文章编号:1004-0609(2010)S1-s0977-04

高能球磨制备涂料用超细钛粉

谢焕文,蔡一湘,谭立新,刘 辛

(广州有色金属研究院 粉末冶金研究所,广州 510650)

摘 要:在无水乙醇和惰性气体的保护下,利用高能球磨法制备重防腐涂料用超细钛粉,通过化学分析、粒度分析仪、扫描电镜等手段对超细钛粉的杂质含量、粒径和形貌进行表征,研究球磨转速、球料比等参数对钛粉粒度以及杂质含量的影响。结果表明:在球磨转速为378 r/min、球料比为2.43、球磨时间为8~18 h的球磨工艺下可制得中值粒径为9.91~2.28 ?m的超细钛粉,其铁含量(质量分数)控制在0.23%~0.28%以内,粉末呈不规则鳞片状;球磨转速相对球料比而言是影响钛粉细化的显著性因素,而球料比则是影响钛粉铁含量增加的显著性因素。

关键词:高能球磨;超细钛粉;分散剂

中图分类号:TF123.7 文献标志码:A

Ultrafine titanium powders for coatings prepared by high energy ball milling

XIE Huan-wen, CAI Yi-xiang, TAN Li-xin, LIU Xin

(Department of Powder Metallurgy, Guangzhou Research Institute of Nonferrous Metals, Guangzhou 510651, China)

Abstract: Ultrafine Ti powders applied for heavy-duty coatings were prepared by high energy ball milling with protection of ethanol and inert-gas. The impurity content, particle size and morphologies of ultrafine Ti powders were characterized by chemical analysis, particle size analyzer and scanning electron microscopy. The effects of such parameters as rotation speed and ball-to-powder ratio on the particle size and impurity content of Ti powders were investigated. The results show that when the rotation rate is 378 r/min, ball-to-powder ratio is 2.43 and milling time is 8-18 h, the ultrafine Ti powders with median diameter of 9.91-2.28 ?m are obtained in which Fe content (mass fraction) is 0.23%-0.28%. The ultrafine Ti powders prepared by ball milling appear irregular flaky. Compared with ball-to-powder ratio, the rotation rate is the significant factor on the refinement of Ti powders, and the ball-to-powder ratio is the significant factor on increment of Fe content in Ti powders.

Key words: high energy ball milling; ultrafine titanium powders; dispersant

钛与聚合物结合制备的涂料用于金属结构表面涂层,能显著提高基体耐蚀、耐磨和抗静电能力,极大地降低金属结构制造和运行成本[1]。随着涂料技术的发展,越来越多的钛涂料得到重视,如钛-环氧树脂、钛-聚芳醚酮等涂料拥有优异的导电、导磁及防腐性能得到了广泛应用[2]。对于作为钛涂料的原料的超细钛粉,研究其制备工艺具有重要意义。目前,超细钛粉的制备方法主要有电解法、气体蒸发法、高能球磨法等[3-4],其中,电解法和气体蒸发法成本较高。本研究以低成本氢化脱氢钛粉为原料,利用高能球磨法制备超细钛粉,以满足重防腐用钛涂料对原料的需求,通过对制备的超细钛粉的杂质含量、粒径和形貌进行表征,研究球磨转速、球料比等参数对钛粉粒度以及杂质含量的影响。

1 实验

1.1 实验设备及原料

球磨试验采用南京大学仪器厂卧式行星球磨机(QM-WX4),球磨罐处于水平卧放方式,机器旋转时,罐内各点所受力的大小与方向都在不断变化,运动轨迹杂乱无章,这就导致磨球与磨料在高速运转中相互之间猛烈碰撞、挤压,大大提高了研磨效率和研磨效果。由于自转,球磨罐没有固定的底面,避免了罐内材料的结底现象[5]。初始钛粉采用中值粒度(D50)为99.73 μm的氢化脱氢钛粉。

1.2 试验方法粉末性能检验

钛粉原料添加适量的无水乙醇作为湿磨介质后放入不锈钢球磨罐中并配以6,10,20 mm 3种不同直径的不锈钢磨球,在氩气保护下进行高能球磨。为了探索球磨工艺对超细钛粉性能的影响,采用不同的球磨转速和球料比在球磨机上进行球磨。

1.3 分析测试

对粉末随机取样分析粉体理化性能。

采用化学分析法测定粉末测定铁含量;采用岛津SA-CP3型离心沉降式粒度分析仪测定粉末粒度;采用JEOL JSM-5910型扫描电镜观察粉末形貌和显微组织。

2 结果与讨论

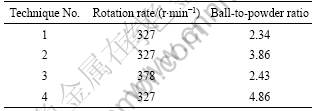

采用4种球磨工艺进行球磨试验和分析,其参数见表1。

表1 球磨工艺参数

Table 1 Parameters of ball milling

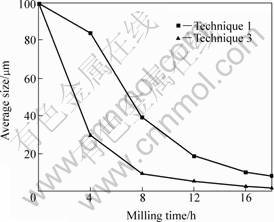

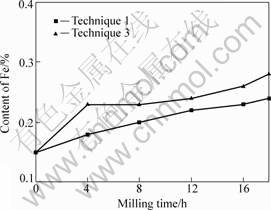

2.1 球磨转速对钛粉粒度和Fe含量的影响

图1所示为采用1#和3#球磨工艺制备的钛粉平均粒度随球磨时间变化的关系。可见,在当前球磨条件下,采用高的球磨转速有利于钛粉的细化:在球磨初期(0~4 h),高的球磨转速导致了钛粉平均粒度的显著减小;而随着球磨时间的延长,球磨转速的不同所导致的钛粉粒度差异在逐渐缩小。图2所示为采用1#和3#球磨工艺制备的钛粉铁含量随球磨时间变化的关系。在当前球磨条件下,采用高的球磨转速会导致钛粉铁含量的明显增加:在球磨初期(0~4 h),高的球磨转速导致了钛粉铁含量的显著增加。

图1 转速不同时钛粉平均粒度与球磨时间的关系

Fig.1 Relationship between average size of Ti powders and milling time at different rotation rates for techniques 1 and 3

图2 转速不同时钛粉铁含量与球磨时间的关系

Fig.2 Relationship between Fe content and milling time at different rotation rates for techniques 1 and 3

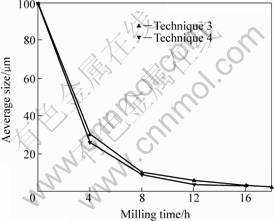

2.2 球料比对钛粉粒度和Fe含量的影响

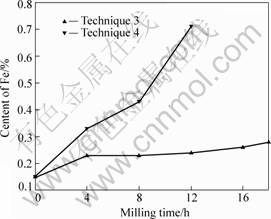

图3所示为采用3#和4#球磨工艺制备的钛粉平均粒度随球磨时间变化的关系。比较3#和4#工艺可以发现,2种球磨工艺制备的钛粉平均粒度在同等球磨时间下非常接近。这表明,在当前球磨条件下,球料比的高低对钛粉的细化作用并不明显。图4所示为采用3#和4#球磨工艺制备的钛粉铁含量随球磨时间变化的关系。比较3#和4#工艺可以发现,在当前球磨条件下,采用高的球料比会导致钛粉铁含量的显著增加:在球磨初期(0~4 h),高的球料比导致了钛粉铁含量的更为明显的增加;而随着球磨时间的延长,球料比的不同所导致的钛粉铁含量差异急剧扩大。

图3 球料比不同时钛粉平均粒度与球磨时间的关系

Fig.3 Relationship between average size of Ti powders and milling time with different ball-to-powder ratios for techniques 3 and 4

图4 球料比不同时钛粉铁含量与球磨时间的关系

Fig.4 Relationship between Fe content and milling time with different ball-to-powder ratios for techniques 3 and 4

2.3 影响钛粉粒度和Fe含量的显著性因素

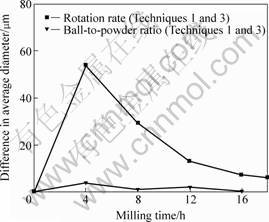

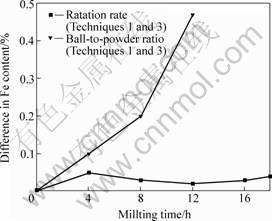

图5所示为球磨转速及球料比不同时钛粉平均粒度差异随球磨时间变化的关系。可见,在当前球磨条件下,球磨转速是影响钛粉细化的显著性因素。图6所示为球磨转速及球料比不同时钛粉铁含量差异随球磨时间变化的关系。可见,在当前球磨条件下,球料比是影响钛粉铁含量增加的显著性因素。

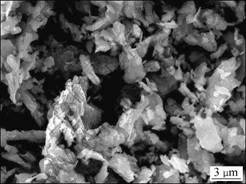

图7所示为球磨前的钛粉形貌,采用气氛保护磨筛氢化钛粉脱氢制得,其形貌呈不规则鳞片状。图8所示为采用上述球磨条件制备的涂料试验用钛粉形貌SEM像。钛粉在高能湿法球磨条件下没有出现明显的团聚现象,其形貌呈细小的鳞片状,较原料更加不规则,粒度在10 ?m以下。对于韧性的钛粉来说,在钢

图5 球磨转速及球料比不同时钛粉的平均粒度差值与球磨时间的关系

Fig.5 Relationship between difference in average diameter of Ti powders and milling time at different rate rotation rates and ball-to-powder ratios

图6 球磨转速及球料比不同时钛粉铁含量差值与球磨时间的关系

Fig.6 Relationship between difference in Fe content and milling time at different rate rotation rates and ball-to-powder ratios

图7 氢化脱氢钛粉的SEM像

Fig.7 SEM image of HDH Ti powder

图8 涂料试验用钛粉SEM像

Fig.8 SEM image of Ti powder used for coatings

球的反复压延作用下,金属钛粉不断地被挤压变形,开始形成层片状结构。在这个形变-断裂-冷焊不断重复的过程中层片状结构发生卷曲,钛粉颗粒尺寸不断减小。

2.4 钛涂料性能分析

针对油气田井用管道环境,将制备的超细钛粉与自行研发的聚芳醚酮共聚物配制成钛涂料,与其他几种现有油气田井用管道使用中的防腐蚀涂料进行对比试验。试验结果表明,其耐腐蚀性、耐沾污积垢性、抗热氧老化性、耐高温高压蒸汽穿透性等各项性能均有不同程度的提高。

3 结论

1) 采用高能湿法球磨成功制备了超细钛粉,在球磨转速为378 r/min、球料比为2.43、球磨时间为8~18 h的球磨工艺下可制得中值粒径D50为9.91~2.28 ?m的超细钛粉,其铁含量(质量分数)控制在0.23%~0.28%以内。

2) 在高能湿法球磨制备超细钛粉的过程中,球磨转速相对球料比而言是影响钛粉细化的显著性因素,而球料比则是影响钛粉铁含量增加的显著性因素。

REFERENCES

[1] 张 驰. 有机钛特种防腐蚀涂料的研究[J]. 广东化工, 2006(5): 25-28.

ZHANG Chi. Researching on anti-corrosion paint of special organic titanic[J]. Guangdong Chemical Industry, 2006(5): 25-28.

[2] 李少羽. 含钛涂料中金属钛与环氧树脂之间相互作用的X射线光电子能谱(XPS)表征[J]. 吉化科技, 1995(2): 28-32.

LI shao-yu. Interaction between Ti and epoxy resin of Ti coating and characterization with XPS[J]. Jilin Chemical Industry Science and Technology, 1995(2): 28-32.

[3] 翁启钢, 周志辉, 林洪波, 袁继维, 袁铁锤. 熔盐电解法制备高纯钛粉[J]. 粉末冶金材料科学与工程, 2010, 15(1), 70-73.

WENG Qi-gang, ZHOU Zhi-hui, LIN Hong-bo, YUAN Ji-wei, YUAN Tie-chui. Preparation of high-purity titanium powder by molten-salts electrolysis[J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(1): 70-73.

[4] 周洪强, 陈志强. 钛及钛合金粉末的制备现状[J]. 稀有金属快报, 2005, 24(12): 11-14.

ZHOU Hong-qiang, CHEN Zhi-qiang. Status of preparing titanium and its alloy powder[J]. Rare Metals Letters, 2005, 24(12): 11-14.

[5] 孙怀涛, 方 莹, 万永敏. 行星球磨机磨球运动规律的研究[J]. 金属矿山, 2007(10): 104-106.

SUN Huai-tao, FANG Ying, WAN Yong-min. Study on ball movement law in planetary ball mill[J]. Metal Mine, 2007(10): 104-106.

(编辑 赵 俊)

通信作者:刘 辛;电话:020-37238137;E-mail:shaneliu118@gmail.com