文章编号:1004-0609(2011)03-0663-06

埋弧堆焊TiC颗粒增强复合涂层的组织与性能

刘均海1, 2, 黄继华1, 刘均波3, 宋桂香4

(1. 北京科技大学 材料科学与工程学院,北京100083; 2. 威海职业学院 机电工程系,威海264210;

3. 潍坊学院 机电工程系,潍坊261041; 4. 威海职业学院 职业技能实训中心,威海264210)

摘 要:以TiFe粉、Cr粉、Ni粉、Fe粉、胶体石墨等为原料,利用合金粉粒埋弧堆焊技术在Q235钢表面原位反应合成TiC颗粒增强Fe基复合涂层。利用SEM,XRD 和EDS等分析了涂层的显微组织,并在室温干滑动磨损条件下测试该涂层的耐磨性能。结果表明:利用合金粉粒埋弧堆焊技术,可以原位合成粒径在2 μm以下、弥散分布的TiC颗粒。涂层组织由TiC颗粒、马氏体和奥氏体构成。涂层平均显微硬度达601HV0.2,约是碳钢基体的3倍。由于TiC颗粒和马氏体的抗磨损性能使涂层具有优异的耐磨性能,因此涂层磨损质量约是基体金属的1/10。埋弧堆焊双层涂层与单层涂层相比,马氏体含量减少,奥氏体和TiC含量增加,耐磨性更好。

关键词:埋弧堆焊;TiC颗粒;涂层;原位合成

中图分类号:TG425 文献标志码:A

Microstructure and performance of submerged-arc weld clad TiC particle reinforced composite coating

LIU Jun-hai1, 2, HUANG Ji-hua1, LIU Jun-bo3, SONG Gui-xiang4

(1. School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Department of Mechanical and Electronic Engineering, Weihai Vocational College, Weihai 264210, China;

3. Department of Mechanical and Electronic Engineering, Weifang University, Weifang 261041, China;

4. Department of Vocational Skills Training Center, Weihai Vocational College, Weihai 264210, China)

Abstract: TiC particle reinforced Fe-based composite coatings were in situ synthesized on the surface of Q235 steel by submerged-arc welding(SAW) using mixture of TiFe, Cr, Ni, Fe and colloidal graphite powers, etc. Microstructures of the coatings were observed by scanning electron microscopy (SEM), the phases in the coatings were determined by X-ray diffractometery (XRD), and the wear resistance of the composite coatings was evaluated under dry sliding wear test conditions at room temperature. The results indicate that the fine TiC particles with diameter less than 2 μm are synthesized by using submerged-arc welding process and distributed in the matrix. The coating consists of TiC particles, martensite and austenite. The microhardness of the coating is 601HV0.2, which is 3 times larger than that of the base material. The wear mass loss of Q235 base material is 10 times more than that of the coating. Compared with the single-layer composite coating, the double composite coating shows better wear resistance due to the increase of austenite and TiC content and the decrease of martensite content.

Key words: submerged-arc welding; TiC; coating layer; in situ synthesis

由于TiC颗粒具备硬度高、熔点高、热稳定性好等特点,可以通过Ti粉或TiFe粉与C反应合成,因此,近年来对制备TiC颗粒增强金属基复合材料的研究成为热点[1-4]。TiC在复合材料中多以微细颗粒析出,呈弥散分布,对基体金属的韧性损害较小。TiC颗粒增强的复合涂层增强了零件的表面强度和综合性能[2]。目前,制备TiC颗粒增强金属基复合涂层的涂层技术主要有:激光熔覆、等离子熔覆、钨极氩弧熔覆和等离子喷涂等[5-13]。在涂层制备技术中,激光熔覆、等离子熔覆设备投资多,工艺复杂,合金粉利用率不高;钨极氩弧熔覆设备投资不高,但制备涂层的工艺复杂,效率低;等离子喷涂和火焰喷涂虽然设备投资少,使用方便,但涂层与基材的结合强度低。药芯焊丝的出现解决了高硬度耐磨材料不能制备焊丝的难题,二氧化碳气体保护焊和埋弧堆焊在制备耐磨涂层方面逐渐成为热点[14]。埋弧焊电弧热量集中,足可以熔化基体与一般陶瓷相形成熔池。熔池被焊剂保护,在加热和反应过程中与空气隔离,避免了合金元素的氧化与烧损,而且操作简单、效率高,堆焊层质量稳定。因为制备药芯焊丝设备投资多,制备工艺要求较高,限制了埋弧堆焊的应用范围。采用合金粉粒埋弧堆焊,可以将特殊功能材料和高硬度耐磨材料颗粒铺在基体上,充分利用埋弧焊的优点,制备出特殊功能的涂层。国内外已经采用这种堆焊工艺制造大面积耐磨合金复合钢板,其堆焊合金采用高铬合金铸铁[15]。目前,关于采用埋弧堆焊技术制备TiC颗粒增强金属基复合涂层的研究尚未见报道。

本文作者将合金粉粒埋弧堆焊技术和原位合成技术相结合,在普通碳钢表面制备无裂纹的原位合成TiC增强复合涂层,探索一种新的涂层制备技术。

1 实验

试样材料由基材、合金粉末和焊丝3部分组成。基材选取Q235碳钢,其化学成分(质量分数)为C≤0.18%,Mn0.35%~0.80%,Si≤0.30%,S≤0.040%和P≤0.040%,试验尺寸为100 mm×200 mm×20 mm。合金粉末材料选取工业TiFe粉、Cr粉、雾化Ni粉、Fe粉和胶体石墨等粉末,其化学成分如表1所示。按照TiFe粉35%、Cr粉35%、Ni粉10%、Fe粉10%、石墨粉10%的比例配置合金粉,并混合均匀。

试验设备选用配有专用埋弧焊小车的美国林肯埋弧焊机DC-1000,堆焊原理如图1所示。在合金粉粒埋弧堆焊时,首先将合金粉粒堆铺在工件上,电弧在焊丝与工件之间燃烧,电弧热将焊丝和电弧区附近的合金粉粒?工件和焊剂熔化,熔池凝固后形成堆焊层?由于相当一部分电弧热消耗在熔化合金粉粒上,所以大大降低了稀释率,提高了堆焊速度?焊丝选用直径为4 mm的H08A普通焊丝,焊剂HJ402的具体成分如表2所列。堆焊工艺参数:工作电流550 A,工作电压33 V,送粉速度11.2 g/s,送丝速度19 mm/s,焊接速度5.6 mm/s。在堆焊多层焊时,堆焊每道焊前均空冷到室温,再按图2所示示意图进行多层堆焊。

图1 合金粉粒填充金属埋弧堆焊示意图

Fig.1 Schematic diagram of deposition by submerged-arc welding adding of alloy powders

采用S-4300型扫描电镜观察试样涂层显微组织,利用Rigaku D/max 2200 PC 自动X射线衍射仪并结合LinkISIS能谱仪对涂层进行物相鉴定;采用Leica VMHT 30M显微硬度计测定涂层沿层深方向的显微硬度分布,载荷19.6 N,加载保持时间20 s。磨损实验在MM200型磨损试验机上进行,将涂层试样采用线切割方法切割成长10 mm、宽10 mm、高10 mm的立方体。选用硬质合金磨环,以Q235钢基材作为标样,

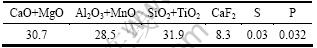

表1 原料粉末的化学成分

Table 1 Chemical compositions of powders for raw materials(mass fraction, %)

圆环转速200 r/min(线速度0.471 m/s),载荷选取392 N,磨损时间选300和900 s。用精度为0.1 mg的分析天平称取试样及标样的磨损质量损失,试验结果均为3个试样的平均值。

表2 埋弧堆焊焊剂的化学成分

Table 2 Chemical compositions of submerged arc welding flux(mass fraction, %)

图2 多层堆焊示意图

Fig.2 Schematic diagram of multiple surface-welding

2 结果与分析

图3所示为埋弧堆焊TiC颗粒增强Fe基复合涂层的宏观形貌。由图3(a)和(b)可见,合金粉粒埋弧堆焊TiC颗粒增强Fe基复合涂层表面光滑、没有裂纹。由图3(c)可见,合金粉粒埋弧堆焊TiC颗粒增强Fe基复合涂层单道焊缝的宽度约为21 mm,焊高为5.77 mm,熔深为3.11 mm。经过图像软件分析计算,焊缝熔合比为58.8%,所配粉末在焊缝中所占比例为15.7%。由图3(d)可见,埋弧堆焊双层涂层是在埋弧堆焊单层涂层基础上又堆焊了一层得到的。

图4所示为采用TiFe-Cr-Ni-C合金粉末在Q235碳钢表面埋弧堆焊制备的复合涂层的XRD谱。由图4可见,涂层的主要组成相为TiC、马氏体和奥氏体。

图5所示为单层、双层合金粉粒埋弧堆焊复合涂层在不同放大倍数下的组织结构。从图5(a)和(b)可以看出,涂层组织结构为典型的胞状结晶结构,大部分胞状晶呈现平行状态,指向涂层表面。由于埋弧堆焊是一种快速加热、快速凝固过程,液态成分变化较大,导致熔池中微区成分分布不均匀,造成熔覆层中晶体生长形态的多样性和凝固组织的多样性。涂层合金的结晶形态受熔池内液相成分和形状因子的影响[16]。形状因子是结晶方向上的温度梯度G与凝固速度R之比G/R。由结合带向熔池内部,温度梯度G逐渐减小形成小的成分过冷区,在液固界面上产生凸起,形成柱

图3 复合涂层的宏观形貌

Fig.3 Macro-morphologies for composite coating layer sections: (a) Single layer; (b) Double layer; (c) Cross-section of single surfacing layer; (d) Cross-section of double layer

状晶;在熔池中部与上部,随着G和G/R的进一步减小,成分过冷更加显著,晶体形成胞状与树枝状的形态,即熔池凝固条件不同,最终形成不同的组织形态。

图5(b)中各点成分能谱分析结果如表3所列。结合图4和表3可知,图5(b)所示涂层组织中A点、B点和C点分别为奥氏体相、马氏体和TiC相。从图5(b)中还可以看出,涂层组织大部分为马氏体、奥氏体和少量TiC颗粒。TiC颗粒不仅存在于奥氏体中,也存

图4 复合涂层的XRD谱

Fig.4 XRD pattern of composite coating

表3 图5(b)中各点成分的能谱分析结果

Table 3 EDS composition test results of points in Fig.5(b)

在于马氏体中。TiC颗粒较为细小,形状较为规则,最大约2 μm,大部分在1 μm左右。

比较图5(a)和(c)及图5(b)和(d)可以得出,双层涂层中的奥氏体、TiC颗粒含量比单层涂层中含量高,马氏体含量正好相反。双层涂层的TiC颗粒尺寸大于单层涂层中的TiC颗粒尺寸。

在埋弧堆焊过程中,电弧在一层较厚的焊剂层下燃烧,部分焊剂在电弧热作用下立即熔化,形成液态熔渣和气泡,包围整个焊接区和液态熔池,隔绝周围的空气,产生了良好的保护作用。同时,Ti和C在熔体中的质量分数达到反应的浓度条件时,即可通过原位反应合成TiC。由于Ti、C原子配比为21:50, 远远超过合成TiC所需的1?1,因此,多余的C原子会溶解在熔体中。

电弧吹力、电磁搅拌等的共同作用可以促进熔体中的Cr、Ni和C趋于均质化。涂层中含有较多的Cr、Ni、C、Ti元素,这些元素能够使C曲线右移,并降低马氏体的转变温度Ms点和Mf点。由于单层涂层中的Cr、Ni、C、Ti元素的含量比双层涂层中Cr、Ni、C、Ti元素的少,因此其对马氏体转变温度Ms和Mf的影响较小。在奥氏体转变为马氏体的过程中,奥氏体通过切变共格机制形成马氏体。由于马氏体转变时体积发生膨胀,对未转变的奥氏体产生压应力,使未转变的奥氏体难以转变为马氏体,因此涂层中产生了

图5 复合涂层显微组织在不同放大倍数下的SEM像

Fig.5 SEM images of microstructures of composite coatings with different magnifications: (a) Single layer with low magnification; (b) Single layer with high magnification; (c) Double layer with low magnification; (d) Double layer with high magnification

表3 图5(b)中各点成分的能谱分析结果

Table 3 EDS composition test results of points in Fig.5(b)

残余奥氏体。另外,Ti与O的亲和力很大,涂层中的Ti是以颗粒氧化物的形式(TiO)弥散分布于涂层中,可以促进涂层金属晶粒细化。由此可见,复合涂层不开裂可能正是因为具有这些组织结构:奥氏体具有良好的塑性和延展性;马氏体转变时体积发生膨胀会减弱涂层因受拉应力开裂的倾向;Ti元素细化涂层金属晶粒,合成少量的硬质相TiC,可提高涂层的韧性,减小涂层开裂倾向。

图6所示为埋弧堆焊TiC颗粒增强Fe基复合涂层熔合区的SEM像。从图6(a)中可以看出,熔合区上侧是马氏体,是埋弧堆焊第一层涂层的组织,下侧则是基体组织;马氏体与基体组织之间无气孔,呈现冶金结合。从图6(b)中可以看出,熔合区上侧是马氏体组织与奥氏体组织,下侧主要是马氏体组织;上侧马氏体组织与下侧马氏体组织在熔合区交织在一起,呈现冶金结合。

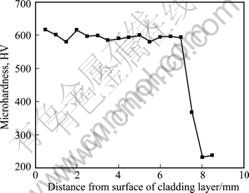

一般来说,零件摩擦时,磨损量与其接触应力、相对速度、润滑条件及摩擦副的材料有关。而材料的耐磨性与材料硬度及显微组织有关。因此,提高涂层的表面硬度是提高材料性能的重要途径。图7所示为涂层沿厚度方向的显微硬度分布。如图7所示,从表面到熔合区的硬度相差不大,显微硬度在575~617HV之间,约是基体金属的3倍。

图8所示磨损试验结果表明,在干滑动磨损试验条件下,涂层的磨损质量损失很小,表明涂层具有良好的耐磨性。特别值得注意的是,随着磨损时间的延长,Q235钢试样的磨损质量损失急剧升高,而涂层的磨损质量损失随磨损时间的延长却变化很小,涂层的磨损质量约是基体金属的1/10。这是因为TiC颗粒和马氏体的抗磨损性大大提高了涂层的抗磨损性能。从磨损试验结果还可以看出,埋弧堆焊双层涂层的耐磨性比单层涂层的耐磨性高,这是因为基体对单层涂层的稀释率比对双层涂层的稀释率更低。

图6 复合涂层熔合区的SEM像

Fig.6 SEM images of fusion zones of composite coatings: (a) Fusion zone between first layer and substrate; (b) Fusion zone between second layer and first layer

图7 涂层沿厚度方向的显微硬度分布

Fig.7 Microhardness(HV) of cladding layer testing along thickness direction

图8 埋弧堆焊涂层和Q235钢磨损质量损失

Fig.8 Wear mass loss as function of time for composite coating as well as Q235 steel

3 结论

1) 采用合金粉粒埋弧堆焊工艺在Q235基体表面原位合成了TiC颗粒增强Fe基复合涂层;无需焊前预热及焊后缓冷,且涂层无裂纹、夹杂、气孔等缺陷。

2) 利用合金粉粒埋弧堆焊技术,可以原位合成粒径在2 μm以下且弥散分布的TiC颗粒。涂层组织由少量TiC颗粒和奥氏体及大量马氏体构成。

3) 涂层平均显微硬度达601HV0.2,约是碳钢基体的3倍。涂层具有良好的耐磨性能,其磨损质量损失约是基体金属的1/10。

4) 埋弧堆焊双层涂层与单层涂层相比,奥氏体和TiC颗粒含量增加,马氏体含量减少,耐磨性增强。

REFERENCES

[1] 刘均海, 黄继华, 宋桂香, 张建纲. TiC/耐热钢钢结硬质合金原位反应合成研究[J]. 粉末冶金技术, 2005, 23(3): 199-203.

LIU Jun-hai, HUANG Ji-hua, SONG Gui-xiang, ZHANG Jian-gang. A study on in situ reactive synthesis of TiC/heat resistant steel-steel bonded carbides[J]. Powder Metallurgy Technology, 2005, 23(3): 199-203.

[2] 孙荣禄, 扬贤金. 激光熔覆原位合成TiC-TiB2/Ni基金属陶瓷涂层的组织和摩擦磨损性能[J]. 硅酸盐学报, 2003, 31(12): 1221-1224.

SUN Rong-lu, YANG Xian-jin. Microstructure, friction and properties of in situ synthesized TiC-TiB2/Ni-based metallic ceramic coating by laser cladding[J]. Journal of the Chinese Ceramic Society, 2003, 31(12): 1221-1224.

[3] 刘慧渊, 黄继华, 魏世忠, 张 华, 赵兴科. 反应火焰喷涂Ti-Ni-C系陶瓷/金属复合涂层[J]. 航空材料学报, 2007, 27(1): 23-24.

LIU Hui-yuan, HUANG Ji-hua, WEI Shi-zhong, ZHANG Hua, ZHAO Xing-ke. Ceramet composite coating synthesized and deposited from Ti-Ni-C system composite powder for reactive flame spray[J]. Journal of Aeronautical Materials, 2007, 27(1): 23-24.

[4] ROBERTA L, ROBERTO O, GIACOMO C. Self-propagating combustion synthesis and plasma spraying deposition of TiC-Fe powder RPS[J]. Ceramics International, 2003, 29(5): 519-526.

[5] TONDU S, SCHNICK T, PAWLOWSKI L. Laser glazing of FeCr-TiC composite coatings[J]. Surface and Coatings Technology, 2000, 123(2/3): 247-251.

[6] CUI Cheng-yun, GUO Zuo-xing, WANG Hong-ying, HU Jian-dong. In situ TiC particles reinforced grey cast iron compostie fabricated by laser cladding of Ni-Ti-C system[J]. Journal of Materials Processing Technology, 2007, 183(2/3): 380-385.

[7] 徐俊龙, 黄继华, 魏世忠, 王海涛, 张 华, 赵兴科. TiC/Fe金属陶瓷复合涂层反应等离子喷涂研究[J]. 稀有金属材料与工程, 2007, 36(3): 688-691.

XU Jun-long, HUANG Ji-hua, WEI Shi-zhong, WANG Hai-tao, ZHANG Hua, ZHAO Xing-ke. Study of TiC/Fe-Ni metal ceramic composite coated by reactive plasma spray[J]. Rare Metal Materials and Engineering, 2007, 36(3): 688-691.

[8] 宋思利, 王新洪, 邹增大, 曲仕尧. 氩弧原位合成TiC颗粒增强Fe基复合层[J]. 焊接学报, 2006, 27(2): 39-42.

SONG Si-li, WANG Xin-hong, ZOU Zeng-da, QU Shi-yao. In situ formation TiC particles reinforced Fe-based alloy composite coating by GTAW[J]. Transactions of the China Welding Institution, 2006, 27(2): 39-42.

[9] LIU Jun-bo, WANG Li-mei, LI Hui-qi. Reactive plasma cladding of TiC/Fe cermet coating using asphalt as a carbonaceous precursor[J]. Applied Surface Science, 2009, 255: 4921-4925.

[10] WANG X H, ZHANG M, LIU X M, QU S Y, ZOU Z D. Microstructure and wear properties of TiC/FeCrBSi surface composite coating prepared by laser cladding[J]. Surface & Coatings Technology, 2008, 202: 3600-3606.

[11] 朱警雷, 黄继华, 王海涛, 张 华, 赵兴科. 反应等离子喷涂TiC/Fe-Ni金属陶瓷复合涂层的显微组织[J].中国有色金属学报, 2008, 18(1): 36-41.

ZHU Jing-lei, HUANG Ji-hua, WANG Hai-tao, ZHANG Huan, ZHAO Xing-ke. Microstructures of TiC/Fe-Ni metal ceramic composite coatings by reactive plasma spray[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(1): 36-41.

[12] 吴玉萍, 林萍华, 王泽华. 等离子熔覆原位合成TiC陶瓷颗粒增强复合涂层的组织与性能[J]. 中国有色金属学报, 2004, 14(8): 1335-1339.

WU Yu-ping, LIN Ping-hua, WANG Ze-hua. Microstructure and properties of in-situ synthesis of TiC particle reinforced composite coating by plasma cladding[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(8): 1335-1339.

[13] TAKAMURA S, HAYASHI K, OHNO N. Static and dynamic erosion behavior of TiC coated graphite in high heat flux plasma[J]. Journal of Nuclear Materials, 1998, 258(10): 961-966.

[14] 倪雪辉, 张清辉, 任立臣, 龚建勋. 埋弧堆焊药芯焊丝的研制[J]. 热加工工艺, 2008, 37(23): 84-86.

NI Xue-hui, ZHANG Qing-hui, REN Li-chen, GONG Jian-xun. Research on flux-cored wire for submerged overlaying[J]. Hot Working Technology, 2008, 37(23): 84-86.

[15] 李亚江, 张永喜, 王 娟. 焊接修复技术[M]. 北京: 化学工业出版社, 2008: 134-171.

LI Ya-jiang, ZHANG Yong-xi, WANG Juan. Welding repair technology[M]. Beijing: Chemical Industry Press, 2008: 134-171.

[16] 王新林, 石世宏. 激光熔覆层凝固特征与凝固组织控制研究[J]. 应用激光, 2001, 20(3): 164-166.

WANG Xin-lin, SHI Shi-hong. Study on solidification feature and the solidification microstructure control of laser cladding layer[J]. Applied Laser, 2001, 20(3): 164-166.

(编辑 何学锋)

基金项目:山东省科技攻关项目(2007GG30003003)

收稿日期:2010-03-09;修订日期:2010-03-30

通信作者:宋桂香,讲师,硕士;电话:0631-5700479;E-mail: junhailiu@sina.com