DOI:10.19476/j.ysxb.1004.0609.2017.06.013

球磨对TiC颗粒增强高速钢复合材料显微组织与性能的影响

彭文静1,陈国强2,周建宇1

(1. 湖南工程学院 工程训练中心,湘潭 411101;

2. 湖南工程学院 机械工程学院,湘潭 411101)

摘 要:研究TiC颗粒与钢基混合粉在高能球磨过程中的显微组织与性能,分析在球磨过程中,粉末颗粒的形貌变化与粒度分布规律,明晰球磨时间对烧结合金致密度、显微组织和力学性能的影响。结果表明:当球磨时间从0 h增加到30 h时,粉末颗粒发生变形破碎,粉末粒度快速降低;当球磨时间进一步增加到40 h时,粉末颗粒间的焊合破碎作用达到平衡,此时,粉末粒度变化趋于平缓,粉末形貌由最初的球形大颗粒变化为细小的层片状。当球磨时间继续增加时,粉末形貌不再有明显变化。烧结合金的致密度、显微组织和力学性能也呈现出相似的变化规律。复合材料的最佳球磨时间为40 h。

关键词:高能球磨;TiC颗粒;高速钢;复合材料

文章编号:1004-0609(2017)-06-1169-07 中图分类号:TG148 文献标志码:A

TiC颗粒具有低密度、高熔点、高硬度等良好的物理性能以及优异的力学性能[1-6],已作为高速钢的增强相得到了广泛应用。高速钢中含有一定比例的TiC硬质相颗粒可以提高基体的耐磨性以及耐高温性能,从而有效拓宽高速钢的应用市场,为高速钢的发展起到极大地促进作用[7-10]。当前,该材料已逐渐成为许多工业部门和新技术领域中不可缺少的工具材料和结构材料。目前,颗粒增强高速钢复合材料的制备方法很多,应用比较广泛的主要有铸造法、热压法和粉末冶金法等[11-15],采用铸造法制备的复合材料,由于基体与颗粒间密度的差别易造成硬质相偏聚,降低材料的力学性能;应用热压法制备的复合材料易造成基体粘结相流失,同时,生产效率低,生产成本较高,对于工业化生产十分不利;粉末冶金法由于其工艺简单,操作便利,生产效率高,目前在颗粒增强高速钢领域已经逐渐受到人们的关注[16-18]。然而,现有的研究主要集中在粉末的烧结领域,龙坚战等[19]开发了一种新型TiC基钢结硬质合金,并研究了合金的烧结性、相种类及硬度的变化规律;BAI等[20-21]对TiC增强钢基复合材料做了系统的论述,表明TiC颗粒是一种热力学上的理想颗粒增强物;TORRALBA等[22]研究了TiC增强M2和T15粉末高速钢的液相烧结性能。对于粉末的前处理阶段,即TiC颗粒增强高速钢的高能球磨方法还鲜有报道,而高性能球磨对后续产品的性能将产生举足轻重的作用[18],因此,本文作者在前人研究的基础上,合理设计复合材料的成分组成,研究球磨工艺对TiC颗粒和高速钢粉末形貌、粒度组成、复合材料致密度和力学性能的影响机理,为制备性能优异的TiC颗粒增强高速钢复合材料提供了坚实的基础。

1 实验

1.1 原料及试样制备

实验用原材料为气雾化法制备的M3/2钢粉(粒径小于124 μm),化学成分如表1所列;TiC粉粒径约为10 μm,纯度大于99.5%。按照TiC颗粒含量为6%进行配料。

表1 M3/2成分组成

Table 1 Components of M3/2 (mass fraction, %)

合金试样的制备流程为:配料→球磨→干燥→擦筛→压制→烧结(1400 ℃)。球磨过程中加入2%的石蜡,0.2%的硬脂酸锌作为成型剂。球磨在XQM型行星式球磨机上进行,球磨时采用d 10 mm和d 4 mm的硬质合金球为磨球,其大小球的质量比为10:1,球料比为10:1,球磨机转速为250 r/min;混合好的粉末在800 MPa的压力下压制成d 20 mm×40 mm的压坯。烧结采用真空烧结炉,烧结工艺为以10 ℃/min的升温速率从室温升温至1100 ℃保温0.5 h,之后以7 ℃/min的升温速率升温至1400 ℃保温1 h,随炉冷至室温取出。

1.2 分析与测试

本实验采用Mastersizer激光衍射粒度分析仪对制得的样品进行粒度分析;根据阿基米德原理测定复合材料的密度;利用HV-10B型小载荷维氏硬度计测定材料的硬度,其加载载荷为3 kg;拉伸试样按照国标GB/T 228-2002设计,厚度为2 mm,拉伸速率为1 mm/min;采用Quanta 200 型环境扫描电镜以及EDAX 能谱仪观察与分析材料的微观组织。

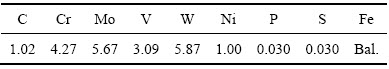

图1 不同球磨时间下粉末的微观形貌

Fig. 1 Morphologies of powders at different ball milling time

2 结果与分析

2.1 球磨时间对混合粉形貌、粒度的影响

图1所示为经过不同时间的高能球磨后,混合粉末颗粒的微观形貌。其中图1(a)所示为未经过球磨的初始混合粉形貌,从图1(a)可以看出,粉末颗粒圆形度较好,TiC颗粒均匀分布在钢粉颗粒表面;经过高能球磨后(见图1(b)、(c)、(d)、(f)和(h)),粉末颗粒发生了明显的细化,且随着球磨时间的延长,细化效果越明显;在球磨初期,随着球磨时间的延长,粉末颗粒发生了明显的破碎作用(见图1(c)和(d)),这是因为在磨球及磨筒的撞击作用下,粉末颗粒的形貌出现了很多的片状结构以及细粉末的聚集体(见图1(e)),这是由于在球磨过程中,钢粉经受磨球的剧烈撞击,研磨并与罐壁之间发生强烈的摩擦,在应力的作用下,短时间内形成了大量的微裂纹,并迅速扩展,造成粉末的薄弱区域因应力超过极限而发生破碎[23-24];随着球磨时间进一步增加,粉末粒度趋于稳定,此时粉末已接近全部破碎,粒度均匀,约为20 μm(见图1(f)和(h));对比图1(g)和(i)可以看出,粉末形貌均呈细小的层片状结构,在较长的球磨时间下,粉末颗粒表面更加平滑,表面的粘结物更加均匀和细化。

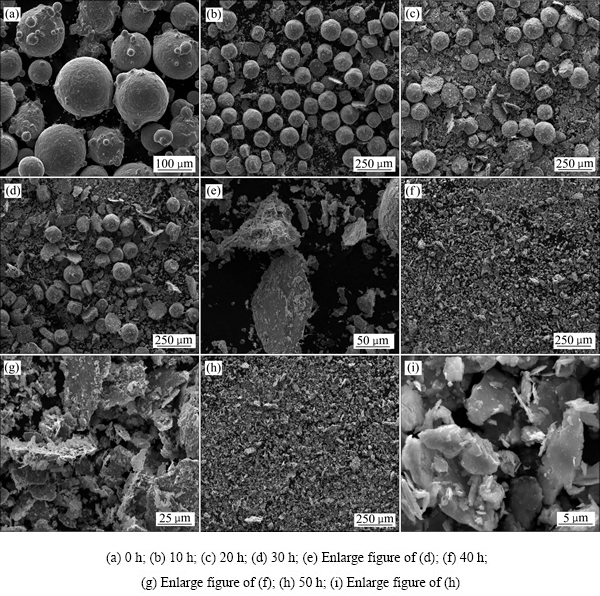

图2所示为在不同球磨时间下混合粉末中位径分布图。从图2可以看出,粉末粒度随着球磨时间的增加先快速减小,随后趋于稳定。这是由于在高能球磨过程中,粉末受到磨球与磨球或磨球与球磨筒的碰撞和挤压,发生了变形、焊合等过程。该过程产生的加工硬化使得粉末塑性降低,脆性增大,从而导致粉末发生了明显的破碎和细化[25]。此时,球磨能量大量地转化为了粉末颗粒的表面能,继续延长球磨时间,粉末颗粒间的冷焊作用增强。当粉末的破碎和焊合逐渐达到平衡时,粉末粒度趋于稳定。从能量的角度分析,粉末颗粒在碰撞作用不断地细化,从而使得颗粒的强度增加,破裂所需的能量也不断的提高,细化过程难以继续进行[24, 26]。因此,即使继续延长球磨时间,粉末粒度也难以发生进一步的细化。

图2 混合粉末在不同球磨时间下的中位径分布图

Fig. 2 Medium diameter distribution of mixed powder at different ball milling time

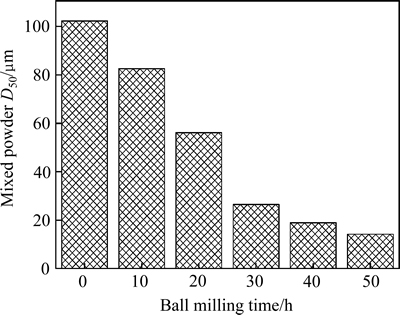

图3 不同球磨时间下烧结体合金致密度

Fig. 3 Density of sintered alloy at different ball milling time

2.2 球磨时间对烧结合金致密性的影响

图3所示为在不同的球磨时间下合金的致密度变化曲线。从图3可以看出,随着球磨时间延长,合金致密度明显增加,当球磨时间增加到40 h后,材料密度趋于稳定;当球磨时间为0 h时,合金密度仅为89.3%,当球磨时间延长到40 h时,合金密度达到96.6%,提高了8.2%。这可能存在两方面的原因,首先,在高能球磨过程中,粉末发生反复变形积蓄了大量的空位和位错等缺陷,为烧结过程中的原子迁移提供了通道;其次,随着球磨时间的增加,粉末粒度减小,粉末比表面积增大,空位源增多,从而促进了相应的表面扩散和体积扩散进程,使得烧结过程能够以更快的速度完成[24-26]。而当球磨时间继续延长到50 h时,致密度已经不再有明显提高,这是因为随着球磨时间的增加,粉末的粒度已经不再有明显细化,烧结后,合金的致密度趋于稳定。

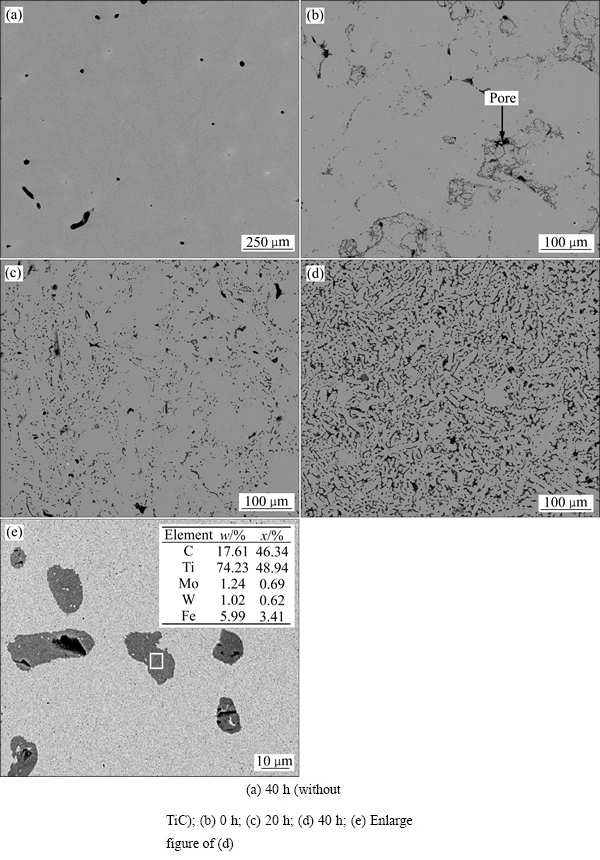

图4所示为不同球磨时间下烧结体合金的微观组织形貌。图4(a)所示为未添加TiC颗粒的粉末球磨40 h后的显微组织形貌。图4(b)~(d)分别为添加碳化钛的混合粉末在球磨0、20和40 h后烧结体合金的微观组织形貌。与图4(a)相比较,添加TiC的粉末烧结后,烧结体中孔洞的数量大大降低。这是因为细小弥散的TiC颗粒可以有效填充钢基粉末之间的空隙,从而有效降低烧结体中的孔洞数量,提高材料致密度,提升材料综合性能。结合图4(e)中能谱分析结果可知,灰黑色相为TiC相,灰色基体为钢基体。从图4可以看出,烧结体的微观形貌遗传了粉末样品微观形貌的基本特点。在图4(b)中,烧结体组织基本保留了原始球形颗粒的形貌,TiC颗粒分布在基体颗粒的边界处;在图4(c)中,仍然存在原始的大球形颗粒,但已有部分粉末颗粒被破碎,均匀分散在大的颗粒周围;而在图4(d)中,已基本看不到大的球形粉末颗粒形状,TiC颗粒与钢基体实现了均匀混合。总之,随着球磨时间的增加,烧结体较为致密,微小孔洞的数量大量减少。

图4 不同球磨时间下烧结体合金的微观形貌

Fig. 4 Morphologies of sintered alloy at different ball milling time

2.3 球磨时间对烧结体合金性能的影响

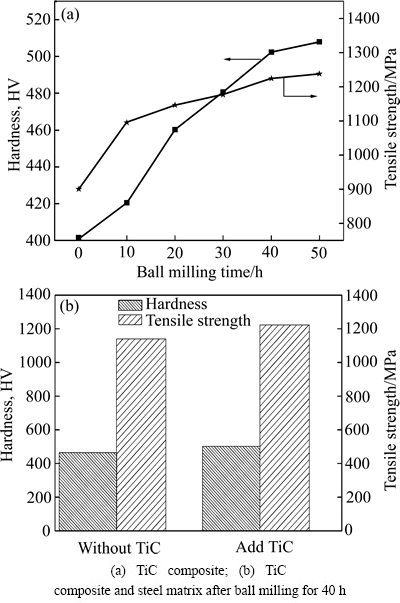

图5所示为经过不同球磨时间后,烧结体的硬度和抗拉强度变化曲线。图5(a)表示在不同的球磨时间下,复合材料的硬度和抗拉强度的变化。从图5(a)可以看出,随着球磨时间的延长,合金的硬度和抗拉强度呈现出相同的变化趋势,均随着球磨时间的延长,首先快速增加,随后趋于稳定。在球磨时间从0 h增加到40 h的过程中,合金的硬度从401.2HV提高到了508HV,增长了26.6%,合金的抗拉强度从900.5 MPa提高到了1138.2 MPa,增长了26.4%。图5(b)所示为经40 h高能球磨后,添加的TiC颗粒对复合材料的硬度和抗拉强度的影响。从图5(b)可以看出,高能球磨后TiC颗粒对基体材料起到了很好的增强作用,硬度从465HV提高到了502HV,抗拉强度从原来的1140 MPa增加到了1224 MPa。从而可以得出,经高能球磨处理后,合金的硬度和强度有了明显的提高。这是因为随着球磨时间的延长,使得粉末的表面活性增高,从而提高了合金的致密度,使得空隙减少,材料性能提高;另一方面,在球磨过程中,TiC颗粒分布得更加均匀弥散,从而使得在烧结过程中,TiC颗粒与钢基体之间有了更好的连接,进一步提高了合金的性能。而当球磨时间继续增加到50 h时,合金的硬度和抗拉强度均保持稳定,这表明继续延长球磨时间, 不会对粉末性能造成明显改善。

图5 不同球磨时间下烧结体的硬度和抗拉强度

Fig. 5 Hardness and tensile strength of sintered alloy at different ball milling time

3 结论

1) 经过高能球磨后,TiC颗粒和钢混合粉形貌由球形颗粒变化为层片状的细小颗粒,颗粒粒度降低至20 μm左右。

2) 高能球磨使烧结体致密度从原来的89.3%上升到了96.6%,提高了7.3%。高能球磨过程一方面提高了合金的致密度,另一方面增强了TiC颗粒分布的均匀性,从而大大提高了合金的硬度和抗拉强度,硬度从原来的401.2HV提高到了508HV,增长了26.6%,抗拉强度从900.5 MPa提高到了1138.2 MPa,增长了26.4%。

3) 随着球磨时间的增加,烧结体的致密度、硬度和抗拉强度均呈现先增加后趋于稳定的变化过程,综合经济的角度考虑,最佳的球磨时间为40 h。

REFERENCES

[1] LEE S H, PARK J J, HONG S M, HAN B S, LEE M K, RHEE C K. Fabrication of cast carbon steel with ultrafine TiC particles[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(S1): 54-57.

[2] FAN Q C, CHAI H F, JIN Z H. Formation of layer-shaped pores in TiC-Fe cermet by combustion synthesis[J]. Transactions of Nonferrous Metals Society of China, 2001, 11(5): 760-763.

[3] LUO Shou-jing, ZU Li-jun. Semi-solid extrusion of TiCp/2024Al composites prepared by contact reaction method[J]. Transactions of Nonferrous Metals Society of China, 2000, 20(3): 304-308.

[4] WEN G, LI S B, ZHANG B S, GUO Z X. Reaction synthesis of TiB2-TiC composites with enhanced toughness[J]. Acta Materialia, 2001, 49(8): 1463-1470.

[5] WANG X H, ZHANG M, ZOU Z D, SONG S L. In situ production of Fe-TiC surface composite coatings by tungsten-inert gas heat source[J]. Surface and Coatings Technology, 2006, 200(20/21): 6117-6122.

[6] BERNS H, WEWERS B. Development of an abrasion resistant steel composite with in situ TiC particles[J]. Wear, 2001, 250(1/12): 1386-1395.

[7] HU S W, ZHAO Y G, WANG Z, LI Y G, JIANG Q C. Fabrication of in situ TiC locally reinforced manganese steel matrix composite via combustion synthesis during casting[J]. Materials and Design, 2013, 44: 340-345.

[8] SUZUKI T, KOBAYASHI S. Mechanisms of TiC layer formation on high speed steel by a single pulse in electrical discharge machining[J]. Electrochimica Acta, 2013, 114: 844-850.

[9] RASOOL G, STACK M M. Wear maps for TiC composite based coatings deposited on 303 stainless steel[J]. Tribology International, 2014, 74(4): 93-102.

[10] ONUOHA C C, KIPOUROS G J, FARHAT Z N, PLUCKNETT K P. The effects of metal binder content and carbide grain size on the aqueous corrosion behaviour of TiC-316L stainless steel cermets[J]. International Journal of Refractory Metals and Hard Materials, 2014, 44(3): 129-141.

[11] 吴中佳, 陈志国, 向 勇, 魏 祥, 张纪帅. 少量铈对高硼高速钢微观组织与力学性能的影响[J]. 中国有色金属学报, 2013, 23(5): 1289-1294.

WU Zhong-jia, CHEN Zhi-guo, XIANG Yong, WEI Xiang, ZHANG Ji-shuai. Effect of small amount of Ce addition on microstructure and mechanical properties of high-boron high speed steel[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1289-1294.

[12] 尤显卿, 王基才, 任 昊. 电冶熔铸WC/钢复合材料的显微缺陷[J]. 中国有色金属学报, 2004, 14(4): 646-651.

YOU Xian-qing, WANG Ji-cai, REN Hao. Micro defects in tungsten carbide particulates reinforced steel matrix composites by electroslag melting and casting[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(4): 646-651.

[13] 王墉哲, 刘俊亮. 回火温度对TiC增强耐磨钢TiC粒子析出行为的影响[J]. 钢铁研究学报, 2015, 27(8): 59-63.

WANG Yong-zhe, LIU Jun-liang. Effect of tempering temperature on precipitation behavior of TiC particles in TiC strengthened antifriction steel[J]. Journal of Iron and Steel Research, 2015, 27(8): 59-63.

[14] 范安平, 肖平安, 李晨坤, 轩翠华, 曲选辉. TiC基钢结硬质合金的研究现状[J]. 粉末冶金技术, 2013, 31(4): 298-303.

FAN An-ping, XIAO Ping-an, LI Chen-kun, XUAN Cui-hua, QU Xuan-hui. Research situation of TiC-based steel bonded carbide[J]. Powder Metallurgy Technology, 2013, 31(4): 298-303.

[15] 王 盈, 邹兵林, 曹学强. Al-Ti-B4C体系熔体内燃烧合成TiC-TiB2颗粒局部增强钢基复合材料[J]. 金属学报, 2014, 50(3): 367-372.

WANG Ying, ZOU Bing-lin, CAO Xue-qiang. Combustion synthesis of TiC-TiB2 particulates locally reinforced steel matrix composites from an Al-Ti-B4C system during casting[J]. Acta Metallurgica Sinica, 2014, 50(3): 367-372.

[16] CHANG S H, TANG T P, HUANG K T, TAI F C. Effects of sintering process and heat treatments on microstructures and mechanical properties of Vanadis 4 tool steel added with TiC powders[J]. Powder Metallurgy, 2010, 53(1): 507-512.

[17] FARID A, GUO S J, SHAH J A, FENG P Z. Effect of adding a type of binder phase on the microstructure, properties and heat treatment of steel bonded TiC cermets[J]. Materials Science Forum, 2007, 534/536: 1161-1164.

[18] BIEDUNKIEWICZ A, BIEDUNKIEWICZ W, FIGIEL P, GABRIEL P U, GRZESIAK D, KRAWCZYK M. Effect of milling time on thermal treatment of TiC, TiB2 /steel powders[J]. Journal of Thermal Analysis and Calorimetry, 2013, 113(1): 379-383.

[19] 龙坚战, 夏艳萍, 陈 冲, 陆必志, 易茂中, 武文花. Al含量对TiC-Fe钢结硬质合金组织与性能的影响[J]. 中国有色金属学报, 2016, 26(2): 383-391.

LONG Jian-zhan, XIA Yan-ping, CHEN Chong, LU Bi-zhi, YI Mao-zhong, WU Wen-hua. Effects of Al content on microstructure and mechanical properties of TiC-Fe alloys[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 383-391.

[20] BAI J L, LIN T, WANG Z. Effect of different binder on the TiC reinforced steel matrix surface composites[J]. Advanced Materials Research, 2015, 1089: 11-14.

[21] BAI J L, LIN T, WANG Z. Research on the TiC reinforced steel matrix surface composites prepared by SHS casting[J]. Applied Mechanics and Materials, 2015, 713/715: 2848-2851.

[22] TORRALBA J M, CAMBRONERO L E G, RUIZ P J M, DAS N M M. Sinterability study of PM M2 and T15 high speed steels reinforced with tungsten and titanium carbides[J]. Powder metallurgy, 1993, 36(1): 55-66.

[23] TAPASZTO O, BALAZSI C. The effect of milling time on the sintering kinetics of Si3N4 based nanocomposites[J]. Ceramics International, 2010, 36(7): 2247-2251.

[24] TRAIPHOL N. Ceramic processing research effects of ball milling time and dispersant concentration on properties of a lead zirconate titanate aqueous suspension for tape casting[J]. Journal of Ceramic Processing Research, 2007, 8(2): 137-141.

[25] NAZARI K A, NOURI A, HILDITCH T. Effects of milling time on powder packing characteristics and compressive mechanical properties of sintered Ti-10Nb-3Mo alloy[J]. Materials Letters, 2015, 140: 55-58.

[26] KHAMMAN O, YIMNIRUN R, ANANTA S. Effect of vibro-milling time on phase formation and particle size of nickel niobate nanopowders[J]. Ceramics International, 2008, 150(1): 12-17.

Effects of ball milling process on microstructure and properties of TiC particles reinforced high speed steel composites

PENG Wen-jing1, CHEN Guo-qiang2, ZHOU Jian-yu1

(1. Engineering Training Center, Hunan Institute of Engineering, Xiangtan 411101, China;

2. School of Mechanical Engineering, Hunan Institute of Engineering, Xiangtan 411101, China)

Abstract: The microstructure and properties of TiC particles mixed with high speed steel powders during high energy ball milling were systematically investigated. The transformation of the powder particle morphology and the distribution of particle size changing with the milling time were also analyzed. In addition, the effects of ball milling time on the density, the structure and mechanical properties of sintered composites were revealed. The results indicate that, when the ball milling time increases from 0 h to 30 h, the deformation and crush of powders presented, resulting in the rapid decrease of the powder particle size. With increasing the ball milling time to 40 h, the welded crushing effect of the particles reaches the balance, while the particle size remains unchanged and the original big spherical particles are changed into the tiny layer powders. When further increasing the ball milling time, the morphology of powders cannot change significantly. The density, structure and mechanical properties of the sintered alloy have the similar trend. Therefore, the optimal ball milling time of the composite material is 40 h.

Key words: high energy ball-mill; TiC particles; high speed steel; composite material

Received date: 2016-07-05; Accepted date: 2016-11-04

Corresponding author: PENG Wen-jing; Tel: +86-731-58689299; E-mail: nanguoqishi163@163.com

(编辑 何学锋)

收稿日期:2016-07-05;修订日期:2016-11-04

通信作者:彭文静,讲师;电话:0731-58689299;E-mail: nanguoqishi163@163.com