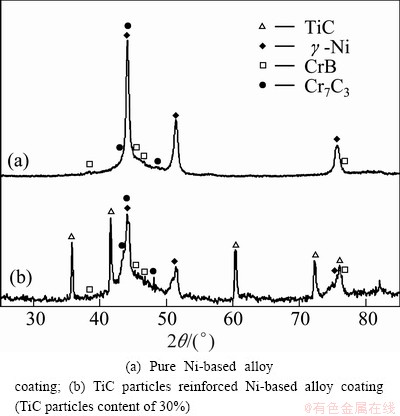

The XRD patterns of the pure Ni-based alloy coating and the TiC particles reinforced Ni-based alloy composite coating are shown in Fig. 1. It can be seen that the pure Ni-based alloy coatings consist of γ-Ni, CrB and Cr7C3. The phases in the TiC particles reinforced Ni-based alloy composite coatings are γ-Ni, CrB, Cr7C3 and TiC, indicating that the TiC particles in the composite coating neither decomposed nor reacted with the Ni-based alloy. Moreover, the diffraction peaks of the hard phases such as CrB and Cr7C3 in the composite coatings are stronger than those in the pure Ni-based alloy coating. This indicates that the contents of CrB and Cr7C3 increase after addition of TiC particles in the composite coating, which is favorable to improving the wear resistance of the composite coating. The TiC particles with high melting point, which act as the heterogeneous nucleation effect, may make the hard phases such as CrB and Cr7C3 precipitate prior to γ-Ni in the cooling process of the sprayed coating [16]. For this reason, the contents of CrB and Cr7C3 are more in the composite coating than in the pure Ni-based alloy coating.

Fig. 1 XRD patterns of coatings

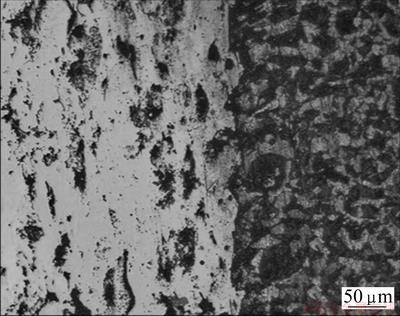

Fig. 2 OM image showing cross-sectional morphology of TiC particles reinforced Ni-based alloy composite coating (TiC particles content of 30%)

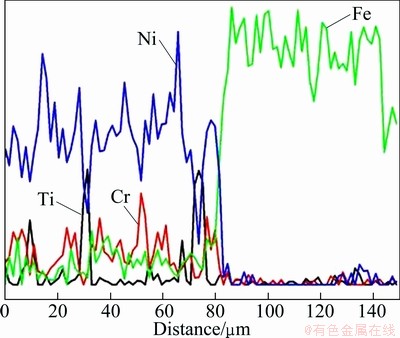

Fig. 3 Line scanning results across interface between composite coating and substrate (TiC particles content of 30%)

Figure 2 shows the cross-sectional morphology of the TiC reinforced Ni-based alloy composite coating. The right side in Fig. 2 is the substrate of 45 carbon steel and the left side is the composite coating. The composite coating exhibits the typical lamellar structure of sprayed coatings with the porosity of 2.6%-3.0%. The line scanning result at the interface is depicted in Fig. 3, which shows that there are some peaks of Ti element because of TiC particles in the coating. As the scanning distance increases at the interface, the peak intensities of the elements Ni and Cr gradually decrease whereas that of the element Fe increases, indicating that the composite coating and the substrate diffuse into each other at the interface. A transition layer with the thickness of 9.4 μm forms across the interface, which results in the metallurgical bond between the composite coating and the substrate.

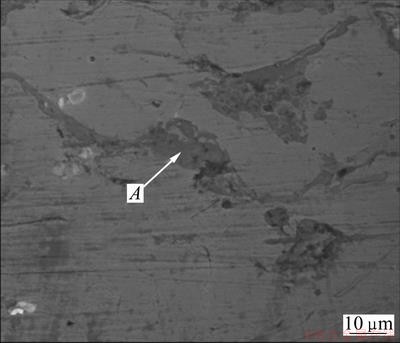

The typical microstructure of the composite coating in a high magnification is shown in Fig. 4. Some of the black areas marked by arrow A distribute in the Ni-based alloy matrix. The element test results show that these areas are composed of 17.34C, 64.2Ti, 0.84Cr, 1.33Fe and 16.28Ni, which indicates that the black areas are mainly TiC phases because a large number of TiC particles might alternately splash with small part of Ni-based alloy powders during the spray process. This typical microstructure may be developed.

Fig. 4 SEM image of composite coating (TiC particles content of 30%)

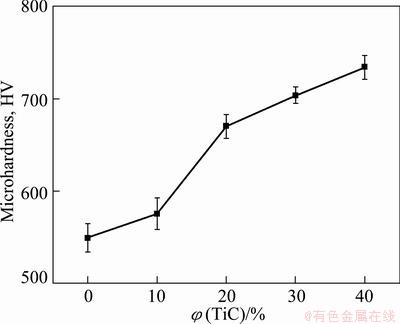

Figure 5 shows the microhardness of the composite coatings as a function of TiC particles content. It is obvious that the microhardness of the composite coatings increases as the TiC particle content increases. With the addition of 10% TiC particles, the microhardness of the coating reaches HV 575, which is large than that of the pure Ni-based alloy (HV 549). When the TiC particle content is 20%, the microhardness dramatically increases to HV 699. As the TiC particle content further increases to 40%, the microhardness of the composite coating gradually increases to HV 734. This means that only when the TiC particle content exceeds 20%, the reinforcement effect of the TiC particles on the Ni-based alloy can be evident, which improves the microhardness of the composite coatings by a great margin. In the microhardness test, enough TiC particles in the composite coating might impede dislocation movement in the Ni-based alloy matrix when the indenter is pressed into the composite coating, then the plastic deformation of the composite coating could be effectively restrained [17]. So the plastic deformation of the composite coating is less than that of the pure Ni-based alloy coating. This is the main reason that the microhardness values of the composite coatings increase with the addition amount of TiC particles.

Fig. 5 Microhardness of composite coatings

3.2 Effect of TiC particle content on tribological behavior and mechanisms of composite coatings

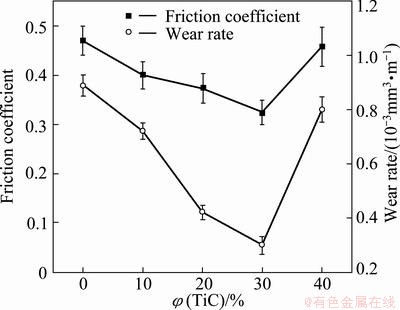

The friction coefficients and wear rates of the composite coatings as a function of the TiC particle content are shown in Fig. 6. The friction coefficient of the pure Ni-based alloy coating is 0.47. As the TiC particle content increases from 10% to 30%, the friction coefficients of the composite coatings take on a decreasing trend. The friction coefficient decreases to the lowest value of 0.33 at the TiC particle content of 30%. However, the friction coefficient of the composite coating reaches 0.45 when the TiC particle content further increases to 40%.

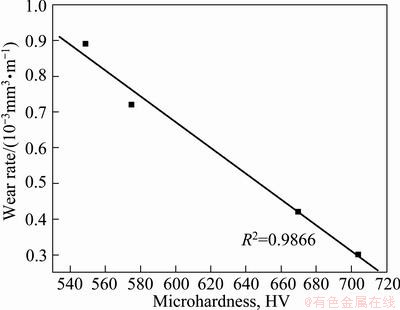

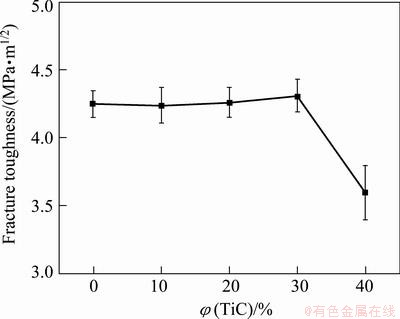

The change trend of the wear rates of the composite coatings is similar to that of the friction coefficients with the increase of TiC particle content. The wear rate is 0.72×10-3 mm3/m at the TiC particle content of 10%, which is reduced by 19% compared with the pure Ni-based alloy coating. The wear rate of the composite coating with 30% of TiC particles is the lowest, which is about one third that of the pure Ni-based alloy coating. But the wear rate of the composite coating dramatically increases to 0.8×10-3mm3/m when the TiC particle content is 40%. This is because when the TiC particle content is less than 30%, the wear rate and the microhardness have a negative linear relationship, as shown in Fig. 7, namely, the wear rate of the composite coating decreases with the increase of the microhardness. Although the microhardness is the highest when the TiC particle content is 40%, the fracture toughness is only 3.6 MPa·m1/2 (Fig. 8), which is considerably lower than that of other composite coatings (about 4.3 MPa·m1/2). This suggests that the excessive TiC particles may lead to the increase of brittleness of the composite coating, and then reduction of the wear resistance. Meanwhile, this also proves that hardness is one of the most important indexes to evaluate the wear resistance of materials, but is not the only one.

Fig. 6 Friction coefficients and wear rates of composite coatings (load of 10 N)

Fig. 7 Microhardness—wear rate correlation for composite coatings

Fig. 8 Fracture toughness of composite coatings vs TiC particles content

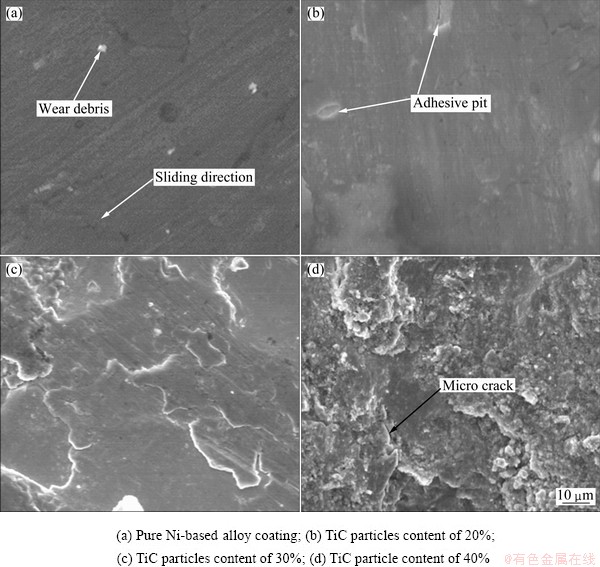

Figure 9 shows the worn surface morphologies of the pure Ni-based alloy coating and the TiC particles reinforced Ni-based alloy composite coatings. Some grooves caused by plastic deformation can be seen on the worn surface of the pure Ni-based alloy coating, as shown in Fig. 9(a), because the coating has suffered from plastic deformation by extrusion of the friction couple. The iterative extrusion of the friction couple on the composite coating may lead to multi-deformation wear, which is the main wear mechanism of the pure Ni-based alloy coating.

The wear mechanisms of the composite coatings change with the addition of TiC particles. The worn surface of the composite coating with 20% TiC particles is shown in Fig. 9(b). The worn surface of the composite coating is relatively smooth with a few adhesive pits. With addition of TiC particles, the plastic deformation of the composite coating is reduced because the microhardness and plastic deformation resistance of the composite coating are greatly improved. The adhesive pits on the worn surface (Fig. 9(b)) suggest that the composite coating has suffered from a certain degree of adhesive wear. It can be inferred that the main wear mechanism of the composite coating with 20% TiC particles is adhesive wear.

Fig. 9 SEM images showing worn surface morphologies of composite coatings with different TiC particle contents

The worn surface of the 30% TiC particles reinforced Ni-based alloy composite coating is shown in Fig. 9(c). A transferred layer is developed on the worn surface during sliding friction and accompanied with some delamination fracture traces. According to EDAX analysis, the transferred layer is composed of ferrous oxides such as Fe2O3 and Fe3O4, which are the debris and/or ferrous oxide of GCr15 steel. The shear strength of the ferrous oxides is less than that of Ni-based alloy or GCr15 steel, so the friction coefficient of the composite coating decreases. The surface of GCr15 steel ball may be easily scratched and worn out in the form of debris, which leads to the formation of transferred layer on the worn surface of the composite coating, because the microhardness of the composite coating with 30% TiC particles is higher than that with 20% TiC particles. In addition, the delamination fracture traces in Fig. 9(c) indicates the transferred layer fractures under the cyclic actions of contact stress and friction as well as frictional heat. It can be concluded that the transferred layer may be gradually developed and then may be destroyed to a degree in later during friction process. The development of the transferred layer on the worn surface of the composite coating may protect the surface and alleviate its adhesive wear. So, the wear rate of the composite coating decreases.

The worn surface of the composite coating with 40% TiC particles is shown in Fig. 9(d). There are many micro-cracks and fracture pits on the worn surface. This is because that the fracture toughness of the composite coatings with 40% TiC particles is much lower than that of other composite coatings due to too many TiC particles in the coatings, which results in the development of micro-cracks and brittle fractures in the friction process and the deterioration of wear resistance. So, it can be found that wear mechanism of the composite coating changes to brittle fracture with the increase of TiC particle content in the composite coating.

It can be concluded from the above analysis that the TiC particles reinforced Ni-based alloy composite coatings exhibit excellent tribological properties. Their friction coefficients are dramatically reduced compared with the pure Ni-based alloy coatings, while their wear resistance is greatly increased. When the content of TiC particles is 30%, both of the friction coefficient and wear rate of the composite coating reach the lowest values. The friction coefficient is 0.33, which is reduced by 30% compared with the pure Ni-based alloy coating; the wear rate is 0.3×10-3 mm3/m, which is about 1/3 that of the pure Ni-based alloy coating.

3.3 Effects of load on tribological behavior and mechanisms of TiC particles reinforced Ni-based alloy composite coatings

Among the TiC particles reinforced Ni-based alloy composite coatings, the composite coating with 30% TiC particles presents the lowest friction coefficient and wear rate. So, the effects of load on its tribological behavior were researched.

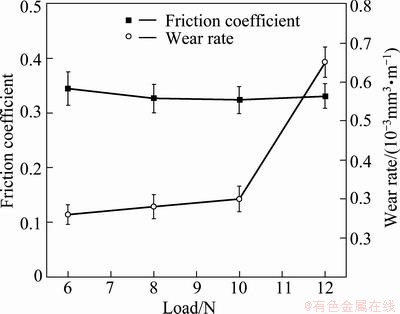

Figure 10 shows the friction coefficients and the wear rates of the TiC particles reinforced Ni-based alloy composite coating as a function of load. Under the load of 6 N, the friction coefficient of the composite coating is 0.34. Under the load increasing to 12 N, the friction coefficient slightly decreases to about 0.33.

The wear rates of the TiC particles reinforced Ni-based alloy composite coatings increase as the load increases. When the loads are less than 10 N, the wear rates slowly increase from 0.26×10-3 mm3/m to 0.3×10-3 mm3/m. When the load is 12 N, the composite coating suffers from severe wear, and the wear rate increases to 0.65×10-3 mm3/m.

Fig. 10 Friction coefficients and wear rates of TiC particles reinforced Ni-based alloy composite coating vs load (TiC particles content of 30%)

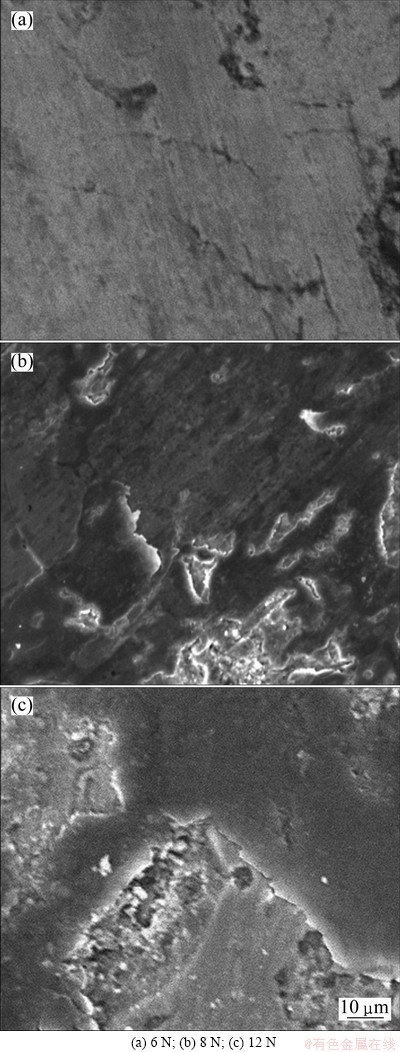

The worn surface morphologies of the TiC particles reinforced Ni-based composite coatings at various loads are shown in Fig. 11. Under the load of 6 N, the worn surface of the composite coating is generally smooth without transferred layer (Fig. 11(a)). The adhesive trace on the worn surface indicates adhesive wear between the composite coating and GCr15 steel. So, the wear mechanism of the composite coating under 6 N is adhesive wear.

The worn surface of the composite coating under the load of 8 N is shown in Fig. 11(b). It can be found that a transferred layer which is similar to that under 10 N (Fig. 9(c)) is produced during friction process. As the load increases to 8 N, the transferred materials of GCr15 steel to the worn surface of the composite coating increase, which gradually results in the formation of the transferred layer due to the increase of real contact area between the composite coating and the GCr15 steel. This indicates that the adhesive wear under 8 N is more severe than under 6 N.

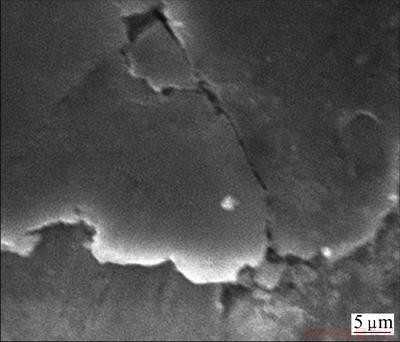

As the load increases to 12 N, the desquamation of the hard phases emerges in the composite coating accompanied with delamination of the transferred layer. The stress concentration generates in the bonding areas between the hard phase particles and the Ni-based alloy matrix as a result of asymmetrical deformation under high load, which induces micro-cracks and desquamation of the hard phases. In addition, the transferred layer may easily desquamate under the cyclic loading because of its low strength. Figure 12 shows the rimous cracks in the transferred layer, which induces fracture delamination of the transferred layer. The above reasons may account for the severe wear of the composite coating under the load of 12 N, and the wear mechanisms of the composite coating are desquamation of the hard phases and the delamination of the transferred layer.

In conclusion, the composite coatings are in a slight wear stage and their wear mechanisms are mainly adhesive wear in the load range of 6-10 N. Under the heavy load of 12 N, the composite coating suffers from severe wear, and the wear mechanisms change into desquamation of the hard phases and the delamination of the transferred layer.

Fig. 11 SEM images showing worn surfaces of TiC particles reinforced Ni-based alloy composite coatings at various loads (TiC particles content of 30%)

Fig. 12 SEM image showing rimous crack on worn surface of composite coating (under 12 N)

4 Conclusions

1) The TiC particles reinforced Ni-based alloy composite coatings are mainly composed of γ-Ni, CrB, Cr7C3 and TiC. A transition layer of 9.4 μm in thickness forms at the interface, indicating the metallurgical bond between the composite coating and the substrate.

2) The TiC particles reinforced Ni-based alloy composite coatings exhibit excellent tribological properties. Their friction coefficients and wear rates are dramatically reduced compared with the pure Ni-based alloy coatings. When the content of TiC particles is 30%, both the friction coefficient and wear rate of the composite coating reach the lowest values. The friction coefficient is 0.33 which is reduced by 30% compared with the pure Ni-based alloy coating; the wear rate is 0.3×10-3mm3/m, which is about 1/3 that of the pure Ni-based alloy coating.

3) In the load range of 6-10 N, the composite coatings are in a slight wear stage and their wear mechanisms are mainly adhesive wear. Under the high load of 12 N, the composite coating suffers from severe wear, and the wear mechanisms change into desquamation of the hard phases and the delamination of the transferred layer.

References

[1] YU Hua-shun. Metel matrix composite and the preparation techniques [M]. Beijing: China Machine Press, 2006: 32-34. (in Chinese)

[2] XIE Song-jing, BAI Wan-jin, YAO Jian-hua. Microstructure and wear resistance of laser clad Ni/SiC ceramic coating [J]. Heat Treatment of Metals, 2006, 31(11): 19-22. (in Chinese)

[3] JU Yi, GUO Shao-yi, CHEN Sheng-zuan, YE Bing-liang. Tribological properties of Ni-clad nano-Al2O3 composite coatings by high-energy laser irradiation [J]. Tribology, 2007, 27(1): 50-53. (in Chinese)

[4] HARSHA S, DWIVEDI D K, AGRAWAL A. Influence of WC addition in Co-Cr-W-Ni-C flame sprayed coatings on microstructure, microhardness and wear behaviour [J]. Surface & Coatings Technology, 2007, 201(12): 5766-5775.

[5] LOTFI B, SHIPWAY P H, MCCARTNEY D G, EDRIS H. Abrasive wear behaviour of Ni(Cr)-TiB2 coatings deposited by HVOF spraying of SHS-derived cermet powders [J]. Wear, 2003, 254 (3-4): 340-349.

[6] CHEN Han-chi, SU Zhuo-xin, AN Shu-chun, WU Yong-zhi. APS TiB2 reinforced 316L stainless steel composite coating and its anti-wear properties [J]. Transactions of the China Welding Institution, 2008, 29(7): 64-68. (in Chinese)

[7] LI Jian, PENG Zhen-wen, YI Dan-qing, LUO Jia. Fracture toughness of Al2O3-ZrO2/W/Cr/Ni/Co cermets [J]. Journal of Materials Science & Engineering, 2009, 27(5): 653-656. (in Chinese)

[8] LI Q, SONG G M, ZHANG Y Z, LEI T C, CHEN W Z. Microstructure and dry sliding wear behavior of laser clad Ni-based alloy coating with the addition of SiC [J]. Wear, 2003, 254(3): 222-229.

[9] LI Q, LEI T C, CHEN W Z. Microstructural characterization of laser-clad TiCp-reinforced Ni-Cr-B-Si-C composite coatings on steel [J]. Surface & Coatings Technology, 1999, 114(2-3): 278-284.

[10] YANG Sen, LIU Wen-jin, ZHONG Min-lin, WANG Zhan-jie. TiC reinforced composite coating produced by powder feeding laser cladding [J]. Materials Letters, 2004, 58(24): 2958-2962.

[11] WANG X H, ZHANG M, LIU X M, QU S Y, ZOU Z D. Microstructure and wear properties of TiC/FeCrBSi surface composite coating prepared by laser cladding [J]. Surface & Coatings Technology, 2008, 202(15): 3600-3606.

[12] la BARBERA-SOSA J G, SANTANA Y Y, STAIA M H, CHICOT D, LESAGE J, CARO J, MESMACQU G, PUCHI-CABRERA E S. Microstructural and mechanical characterization of Ni-base thermal spray coatings deposited by HVOF [J]. Surface & Coatings Technology, 2008, 202(18): 4552-4559.

[13]  M A, PENUELAS I, CADENAS M, del

M A, PENUELAS I, CADENAS M, del  BATTEZ A, FELGUEROSO D. Microstructural study of NiCrBSi coatings obtained by different processes [J]. Wear, 2007, 263(1): 619-624.

BATTEZ A, FELGUEROSO D. Microstructural study of NiCrBSi coatings obtained by different processes [J]. Wear, 2007, 263(1): 619-624.

[14] LIU Sheng-lin, ZHENG Xue-ping, GENG Gang-qiang. Dry sliding wear behavior and corrosion resistance of NiCrBSi coating deposited by activated combustion-high velocity air fuel spray process [J]. Materials and Design, 2010, 31(2): 913-917.

[15] MA Qin, YANG Yan-qin, KANG Mo-kuang. Study of K1C values of HP MoSi2 matrix composite estimated by indentation method [J]. Rare Metal Materials and Engineering, 1996, 25(2): 30-32. (in Chinese)

[16] WEN Jiu-ba. Material science and engineering [M]. Harbin: Harbin Institute of Technology Press, 2007: 76. (in Chinese)

[17] GU Sheng-ting, HOU Yi-fang, CHAI Guo-zhong, WU Hua-ping, YAO Jian-hua. Laser cladding of elasto-plastical properties of particle reinforced H13-TiC composite Coatings [J]. Chinese Journal of Lasers, 2011, 38(6): 186-191. (in Chinese).

蔡 滨,谭业发,何 龙,谭 华,高 立

解放军理工大学 野战工程学院,南京 210007

摘 要:运用等离子喷涂技术制备了TiC颗粒增强镍基合金复合涂层,分析了TiC颗粒增强镍基合金复合涂层的微观结构,研究了其摩擦磨损行为与机理。结果表明:TiC颗粒增强镍基合金复合涂层主要由γ-Ni,CrB,Cr7C3和TiC构成;复合涂层与基底材料间形成了厚度为9.4 μm的过渡层,达到了冶金结合。当TiC颗粒含量为30%(体积分数)时,复合涂层的摩擦系数和磨损率均最低,即其摩擦系数为0.33,较纯镍基合金涂层降低了30%;其磨损率为0.3×10-3mm3/m,是纯镍基合金涂层的1/3。当载荷在6~10 N的范围内时,复合涂层呈轻微磨损,其磨损机理主要为粘着磨损;当载荷达到12 N时,复合涂层产生严重磨损,其磨损机制转变为硬质相的脱落和转移层的层脱剥落。

关键词:等离子喷涂;复合涂层;TiC颗粒;镍基合金;摩擦与磨损

(Edited by Hua YANG)

Corresponding author: Ye-fa TAN; Tel: +86-25-80821055; E-mail: tanyefa7651@163.com

DOI: 10.1016/S1003-6326(13)62648-5