文章编号:1004-0609(2011)06-1328-07

高能球磨工艺对Cu-10Cr-0.5Al2O3组织与性能的影响

张 寅,李小强,叶永权,李元元

(华南理工大学 机械与汽车工程学院,广州 510640)

摘 要:利用高能球磨方法对Cu-10Cr-0.5Al2O3(质量分数,%)混合粉末进行预处理,采用电场活化烧结技术对球磨粉末进行烧结,运用XRD、SEM、硬度、断裂强度和电导率等测试方法研究球磨时间对Cu-10Cr-0.5Al2O3复合粉末烧结前后组织和性能的影响。结果表明:随着球磨时间的增加,Cu晶粒更加细化,第二相分布更加弥散,以致烧结材料的强度和硬度逐渐增大,球磨20 h后,烧结样品的强度和硬度分别达到952 MPa和285 HV;由于晶粒细化、高度弥散的第二相以及铜相的晶格畸变加强对电子的散射作用,烧结试样的电导率也随球磨时间的延长而逐渐下降,球磨20 h后,烧结样品的电导率下降到51%(IACS)。

关键词:铜基粉末;第二相;高能球磨;电场活化烧结

中图分类号:TF124.5 文献标志码:A

Influence of high-energy ball milling on

structure and performance of Cu-10Cr-0.5Al2O3

ZHANG Yin, LI Xiao-qiang, YE Yong-quan, LI Yuan-yuan

(School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China)

Abstract: Cu-10Cr-0.5Al2O3 (mass fraction, %) powder mixtures were pretreated by high-energy ball milling and subsequently sintered by electric field activated sintering technique. The influence of milling time on the structure and performance of Cu-10Cr-0.5Al2O3 before and after sintering was studied by XRD, SEM, hardness, rupture strength and conductivity test. The results show that, with increasing the milling time, the Cu grain size decreases and the distribution of the second phase becomes more uniform, consequently the strength and hardness of the sintered samples increase and reach 952 MPa and 285 HV, respectively, after powders milled for 20 h. Because of the grain refinement, the uniform distribution of second phase and the lattice distortion of Cu phase, the electron scattering in the sintered samples is enhanced, causing a decrease of conductivity. After 20 h milling, the conductivity of sintered samples decreases to 51%(IACS).

Key words: copper base powders; second phase; high-energy ball milling; electric field activated sintering

导电铜基复合材料作为一类新兴材料,由于具有较高强度及优良的导电导热性能,在汽车工业、微电子行业、电器机车架空线、电子、电气和宇航等领域都有着巨大的应用潜力[1-3]。Cu-Cr合金作为导电铜基复合材料的一种,已被公认为是满足真空开关基本要求的最佳触头材料之一,近年来在国内外得到了普遍应用[4]。但目前生产的Cu-Cr合金常常存在一些质量问题,如材料中气体含量过高,材料中Cr相颗粒尺寸难于控制、难以充分致密等。这就需要不断完善Cu-Cr合金的制备技术,甚至开发新的技术。胡勇等[5]采用真空感应熔炼方法制备Cu-Cr合金,因真空感应熔炼和浇注过程都是在真空条件下进行的,大大降低了材料的含气量,提高了合金的纯度,且该方法工艺简单,成本低廉,被认为是一种大规模生产Cu-Cr触头材料的方法[6]。但由于Cu和Cr的熔点悬殊,且密度相差较大,在凝固时易产生偏析,尤其是在Cr含量高的合金中。LI等[7]和李金平等[8-9]对机械合金化制得的Cu-Cr合金粉进行爆炸烧结,结果表明,爆炸烧结不仅可以克服Cu-Cr偏析,而且由于在极短时间内爆炸合成,晶粒来不及长大,可以保留机械合金化制得的纳米晶的初始特征,因而有望得到性能较好的Cu-Cr触头材料,但爆炸时的炸药用量难以控制。另外,若为了提高致密度而使用高爆速炸药,爆炸压实坯内部还会产生径向裂纹。采用高能球磨法制备Cu-Cr粉末具有独特的优势,不仅可以增大固溶度,促进第二相的弥散分布,细化复合粉末的粒度和晶粒度,提高烧结活性,降低烧结温度和提高烧结致密度,且该法工艺简单,成本也很低廉。近年来迅速发展起来的集成形和烧结于一体的电场活化烧结技术[10-12]具有高效、节能、环保和操作简便等一系列优点,同时该方法还可净化、活化粉末表面,降低扩散激活能,促进烧结,有效抑制晶粒长大,另外,烧结过程中施加的烧结压力也利于获得高致密甚至全致密的材料。为此,本文作者采用高能球磨与电场活化烧结相结合的方法制备高强导电铜基材料,即先采用高能球磨技术制备Cu-10Cr-0.5Al2O3细晶铜基复合粉末,再对球磨后的粉末进行电场活化烧结,并重点研究高能球磨工艺对Cu-10Cr-0.5Al2O3合金显微组织和性能的影响。

1 实验

1.1 实验材料及测试方法

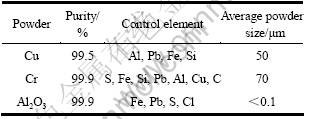

实验选用的铜粉为电解铜粉,铬粉为机械破碎铬粉,氧化铝粉为市售纳米粉,初始粉末的特征如表1所列。

表1 初始粉末的特征

Table 1 Characteristics of original powders

试样的X射线衍射分析在D/max-ⅢA型全自动X射线衍射仪上进行,加速电压为50 kV,扫描速度为10 (°)/min;形貌观察在JEOL-6460LA扫描电子显微镜上进行,加速电压为15 kV;硬度测试在HX-1000型维氏显微硬度计上进行,测试载荷为9.8 N,每次加载时间为10 s,每个试样的硬度取7个点的平均值;横向断裂强度测试在CMT5105型万能实验机上进行;电导率的测试则采用QJ19型双臂两用电桥测试仪。

1.2 铜基复合材料的制备过程

1.2.1 高能球磨制备粉末

将上述初始粉末按Cu-10Cr-0.5Al2O3成分配比后于容积为2 L的V型混粉机中预混合12 h,然后装入QM-2SP行星球磨机中进行高能球磨。球磨罐和磨球材料均为GCr15,球磨中大球(直径20 mm)、中球(直径8 mm)和小球(直径4 mm)的质量比为1?2?1,球料质量比为10?1,球磨机转速为226 r/min,正反转交替时间为15 min,加速时间和减速时间均为10 s,球磨介质为高纯氩气,为防止球磨过程中粉末过度焊合,加入无水酒精作为过程控制剂。

1.2.2 烧结成形

每次烧结时,将20 g的Cu-10Cr-0.5Al2O3粉末装入内径为20 mm、外径为50 mm的Al2O3陶瓷模具 中,利用自制的电场活化烧结设备进行烧结成形。选用的脉冲电流参数如下:基值电流为120 A,峰值电流为2.7~3.0 kA,频率为50 Hz,占空比为50%。通电时间(即烧结时间)为3~7 min,烧结压力为30 MPa。断电后,试样随模空冷至100 ℃以下,然后脱模取样。

2 结果与讨论

2.1 球磨对铜基粉末的影响

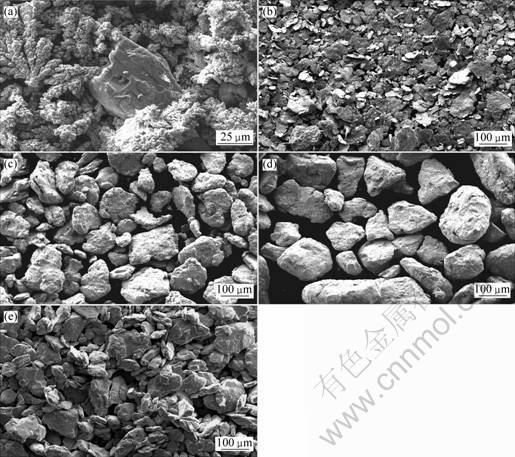

图1所示为不同球磨时间粉末的SEM像。由图1可以看出:球磨5 h后,复合粉末呈现片状形貌,并且每一个粉末颗粒由多层更薄的片层的组成(见图1(b));经10 h机械球磨后,复合粉末仍呈片状,由于焊合作用强化粉末颗粒厚度明显增大;粉末颗粒的棱角处有断裂痕迹,表明球磨过程中发生焊合的同时还发生了断裂;经15 h球磨后,复合粉末呈近球状,粉末颗粒也因焊合而进一步长大;经20 h球磨后,由于加工硬化,较大的粉末颗粒被逐渐破碎成为尺寸较小的颗粒,粉末颗粒由较大的近球状颗粒和较小的块状颗粒组成,但由于铜具有良好的塑性,粉末平均尺寸仍约为50 μm,此时,粉末颗粒比较密实,如图1(e)所示。以上结果表明,在球磨过程中,颗粒的形状和尺寸都发生了显著变化。球磨粉末是粉末颗粒经历反复锻延、冷焊、断裂以及重焊的过程[13-14]。在球磨的初期阶段,金属粉末内部的缺陷少, 具有良好的塑性,因此,在高速磨球的冷镦和碾压轧制作用下,不同粉末间的焊合形成了复合粉,同时,粉末在磨球的反复冲击下发生了压缩塑性变形,粉末变成了层片状甚至碎块状。随着球磨时间的延长,复合粉末的塑性变形不断累积,球磨导致复合粉末不断加工硬化,同时球磨导致Al2O3和Cr在Cu相中的弥散分布以及Cr在Cu中实现强制固溶,这些因素均会使粉末变得越来越脆,再加上颗粒中层与层间的缝隙,使得粉末在磨球的高速撞击下不断发生断裂。粉末断裂后,露出的新鲜金属表面在磨球的作用下又重新焊合。球磨初期,焊合明显强于断裂,所以,随球磨时间的延长,粉末尺寸逐渐变大,而长时间球磨后,因断裂效应得到强化,又导致粉末尺寸逐渐下降。

图1 球磨不同时间后粉末的SEM像

Fig.1 SEM images of composite powders milled for different times: (a) 0; (b) 5 h; (c) 10 h; (d) 15 h; (e) 20 h

在球磨过程中,Cu和Cr发生了明显塑性变形,大塑性变形诱发复合粉末中Cu和Cr相发生了晶格畸变,同时产生大量位错,形成了位错胞和亚晶粒,最终细化了Cu和Cr的晶粒。球磨粉末的XRD谱(见图2)也证实了这一点,随球磨时间的延长,Cu和Cr的衍射峰逐渐变矮变宽。由于Al2O3的含量非常少,在混合粉末和球磨粉末的衍射谱中并未观察到相应的衍射峰。

图2 不同球磨时间后复合粉末的XRD谱

Fig.2 XRD patterns of composite powders milled for various times

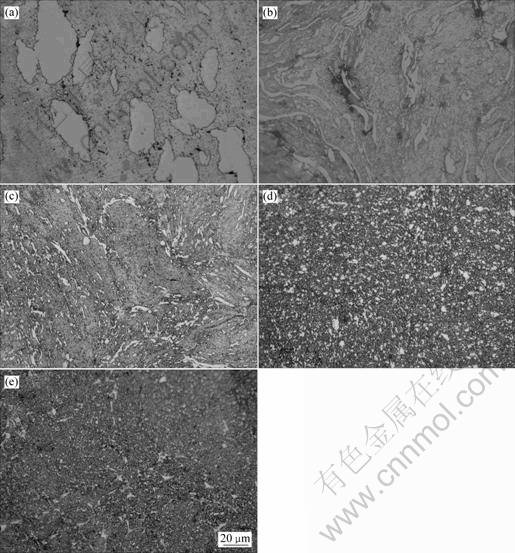

2.2 球磨时间对烧结材料显微组织的影响

图3所示为球磨不同时间粉末电场活化烧结后的金相组织。由图3可以看出,随球磨时间的延长,Cr和Al2O3的颗粒尺寸不断减小,且在铜基体中的分布越来越均匀。混合粉经烧结后,第二相Cr(见图3中灰白色)形貌发生了改变,由烧结前的近球形变为粗大的扁平状,同时还含有少量狭长的条带状颗粒,表面Cr在烧结的过程中烧结压力的作用下发生了塑性变形,只是变形量不大,Cr相在Cu基体中的分布明显不均匀。粉末球磨5 h后再烧结,Cr相在基体中呈条带状分布且相对较均匀。引起Cr相呈条带状的原因有如下两个方面:一是球磨过程中Cr粉末颗粒经过多次反复的碰撞和剪切变形作用,变为薄片状,在多次无规则碰撞下,Cr相在复合粉末中发生扭曲变形,这种扭曲的片状Cr相在后续电场活化烧结中继续保持了其弯曲形貌,这也是导致烧结后Cr相的横截面呈曲折条带状的主要原因;二是单向压制变形虽然在宏观上属于平面应变,但对于每一个Cr相而言并不是严格的平面应变,由于Cr呈体心立方结构,在变形过程中,Cr的变形主要在{011}密排面上,滑移方向为 ,在每个滑移面上仅有两个滑移方向,烧结加压变形时最易于在这两个方向变形,Cr相会发生扭曲[15]。显然,Cr相的曲折条带形貌有助于阻碍Cu基体的变形,起到强化的作用。当球磨10 h的粉末烧结后,其中Cr相的条带状变得窄长,且少量条带发生断裂。这主要是由于随着球磨时间的增加,Cr相变形加剧。烧结过程中元素扩散和Cr相表面自由能降低是引起条带断裂的另一原因。随球磨时间的进一步延长,烧结合金中Cr相的逐渐演变成许多细小的粒子,Cr相在基体中的分布也更加均匀。这主要是由于球磨时间延长到一定程度后,Cr相的塑性变得很差,在变形过程中容易发生断裂。断裂后的Cr粒子非常细小,均匀弥散分布于基体中,和细小的Al2O3粒子一起对基体起到弥散强化的作用。

,在每个滑移面上仅有两个滑移方向,烧结加压变形时最易于在这两个方向变形,Cr相会发生扭曲[15]。显然,Cr相的曲折条带形貌有助于阻碍Cu基体的变形,起到强化的作用。当球磨10 h的粉末烧结后,其中Cr相的条带状变得窄长,且少量条带发生断裂。这主要是由于随着球磨时间的增加,Cr相变形加剧。烧结过程中元素扩散和Cr相表面自由能降低是引起条带断裂的另一原因。随球磨时间的进一步延长,烧结合金中Cr相的逐渐演变成许多细小的粒子,Cr相在基体中的分布也更加均匀。这主要是由于球磨时间延长到一定程度后,Cr相的塑性变得很差,在变形过程中容易发生断裂。断裂后的Cr粒子非常细小,均匀弥散分布于基体中,和细小的Al2O3粒子一起对基体起到弥散强化的作用。

图3 球磨不同时间粉末烧结后的显微组织

Fig.3 Microstructures of sintered milled by different times: (a) 0; (b) 5 h; (c) 10 h; (d) 15 h; (e) 20 h

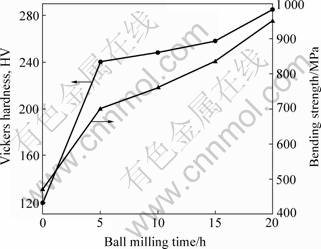

2.3 球磨时间对烧结材料性能的影响

图4所示为球磨时间对粉末电场活化烧结后力学性能的影响。由图4可见,随着球磨时间的延长,粉末烧结后的弯曲强度和硬度都相应得到提高。对于未球磨的混合粉末,其烧结后的硬度和强度仅分别为120 HV和474 MPa;而球磨5 h粉末烧结后的硬度和强度有大幅度提高,硬度达到240 HV,为混粉时的2倍,强度也已增至690 MPa。随球磨时间继续延长,烧结后的强度和硬度也继续增加,但增加速度有所减缓。球磨20h粉末烧结后的强度和硬度分别达到952 MPa和285 HV。

图4 球磨时间对烧结材料硬度和弯曲强度的影响

Fig.4 Effect of milling time on hardness and bending strength of sintered specimens

在球磨过程中,粉末在冲击、剪切和摩擦等多种力的作用下,除Cu和Cr发生了晶粒细化和晶格畸变量增加外,还使得Al2O3颗粒更加均匀弥散分布于Cu基体中,此外,球磨导致Cr颗粒产生显著变形,由颗粒状逐渐向细条带状、细小颗粒状转变,甚至导致部分Cr在Cu中形成强制固溶,总体上,铜基体中Cr的分布随球磨时间的延长变得越来越均匀和弥散。电场活化烧结因具有烧结温度低和烧结时间短的特点,可在较大程度上维持原始粉末内部的组织形态,即可使得球磨过程中形成的细晶组织、相弥散以及Cr变形形态等较好地保留下来。大量的晶界、第二相的弥散分布、形变Cr以及Cu中强制固溶的Cr对位错均具有阻碍作用,从而导致烧结后的材料具有较高的强度和硬度。球磨时间越长,晶界越多,Al2O3和Cr相的弥散度越高,Cr的变形量越大,Cr在Cu中的固溶量越大,它们对位错的阻碍作用也越强,以致烧结材料的强度与硬度也越高。但材料经长时间球磨后,晶粒细化速度、第二相弥散度速度均会减慢,而且Cr相由细条带状破碎而形成细小的弥散分布的颗粒,Cr在Cu中的固溶量趋于平衡,因此,强化效果也相应变缓,进而导致烧结材料强度与硬度值的增加减缓。

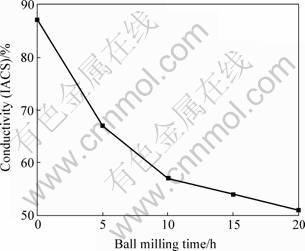

球磨时间对烧结材料电导率的影响如图5所示。由图5可知,随着球磨时间的增加,烧结材料的电导率呈现明显的下降趋势。对于混合粉末,烧结后的电导率为87%。粉末经5 h球磨再烧结后,电导率则已下降到67%。随着球磨时间的进一步增加,烧结材料的电导率下降变缓。

由金属电子理论可知,当晶体点阵完整性遭到破坏时,会对电子波产生散射,从而形成电阻;晶体中的异类原子、位错、空位、晶界和相界均会使得理想点阵的周期性遭受破坏,从而降低金属的导电性。在球磨过程中,Cu和Cr相不断发生塑性变形,从而引起Cu和Cr晶格畸变,形成大量位错,Cu和Cr晶粒细化,晶界增加;同时,异类原子Cr在球磨作用下强制进入Cu的晶格点阵中,进一步加重了Cu基体的晶格畸变。此外,Cr相及Al2O3粒子作为第二相弥散分布于Cu基体中,会引起相界增大,这些因素均必然增加对电子的散射作用,以致烧结合金的电导率下降。材料经长时间球磨,由于晶粒细化速度、位错增殖速度和Cr在Cu中的固溶速度及第二相粒子弥散速度等均逐渐减缓,因此,导致电导率的下降趋势也相应减缓。

图5 球磨时间对烧结材料电导率的影响

Fig.5 Effect of ball milling time on conductivity of sintered specimens

2.4 球磨时间对烧结材料断口形貌的影响

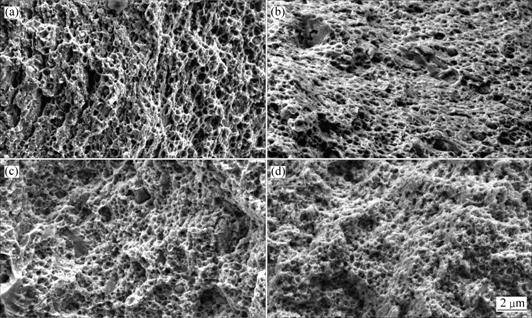

图6所示为球磨不同时间的粉末经电场活化烧结后的(致密度均大于94%)弯曲断口形貌。由图6可知,所有断口均呈现为韧性断裂,且随着球磨时间的延长,断口韧窝逐渐减小。这是由于随球磨时间的延长,第二相Cr和Al2O3的粒度及基体Cu的晶粒尺寸均逐渐减小,且第二相的分布越来越均匀,此外,球磨粉末由于加工硬化其塑性变形能力及应变硬化指数增大,导致内缩颈越来越难于发生,从而导致微孔的尺寸和深度减小。从断口韧窝的减小可以推断材料的塑性也相应减小,而硬度相应增大。对于球磨时间较短时的断口,还可观察到局部存在Cu、Cr两相间的分离断裂现象,且随着球磨时间的延长,Cu、Cr两相间分离界面处可以看到越来越明显的撕裂棱,这些撕裂棱是金属间韧性断裂留下的痕迹,表明Cu、Cr相间在球磨和电场活化烧结作用下已形成了相当充分的冶金结合,并且球磨有利于促进Cu、Cr相间形成冶金结合。长时间球磨后,由于Cr相的充分细化和在Cu中的弥散分布以及两相间良好的冶金结合,故仅从断口已难以分辨Cu、Cr两相的界面。

图6 球磨不同时间粉末烧结后的断口形貌

Fig.6 Fracture surface morphologies of sintered specimen milled by different times: (a) 5 h; (b) 10 h; (c) 15 h; (d) 20 h

3 结论

1) 采用高能球磨方法对Cu-10Cr-0.5Al2O3混合粉末进行预处理,再采用电场活化烧结技术对球磨粉末进行烧结,可制备出高强、高硬的铜基导电材料。

2) 随着球磨时间的延长,Cu晶粒更加细化,第二相分布更加弥散均匀,烧结材料的强度和硬度呈现明显上升趋势,球磨20 h粉末烧结后的强度和硬度分别达到952 MPa和285 HV。但由于晶粒细化、第二相的高度弥散、强制固溶以及晶格畸变等作用,烧结试样的电导率反而随球磨时间的延长而下降。

REFERENCES

[1] 宣守蓉, 范鲁海. 弥散强化铜基复合材料的现状与发展[J]. 梅山科技, 2009(1): 56-60.

XUAN Shou-rong, FAN Lu-hai. Current state and development trend of dispersion strengthened copper matrix composites[J]. Baosteel Meishan, 2009(1): 56-60.

[2] 程建奕, 汪明朴. 高强高导高耐热弥散强化铜合金的研究现状[J]. 材料导报, 2004, 18(2): 38-41.

CHEN Jian-yi, WANG Ming-pu. Progress in research on high-strength high-conductivity and high-heat resistance dispersion strengthened copper alloy[J]. Materials Review, 2004, 18(2): 38-41.

[3] 刘京雷, 阮 峰, 王尔德, 刘祖岩. 高强导电铜基材料的研究现状和发展前景[J]. 材料导报, 2005, 19(7): 8-11.

LIU Jing-lei, RUAN Feng, WANG Er-de, LIU Zu-yan. Progress in research on high-strength and high-conductivity copper- matrix material [J]. Materials Review, 2005, 19(7): 8-11.

[4] 王永兴, 邹积岩. 热等离子体技术在真空开关铜铬触头材料制造中的应用[J]. 材料导报, 1996(6): 32-34.

WANG Yong-xing, ZOU Ji-yan. Application of hot plasma technology in producing CuCr contact materials[J]. Materials Review, 1996(6): 32-34.

[5] 胡 勇, 赵 才, 党淑娥, 范志康. 熔炼法制备CuCr合金的研究现状[J]. 铸造设备研究, 2004(6): 51-54.

HU Yong, ZHAO Cai, DANG Shu-e, FAN Zhi-kang. The research actualities of CuCr alloy prepared by melting methods[J]. Research Studies on Foundry Equipment, 2004(6): 51-54.

[6] 张程煜, 王 江, 张 晖, 杨志懋, 丁秉钧, 秦国义. CuCr25系列合金的耐电强度[J]. 高压电器, 2001, 37(4): 749-752.

ZHANG Cheng-yu, WANG Jiang, ZHANG Hui, YANG Zhi-mao, DING Bing-jun, QIN Guo-yi. Dielectric strength of CuCr25 series alloys[J]. High Voltage Apparatus, 2001, 37(4): 749-752.

[7] LI Jing-ping, MENG Song-he, HAN Jie-cai. Structure and flaws of CuCr alloys by explosive compaction[J]. Journal of Harbin Institute of Technology, 2005, 12(2): 135-138.

[8] 李金平, 梦松鹤, 李广维, 纪 松. 爆炸压实CuCr合金的压实能与压实密度关系的研究[J]. 兵器材料与工程, 2004, 27(4): 44-47.

LI Jing-ping, MENG Song-he, LI Guang-wei, JI Song. Study on the relationship between compact density and compaction energy of CuCr alloys by explosive compaction[J]. Ordnance Material Science and Engineering, 2004, 27(4): 44-47.

[9] 李金平, 李 垚, 梦松鹤, 罗守靖, 纪 松, 陈子明. 爆炸压实CuCr合金过程中的能量与变形[J]. 材料科学工艺, 2004, 12(2): 117-120.

LI Jin-ping, LI Yao, MENG Song-he, LUO Shou-jing, JI Song, CHEN Zi-ming. Energy and deformation during explosive compaction of CuCr alloys[J]. Material Science and Technology, 2004, 12(2): 117-120.

[10] MUNIR Z A, ANSELMI-TAMBURINI U, OHYANAGI M. The effect of electric field and pressure on the synthesis and consolidation of materials: a review of the spark plasma sintering method[J]. Materials Science, 2006, 41(10): 763-777.

[11] KIM Y M, LEE K H, KIM E P, CHEONG D I, HDNG D S H. Fabrication of high temperature oxides dispersion strengthened tungsten composites by spark plasma sintering process[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(5): 842-846.

[12] WANG X, CASOLCO S R, XU G. Finite element modeling of electric current-activated sintering[J]. Acta Materialia, 2007, 55(10): 3611-3622.

[13] MURTY B S, RANGANATHAN S. Novel materials synthesis by mechanical alloying/milling[J]. International Materials Reviews, 1998, 43(3): 1-141.

[14] MAURICE D, COURTNEY T H. Modeling of mechanical alloying: part Ⅰ. Deformation coalescence and fragmentation mechanisms[J]. Metallurgical and Materials Transactions, 1994, 25A(1): 147-158.

[15] SUN S J, SAKAI S, SUZUKI H G. TEM observation of Cr fibers in Cu-15Cr-0.5Fe in situ composites[J]. Materials Transactions, 2000, 41(5): 613-616.

(编辑 龙怀中)

基金项目:国家高技术研究发展计划资助项目(2007AA03Z112);新世纪优秀人才支持计划项目(NCET-10-0364);中央高校基本科研业务费专项资金重点项目(2009ZZ0019);广东省自然科学基金资助项目(x2jqB6080210)

收稿日期:2010-06-22;修订日期:2010-09-03

通信作者:李小强,教授;电话:13535428716;E-mail: Lixq@scut.edu.cn