DOI:10.19476/j.ysxb.1004.0609.2018.04.09

AZ31/AA5083双金属筒形件气压胀形-冷缩结合工艺

王 刚,孔得红,谢允聪,程 涛,王文娟

(哈尔滨工业大学(威海) 材料科学与工程学院,威海 264209)

摘 要:通过气压胀形实验研究AZ31/AA5083双金属筒形件气压胀形-冷缩结合工艺的基本成形规律。结果表明:双金属筒形件的适宜成形温度为450 ℃左右,双金属筒形件因两种金属热膨胀系数不同而收缩不同,在筒间形成过盈配合,筒间残余接触应力取决于双金属收缩量的差异,计算出筒间残余接触应力为2.96 MPa,接触应力过大会导致底部失稳凸起;同时,给出筒底凸起失稳发生的判据。降低成形温度、增大筒底圆角半径和保压冷却等能够防止内层筒筒底失稳;内外层筒形件壁厚不均匀,底部圆角处减薄率达到80%,最易发生破裂;加载路径对壁厚分布几乎没有影响。

关键词:双金属筒形件;气压胀形;冷缩结合;残余接触应力

文章编号:1004-0609(2018)-04-0712-07 中图分类号:TG306;TG146.2 文献标志码:A

随着人们节能意识、环保意识的增强,铝、镁合金等轻质高强材料逐渐受到各国的高度重视,成为实现轻量化、降低能耗和减少污染的重要材料。铝、镁合金应用的交叉性和广泛性,使探究铝/镁合金复合结构的成形与结合方法成为必要课题。

目前,镁/铝合金复合材料或复合结构的生产方法主要有轧制、扩散焊接和爆炸焊接、拉深和挤压等方法,轧制可以方便的生产大尺寸的结合强度较高的复合板,但不宜生产厚度小的复合板[1];焊接获得的焊接接头性能良好,但镁/铝异种合金焊接易形成金属间化合物,引发热裂纹,严重影响构件的质量[2];杨琳等[3]研究热拉深成形镁/铝合金复合结构的技术,但其不能成形形状复杂的空心件,也未考虑两种合金之间的结合情况。池成忠等[4-5]研究5052/AZ31/5052镁铝复合板在170和230℃时的成形极限曲线,分析了胀形试样破裂处的断口形貌及胀形过程界面扩散行为,并进行了不同成形条件下的热拉深试验,研究了成形温度、凸模温度、拉深速度和凹模圆角半径对板料成形性能的影响。王开坤等[6]采用ABAQUS有限元软件对 A356/AZ91D 双金属复合管在半固态多坯料挤压工艺下进行数值模拟研究,得到变形体在不同变形温度下的温度场和应力、应变分布;ASGARI等[7]采用非等通道横向挤压工艺在不同温度下制得AZ80/Al 复合棒材,并测试研究了两合金的连接质量和连接强度,但挤压工艺容易产生波浪、竹节等缺陷。镁/铝复合结构由于加工技术的限制,目前应用还很少,迫切需要开发新的成形方法。

超塑性气压胀形已广泛应用于镁合金、铜合金、铝合金、钛合金和高温合金等板壳件的成形中[8-9],本文作者针对AZ31/AA5083双金属复合筒形件气压胀形-冷缩结合工艺进行探索,研究镁/铝双金属板同步气压胀形变形规律。

1 实验

1.1 实验原理

利用镁/铝合金的超塑性气压胀形的温度区间彼此重叠和热膨胀系数的差异,加热后通过超塑性气压胀形方式成形筒形件,冷却后由镁和铝合金的冷缩量不同而提供双层筒间的残余接触压力,实现镁/铝双金属复合结构的结合。双金属筒形件气胀成形-冷缩结合原理如图1所示。

实验过程:镁合金热膨胀系数约2.4×10-5~ 2.8×10-5 ℃-1,铝合金热膨胀系数约2.1×10-5~ 2.4×10-5 ℃-1,故镁应位于外层,铝位于内层,将双金属板镁板在下铝板在上共同放入凹模和进气板之间,然后将板材和模具放入高温电阻炉中,加热到试验温度附近用液压机加载密封模具,待加热到成形温度后,保温10 min,打开气体减压阀,向模具装置中通入氩气,为成形提供稳定压力,使双金属板料在设定温度和气压下同时胀形。胀形结束后,去除气压,取出胀形后的筒形件,进行后续工作。

图1 双金属筒形件气压胀形示意图

Fig. 1 Schematic diagrams of gas blow forming of bimetallic cylinder

1.2 实验材料和模具

选用板厚为1.0 mm的AA5083轧制铝合金板材及板厚为1.5 mm的AZ31轧制镁合金板材作为实验材料,其中AA5083板材晶粒尺寸为12 μm,AZ31板材晶粒尺寸为8 μm。

成形的筒形件直径80 mm,高度24 mm,法兰入口圆角半径4 mm。

实验前将板材切割成140 mm×140 mm大小的平板,为便于放入圆形加热装置内,剪去四角。在不同成形温度、加载路径下进行双金属筒形件气压胀形实验,确定适宜成形温度,分析AZ31/AA5083双金属筒形件气压胀形-冷缩结合工艺成形规律。

2 结果与分析

2.1 成形温度确定

AZ31镁合金一般超塑性成形温度为350~400 ℃[10],AA5083铝合金一般超塑性成形温度为450~525 ℃[11],在400~525 ℃内,随温度的升高,AA5083板材的超塑性提高,而AZ31板材的超塑性并非降低,文献[12-13]中的结果表明,在10-3 s-1的应变速率下,随着温度升高,伸长率增大,而在10-4~10-5 s-1的应变速率下,随着温度升高,伸长率减小。文献[14]中的结果表明,在420~460 ℃的温度区间,10-3 s-1的应变速率下,随着温度升高,AZ31的塑性随之提高,因此,在400 ℃以上的温度范围内,AZ31镁合金和AA5083铝合金可同步气压胀形,并且温度越高,综合成形性能越好,但从节能和生产率的角度考虑,按以下标准确定适宜成形温度:双金属筒形件无成形缺陷,筒底圆角半径小。

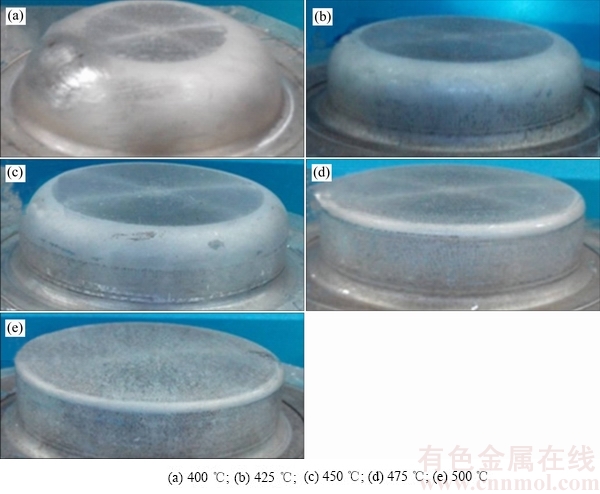

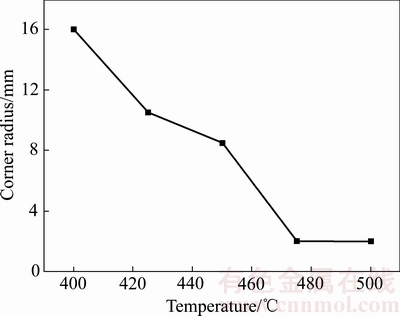

在400~500 ℃温度区间以25 ℃间隔进行不同成形温度的双金属筒形件超塑性气压胀形实验,加载方式为:初始压力1.6 MPa,每600 s增加0.4 MPa,至最大压力4.4 MPa,并在最大压力下保压8100 s,在此成形参数下,成形过程应变速率大部分介于10-3 s-1和10-4 s-1的范围内,双金属筒形件的照片如图2所示,筒底圆角半径大小如图3所示,纵剖面照片如图4所示。

图2和3表明,在400~500 ℃温度区间内,随着温度的升高,胀形件轮廓愈来愈清晰,筒底圆角半径逐渐减小,475 ℃底面圆角半径约为1 mm,成形温度升高到500 ℃,底面圆角半径基本上保持不变,说明进一步提高温度,并不能使底面圆角半径明显减小。从图4可以看出,在450 ℃及以下进行超塑性气压成形时,双层筒间紧密结合,界面结合质量良好,无扩散连接现象;475 ℃及以上成形时,内层筒筒底冷却后因冷缩产生的接触压力而弹性屈曲失稳,内外筒底间产生空隙,底部界面无法贴合,如图4(b)所示。在上述几何条件和加载方式下,获得未发生底面失稳凸起的AZ31/AA5083双金属筒形件的临界温度介于450~475 ℃间。

图2 不同成形温度下成形的筒形件

Fig. 2 Photographs of cylinders at different forming temperatures

图3 不同温度下筒形件筒底圆角半径

Fig. 3 Bottom corner radius of as-formed cylinders at different forming temperatures

图4 不同温度下成形筒形件的纵剖面

Fig. 4 Vertical section of as-formed cylinders at different temperatures

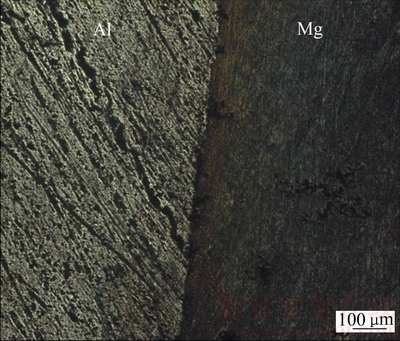

将镁/铝结合界面处磨光并用苦味酸处理,采用金相显微镜放大100倍对成形的复合管结合界面进行观测,显微图像如图5所示,由图5可以看出,界面结合非常紧密,无冶金结合现象。

综上所述,AZ31/AA5083双金属筒形件的适宜成形温度为450 ℃, 在该温度下成形,所得双金属筒形件圆角半径较小,且结合紧密,底面无凸起缺陷。

图5 Mg/Al界面光学显微像

Fig. 5 Microscopic image of Mg/Al interface

2.2 双金属筒形件壁厚分布规律

2.2.1 壁厚分布规律

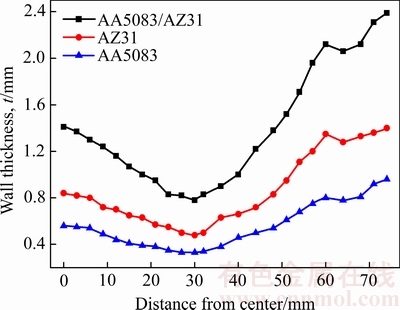

取成形温度为450 ℃,加载方式:初始压力为1.6 MPa,每600 s增加0.4 MPa,达到最大压力4.4 MPa,并保压8100 s的筒形件分析,用游标卡尺测量壁厚,壁厚分布如图6所示。

双金属筒形件总壁厚分布规律与内层和外层筒形件分布规律几乎一致,壁厚分布不均匀,随着测量位置距中心距离的增加,壁厚逐渐减小,靠近底部圆角处厚度变薄最严重,壁厚最小,沿侧壁方向,自筒底至法兰壁厚逐渐增加。

原因在于自由胀形阶段穹顶壁厚最薄,其最先贴模,已贴模材料受摩擦约束,几乎不流动,只有未贴模部分继续变形减薄,所以最后贴模的圆角部分靠近底部直边段的部分最薄,减薄率达到80%左右,导致壁厚分布不均匀。

图6 双金属筒形件壁厚分布

Fig. 6 Wall thickness distribution of bimetal cylinder

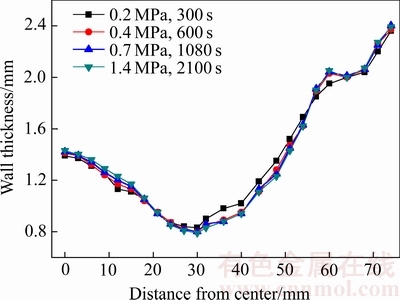

2.2.2 加载路径对壁厚分布的影响

采用初始压力1.6 MPa,最大压力4.4 MPa,不同加载路径进行胀形试验,胀形件壁厚分布如图7所示,图7中0.2 MPa/300 s表示每300 s加载0.2 MPa,其它依此类推。由图7可以看出,4种加载路径下,壁厚分布曲线几乎重合,表明初始压力和最大压力一致时,多阶段阶梯加载方式对胀形件的壁厚分布没有明显影响。这可能是因为这4种加载路径的平均加载速率几乎一致的缘故。

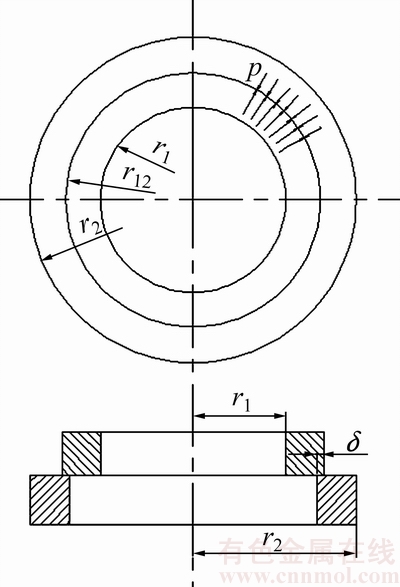

2.3 筒间残余接触压力理论计算

镁/铝双金属筒形件的外层镁管和内层铝管在成形后冷却时因收缩量的不同,可将双金属筒形件视为两个过盈配合的圆筒,如图8所示。可近似认为,结合力或残余接触应力的大小取决于内筒和外筒在冷却过程中形成的过盈配合量。由变形协调条件和拉梅公式可推导出过盈量δ与筒间残余接触压力p的解析方程[15]。

图7 不同加载路径下双金属筒形件壁厚分布

Fig. 7 Wall thickness distribution of bimetal cylinder under different loading paths

根据拉梅公式,内层筒在压力p的作用下,应力分量( 、

、 )与位移分量(u1)分别为

)与位移分量(u1)分别为

(1)

(1)

(2)

(2)

式中:r1为内层筒内半径,mm;r12为内外层筒界面半径,mm;E1为内层筒的弹性模量,GPa;μ1为内层筒的泊松比。

图8 双金属筒残余接触应力

Fig. 8 Residual contact stress of bimetal cylinder

外层筒在压力p的作用下,应力分量( 、

、 )与位移分量(u2)分别为

)与位移分量(u2)分别为

(3)

(3)

(4)

(4)

式中:r2为外层管外半径,mm;E2为外层管的弹性模量,GPa;μ2为外层管材的泊松比。

过盈量即为内、外层管材位移之和:

(5)

(5)

将式(2)、(4)代入式(5),得到过盈量δ与残余接触应力p之间的关系式为

(6)

(6)

过盈量可由材料的热膨胀规律计算得到,由于热膨胀系数随温度升高而增大,故采用室温至成形温度间的平均热膨胀系数估算夹紧力,AZ31镁合金的热膨胀系数取2.78×10-5 ℃-1,AA5083铝合金的热膨胀系数取2.25×10-5 ℃-1。

r2为筒形件外径,r1为筒形件内径,r12为内外筒界面半径,取靠近底部拐角处的直边段的尺寸,r1=40 mm,r12=39.6 mm,r2=39 mm。AZ31镁合金弹性模量E2=44.8 GPa,泊松比μ2=0.35;AA5083铝合金E1=70.3 GPa,μ1=0.33。δ值可由线膨胀系数的定义算出,为0.0399 mm,温度改变量Δt=430 ℃,将以上数值代入式(6),计算可得AZ31/AA5083筒形件筒间残余接触应力p=2.96 MPa。

2.4 内层筒底凸起失稳分析

选取475 ℃下双金属筒形件来分析内层筒底凸起失稳影响因素。将内层筒底凸起看成是沿周边均匀受压薄圆板的屈曲,如图9所示,P为筒形件内层底面沿周边均匀接触应力。

根据文献[16],假设满足固定边的边界条件,筒形件内层筒底发生失稳凸起的临界残余接触应力 为

为

(9)

(9)

式中:E为内层筒材料弹性模量,MPa;t为筒形件内层筒底厚度,mm;μ为内层筒材料泊松比,取0.33;R为内层筒筒底半径,mm。

图9 内层筒形件筒底受力图

Fig. 9 Free body diagram for bottom of inner cylinder

将铝的弹性模量72 GPa和泊松比0.33,内层筒筒底半径38 mm(减去圆角半径部分)、筒底厚度0.28 mm(按最薄处计算)代入式(9),计算得到 =5.37 MPa,大于前面计算得到的筒间残余接触压力2.96 MPa,理论上不应该产生屈曲。但考虑到外层镁筒筒底中间厚,两边薄,筒底中心厚度约0.8 mm,靠近侧壁圆角处厚度只有约0.5 mm,这样覆盖在外层镁筒筒底之上的内层铝筒筒底呈现出近似薄球壳而不是平直的圆平板形状,使之发生屈曲所需的边界压应力减小很多,所以式(9)还应该乘以一个系数K(称为内层筒底形状修正系数),其取值约为0.6。

=5.37 MPa,大于前面计算得到的筒间残余接触压力2.96 MPa,理论上不应该产生屈曲。但考虑到外层镁筒筒底中间厚,两边薄,筒底中心厚度约0.8 mm,靠近侧壁圆角处厚度只有约0.5 mm,这样覆盖在外层镁筒筒底之上的内层铝筒筒底呈现出近似薄球壳而不是平直的圆平板形状,使之发生屈曲所需的边界压应力减小很多,所以式(9)还应该乘以一个系数K(称为内层筒底形状修正系数),其取值约为0.6。

所以,当冷缩结合提供的作用在内层筒筒底上的筒间接触压力P大于或等于 时,内层筒筒底发生失稳凸起。也就是说,要防止内层筒筒底凸起,P应当小于

时,内层筒筒底发生失稳凸起。也就是说,要防止内层筒筒底凸起,P应当小于 ,当筒形件尺寸和材质一定时,可采取保压冷却的方式来降低筒间残余接触压力。

,当筒形件尺寸和材质一定时,可采取保压冷却的方式来降低筒间残余接触压力。

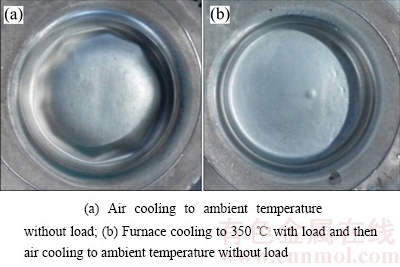

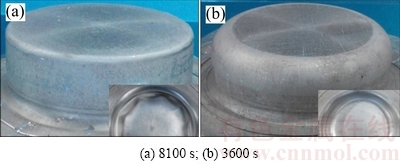

在475 ℃胀形后分别采用卸压空冷方式以及保压炉冷至350 ℃后卸压空冷的方式进行筒形件的冷却,得到的双金属筒形件如图10所示。

实验结果表明,直接卸压空冷后内层筒形件底部凸起约10 mm,如图9(a)所示,而保压炉冷至350 ℃后卸压空冷的筒形件底部平整,成形质量较好,如图9(b)所示,这是因为如果胀形结束后就卸载气压,冷却过程中内层筒筒底受双向压应力作用,随着冷却温度降低,筒形件筒间残余接触应力逐渐增大,导致筒底所受压应力增大,当达到失稳临界应力时,内层筒筒底凸起;而胀形结束后保持气体压力不变进行保压冷却,冷却过程中内层筒底保持三向受压的应力状态,内部气压会阻止筒形件收缩,使外层筒侧壁产生微量塑性变形,减小筒间残余接触应力,直到在某个温度下气压不足以使侧壁产生微量塑性变形为止,因此,保压冷却相当于使产生冷缩的温度降低,冷缩区间减小,这样,冷却到室温后,筒间的接触应力较较相同温度下直接卸压冷却时的残余接触应力小,小于临界失稳应力,不足以引起内层筒底凸起,保压冷却为消除内筒底部凸起失稳提供了一种途径。

图10 不同冷却方式下胀形件照片

Fig. 10 Photographs of as-formed cylinders at different cooling processes

筒底圆角半径对筒底凸起影响很大,在475 ℃成形温度下,保持其他条件不变,只是减少保压时间到3600 s,其胀形件照片如图11所示。由图11可以看出,减少保压时间,筒底圆角半径增大,筒形件底部成形质量良好,未见凸起产生。圆角的存在,相当于减小了平直的筒底半径,根据式(9),筒底半径越小,临界失稳压力就越大,所以不发生失稳凸起。

图11 不同成形时间下胀形件照片

Fig. 11 Photographs of as-formed cylinders at different forming time

综上所述,影响双金属筒形件内层筒底失稳凸起的因素主要包括成形温度、圆角半径、筒形件直径、内层板材厚度以及内层板材材料常数的大小。成形温度越高,双金属筒形件冷却到失稳的过程中板间接触压力越大,故双金属筒形件中内层筒底失稳凸起也更易发生;筒间结合力越大,作用在内层筒筒底的周向接触压力越大,失稳凸起也越容易发生;底面圆角越大,相当于筒底面半径越小,发生屈曲的临界接触压力越大,则失稳凸起越难于发生;筒形件直径越大,板厚越小,内层筒筒底面失稳凸起所需的临界接触压力越小,失稳凸起越容易发生;材料的弹性模量越大,泊松比越小,发生屈曲的临界接触压力越大,失稳凸起越难发生。

3 结论

1) 利用镁/铝合金的超塑气胀温度区间彼此重叠和热膨胀系数的差异,通过气压胀形-冷缩结合工艺成功地成形出了直径为80 mm、高度为24 mm的结合良好的AZ31/AA5083双金属筒形件。AZ31/AA5083双金属筒形件的适宜成形温度为450 ℃左右。

2) 镁/铝双金属筒形件间因冷缩不同而形成过盈配合,给出了筒间残余接触应力计算公式。筒间残余接触应力过大会导致内层筒筒底失稳凸起,将双金属筒形件内层筒筒底视为沿周边均匀受压薄圆板给出了内层筒底发生凸起失稳的临界接触压力计算公式。可预测内层筒底是否发生凸起,并可采用降低成形温度、保压冷却等措施防止筒底凸起。

3) 内外层筒形件壁厚不均匀,底部圆角处最薄,最大减薄率可达到约80%,最易发生破裂,分阶段阶梯式加载对双金属筒形件壁厚分布几乎无影响。

REFERENCES

[1] ZHANG X P, CASTAGNE S, YANG T H, GU C F, WANG J T. Entrance analysis of 7075 Al/Mg-Gd-Y-Zr/7075 Al laminated composite prepared by hot rolling and its mechanical properties[J]. Materials & Design, 2011, 32(3): 1152-1158.

[2] YAN Y B, ZHANG Z W, SHEN W, WANG J H, ZHANG L K, CHIN B A. Microstructure and properties of magnesium AZ31B-aluminum 7075 explosively welded composite plate[J]. Materials Science and Engineering A, 2010, 527(9): 2241-2245.

[3] 杨 琳, 樊 奇, 曹晓卿, 徐平平, 王文先. 镁/铝合金双金属叠层板的拉深性能[J]. 中国有色金属学报, 2014, 24(9): 2213-2219.

YANG Lin, FAN Qi, CAO Xiao-qing, XU Ping-ping, WANG Wen-xian. Deep drawability of Mg/Al bimetal laminated sheet[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(9): 2213-2219.

[4] 赵 玲, 池成忠, 余春燕, 林 鹏, 梁 伟. 镁铝层合板拉深成形性能的试验研究[J]. 锻压技术, 2015, 40(4): 24-27.

ZHAO Ling, CHI Cheng-zhong, YU Chun-yan, LIN Peng, LIANG Wei. Experimental study on drawing formability of magnesium aluminum laminates[J]. Forging & Stamping Technology, 2015, 40(4): 24-27.

[5] 马艳彦, 池成忠, 林 鹏, 闫辰侃, 梁 伟. 5052/AZ31/5052镁铝复合板成形极限及界面扩散行为[J]. 稀有金属材料与工程, 2016, 45(8): 2086-2091.

MA Yan-yan, CHI Cheng-zhong, LIN Peng, YAN Chen-kan, LIANG Wei. Forming limit and interface diffusion behavior of 5052/AZ31/5052 tri-layer clad sheet[J]. RareMetalMaterials andEngineering, 2016, 45(8): 2086-2091.

[6] WANG Kai-kun, SUN Jian-lin, MENG Hai-feng, DU Yan-mei, WANG Xi. Numerical simulation on thixo-co-extrusion of double-layer tube with A356/AZ91D[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(S3): s921-s925.

[7] ASGARI M, FERESHTEH-SANIEE F. Production of AZ80/Al composite rods employing non-equal channel lateral extrusion[J]. Transactions ofNonferrousMetals Society of China, 2016, 26(5): 1276-1283.

[8] MITUKIEWICZ G, ANANTHESHWARA K, ZHOU G, MISHRA R K, JAIN M K. A new method of determining forming limit diagram for sheet materials by gas blow forming[J]. Journal of Materials Processing Technology,2014, 214(12): 2960-2970.

[9] 李 超, 李彩霞, 赵 闪. 脉冲电流条件下工业态AZ31 镁合金板材的气胀成形[J]. 中国有色金属学报, 2015, 25(3): 553-558.

LI Chao, LI Cai-xia, ZHAO Shan. Gas blow forming of commercial AZ31 magnesium assisted by pulse current[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 553-558.

[10] JEONG H G, JEONG Y G, KIM W J. Microstructure and superplasticity of AZ31 sheet fabricated by differential speed rolling[J]. Journal of Alloys and Compounds, 2009, 483(1): 279-282.

[11] YOGESHA B, DIVYA H V, BHATTACHARYA S S. Superplasticityandsuperplastictensile behavior ofAA5083[J]. Advanced Materials Research,2014, 902: 24-28.

[12] 刘满平, 马春江, 王渠东, 吴国华, 朱燕萍, 丁文江. 工业态AZ31镁合金的超塑性变形行为[J]. 中国有色金属学报, 2002, 12(4): 797-800.

LIU Man-ping, MA Chun-jiang, WANG Qu-dong, WU Guo-hua, ZHU Yan-ping, DING Wen-jiang. Superplastic deformation behavior of commercial magnesium alloy AZ31[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(4): 797-800.

[13] 张青来, 肖富贵, 郭海玲, 胡永学, 高 霖. AZ31B镁合金热拉伸流变应力研究[J]. 塑性工程学报, 2009, 16(1): 167-172.

ZHANG Qing-lai, XIAO Fu-gui, GUO Hai-ling, HU Yong-xue, GAO Lin. Study on flow stress of AZ31B magnesium alloy at elevated temperature[J]. Journal of Plasticity Engineering, 2009, 16(1): 167-172.

[14] 李思奕. AZ31/7475双金属复合管气压胀形-冷缩结合工艺研究[D]. 哈尔滨: 哈尔滨工业大学, 2016.

LI Si-yi. Research on gas blow forming-cooling contraction bonding process of AZ31/7475 bimetal composite tubes[D]. Harbin: Harbin Institute of Technology, 2016.

[15] 蔡 凡, 李初晔, 马 岩. 过盈配合产生的接触压力和拔出力计算[J]. 机械设计与制造, 2010, 10: 7-9.

CAI Fan, LI Chu-ye, MA Yan. Contact pressure and pull-out force reflect on the interference fit[J]. Machinery Design and Manufacture, 2010, 10: 7-9.

[16] CHONAN S. Vibration and stability of annular plates under conservative and non-conservative loads[J]. Journal of Sound and Vibration, 1982, 80(3): 413-420.

Gas blow forming-cooling contraction bonding process of AZ31/AA5083 bimetallic cylinder

WANG Gang, KONG De-hong, XIE Yun-cong, CHENG Tao, WANG Wen-juan

(School of Materials Science and Engineering, Harbin Institute of Technology at Weihai, Weihai 264209, China)

Abstract: The forming behavior of gas blow forming-cooling contraction bonding of AZ31/AA5083 bimetal cylinder was researched by gas blow forming tests. The experimental results show that the optimum temperature is about 450 ℃. The residual contact stress between bimetallic cylindrical components results from interference fit and is about 2.96 MPa. The excessive contact stress can lead to instability at the bottom of inner cylindrical component and the corresponding instability criterion is proposed. Decreasing forming temperature, increasing the round corner radius of bottom and cooling with the gas pressure can avoid the instability. The wall thickness distribution of internal and external cylinders is non-uniform and the thickness thinning rate of corners on the bottom reaches up to 80% and thus this location is the most vulnerable to rupture. With the same initial pressure and the maximum pressure, the loading path has no effect on the wall thickness distribution.

Key words: bimetal cylinder; gas blow gagforming; cooling contraction bonding; residual contact stress

Foundation item: Projects(HIT. NSRIF. 201013) supported by the Innovation Foundation for Scientific Research of HIT, China

Received date: 2017-02-16; Accepted date: 2017-05-23

Corresponding author: WANG Gang; Tel: +86-631-5687324; E-mail: wg@hitwh.edu.cn

(编辑 李艳红)

基金项目:哈尔滨工业大学科研创新基金资助(HIT. NSRIF. 201013)

收稿日期:2017-02-16;修订日期:2017-05-23

通信作者:王 刚,副教授,博士;电话:0631-5687324;E-mail: wg@hitwh.edu.cn