文章编号:1004-0609(2008)01-0036-06

反应等离子喷涂TiC/Fe-Ni金属陶瓷复合涂层的显微组织

朱警雷,黄继华,王海涛,徐俊龙,赵兴科,张 华

(北京科技大学 材料科学与工程学院,北京 100083)

摘 要:采用前驱体碳化复合技术制备Ti-Fe-Ni-C系粉末,并通过反应等离子喷涂技术(RPS)原位合成并沉积了TiC /Fe-Ni基金属陶瓷复合涂层。利用XRD、SEM和EDS研究复合粉末和涂层的成分、组织结构,考察复合粉末的TiC含量及复合粉末粒度对涂层组织结构的影响。结果表明:采用前驱体碳化复合技术制备的反应喷涂复合粉末粒度均匀、无有害相生成;TiC/Fe-Ni复合涂层由不同含量TiC颗粒分布于晶粒内部而形成的晶内型复合强化片层叠加而成,基体主要为(Fe、Ni)固溶体,TiC颗粒呈纳米级;涂层TiC含量较高时,纳米级TiC颗粒弥散分布更均匀;喷涂粉末粒度较大时,片层厚度较大,孔隙率较高。

关键词:TiC /Fe-Ni;反应等离子喷涂;前驱体;金属陶瓷复合涂层

中图分类号:TG 407 文献标识码:A

Microstructures of TiC/Fe-Ni metal ceramic composite coatings by reactive plasma spray

ZHU Jing-lei, HUANG Ji-hua, WANG Hai-tao, XU Jun-long, ZHAO Xing-ke, ZHANG hua

(School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: A kind of Ti-Fe-Ni-C system composite powders for reactive spraying was prepared by precursor carbonization process. TiC/Fe-Ni metal ceramic composite coatings were synthesized and deposited by reactive plasma spray (RPS) of the composite powders. XRD, SEM and EDS were employed to analyze the compositions and microstructures of these composite powders and coatings. The influence of particle size of spraying powders, different contents of TiC of composite coatings on microstructure and composition of the composite coatings were investigated. The results show that the TiC/Fe-Ni composite coatings prepared by RFS are composed of layers in which the nanoscale TiC particles are dispersed within Fe-Ni solid solution alloy matrix. The higher the content of TiC of coatings is, the better the distribution of the nanoscale TiC particles dispersed within Fe-Ni matrix is. The larger the particle size of powders is,the thicker the layers are and the higher the porosity of coatings is.

Key words: TiC/Fe-Ni; reactive plasma spray; precursor; metal ceramic composite coating

反应等离子喷涂(RPS)是近期发展的一种制备陶瓷/金属复合涂层的新技术,它将自蔓延高温合成 (SHS)与等离子喷涂技术相结合,在合成材料的同时将合成材料沉积成为涂层。这种技术不仅工序少、原料价格低廉,而且涂层中的陶瓷相为原位合成 、晶粒细小,与金属基体之间结合良好,可明显提高涂层耐磨性能[1?2]。

TiC颗粒增强金属复合涂层是一种具有广泛工业应用前景的金属陶瓷复合耐磨涂层,因为其具有低摩擦因数、高硬度、低密度以及良好的高温稳定性,有希望逐渐取代传统以WC、Cr3C2颗粒为增强相的复合涂层[3?4];同时在基体相的选择方面,铁镍合金由于其较低的热膨胀率,可大大降低涂层在形成过程中金属相收缩产生的热应力,且其良好的强韧性、耐磨、抗氧化、耐高温腐蚀等性能使它具有广泛的应用前景[5]。

目前,反应等离子喷涂(RPS)采用简单的机械混合粉末或团聚粉末(添加少量的有机粘结剂制粒),虽然可以制备金属陶瓷涂层,但涂层性能不理想。其主要问题是在高速焰流作用下各组元粉末容易分离,组元粉末无法充分反应,使涂层的成分不均匀,涂层质量不稳定[6?10]。本文作者以本实验室开发的前驱体碳化复合技术[11?17]研究以TiFe粉、羰基镍粉和蔗糖为原料,以蔗糖作为碳的前驱体碳化复合制备Ti-Fe-Ni-C反应喷涂复合粉末,并应用反应等离子喷涂技术制备TiC/ Fe-Ni复合涂层,同时研究喷涂复合粉末不同TiC含量、粒度对涂层显微结构的影响。

1 实验

前驱体碳化复合技术制备Ti-Fe-Ni-C系反应喷涂复合粉末的具体工艺过程为:原料粉末按配比(见表1)混合球磨→混合粉末烘干→碳化→破碎筛分。球磨的球料比为4?1,球磨方式为湿磨,球磨介质为酒精,球磨时间 24 h。在氮气保护热处理炉中进行碳化,碳化条件为:氮气保护下250 ℃碳化1 h后,再在300 ℃碳化2 h。喷涂实验在100 mm×100 mm×8 mm的中碳钢板上进行,喷涂前对中碳钢板板面喷沙处理,使表面清洁同时增加表面粗糙度。喷涂设备是美国生产的METCO?7M型等离子喷涂设备,保护气为氩气。等离子喷涂工艺参数:氩气流量40 L/min,氢气流量4 L/min,电流500 A,电压70 V,喷涂距离150 mm。涂层经切片制备金相试样,用 Rigaku Rotaflex D /max-rb X射线衍射分析涂层的相组成,Leo?1450扫描电子显微镜观察其组织结构,Leica显微硬度仪测定其显微硬度,实验载荷1.96 N。

表1 复合粉末的化学成分

Table 1 Chemical composition of composite powders (mass fraction, %)

2 结果与讨论

2.1 Ti-Fe-Ni-C系喷涂粉末相组成和显微结构

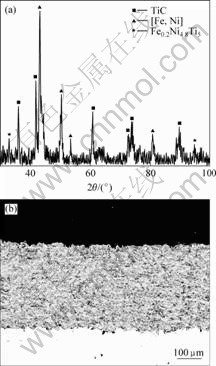

图1(a)所示为采用前驱体碳化复合技术制备的Ti-Fe-Ni-C反应喷涂复合粉末的XRD谱。可以看出,喷涂粉末的相组成为FeTi和Ni,这些都是原料相,说明在碳化过程中除碳化外,没有发生其他的化学合成反应,没有形成TiC且没有其他杂质。XRD谱中看不到碳化后生成的碳,主要原因是碳化后所得碳的型态为无定型碳,它没有统一的晶体结构,在XRD谱中无法显示出来。通过碳化蔗糖生成的无定型碳起到两个作用:一是无定型碳活性更强,对原位合成TiC有利;二是起到了粘接剂的作用,防止喷涂过程中碳的流失。复合粉末颗粒的形貌如图1 (b)所示,可见复合粉末颗粒均匀,大小在100 μm左右;粉末形状为不规则状,但棱角较小,流动性较好。图1(c)所示为复合粉末横截面的SEM像,可以看到粉末是由细小的原料粉末TiFe颗粒团聚而成,TiFe粒度在2~6 μm左右。而且每一个细小的TiFe颗粒都被新生成的无定型碳相互粘结在一起,这种通过无定型碳的粘结结构的结合强度高,使TiFe和碳在反应喷涂中紧密的结合在一起,有效防止分离,避免反应不充分而导致残留有害相。同时TiFe与碳的结合面积增大,有利于促进TiC的原位合成反应,在短暂的喷涂过程中充分放热,可以有效地熔化喷涂颗粒,提高TiC在融化的喷涂颗粒中的形核率,使涂层中生成的TiC粒度细小,提高喷涂涂层片层之间的结合强度,降低涂层的孔隙率。

图1 Ti-Fe-Ni-C反应喷涂复合粉末的XRD谱、粉末形貌及横截面SEM像

Fig.1 XRD pattern(a), powders morphology(b), cross-section SEM micrograph(c) of Ti-Fe-Ni-C powders for RPS

2.2 反应等离子喷涂TiC/Fe-Ni复合涂层分析

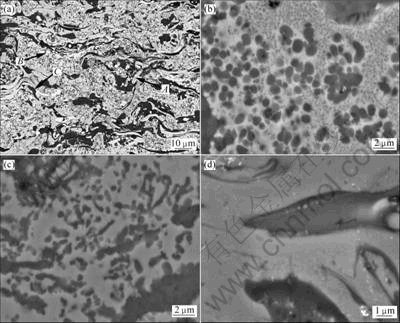

图2(a)所示为采用Ti-Fe-Ni-C反应喷涂复合粉末制备的TiC/Fe-Ni复合涂层的XRD谱。从图2(a)中可以看到,涂层中除基体(Fe、Ni)固溶体外,还生成大量的TiC和少量的Fe0.2Ni4.8Ti5,没有残留的TiFe粉末,说明所制备的喷涂复合粉末在喷涂过程没有发生分散。图2(b)所示为Ti-Fe-Ni-C反应喷涂复合粉末制备的TiC/Fe-Ni复合涂层断面的SEM像,可见涂层呈现出典型的热喷涂涂层的片层结构,涂层中片层厚度较小,表明制备的Fe-Ni-Ti-C反应喷涂复合粉末在喷涂过程中所发生的原位合成TiC反应剧烈,所放出的反应热加上等离子焰流的热量,快速地使喷涂粉末熔化或软化,形成了典型的热喷涂组织。涂层很致密,空隙率很小,涂层与基体间的结合处未出现明显的孔洞或其他缺陷,有着良好的结合面,这将提高涂层与中碳钢板基体的结合强度。

图2 TiC/Fe-Ni反应等离子喷涂复合涂层XRD谱和 SEM像

Fig.2 XRD pattern(a) and SEM micrograph(b) of TiC/Fe-Ni compound coatings prepared by RPS

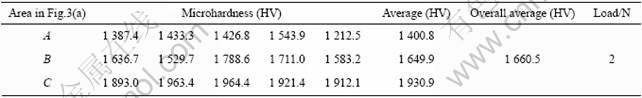

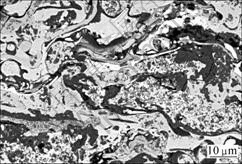

图3(a)所示为涂层的典型组织的局部高倍SEM像,可看到涂层由颜色不同的片层组织构成,片层颜色的差异显示不同的TiC粒度和含量,即不同TiC粒度和含量的片层重叠排列的结构。在摩擦过程中,这种多层多相的结构会有效地阻碍裂纹扩展,增强涂层的抗疲劳性能。图3(b)所示为涂层中白色片层的显微照片,层中的TiC颗粒大致呈球形,粒度为200 nm左右,而且均匀地弥散分布于(Fe、Ni)固溶体基体中。TiC颗粒达到纳米级的原因可能是在严酷的喷涂条件下-焰流温度高达16 000 ℃以上,粒子飞行速度达到850 m/s,喷涂距离为20 cm,喷涂粉末的飞行时间仅为2.3×10?4 s,基体的凝固速度超过104 K/s,原位生成的TiC颗粒被快速移动的固液界面“捕捉”,形成TiC颗粒分布于晶粒内部的晶内型复合强化组织,有效地阻碍了纳米级TiC晶粒的扩散聚集长大。

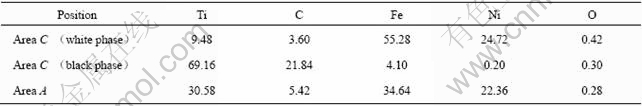

图3(c)所示为涂层中麻点区域的显微照片,其结构与A区域的相似,TiC颗粒的粒度要比涂层中A区域的TiC粒度大,大约为500 nm左右。这两种片层有相同的结构,都是由大量细小的TiC均匀分散分布于(Fe、Ni)固溶体金属基体中,形成了一种复合材料的结构,能提高涂层的强度和韧性,提高硬度和耐磨性。而且这些均匀弥散分布于金属集体中的细小TiC颗粒可以有效地阻止位错的运动和微裂纹的扩张,可以有效地提高涂层的硬度和耐磨性。图3(d)所示为涂层中的C区域,结合XRD和EDS(表2)结果可以看到,C区域是TiC颗粒富集区。在连续喷涂过程中,局部的持续供热会使得温度上升,导致TiC晶粒发生长大甚至是聚集行为,这样就形成了涂层中的麻点区域和TiC颗粒富集区。采用Leica显微硬度仪测定其不同区域的显微硬度(如表3所列),涂层片层的最高显微硬度HV0.2值达到了1 930.9,该区域为TiC颗粒富集区。

图3 Ti-Fe-Ni-C系反应等离子喷涂复合涂层的典型组织SEM像

Fig.3 SEM micrographs of typical microstructure of Ti-Fe-Ni-C compound coatings prepared by RPS: (a) Typical morphology; (b) Area A in Fig.3(a); (c) Area B in Fig.3(a); (d) Area C in Fig.3(a)

表2 反应等离子喷涂TiC/Fe-Ni复合涂层不同区域EDS分析结果

Table 2 EDS analysis results of different zones of TiC/Fe-Ni compound coating prepared by RPS (mass fraction, %)

表3 TiC/Fe-Ni复合涂层的片层区域显微硬度

Table 3 Microhardness of different zones of TiC/Fe-Ni coating prepared by RPS

2.3 不同TiC含量涂层组织结构的比较

图4所示为利用TiC含量为30%的喷涂复合粉末(40~63 μm)制备的涂层SEM像。可见涂层显微组织为典型的热喷涂涂层的片状结构,片层厚度较小,表明制备的Fe-Ni-Ti-C系反应喷涂复合粉末在喷涂过程中所发生的原位合成TiC反应剧烈,所放出的反应热加上等离子焰流的热量,可有效地使喷涂粉末熔化或软化,通过高速气流喷射到基体上形成了典型的热喷涂组织。涂层具有多层多相的结构,由颜色有明显差异的麻点片层和黑色片层交替叠加而成。在含TiC量30%的涂层中,麻点区域面积大量减少,TiC聚集区域基本与含TiC量42%的涂层(图3(a))几乎一样,表明TiC含量高的喷涂复合粉末在喷涂过程中,更容易导致钛铁粉与蔗糖热分解后的碳发生自蔓延反应,从而原位合成更多纳米级TiC颗粒,反应放出的热量更多。这些热量被TiC颗粒吸收从而降低了TiC颗粒之间的过冷度,阻碍纳米级TiC颗粒发生扩散长大。

图4 含30%TiC涂层(40~63 μm)的SEM像

Fig.4 SEM micrograph of coatings containing 30%TiC (Particle size 40?63 μm)

2.4 喷涂粉末粒度对组织结构的影响

图5所示为采用63~106 μm的喷涂复合粉末(42%TiC)制备的TiC/Fe-Ni复合涂层的SEM照片,其涂层中的片层厚度明显大于采用40~63 μm的喷涂复合粉制备的涂层厚度(如图3(a)),而且涂层孔隙率较大。这可能由于同时熔化或熔融大粒度的喷涂粉末需要更多的热量,易导致喷涂过程中的大颗粒喷涂粉末熔化不完全,因此在与基体的碰撞中粉末变形小,导致片层厚度增加,并产生较大的孔隙率。

图5 63~106 μm喷涂粉末制备的涂层(42%TiC)SEM像

Fig.5 SEM micrograph of coatings prepared by powders (42%TiC) with particle size of 63?106 μm

3 结论

1) 利用前驱体碳化复合技术制备了Ti-Fe-Ni-C系反应热喷涂复合粉末,通过等离子喷涂对所制备的Fe-Ni-Ti-C系反应热喷涂复合粉末进行喷涂,制备了TiC增强FeNi基复合涂层。

2) TiC增强FeNi基复合涂层由不同含量TiC颗粒分布于晶粒内部而形成晶内型复合强化片层组织交替叠加而成,其中TiC颗粒呈纳米级,基体主要由(Fe,Ni)固溶体组成,含有少量的Fe0.2Ni4.8Ti5金属化合物。

3) 与TiC含量为30%的涂层相比,含42%TiC的涂层中细小的TiC颗粒更多,TiC颗粒大量弥散分布在基体上的程度更好。

4) 喷涂粉末粒度较大时,在喷涂过程中喷涂粉末反应不充分,涂层中片层厚度较大,孔隙率较高。

REFERENCES

[1] 周 静, 韦云隆, 张隆平, 吴护林. 等离子喷涂耐磨涂层及热障涂层新进展[J]. 表面技术, 2001, 30(2): 23?25.

ZHOU Jing, WEI Yun-ling, ZHANG Long-ping, WU Hu-ling. The development of wear resistant coating and TBC by plasma spraying process[J]. Surface Technology, 2001, 30(2): 23?25.

[2] 胡正前, 张文华, 孙文华. 等离子喷涂TiC-Ni-Mo金属陶瓷涂层成分对组织与性能影响的研究[J]. 复合材料学报, 1999, 16(3): 87?92.

HU Zheng-qian, ZHANG Wen-hua, SUN Wen-hua. Effect of the ingredient of plasma spraying TiC-Ni-Mo cermets coating on the microstructure and properties[J]. Acta Materiae Compositae Sinica, 1999, 16(3): 87?92.

[3] 胡正前, 张文华, 汪晓霞. 等离子喷涂TiC-Ni-Mo金属陶瓷涂层结构与性能的研究[J]. 金属热处理, 1998, 9: 1?3.

HU Zheng-qian, ZHANG Wen-hua, WANG Xiao-xia. Study on microstructure and properties of TiC-Ni-Mo cermets coatings by plasma spraying[J]. Heat Treatment of Metal, 1998, 9: 1?3.

[4] ECONOMOU S, DE BONTE M, CELIS J P, SMITH R W, LUGSCHEIDER E. Processing, structure and tribological behaviour of TiC-reinforced plasma sprayed coatings[J]. Wear, 1998, 220: 34?50.

[5] ECONOMOU S, DE BONTE M, CELIS J P, SMITH R W, LUGSCHEIDER E. Tribological behaviour at room temperature and at 550 ℃ of TiC-based plasma sprayed coatings in fretting gross slip conditions[J]. Wear, 2000, 244: 165?179.

[6] TONDU S, SCHNICK T, PAWLOWSKI L, WIELAGE B, STEINH?USER S, SABATIER L. Laser glazing of FeCr-TiC composite coatings[J]. Surface and Coatings Technology, 2000, 123: 247?251.

[7] 刘长松, 殷 声. 反应热喷涂的发展[J]. 材料保护, 2000, 33(1): 83?85.

LIU Chang-song, YIN Sheng. Advance in reactive thermal spraying[J]. Materials Protection, 2000, 33(1): 83?85.

[8] ANANTHAPADMANABHAN P V, TAYLOR P R, ZHU Wen-xian. Carbide-iron composite coating by reactive plasma spraying of limonite[J]. Journal of Alloys and Compounds, 1999, 287: 121?125.

[9] LICHERI R, ORR? R, CAO G, CRIPPA A, SCHOLZ R. Self-propagating combustion synthesis and plasma spraying deposition of TiC-Fe powders[J]. Ceramics International, 2003, 29: 519?526.

[10] VALENTE T, GALLIANO F P. Corrosion resistance properties of reactive plasma-sprayed titanium composite coatings[J]. Surface and Coatings Technology, 2000, 127: 86?92.

[11] 刘慧渊, 黄继华, 杨四新, 张建纲. C/Ti原子比对火焰喷涂TiC/Fe复合涂层组织结构和硬度的影响[J]. 复合材料学报, 2005(3): 80?84.

LIU Hui-yuan, HUANG Ji-hua, YANG Si-xin, ZHANG Jian-gang. Influence of C/Ti atomic ratio on microstructure and hardness of TiC/Fe composite coating by reactive flame spray[J]. Acta Materiae Compositae Sinica, 2005(3): 80?84.

[12] 黄继华, 刘长松, 党全坤, 殷 声. TiC/Fe-Al 复合涂层反应火焰喷涂研究[J]. 粉末冶金技术, 2002, 20(4): 219?222 .

HUANG Ji-hua, LIU Chang-song, DANG Quan-kun, YIN Sheng. A study on reactive flame spraying for TiC/Fe-Al composite coating[J]. Powder Metallurgy Technology, 2002, 20(4): 219?222.

[13] LIU Hui-yuan, HUANG Ji-hua. Reactive thermal spraying of TiC-Fe composite coating by using asphalt as carbonaceous precursor[J]. Journal of Materials Science, 2005, 40: 4149?4151.

[14] LIU Hui-yuan, HUANG Ji-hua, YIN Chang-feng, ZHANG Jian-gang, LIN Guo-biao. Microstructure and properties of TiC-Fe cermets coatings by reactive flame spraying using asphalt as carbonaceous precursor[J]. Ceramics International, 2007, 33: 827?835.

[15] LIU Hui-yuan, HUANG Ji-hua. Reactive flame spraying of TiC-Fe cermet coating using asphalt as a carbonaceous precursor[J]. Surface & Coatings Technology, 2006, 200: 5328?5333.

[16] 刘慧渊, 黄继华, 张建纲. 反应火焰喷涂的TiC/Fe金属陶瓷复合涂层[J]. 中国有色金属学报, 2004, 14(8): 1389?1393.

LIU Hui-yuan, HUANG Ji-hua, ZHANG Jian-gang. [J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1389?1393.

[17] 刘慧渊, 黄继华. 以沥青为前驱体制备TiC/FeCrNi反应火焰喷涂复合涂层[J]. 稀有金属材料与工程, 2006, 35(7): 1061?1064.

LIU Hui-yuan, HUANG Ji-hua. Fabrication of TiC/FeCrNi composite coatings by reactive flame spray using asphalt as carbonaceous precursor[J]. Raremetal Materials and Engineering, 2006, 35(7): 1061?1064.

基金项目:河南杰出人才创新基金资助项目(0421001000);焊接国家重点实验室开放资助项目

收稿日期:2007-06-23;修订日期:2007-10-19

通讯作者:黄继华,教授;电话:010-62334859;E-mail: jihuahuang47@sina.com

(编辑 何学锋)