石墨含量对石墨/TiC/镍基合金复合涂层微观组织与摩擦学性能的影响

来源期刊:中国有色金属学报(英文版)2011年第8期

论文作者:蔡滨 谭业发 屠义强 王小龙 徐婷

文章页码:1741 - 1749

关键词:碳化钛;石墨;镍基合金;等离子喷涂;复合涂层;摩擦磨损

Key words:TiC; graphite; Ni-base alloy; plasma spray; composite coating; friction and wear

摘 要:

为了降低TiC/镍基合金复合涂层的摩擦因数并增强其耐磨性能,运用等离子喷涂技术在45#钢表面制备石墨/TiC/镍基合金(GTN)复合涂层。研究石墨含量对GTN涂层组织和摩擦学性能的影响。结果表明,石墨的加入有效地降低了涂层的摩擦因数,提高了其耐磨性。6.56GTN涂层和12.71GTN涂层分别在低载荷与高载荷摩擦条件下呈现出优异的减摩耐磨性能。在低载荷条件下,GTN涂层的磨损机理主要表现为多次塑变磨损,伴有轻微的磨粒磨损,且随着石墨含量的增加逐渐转变为多次塑变、层脱和微切削磨损;在载荷增加后,脆性断裂、微观切削和粘着为其主要的磨损机理,且随着石墨含量的增加逐渐转变为微观切削和脆性剥落。

Abstract:

In order to reduce the friction coefficients and further improve the anti-wear properties of Ni-base alloy coatings reinforced by TiC particles, graphite/TiC/Ni-base alloy (GTN) coatings were prepared on the surface of 45 carbon steel. The effects of graphite content on the microstructure and tribological properties of the GTN coatings were investigated. The results show that the addition of graphite to the GTN coatings may greatly reduce the friction coefficients and improve their wear resistance. The 6.56GTN and 12.71GTN coatings exhibit excellent integrated properties of anti-friction and wear resistance under low and high loads, respectively. Under a low load, the wear mechanisms of the GTN coatings are mainly multi-plastic deformation with slight abrasive wear and gradually change into mixture of multi-plastic deformation, delamination and micro-cutting wear with the increase of graphite fraction. As the load increases, the main wear mechanisms gradually change from micro-cracks, micro-cutting and adhesive wear to micro-cutting and micro-fracture with the increase of graphite fraction.

CAI Bin, TAN Ye-fa, TU Yi-qiang, WANG Xiao-long, XU Ting

Department of Mechanical Engineering, PLA University of Science and Technology, Nanjing 210007, China

Received 13 September 2010; accepted 20 December 2010

Abstract: In order to reduce the friction coefficients and further improve the anti-wear properties of Ni-base alloy coatings reinforced by TiC particles, graphite/TiC/Ni-base alloy (GTN) coatings were prepared on the surface of 45 carbon steel. The effects of graphite content on the microstructure and tribological properties of the GTN coatings were investigated. The results show that the addition of graphite to the GTN coatings may greatly reduce the friction coefficients and improve their wear resistance. The 6.56GTN and 12.71GTN coatings exhibit excellent integrated properties of anti-friction and wear resistance under low and high loads, respectively. Under a low load, the wear mechanisms of the GTN coatings are mainly multi-plastic deformation with slight abrasive wear and gradually change into mixture of multi-plastic deformation, delamination and micro-cutting wear with the increase of graphite fraction. As the load increases, the main wear mechanisms gradually change from micro-cracks, micro-cutting and adhesive wear to micro-cutting and micro-fracture with the increase of graphite fraction.

Key words: TiC; graphite; Ni-base alloy; plasma spray; composite coating; friction and wear

1 Introduction

With rapid development of modern technology, high requirements on the service life and reliability of parts used in machinery are put forward and become increasing urgent. So it is an important pursuing aim to prolong the service life and economize energy and materials by providing machine parts with excellent tribological performance. As important surface strengthening materials, Ni-base alloy coatings have been successfully applied to machine parts in mechanical engineering because of their excellent properties such as high hardness, high bonding strength, anti-wear and corrosion resistance [1-4]. In order to further improve the wear resistance of Ni-base alloy coatings, a series of Ni-base alloy composite coatings reinforced by hard ceramic particles, such as WC [5], SiC [6], TiC [7], B4C [8] and Cr3C2 [9], were prepared by different kinds of surface technologies and their wear properties were researched. For example, the wear resistance of Ni-base alloy coatings reinforced by 61.6% WC was increased by 2 times [5]. But these particle-reinforced coatings usually exhibit high friction coefficients under the condition of high contact stress and no liquid lubrication, which results in large consume of energy. Thus, it becomes an important problem to decrease the friction coefficients of Ni-base alloy coatings reinforced by the second hard phases and further improve their wear resistance.

One of the effective methods to reduce the friction coefficients of coatings is to add solid lubricant particles such as graphite and MoS2 to the matrix [10]. Previous studies showed that a solid lubricant film might form on the worn surface to reduce friction coefficient due to the lamellar structure and softness of these solid lubricant materials [11-13]. NIE et al [11] prepared graphite/oxide composite coatings by electrolytic plasma process, and the friction coefficients of the coatings could be reduced to 0.22. However, most researches mainly focused on adding single solid lubricant particles to Ni-base alloy and there is few report on incorporating both solid lubricant particles and the second hard phases at the same time by thermal spray technology to reduce the friction coefficients and improve the wear resistance of Ni-base alloy coatings. Therefore, in this work, Ni-base alloy coatings incorporated with both TiC and graphite particles (graphite/TiC/Ni-base alloy) were prepared on the surface of 45 carbon steel by plasma spray technology. The effects of graphite content on the tribological properties of the composite coatings were investigated under dry sliding friction conditions to provide experimental proofs and instructions for the composite coatings in engineering application.

2 Experimental

2.1 Specimen preparation

The spray composite materials of graphite/TiC/ Ni-base alloy (abbreviated by GTN) were composed of Ni-base alloy powders, TiC wrapped by nickel powders and graphite wrapped by nickel powders. The chemical composition of the Ni-base alloy powders with size ranging from 55 to 128 μm was 15.5% Cr, 3% B, 4% Si, 14% Fe, 0.75% C and balance Ni (mass fraction). The TiC wrapped by nickel powders with the size ranging from 22 to 36 μm contained 35.45% nickel and the graphite wrapped by nickel powders with size ranging from 75 to 128 μm contained 75% nickel. In order to investigate the effects of graphite content on the microstructure and tribological properties of GTN composite coatings, some typical composite coatings with different graphite fractions were prepared by plasma spray technology, as shown in Table 1.

Table 1 Composition of GTN composite coatings (Volume fraction, %)

45 carbon steel was chosen as the substrate, which was treated by degreasing and rust cleaning. The spray composite materials of GTN were sprayed on the surface of 45 carbon steel by plasma spray. The spray technological parameters were electric current of 600 A, voltage of 40 V and spray distance of 80 mm. The specimens were discs with dimensions of d 60 mm×7 mm, in which the thickness of the GTN coatings was 500 μm and the surface roughness was 0.5 μm after grounding by diamond wheel.

2.2 Tribological tests

Tribological tests were carried out in an HT-500 ball-on-disc tribometer at room temperature. The upper specimen was a Si3N4 ball with diameter of 4 mm, surface roughness of 0.05 μm and hardness of HV1500. The lower one was the GTN composite coatings. The Si3N4 ball slid against the GTN coatings under dry sliding friction condition at speed of 0.1 m/s under different normal loads of 6, 8, 10 and 12 N, respectively. The wear loss of the specimen was measured by the balance of TG328A with the accuracy of 0.1 mg.

2.3 Surface analysis

The hardness of the GTN composite coatings was measured by a DHV-1000 micro-hardness tester. The microstructure and worn surfaces of the GTN composite coatings were observed by a QUANTA200 scanning electronic microscope (SEM). The chemical compositions of the worn surface and wear debris were respectively tested on an energy-dispersive X-ray spectroscope (EDX) attached to the SEM.

3 Results and discussion

3.1 Microstructure and micro-hardness of GTN composite coatings

The microstructure of 0GTN coating is shown in Fig. 1(a). It is found that the coating is in a dense structure state and there are some grey areas (marked by A). EDX spectrum of area A is shown in Fig. 1(b). It indicates that the grey structure is mainly composed of TiC. The molar ratio of C to Ti is 3?5, for TiC particles were partially dissolved into melted Ni-base alloy in spray process and developed into a mixed structure of MCx, in which x changes from 0.5 to 1 [14]. The melted TiC particles might precipitate with some elements from the Ni-base alloy, which accounts for the existence of Ni and Cr elements in the grey structure. Figure 1(c) shows the EDX spectrum of area B in the grayish structure of the coating. It is evident that the main part of the grayish structure is the matrix of Ni-base alloy. The existence of 2.63% Ti in area B means that Ti diffused into the Ni-base alloy in spray process. So, it can be inferred that the metallurgical bond was developed between TiC and Ni-base alloy because of the diffusion.

The microstructure of the composite coatings is dramatically changed after the addition of graphite to GTN. The microstructure of 12.71GTN coating is shown in Fig. 2(a), there are three typical areas, i.e. the grayish area, the grey area and the black area. The grayish structure is the matrix of Ni-base alloy. Figure 2(b) shows the EDX spectrum of area A and it consists of 100% C in this area, indicating that the black structure is graphite. Graphite would not react with other element in the spray process because it is wrapped by nickel. So it can exhibit lubrication effect and reduce friction coefficient in the friction process. EDX spectrum of area B indicates that it is composed of TiC and a little Ni (Fig. 2(c)). The dispersion of TiC particles in the matrix of Ni-base alloy may greatly improve the wear resistance of the composite coatings.

Fig. 1 SEM image (a) and EDX spectra (b, c) of 0GTN coating

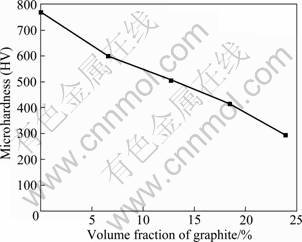

The microhardness of the composite coatings with the change of graphite fraction is shown in Fig.3. It is found that the microhardness decreases with the increase of graphite fraction. The microhardness of 0GTN coating is the highest (HV769.8) among all the coatings and that of 23.90 GTN coating is the least (HV 293.3). Because graphite is soft and may be easily deformed under contact stress, the higher the fraction of graphite in the composite coatings is, the lower the capability of anti-plastic deformation is, which results in the smaller microhardness of the composite coatings.

Fig. 2 SEM image (a) and EDX spectra (b, c) of 12.71GTN coating

3.2 Tribology

3.2.1 Tribology of GTN composite coatings

The friction and wear results of the GTN composite coatings are shown in Fig.4. It is found that the addition of graphite to the coatings greatly reduces the friction coefficients and improves their wear resistance. For example, the friction coefficient of 0GTN coating is in the range of 0.35-0.44 and the wear loss changes from 2.9 to 6.4 mg, which are much larger than those of other composite coatings with graphite. The friction coefficient of 6.56GTN coating is about 44% lower than that of 0GTN coating. The changing trend of friction coefficients with graphite fraction is shown in Fig. 4(a). But as the graphite fraction in GTN coatings further increases, the decreasing trend of friction coefficients becomes slow. The friction coefficient of GTN coatings reaches the minimum when the volume fraction of graphite is 18.47%. As the load changes from 6 to 12 N, the friction coefficient of 18.47GTN coating remains the minimum range of 0.14-0.25, which is reduced by 54% than that of the 0GTN coating.

Fig. 3 Microhardness of composite coatings vs volume fraction of graphite

Fig. 4 Friction coefficient (a) and wear loss (b) of composite coatings vs volume fraction of graphite under different loads

Compared with the composite coatings with no graphite (0GTN), the wear loss of the GTN composite coatings decreases in great margin, as shown in Fig. 4(b). For example, under friction conditions with loads of 6 and 8 N, the wear loss of 6.56GTN coating reaches the minimum, which are 1.3 and 1.8 mg and 55% and 60% lower than those of the 0GTN coating, respectively. If the loads increase to 10 and 12 N, the wear losses of the 12.71GTN coating are the lowest (3 and 2.7 mg), and they are 53% and 45% lower than those of the 0GTN coating, respectively. If the volume fraction of graphite in the GTN composite coatings increases to 18.47%-23.90%, the wear loss increases, which means that the wear resistance of the GTN composite coatings will be deteriorated if the graphite fraction exceeds a certain value.

In summary, the addition of graphite to the GTN composite coatings may greatly reduce the friction coefficients and improve the wear resistance. Under low load friction conditions (load≤8 N), the 6.56GTN coating presents better integrated property of anti-friction and wear resistance than other GTN composite coatings, and the friction coefficients and wear losses are respectively reduced by 44% and 58% than those of 0GTN coating. At high loads (load≥10 N), the anti-friction properties and wear resistance of GTN composite coating with 12.71% graphite exhibits excellent integrated tribological property, and the friction coefficients and wear losses of 12.71GTN coating are respectively 39% and 50% lower than those of the 0GTN coating.

3.2.2 Effects of graphite fraction on tribological properties of GTN coatings under low load friction conditions

Under low load (6 N) friction conditions, the SEM images of the worn surfaces of 0GTN and 6.56GTN coatings are shown in Fig. 5. As shown in Fig. 5(a), the worn surface of the 0GTN coating is accidented and there are many slight ploughing traces, some pits and micro-fracture areas. The ploughing traces indicate that the coating material suffered from micro-cutting by the counterpart of Si3N4 ball under dry sliding friction condition because Si3N4 ball with hardness of HV 1500 is harder than 0GTN coating with hardness of HV 769.8. Meanwhile, with the proceeding of the repeat scratching actions occurred on the coating surface, the coating materials suffer from multi-plastic deformation, which results in the decrease of toughness and capability of plastic deformation. So the surface of materials would be worn out by multi-plastic deformation wear and brittle fracture, which also accounts for the formation of the micro-fracture areas and pits on the worn surface.

Fig. 5 SEM images of worn surfaces of GTN coatings and EDX spectra of typical areas at 6 N: (a) SEM image of 0GTN; (b) SEM image of 6.56GTN; (c) SEM image of 12.71GTN; (d) SEM image of 18.47GTN; (e) EDX spectrum of area A; (f) EDX spectrum of area B

Figure 5(b) shows the worn surface morphology of 6.56GTN coating. It can be seen that the worn surface is relatively flat accompanied with many slight multi-plastic deformation and adhesive traces, as shown in the grey areas marked by A. Meanwhile, there are some white protruding areas marked by B, which exhibit the shape of floccule on the worn surface. It can be inferred that the main wear mechanisms of the 6.56GTN coating are multi-plastic wear accompanied with adhesive wear.

The two typical areas of 6.56GTN coating marked by A and B in Fig. 5(b) were analyzed by EDX, respectively. Compared with the chemical elements in the Ni-base alloy matrix of 0GTN coating shown in Fig. 1(c), it is concluded that the grey area is mainly the matrix of Ni-base alloy. In addition, 4.46% element O is detected indicating that the oxidation reaction has taken place because of friction heat in the friction process. The fraction of element C is 2 times that in the matrix of Ni-base alloy with 0GTN coating, which indicates that graphite exists on the surface of grey area. Graphite might be squeezed out to the friction surface of the 6.56GTN coating under high contacting stress in the sliding friction process. Because graphite is in the lamellar structure, in which C atoms combine in covalent bonds and the layers combine in molecule bonds, slip may easily occur under the action of frictional shearing strength. Because of the solid lubrication effect of graphite, the friction coefficient and wear loss of 6.56GTN coating decrease compared with those of 0GTN coating.

As shown in Figs. 5(e) and (f), the content of Ti in area A is about 5 times that in area B, indicating a large amount of TiC phases distributed in these protruding areas. In fact, these areas are resulted from the accumulation of a great deal of wear debris with abundant TiC phases adhered to the worn surface of the GTN composite coatings. During the friction process, more and more debris come together and lead to a larger proportion of these kinds of areas on the worn surface. So when the GTN composite coatings are worn against Si3N4 ball, these protruding areas become the main contacting areas and protect the GTN composite coatings from further wearing out. As a result, the wear loss of 6.56GTN coating is much less than that of 0GTN coating. Also, severe adhesion induces high flash temperature on the tribo-interface, which results in aggressive oxidation of metal materials in the areas. So the content of element O in area B is about 6 times that in area A.

As the volume fraction of graphite increases to 12.71%, the worn surface of the coating is shown in Fig. 5(c). It is found that the worn surface of 12.71GTN coating is smoother and fewer adhesive spalling pits are seen compared with the 6.56GTN coating (Fig. 5(b)), but there are some plastic furrows and micro-cracks as well as fracture traces. The plastic furrows in curve shape indicate that more severe non-uniform plastic deformation has taken place. The micro-cracks and the fracture traces indicate more micro-fracture wear on the surface of 12.71GTN coating, which also leads to more wear mass loss of the 12.71GTN coating than the 6.56GTN coating. So the main wear mechanisms of the 12.71GTN coating are multi-plastic wear and micro-fracture wear under low load friction condition.

The worn surface of 18.47GTN coating is shown in Fig. 5(d). It can be found that there are many micro-ploughing grooves, micro-cracks, fracture traces and some plastic deformation areas on the worn surface. So the main wear mechanisms of 18.47GTN coating are the mixture of micro-cutting, multi-plastic deformation wear and micro-crack wear at low load friction condition.

3.2.3 Effects of graphite fraction on tribological properties of GTN coatings under high load friction conditions

When the load increases to 12 N, the worn surface morphology and wear debris as well as EDX spectra of debris of the 0GTN and 6.56GTN coatings are shown in Fig. 6. It can be seen that the worn surface of the 0GTN coating becomes very accidented and there are many pits and ploughing traces as well as micro-cracks on the surface (Fig. 6(a)). The microstructure of wear debris is shown in Fig. 6(b), containing mainly different sizes of slices and blocks. The elements of C, Si, Ti, Cr, Fe and Ni in the wear debris are from the 0GTN coating material, while the existence of element N in the tribo-counterpart of Si3N4 balls indicates that there is also some wear debris of Si3N4. The element O in the debris is 29.43%, indicating severe friction heat occurring and inducing adhesion and oxidation of the coating material, which resulted in the high friction coefficient (0.40) and large wear loss. The slices are mainly developed as a result of micro-cutting by the counterpart of Si3N4 ball in the friction process. In addition, with the increase of normal load, the contact stress of the GTN/Si3N4 tribo-couple increases and leads to serious micro-cracks on the surface of 0GTN coating, which results in the micro-fracture of the coating material and the formation of block debris. So the main wear mechanisms of the 0GTN coating are micro-cutting, micro-fracture accompanied with adhesive wear under high load of friction condition.

Compared with 0GTN coating, the worn surface of the 6.56TN coating is relatively flat and there are a small number of pits with small size on the worn surface (Fig. 6(d)). The wear debris is much smaller in size and mainly includes grainy blocks and a few slices, as shown in Fig. 6(e). The decrease in number and size of slices indicates the reduction of micro-cutting wear of the coating material. According to the tribological test result (Fig. 4(a)), the friction coefficient is 0.27 when the 6.56GTN coating is worn against Si3N4 ball under the load of 12 N, which illustrates the addition of 0.56% (volume fraction) graphite in the coating material greatly reduces the friction coefficient. The EDX result of the wear debris is shown in Fig. 6(f). It is found that the fraction of element O decreases by 40% compared with 0GTN coating, indicating that the oxidation of the coating materials resulted from high friction heat is greatly reduced. So the frictional intensity and adhesion on the interface between the 6.56GTN coating and Si3N4 ball are greatly alleviated because of the lubrication effect of graphite, which also decreases the friction coefficient of 6.56GTN/Si3N4 tribo-couple. The reduction of friction coefficient decreases the shear stress on the frictional surface of 6.56GTN coating, then improves the critical stress (σm) of plastic deformation [15]. It suggests that the generation of fatigue micro-fracture and delamination would be reduced. Therefore, the wear loss of 6.56GTN coating is lower than that of 0GTN coating under high load (12 N) frictional condition.

Fig. 6 Worn surfaces and wear debris of 0GTN and 6.56GTN coatings and EDX spectra of debris at 12 N: (a) Worn surface of 0GTN; (b) Wear debris of 0GTN; (c) EDX spectrum of wear debris of 0GTN; (d) Worn surface of 6.56GTN; (e) Wear debris of 6.56GTN; (f) EDX spectrum of wear debris of 6.56GTN

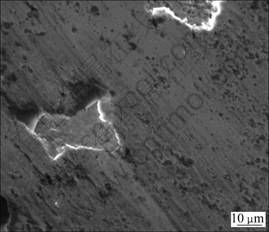

Figure 7 shows that the worn surface of the 12.71GTN coating exhibits many ploughing traces and spalling areas as well as micro-cutting debris. The increase of graphite fraction induces more effective lubrication and reduces adhesive wear. It can be inferred that the wear mechanisms of the 12.71GTN coating are micro-cutting wear accompanied with fatigue delamination under high load friction condition. Compared with the 6.56GTN coating, the low friction coefficient of 12.71GTN coating decreases the fatigue delamination on the worn surface. So the wear loss of 12.71GTN coating is less than that of 6.56GTN coating.

Fig. 7 Worn surface morphology of 12.71GTN at 12 N

The worn surface morphology and wear debris with its EDX spectrum of the 18.47GTN coating are shown in Fig. 8. It is found that there are many micro-cutting and fracture traces on the worn surface (Fig. 8(a)). The SEM image of wear debris (Fig. 8(b)) shows that the debris is composed of many small slices and some big blocks. So it can be inferred that the main wear mechanisms of 18.47GTN coating are micro-cutting accompanied with brittle fracture wear under high load frictional condition. The EDX spectrum of the debris shows that the mass fraction of element C is 21.71%, which is nearly 2.4 times that in the debris of the 0GTN coating (Fig. 8(c)). Because of the high graphite fraction in the coating, the graphite-rich transferred layer which is mainly composed of wear debris may develop and cover the worn surface of 18.47GTN coating well, so the fiction coefficient further decreases due to the effective lubrication of graphite. But the increasing graphite content may bring about the coating surface material to generate severe multi-plastic deformation and then result in serious brittle fractures. Also, more pits may be developed because of the squeezing out of graphite phases from coating material. Therefore, under high load frictional condition, although the friction coefficient may be greatly reduced, the wear loss of the GTN composite coatings with too high graphite fraction increases.

Fig. 8 Worn surface (a), wear debris (b) of 18.47GTN coating and EDX spectrum (c) of wear debris at 12 N

4 Conclusions

1) The microstructure of the GTN composite coatings is dense, in which TiC and graphite particles are dispersed uniformly in Ni-base alloy matrix. The microhardness of the GTN composite coatings decreases with the increase of graphite fraction.

2) The addition of proper graphite to the TiC/ Ni-base alloy composite coatings may greatly decrease the friction coefficients and improve their wear resistance. The 6.56GTN coating and 12.71GTN coating all exhibit excellent integrated property of anti-friction and wear resistance under low load (≤8 N) and high load (≥10 N) friction conditions.

3) Under low load friction conditions (load≤8 N), the wear mechanisms of the GTN composite coatings are mainly multi-plastic wear with slight abrasive wear, and with the increase of graphite, fraction gradually changes into mixture of multi-plastic deformation wear and delamination accompanied with micro-cutting wear. As the load increases (≥10 N), the main wear mechanisms of the GTN composite coatings gradually change from micro-cracks, micro-cutting wear and adhesive wear to micro-cutting wear and micro-fracture with the increase of graphite fraction.

References

[1] KIM SEON JIN, KIM JUN KI. Effects of temperature and contact stress on the sliding wear of Ni-base Deloro 50 hardfacing alloy [J]. Journal of Nuclear Materials, 2001, 288(2-3): 163-169.

[2] CHUANG Y C, LEE S C, LIN H C. Effect of temperature on the sliding wear behavior of laser surface alloyed Ni-base on Al-Mg-Si alloy [J]. Applied Surface Science, 2006, 253(3): 1404-1410.

[3] SAIJADI S A, ZEBARJAD S M, GUTHRIE R I L, ISAC M.Microstructure evolution of high-performance Ni-base superalloy GTD-111 with heat treatment parameters [J]. Journal of Materials Processing Technology, 2006, 175(1-3): 376-381.

[4] YUAN Xiao-min, SI Song-hua, HE Yi-zhu.Microstructure and corrosion wear performance of alloy layers of oxy-acetylene flame and plasma arc spraying welding [J]. Journal of Chinese Society for Corrosion and Protection, 2003, 23(5): 307-311. (in Chinese)

[5] MIRANDA J C, RAMALHO A. Abrasion resistance of thermal sprayed composite coatings with a nickel alloy matrix and a WC hard phase [J]. Tribology Letters, 2001, 11(1): 37-48.

[6] LI Q, SONG G M, ZHANG Y Z. Microstructure and dry sliding wear behavior of laser clad Ni-based alloy coating with the addition of SiC [J]. Wear, 2003, 254: 222-229.

[7] QI X, EIGEN N, AUST E, GARTNER F, KLASSEN T, BORMANN R. Two body abrasive wear of nano- and microcrystalline TiC-Ni-based thermal spray coatings [J]. Surface and Coatings Technology, 2006, 200(16-17): 5037-5047.

[8] NABEEN K S, MIHO K, TETSUO S. Co-deposition of B4C particles and nickel under the influence of a redox-active surfactant and anti-wear property of the coatings [J]. Surface and Coatings Technology, 2005, 200(7): 2414-2419.

[9] HOU Qing-yu, HE Yi-zhu, GAO Jia-sheng. Microstructure and wear resistance of Cr3C2/Ni composite coating deposited by plasma transferred arc surfacing [J]. Materials for Mechanical Engineering, 2007, 31(2): 53-56. (in Chinese)

[10] PAN Jiao-liang, WANG Yin-zhen, LI Fang-po, GAO Hai-jun. Effect of MoS2 coated with nickel on tribological properties of Ni-based coating [J]. Tribology, 2008, 28(3): 225-229. (in Chinese)

[11] NIE X, WANG L, KONCA E, ALPAS A T. Tribological behaviour of oxide/graphite composite coatings deposited using electrolytic plasma process [J]. Surface and Coatings Technology, 2004, 188-189(6): 207-213.

[12] JIA Jun-hong, CHEN Jian-min, ZHOU Hui-di, WANG Jing-bo, ZHOU Hua. Friction and wear properties of bronze-graphite composite under water lubrication [J]. Tribology International, 2004, 37(5): 423-429.

[13] WANG Hai-dou, XU Bin-shi, LIU Jia-jun, ZHUANG Da-ming, WEI Shi-cheng, JIN Guo.The iron sulfide coatings prepared by plasma spraying and their friction-reduction performance [J]. Surface and Coatings Technology, 2007, 201(9-11): 5286-5289.

[14] LI Q, LEI T C, CHEN W Z. Microstructural characterization of laser-clad TiCp-reinforced Ni-Cr-B-Si-C composite coatings on steel [J]. Surface and Coatings Technology, 1999, 144: 278-284.

[15] BHUSHAN B. Introduction to tribology [M]. GE Shi-rong. Beijing: China Machine Press, 2007. (in Chinese)

蔡 滨, 谭业发, 屠义强, 王小龙, 徐 婷

解放军理工大学 机械装备系,南京 210007

摘 要:为了降低TiC/镍基合金复合涂层的摩擦因数并增强其耐磨性能,运用等离子喷涂技术在45#钢表面制备石墨/TiC/镍基合金(GTN)复合涂层。研究石墨含量对GTN涂层组织和摩擦学性能的影响。结果表明,石墨的加入有效地降低了涂层的摩擦因数,提高了其耐磨性。6.56GTN涂层和12.71GTN涂层分别在低载荷与高载荷摩擦条件下呈现出优异的减摩耐磨性能。在低载荷条件下,GTN涂层的磨损机理主要表现为多次塑变磨损,伴有轻微的磨粒磨损,且随着石墨含量的增加逐渐转变为多次塑变、层脱和微切削磨损;在载荷增加后,脆性断裂、微观切削和粘着为其主要的磨损机理,且随着石墨含量的增加逐渐转变为微观切削和脆性剥落。

关键词:碳化钛;石墨;镍基合金;等离子喷涂;复合涂层;摩擦磨损

(Edited by FANG Jing-hua)

Corresponding author: CAI Bin; Tel: +86-25-80821174; E-mail: benjamincb1985@163.com

DOI: 10.1016/S1003-6326(11)60924-2