新型TiC钢结硬质合金致密化技术

熊拥军,李溪滨,刘如铁,赵福安

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:采用行星式球磨机对Fe-3.0Cr-3.0Mo-0.5Cu-0.5C-33TiC新型钢结硬质合金混合粉末进行高能球磨,对烧结后的合金进行热等静压和锻造处理,研究球磨时间、热等静压及锻造工艺对合金组织、性能及孔隙度的影响。研究结果表明:高能球磨使粉末细化和成分均匀化,促进烧结进程,随球磨时间的延长,合金组织细化且致密;热等静压和锻造工艺可进一步减小和消除合金中烧结后残留的孔洞等缺陷;锻造作为最后工艺,可使TiC颗粒之间的连接破碎,促使硬质相颗粒弥散分布,从而改善烧结组织,提高合金的致密性及力学性能。

关键词:TiC钢结硬质合金;致密化;高能球磨;热等静压;锻造

中图分类号:TF125.3 文献标志码:A 文章编号:1672-7207(2009)06-1563-05

Densification processing of a new steel bonded titanium carbide

XIONG Yong-jun, LI Xi-bin, LIU Ru-tie, ZHAO Fu-an

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The Fe-3.0Cr-3.0Mo-0.5Cu-0.5C-33TiC mixed powders were prepared by high energy ball milling in a planetary ball mill. The sintered alloy was treated by HIP (hot isostatic pressing) and forging. The effect of ball milling time, HIP and forging on the microstructure, properties and porosity of alloy was studied. The results show that high energy ball milling refines and homogenizes the mixed powders, accelerates the sintering process, and with the increase of milling time, the grain is finer and the alloy is denser. HIP and forging is beneficial to decrease or remove the pole formed during the sinter course, and as the last process, forging breaks the junctions between TiC particles, the microstructure and mechanical properties of alloy are improved.

Key words: steel bonded titanium carbide; densification; high energy ball milling; HIP (hot isostatic pressing); forging

TiC钢结硬质合金是以TiC作硬质相,以钢作粘结剂,通过粉末冶金方法制备而成的一种钢基复合材料。由于其硬质相TiC具有高硬度(HV 3 200)、高熔点(3 150 ℃)和良好的高温稳定性,其粘结相钢具有良好的塑性,使得TiC钢结硬质合金综合了硬度高、抗粘附性好、耐磨和耐热性好,可机加工和可热处理等特点。自20世纪60年代以来,TiC钢结硬质合金得到了快速发展,并在模具、刀具和耐磨零件等领域得到广泛应用[1-4]。由于成分及工艺等方面原因,我国目前生产的TiC钢结硬质合金的性能尚不理想,特别是其关键指标孔隙度过大,严重制约了其在航天、航海、军工等行业特殊工况下的应用。高能球磨、热等静压、锻造等工艺作为重要的材料制备和处理手段,被广泛应用于材料领域的生产和研究,在钢结硬质合金领域,研究人员对采用这些手段进行钢结硬质合金制备和处理进行了研究[5-10],但多限于TiC原位合成硬质合金的研究,而同时采用3种工艺且直接以TiC化合物作为成分组元添加的研究目前尚未见报道。为此,本文作者对一种新型TiC钢结硬质合金混合粉末进行高能球磨处理,并对烧结后的合金进行热等静压和锻造处理,并就这几种工艺对合金孔隙度及综合性能的影响进行研究。

1 实 验

1.1 原料及试样制备

实验采用的原料粉末有TiC粉、Cr-Fe粉、Mo粉、Cu粉、C粉、Fe粉(其中TiC粒度为4.3 ?m,Cr-Fe粉、Mo粉和Fe粉的粒度均小于7.5 ?m),按表1所示的成分进行配料。

表1 实验用TiC钢结硬质合金的成分

Table 1 Chemical compositions of steel bonded titanium carbide w/%

为便于压制,粉末中添加2%(质量分数)的石蜡作为成形剂。

合金制备工艺为:配料→高能球磨→烘干→过筛→ 模压→真空烧结→热等静压→锻造。在烧结、锻造和热等静压后分别取样加工成金相和抗弯试样。

高能球磨采用南京大学仪器厂生产的QM-1SP4型行星式球磨机,磨球为不锈钢球,球料质量比为10?1。采用湿磨方式,球磨介质为正己烷,转速为300 r/min,粉末分6批,分别球磨0,1,5,10,20和30 h。

采用美国ABB公司QIH-6型热等静压设备进行热等静压,压力为14×107 Pa;温度为1 260 ℃,保温保压时间为0.5 h。

锻造采用75 kg气锤和自制锻模,最高温度为1 200 ℃。

1.2 性能测试

采用排水法测定合金密度,采用HBRVU-187.5型布洛维光学硬度计测定合金硬度,采用LJ-3000A型机械式拉力试验机测试合金抗弯强度,用LeicaMeF3A金相显微镜对试样组织进行观察,运用Leica Q550定量分析系统对试样的孔隙度进行分析。

2 结果及分析

2.1 高能球磨对合金致密性及综合性能的影响

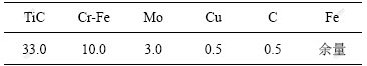

图1所示为粉末球磨不同时间后,经1 400 ℃真空烧结和960 ℃淬火及低温回火后合金的金相照 片。其中:灰白色的是TiC相,以不规则多边形为 主,部分颗粒粘接形成桥接相;颜色较深的组织为钢基体,以回火马氏体为主,兼有少量残余奥氏体。随着球磨时间的增加,合金基体组织细化,TiC颗粒粒度减小且分布趋于均匀。在球磨初期合金中存在的较粗大的桥接相在球磨20 h后已变得十分细小,基体组织需放大1 000倍以上才可分辨。

球磨时间/h:(a) 1; (b) 5; (c) 10; (d) 20; (e) 30

图1 球磨时间不同时烧结合金的组织形貌

Fig.1 Microstructures of material sintered after ball milling for different time

图2所示为球磨时间与合金孔隙度的关系。从图2可以看出:未进行高能球磨处理的合金孔隙度最高(4.88%);随着球磨时间的增加,合金孔隙度迅速减小,球磨10 h后,孔隙度减小的速度变缓,球磨30 h后,孔隙度达到最低值(0.42%)。合金孔隙度随球磨时间的增加而减小的原因在于高能球磨可促进烧结进程,一是在高能球磨过程中,粉末由于反复变形积蓄了大量的空位、位错等缺陷,为烧结过程中的原子迁移提供了通道;二是随球磨时间增加,粉末粒度减小,粉末总的比表面增大,空位源增多,从而促进相应的表面扩散和体积扩散进程,使得烧结过程更快、更完全[11-12]。

图2 合金孔隙度随球磨时间的变化曲线

Fig.2 Change curve of porosity of alloys with ball milling time

2.2 热等静压对合金致密性及综合性能的影响

采用高能球磨30 h时对粉末烧结样进行热等静压处理。表2所示为热等静压处理前、后合金的性能比较结果。从表2可以看出:经热等静压处理后,合金孔隙度减小,综合性能明显提高,其硬度提高14.9%,抗弯强度提高34.4%,孔隙度由0.42%减小到0.26%。

表2 热等静压前、后合金的性能

Table 2 Mechanical properties of alloy before and after HIP

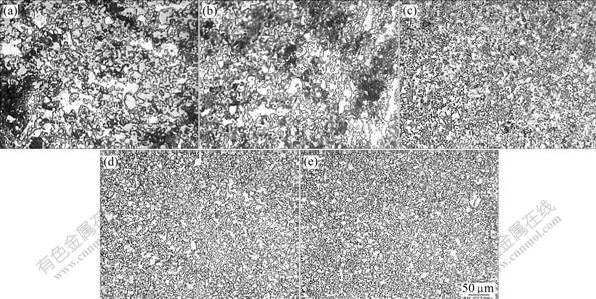

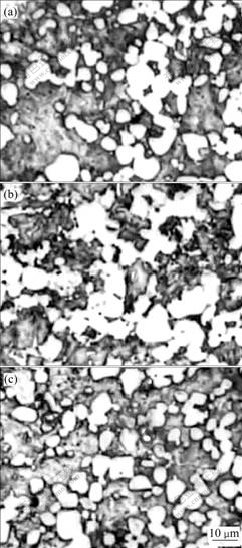

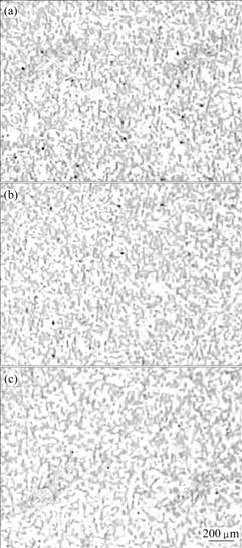

图3和图4所示为热等静压前、后合金的显微组织和孔隙度照片。从图3可以看出:热等静压前TiC颗粒呈不规则多边形,边界清晰,分布不太均匀,部分颗粒之间相互连接;热等静压后,TiC颗粒形状更加不规则且边界模糊,颗粒之间连接现象加剧。从图4可以看出:烧结后的基体组织中存在着一定数量的孔洞,经热等静压处理后,孔洞变小或消失。

(a) 热等静压前;(b) 热等静压后;(c) 锻造后

图3 热等静压和锻造前、后合金的显微组织

Fig.3 Microstructures of alloy before and after HIP and forging

(a) 热等静压前;(b) 热等静压后;(c) 锻造后

图4 热等静压及锻造前、后的孔隙度

Fig.4 Porosities of alloy before and after HIP and forging

TiC虽然与其他组元一般不发生反应,但在一定温度条件下,其自身可出现碎化现象,在随后的冷却过程中,碎裂的TiC颗粒又出现合并现象[13]。热等静压过程不仅有一个温度的升高和冷却过程,且在这一过程中,始终保持着140 MPa的高压,这一压力的存在有助于减小和消除烧结过程产生的孔洞等基体组织缺陷,对TiC颗粒的合并过程也有促进作用。故经过热等静压处理后,基体组织更加致密,而TiC颗粒之间的连接现象加剧。从理论上说,TiC颗粒的连接对合金性能产生不利影响,特别是对强度有影响,但对于用粉末冶金方法制备的TiC钢结硬质合金来说,其致密性对合金强度的影响更大[14-15]。

2.3 锻造对合金致密性及综合性能的影响

钢结硬质合金的基体为合金钢,故而可通过锻造来减少合金内部缺陷,改善组织结构和性能,但高体积分数的TiC硬质颗粒的存在又为锻造带来了一定的困难,采用普通的自由锻造易产生裂纹,使试样报废。本试验采用自制的锻模进行锻造,其原理是将2块中间带弧形凹槽的锻模夹住试样进行锻造,气锤不与试样接触,其锻造力通过锻模传导至试样。与自由锻造时试样内部受力情况不同,锻模锻造时,试样受到的是多向压应力,这种多向压力的受力状态有利于增强金属的塑性流动,使得锻造裂纹出现的概率大大降低。在锻造过程中,合金的变形基本上是钢基体的塑性变形,基体中的微小缺陷在此过程中会逐渐闭合,基体密度提高。硬而脆的TiC颗粒不产生塑性变形,但能吸收基体传递的能量而破碎,故锻造前TiC颗粒之间互相连接较严重,而锻造后大部分互相连接的TiC颗粒从连接处被击断,轮廓变得更清晰,分布也更加弥散均匀。

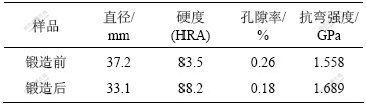

表3所示为采用锻模锻造前、后合金的各项性能指标。从表3可以看出:锻造前试样直径为37.2 mm,锻造后试样直径为33.1 mm,直径减少幅度达到11%,充分的变形量是锻造过程中合金致密化及组织改善的保证。孔隙度由锻造前的0.26%减小到0.18%,硬度(HRA)和抗弯强度则分别由锻造前的83.5和1.558 GPa提高到锻造后的88.2和1.689 GPa。

表3 锻造前、后合金的主要性能

Table 3 Main mechanical properties of alloy before and after forging

从图3(c)和图4可以看出,通过热等静压、锻造后合金组织中残留的微小孔洞被进一步消除,部分互相连接的TiC颗粒从连接处被击断,形成弥散分布的颗粒,合金由烧结态组织转变为锻造态组织[16]。

3 结 论

a. 在高能球磨过程中,粉末的反复变形使其烧结活性增强,粒度减小缩短了原子迁移的距离。随着球磨时间的增加,烧结后合金的组织细化,成分均匀性增加,合金的硬度和抗弯强度增大,孔隙度减小。

b. 经过热等静压处理后,合金烧结后存在的孔洞等组织缺陷减小或消失,合金致密化;合金综合性能明显提高,其中:硬度提高14.9%,抗弯强度提 高34.4%。

c. 通过合理的锻模锻造工艺,热等静压后合金中仍存在的细小孔洞进一步消除,部分互相连接的TiC颗粒从连接处被击断并形成弥散分布,合金组织得到改善,合金硬度和抗弯强度较锻造前分别提高5.6%和8.4%。

参考文献:

[1] Akhtar F. Microstructure evolution and wear properties of in situ synthesized TiB2 and TiC reinforced steel matrix composites[J]. Journal of Alloys and Compounds, 2008, 459(1/2): 491-497.

[2] Jiang Q C, Ma B X, Wang H Y, et al. Fabrication of steel matrix composites locally reinforced with in situ TiB2-TiC particulates using self-propagating high-temperature synthesis reaction of Al-Ti-B4C system during casting[J]. Composites: Part A, 2006, 37(1): 133-138.

[3] WANG Jing, WANG Yi-san, DING Yi-chao. Production of (Ti,V)C reinforced Fe matrix composites[J]. Materials Science and Engineering A, 2007, 454/455: 75-79.

[4] Farid A, GUO Shi-ju, FENG Pei-zhong, et al. TiC-maraging stainless steel composite: microstructure, mechanical and wear properties[J]. Rare Metals, 2006, 25(6): 630-635.

[5] Farid A, GUO Shi-ju, CUI Feng-e, et al. TiB2 and TiC stainless steel matrix composites[J]. Materials Letters, 2007, 61(1): 189-191.

[6] Farid A. Processing, microstructure, properties and wear behavior of in situ synthesized TiB2 and TiC thick films on steel substrates[J]. Surface and Coatings Technology, 2007, 201(24): 9603-9609.

[7] Degnan C C, Shipway P H. A comparison of the reciprocating sliding wear behaviour of steel based metal matrix composites processed from self-propagating high-temperature synthesised Fe-TiC and Fe-TiB2 masteralloys[J]. Wear, 2002, 252(9/10): 832-841.

[8] WANG Jing, WANG Yi-san. In-situ production of Fe-TiC composite[J]. Materials Letters, 2007, 61(22): 4393-4395.

[9] WANG Xin-hong, ZOU Zeng-da, QU Shi-yao. Microstructure of Fe-based alloy hardfacing reinforced by Tic-VC particles coating[J]. Journal of Iron and Steel Research International, 2006, 13(4): 51-55.

[10] Patrik P, Anders E W, Steven S. Self-propagating high-temperature synthesis and iquid-phase sintering of TiC/Fe composites[J]. Journal of Materials Processing Technology, 2002, 127(2): 131-139.

[11] Mansour R, Mohammad R R, Amir H R. Effect of nanocrystalline TiC powder addition on the hardness and wear resistance of cast iron[J]. Materials Science and Engineering A, 2007, 454/455: 144-147.

[12] Akhtar F, Guo S J. Microstructure, mechanical and fretting wear properties of TiC-stainless steel composites[J]. Materials Characterization, 2008, 59(1): 84-90.

[13] 株洲硬质合金厂. 钢结硬质合金[M]. 北京: 冶金工业出版社, 1982: 84-85.

Zhuzhou Cemented Carbide Plant. Steel bonded carbide[M]. Beijing: Metallurgical Industry Press, 1982: 84-85.

[14] WANG Jing, WANG Yi-san, DING Yi-chao. Reaction synthesis of Fe-(Ti,V)C composites[J]. Journal of Materials Processing Technology, 2008, 197(1): 54-58.

[15] Pagounis E, Talvitie M, Lindroos V K. Microstructure and mechanical properties of hot work tool steel matrix composites produced by hot isostatic pressing[J]. Powder Metallurgy, 1997, 40(2): 55-59.

[16] 王荣滨, 海 波. GT35曲柄热压辊锻成形模[J]. 硬质合金, 1996, 13(4): 236-241.

WANG Rong-bin, HAI Bo. GT35 crank hot-pressing rotary-forging forming die[J]. Cemented Carbide, 1996, 13(4): 236-241.

收稿日期:2009-01-10;修回日期:2009-03-31

基金项目:国家民口配套项目(MKPT-02-204)

通信作者:熊拥军(1970-),男,江西南昌人,博士研究生,从事粉末冶金减摩耐磨材料研究;电话:0731-88876566;E-mail: xt7073@sohu.com