文章编号:1004-0609(2008)11-1983-06

以蔗糖为前驱体火焰喷涂原位TiC增强Ni基复合涂层的制备

张守全1, 2,王海涛1,黄继华1,朱警雷1,刘慧渊1,张 华1

(1. 北京科技大学 材料科学与工程学院,北京 100083;

2. 厦门金鹭特种合金有限公司,厦门 361006)

摘 要:以蔗糖为碳源,采用前驱体热分解技术制备Ni-Ti-C系反应热喷涂混合粉末,通过氧乙炔火焰喷涂技术合成并同时沉积原位TiC颗粒增强的Ni基合金复合涂层。利用XRD和SEM研究混合粉末和涂层的相成分和组织结构,分析TiC/Ni复合涂层的硬度和耐磨性。结果表明:反应火焰喷涂TiC/Ni复合涂层主要由TiC和Ni基体组成,并含少量的Ni3Ti和Ti3O5;涂层由复合强化片层相互叠加而成,复合强化片层中TiC颗粒均匀分布于 Ni基体中,TiC颗粒呈球形,粒度达到亚微米级;涂层具有较高的硬度和耐磨性,复合强化片层显微硬度为HV0.2 1 433,涂层的耐磨性能远优于基板材料45号钢和对比涂层Ni60的耐磨性。

关键词:TiC/Ni复合涂层;反应热喷涂;蔗糖;原位TiC颗粒

中图分类号:TG 407 文献标识码:A

Preparation of in situ TiC reinforced Ni-based composite coatings by flame spraying using sucrose as carbonaceous precursor

ZHANG Shou-quan1, 2, WANG Hai-tao1, HUANG Ji-hua1, ZHU Jing-lei1, LIU Hui-yuan1, ZHANG Hua1

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Xiamen Golden Egret Special Alloy Co. Ltd., Xiamen 361006, China)

Abstract: A kind of Ni-Ti-C composite powder for reactive thermal spraying was prepared by thermal decomposition of precursor with sucrose as carbon source. In-situ TiC reinforced Ni-based composite coatings were synthesized and deposited simultaneously by oxyacetylene flame spraying of the composite powder. XRD and SEM were employed to analyze the compositions and microstructures of these composite powders and coatings. The hardness and wear resistance of TiC/Ni composite coatings were investigated. The results show that the composite coating is composed of TiC, Ni and a little Ni3Ti and Ti3O5. The coating is formed by superposition of composite layers in which many TiC particles are uniformly distributed in Ni matrix, and the TiC particles in these layers are spherical or near-spherical with submicron-scale sizes. The microhardness of the composite layers reaches HV0.2 1 433. The wear resistance of TiC/Ni composite coating is much better than those of 45# steel substrate and Ni60 coating.

Key words: TiC/Ni composite coating; reactive thermal spraying; sucrose; in-situ TiC particle

TiC陶瓷相具有低摩擦因数、高硬度、低密度以及良好的高温稳定性,TiC颗粒增强金属陶瓷复合涂层已经逐步发展成为一种具有广泛工业应用前景的耐磨涂层[1?2]。热喷涂技术是制备金属陶瓷复合涂层的有效方法之一,但TiC的高熔点使直接喷涂含TiC的金属陶瓷粉末成形性较差,陶瓷相在涂层中分布不均匀,粒度较大,陶瓷/金属结合界面易受污染,降低了涂层的性能[3?4]。反应热喷涂技术制备原位生成的TiC颗粒增强金属陶瓷复合涂层可以在合成TiC的同时沉积涂层,不仅减少了工序,而且涂层中的陶瓷相为原位合成,晶粒细小,与金属粘结相结合良好,可显著提高涂层的耐磨性能[5?6]。

传统反应热喷涂采用添加化学粘结剂的制粒方法,喷涂喂料中的反应组元在高温、高速焰流作用下容易分离,造成体系反应不完全,涂层质量较差且不够稳定[7?9]。本文作者采用纯钛粉、羰基镍粉和碳的前驱体(蔗糖)为原料制备Ni-Ti-C系反应热喷涂复合粉末,热分解蔗糖生成的碳既是反应组元又是原料粉末的粘结剂。前驱体碳化制得的喷涂喂料经氧乙炔火焰喷涂沉积TiC/Ni基复合涂层,研究涂层的组织结构、硬度和耐磨性。

1 实验

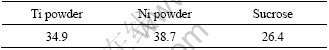

实验以纯钛粉(d<50 μm)、羟基Ni粉(d<2.5 μm)和蔗糖(碳的前躯体)为原料,制备Ni-Ti-C系反应热喷涂复合粉末。钛粉、镍粉和蔗糖混合湿磨8~12 h(球料质量比为4?1,球磨介质为酒精),混合物浆料在45~60 ℃ 时烘干,烘干后的块状混合物装入氮气保护的热处理炉中,在200和300 ℃下分别保温2 h和1 h使蔗糖充分热分解[10],最后将得到的多孔块状固体进行破碎和筛分,制备出40~60 μm的反应热喷涂原料粉末。本课题组的前期研究结果表明[10?11]:反应热喷涂混合粉末中的C与Ti摩尔比对涂层组织结构和硬度有较大的影响,当C与Ti摩尔比为1时,涂层具有较好的微观组织和较高的硬度;Ni含量在大于40%(质量分数)时可保证Ni-Ti-C系反应的充分进行,减少氧化物的生成,改善组织结构,提高涂层的耐磨性能。本实验中原料粉末蔗糖碳化前的配比和碳化后复合粉末中的元素含量分别列于表1和表2。

表1 原料粉末蔗糖碳化前的组成

Table 1 Composition of powders before sucrose carbonization (mass fraction, %)

表2 碳化后复合粉末的元素含量

Table 2 Composition of powders after sucrose carbonization (mass fraction, %)

利用长城喷涂技术研究所研制的CP?D3型氧乙炔火焰喷枪在经过喷沙预处理的45号钢板(100 mm×50 mm×10 mm)上沉积TiC/Ni复合涂层,喷涂距离为15~20 cm,O2压强为0.8 MPa,C2H2压强为0.1 MPa,载气(N2)流量为5 mL/min。

涂层经切片制备金相试样,用Rigaku Rotaflex D/max?rb X射线衍射(Cu靶)分析涂层的相组成,Leo? 1450扫描电子显微镜观察其组织结构,Leica显微硬度仪测定其显微硬度。涂层的耐磨实验在OPTIMOL公司(德国)SRV摩擦磨损实验机上进行,选用基板45号钢和相同工艺制备的Ni60自熔合金涂层(0.8%C,16%Cr,4.5%Si,3.5%B,Fe含量≤15%,余量Ni,质量分数)作为对比试样。实验采用球-盘对磨方式,用Talysurf 5P?120表面轮廓仪测量涂层磨痕在与摩擦运动垂直方向上的横截面面积,用磨痕的横截面面积表征涂层的耐磨损性。图1所示为SRV摩擦磨损实验机的示意图,实验条件列于表3

图1 SRV摩擦磨损实验机示意图

Fig.1 Schematic illustration of optimal SRV friction and wear tester

表3 磨损的实验条件

Table 3 Conditions of wear-resisting property test

2 结果与讨论

2.1 前驱体碳化Ni-Ti-C系复合粉末相的组成和显微 结构

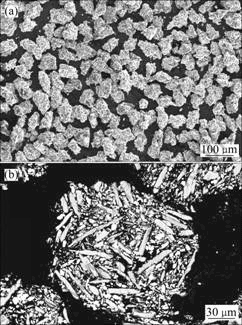

以Ti粉、Ni粉和蔗糖为原料制备的Ni-Ti-C系反应热喷涂复合粉末的XRD谱如图2所示。由图可知,复合粉末由原料Ti粉和Ni粉组成,原料混合物在蔗糖热解过程中没有生成TiC或其它杂质。XRD谱中没有碳的衍射峰,这主要是因为有机物在低温下碳化后生成非晶碳,在XRD谱中无法显示出来[12]。图3(a)所示为复合粉末的形貌。可见粉末团粒呈不规则 状,粒度均匀。图3(b)所示为复合粉末团粒的内部结构。白色小颗粒为羰基Ni粉,粒度小于2.5 μm;白色的棒状相为单质Ti粉,单质Ti粉塑性很好,球磨细化后成为片状,在团粒横截面照片中表现为短棒状;Ti和Ni之间的黑色区域是蔗糖热解碳化后生成的非晶碳,它既是反应组元又是粘结剂。Ni-Ti-C混合粉末中2.5 μm的Ni颗粒和片状Ti粉被碳粘结,形成热喷涂喂料的团粒结构。

图2 Ni-Ti-C系反应喷涂复合粉末的XRD谱

Fig.2 XRD pattern of Ni-Ti-C composite powders

图3 Ni-Ti-C系反应喷涂复合粉末的SEM形貌和横截面像

Fig.3 SEM morphology(a) and cross-section SEM image(b) of Ni-Ti-C composite powders

2.2 反应火焰喷涂制备TiC/Ni复合涂层的组织结构

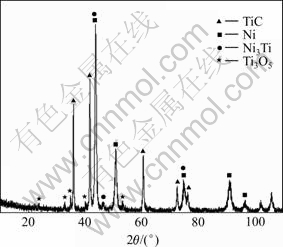

图4所示为反应火焰喷涂TiC增强Ni基复合涂层的XRD谱。由图可知,涂层中生成大量的TiC增强相和少量钛的氧化物,一部分Ni和Ti反应生成少量的Ni3Ti金属间化合物,大部分Ni作为基体金属粘结陶瓷相颗粒。在理想平衡状态下,Ni-Ti-C三元系发生如下反应:Ti+Ni+C→TiC+Ni,形成金属Ni粘结TiC颗粒的复合强化结构。JIANG等[13]研究发现,在非平衡状态下的Ni-Ti-C三元系中必然存在Ti与Ni的反应,生成金属间化合物(Ni3Ti和NiTi等)。在反应火焰喷涂过程中,Ni-Ti-C体系中首先出现Ti-Ni液相,并生成少量金属间化合物,然后C溶解于Ti-Ni液相中与Ti原子发生反应,TiC从液相中析出[14?15]。混合粉末团粒在火焰喷涂的快速非平衡过程中反应不能充分进行,生成中间过渡相,最终产物为TiC和Ni、Ni3Ti,并发生少量Ti的氧化。从涂层的XRD谱中未见单质Ti的衍射峰,说明蔗糖碳化后的碳可牢固粘结原料粉末,反应组元在热喷涂的焰流作用下不会发生分离,涂层中无原料粉末残留。

图4 反应火焰喷涂TiC/Ni复合涂层的XRD谱

Fig.4 XRD pattern of TiC/Ni composite coating prepared by reactive flame spraying

图5所示为反应火焰喷涂TiC/Ni复合涂层的SEM像。图5(a)所示为涂层的宏观背散射像。由图可知,TiC/Ni复合涂层呈现热喷涂组织的片层结构,但片层间的界面不明显,无明显的硬质相聚集区域,涂层组织均匀。在热喷涂过程中,后续喷涂颗粒对已沉积片层的连续冲击和再加热作用有利于涂层中片层之间的结合。从图5(a)中可知:最后沉积的涂层表面片层界面比内部片层界面明显。图5(b)所示为图5(a)中A区的放大照片。由图可知,涂层中各片层界面模糊,组织结构相同。由图5(c)可以看出,涂层中形成大量硬质相颗粒均匀分布的复合强化片层结构,各片层中硬质相颗粒含量差别不大,无明显的硬质相聚集或着贫化区域,组织结构均匀。图5(d)所示为复合强化片层的放大照片,图中黑色颗粒是原位反应生成的TiC,白色粘结相主要是Ni。TiC/Ni复合涂层中的TiC颗粒大致呈球形,粒度约为200~500 nm,而且均匀地分布于Ni基体中,这表明以蔗糖为碳源制得的反应喷涂混合粉末具有紧密的团粒结构,在喷涂过程中Ti和C不会发生分离,生成了大量的TiC颗粒。复合粉末在喷涂过程中发生的反应放热与氧乙炔火焰共同作用,可以快速地使喷涂粉末熔化或软化,形成热喷涂组织。

图5 反应火焰喷涂TiC/ Ni复合涂层的SEM像

Fig.5 SEM images of TiC/Ni composite coatings prepared by reactive flame spraying: (a) Coating; (b) High magnification of A zone; (c) Composite layers; (d) Submicron-scale TiC particles

TiC/Ni复合涂层中大量细小的TiC颗粒弥散分布于金属基体中,形成一种复合材料的结构,对金属基体起到增强的作用,这些亚微米级的TiC颗粒可以有效地阻止位错的运动和微裂纹的扩张,提高涂层的硬度和耐磨性[16]。涂层中的TiC颗粒达到亚微米级的原因可能是在高温的喷涂条件下,喷涂粉末在3 000 ℃左右的焰流中被加热至熔化或半熔化状态后快速碰撞到基板上,原位生成的TiC颗粒被快速凝固的固液界面“捕捉”,有效地阻碍了TiC晶粒的聚集和长大,形成亚微米TiC颗粒均匀分布于金属基体中的复合强化组织。

2.3 TiC/Ni复合涂层的硬度和耐磨性

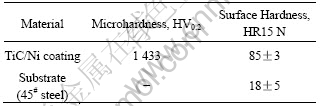

TiC/Ni复合涂层由细小硬质相颗粒均匀分布的复合强化片层构成,片层之间界面结合良好,没有明显的TiC聚集或贫化的特征区域,涂层显微硬度为复合强化片层中30次测量值的平均值。表4所列为TiC/Ni复合涂层的显微硬度和表面硬度。由表可知,涂层平均显微硬度值达到HV0.2 1 433,表面硬度远大于基板硬度。王振廷等[17]报道了分别采用感应熔覆、激光熔覆技术制备的微、纳米碳化钨增强镍基复合材料涂层 (50%Ni,体积分数)和TiC-TiB/Ni基金属陶瓷涂层[18],其显微硬度值均小于HV0.2 1 000。反应火焰喷涂TiC/Ni复合涂层具有较高的硬度可能是因为基体相中生成大量硬度很高的TiC颗粒(HV 3 200[19])和少量的硬脆金属间化合物,同时基体相Ni合金也可能因为热喷涂的快速非平衡冷却过程而细化了晶粒,增加了强度。

表4 TiC/Ni复合涂层的硬度

Table 4 Hardness of TiC/Ni composite coating

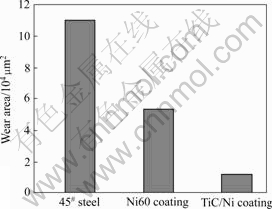

相同工艺制备的TiC/Ni复合涂层和Ni60自熔合金涂层,以及基板45号钢的试样在SRV摩擦磨损实验机上检测其耐磨性。3个试样磨损区域中间横截面的轮廓曲线如图6所示:45号钢的磨痕较窄,最大深度超过80 μm,说明存在着集中磨损;Ni60涂层的磨痕变宽,最大深度超过30 μm;TiC/Ni复合涂层磨痕轮廓曲线平缓,磨损区域较小,深度小于10 μm。图7所示为3个试样的磨痕中间横截面磨损面积的比较。由图可知,在相同的磨损条件下,通过反应火焰喷涂制备的TiC/Ni复合涂层的磨痕横截面磨损面积明显小于基板材料45号钢和对比涂层Ni60,分别约为45号钢和Ni60涂层的1/12和1/6。通过反应火焰喷涂方法制备的TiC/Ni复合涂层拥有良好的耐磨性能,这主要是因为涂层组织结构均匀,原位生成硬质颗粒的弥散分布状态对涂层强化非常有利。

图6 TiC/Ni复合涂层、Ni60涂层和金属基板的磨痕截面轮廓曲线

Fig.6 Fretting track profiles of TiC/Ni composite coating, Ni60 coating and metal substrate

图7 TiC/Ni复合涂层、Ni60涂层和金属基板的磨痕截面磨损面积

Fig.7 Wear area of TiC/Ni composite coating, Ni60 coating and metal substrate

3 结论

1) 以蔗糖为碳源制备了Ni-Ti-C系反应热喷涂混合粉末,蔗糖热分解后生成的碳既是反应组元,又是混合粉末团粒结构中的粘结剂。通过氧乙炔火焰喷涂Ni-Ti-C混合粉末制备了原位TiC颗粒增强的Ni基合金复合涂层。

2) TiC/Ni复合涂层主要由TiC和Ni组成,生成少量Ni3Ti 和Ti的氧化物。涂层由TiC颗粒均匀分布于Ni基体中形成的复合强化片层组织交替叠加而成,其中TiC颗粒呈球形,粒度为200~500 nm。

3) 涂层组织结构均匀,亚微米级TiC颗粒弥散分布的颗粒强化机制使涂层硬度和耐磨性显著提高。涂层的显微硬度为HV0.2 1 433,磨痕横截面磨损面积明显小于基板材料45号钢和对比涂层Ni60,分别约为45号钢和Ni60涂层的1/12和1/6。

REFERENCES

[1] 胡正前, 张文华, 汪晓霞. 等离子喷涂TiC-Ni-Mo金属陶瓷涂层结构与性能的研究[J]. 金属热处理, 1998, 9(9): 1?3.

HU Zheng-qian, ZHANG Wen-hua, WANG Xiao-xia. Study on microstructure and properties of TiC-Ni-Mo cermets coatings by plasma spraying[J]. Heat Treatment of Metal, 1998, 9(9): 1?3.

[2] ECONOMOU S, BONTE M D, CELIS J P. Processing,structure and tribological behaviour of TiC-reinforced plasma sprayed coatings[J]. Wear, 1998, 220(1): 34?50.

[3] ECONOMOU S, BONTE M D, CELIS J P. Tribological behaviour at room temperature and at 550 ℃ of TiC-based plasma sprayed coatings in fretting gross slip conditions[J]. Wear, 2000, 244(1/2): 165?179.

[4] TONDU S, SCHNICK T, PAWLOWSKI L. Laser glazing of FeCr-TiC composite coatings[J]. Surface and Coatings Technology, 2000, 123(2/3): 247?251.

[5] ANANTHAPADMANABHAN P V, TAYLOR P R. Titanium carbide-iron composite coating by reactive plasma spraying of ilmenite[J]. Journal of Alloys and Compounds, 1999, 287(1/2): 121?125.

[6] ROBERTA L,ROBERTO O, GIACOMO C. Self-propagating combustion synthesis and plasma spraying deposition of TiC-Fe powder RPS[J]. Ceramics International, 2003, 29(5): 519?526.

[7] VALENTE T, GALLIANO F P. Corrosion resistance properties of reactive plasma-sprayed titanium composite coatings[J]. Surface and Coatings Technology, 2000, 127(1): 86?92.

[8] 刘长松, 殷 声. 反应热喷涂的发展[J]. 材料保护, 2000, 33(1): 83?85.

LIU Chang-song, YIN Sheng. Advance in reactive thermal spraying[J]. Materials Protection, 2000, 33(1): 83?85.

[9] 黄继华, 刘长松, 党全坤. TiC/Fe-Al复合涂层反应火焰喷涂研究[J]. 粉末冶金技术, 2002, 20(4): 219?222.

HUANG Ji-hua, LIU Chang-song, DANG Quan-kun. A study on reactive flame spraying for TiC/Fe-Al composite coating[J]. Powder Metallurgy Technology, 2002, 20(4): 219?222 .

[10] 刘慧渊, 黄继华, 杨四新, 张建纲. C/Ti原子比对反应火焰喷涂TiCFe复合涂层组织结构和硬度的影响[J]. 复合材料学报, 2005, 22(3): 80?84.

LIU Hui-yuan, HUANG Ji-hua, YANG Si-xin, ZHANG Jian-gang. Influence of C/Ti atomic ratio on microstructure and hardness of TiC/Fe composite coating by reactive flame spray[J]. Acta Materiae Compositae Sinica, 2005, 22(3): 80?84.

[11] 刘慧渊, 黄继华, 魏世忠, 张 华, 赵兴科. 反应火焰喷涂Ti-Ni-C系陶瓷/金属复合涂层[J]. 航空材料学报, 2007, 27(1): 23?24.

LIU Hui-yuan, HUANG Ji-hua, WEI Shi-zhong, ZHANG Hua, ZHAO Xin-ke. Ceramet composite coating synthesized and deposited from Ti-Ni-C system composite powder for reactive flame spray[J]. Journal of Aeronautical Materials, 2007, 27(1): 23?24.

[12] 王君林, 关振中. 一种玻璃碳制备过程的X射线分析[J]. 材料科学与工艺, 1995, 3(4): 39?43.

WANG Jun-lin, GUAN Zhen-zhong. X-rays analysis of the formation of glassy carbon[J]. Materials Science and Technology, 1995, 3(4): 39?43.

[13] JIANG Q C, ZHAO F, WANG H Y, ZHANG Z Q. In situ TiC-reinforced steel composite fabricated via self-propagating high-temperature synthesis of Ni-Ti-C system[J]. Materials Letters, 2005, 59(16): 2043?2047.

[14] 殷 声, 唐 清, 缪曙霞. SHS法制备TiC-Ni和TiC-Ni-Mo硬质合金[J]. 粉末冶金技术, 1993, 11(3): 179?182.

YIN Sheng, TANG Qing, MIAO Su-xia. TiC-Ni and TiC-Ni-Mo hard alloys produced by SHS powder[J]. Powder Metallurgy Technology, 1993, 11(3): 179?182.

[15] 殷 声, 缪曙霞, 廖湘巍. SHS-加压法制备TiC/Ni梯度材料[J]. 北京科技大学学报, 1993, 15(1): 99?103.

YIN Sheng, MIAO Su-xia, LIAO Xiang-wei. Preparation of TiC/Ni functionally gradient materials by SHS-processing[J]. Journal of University of Science and Technology Beijing, 1993, 15(1): 99?103.

[16] GAO M X, PAN Y, OLIVEIRA F J. Interpenetrating microstructure and fracture mechanism of NiAl/TiC composites by pressureless melt infiltration[J]. Materials Letters, 2004, 58(11): 1761?1765.

[17] 王振廷, 陈华辉. 碳化钨颗粒增强金属基复合材料涂层组织及其摩擦磨损性能[J]. 摩擦学学报, 2005, 25(3): 203?206.

WANG Zhen-ting, CHEN Hua-hui. Microstructure and friction and wear behavior of induction clad Ni-based composite coating reinforced with micro- and naro-WC particulates[J]. Tribology, 2005, 25(3): 203?206.

[18] 孙荣禄, 扬贤金. 激光熔覆原位合成TiC-TiB/Ni基金属陶瓷涂层的组织和摩擦磨损性能[J]. 硅酸盐学报, 2003, 31(12): 1221?1224.

SUN Rong-lu, YANG Xian-jin. Microstructure, friction and properties of in situ synthesized TiC-TiB2/Ni-based metallic ceramic coating by laser cladding[J]. Journal of the Chinese Ceramic Society, 2003, 31(12): 1221?1224.

[19] MCCOLM I J. Ceramic hardness[M]. New York: Plenum Press, 1990.

基金项目:哈尔滨工业大学现代焊接生产技术国家重点实验室开放课题资助项目

收稿日期:2008-04-11;修订日期:2008-07-15

通讯作者:黄继华,教授,博士;电话:010-62334859;E-mail: jihuahuang47@sina.com

(编辑 龙怀中)