Effect of cold-rolling and annealing on interfacial structures and properties of A500/steel bimetal strip

LI Bao-mian(李宝绵), HAN Jian-fen(韩建芬),XU Guang-ming(许光明), CUI Jian-zhong(崔建忠)

(Key Laboratory of Electromagnetic Processing of Material, Ministry of Education, Northeastern University, Shenyang 110004, China)

Abstract: The effect of cold-rolling, by both a series of small passes and single-pass with different deformations as well as the subsequent annealing, on the interfacial structures and properties of A500(AlSn8Pb2Si2.5Cu0.8Cr0.2)/steel bimetal strip produced by liquid-solid roll cladding was investigated. Experimental results of the cold-rolling by a series of small passes show that the interfacial bonding strength increases slightly when the total deformation is less than 7.32% and then decreases gradually with the increase in deformation. Subsequent annealing has no effect on the interfacial structures and properties. The effect of cold-rolling by single-pass less than 33.2% deformation on the interfacial structures and properties is the same as that of multi-pass cold-rolling, whereas cold-rolling by single-pass more than 33.2% deformation followed by annealing at 350℃ for 2.5h can make the interfacial bonding strength increase to a great extent. Metallographic examination of the interface shows that there exist only transverse cracks within the interfacial layer and the clad strip does not split along the interface during cold-rolling if the thickness of interfacial layer is less than 4-5μm. The thick interfacial layer(>5-6μm), however, crumbles during cold-rolling, thus resulting in the splitting of the clad strip.

Key words: liquid-solid roll cladding; bimetal bearing strip; interface; interfacial bonding strength CLC number: TG335.85

Document code: A

1 INTRODUCTION

Al-Sn base alloys have more and more replaced copper alloys and Babbitt alloys for engine bearing applications since 1960s because of their better anti-seizure property, wear resistance, and corrosion resistance[1-4]. However, the recent trend toward the high-speed, high specific loading, and light-mass constrution of automotive engines has been imposing higher requirements of load capacity, wear resistance, and high-temperature properties on bearing materials. In order to meet these requirements, a new engine bearing alloy, A500(AlSn8Pb2Si2.5Cu0.8Cr0.2), was developed in Japan and USA[5]. This alloy shows excellent performance characteristics, particularly wear resistance, conformability, anti-seizure, and load capacity because of the fine and uniform distribution of Sn, Pb soft phases as well as Si, Cu, Cr hard phases[6-9]. In order to assure the excellent performance characteristics of A500 alloy, it is usually bonded to a steel backing by either powder metallurgy or rapid solidification process[10-12]. Such complicated and costly manufacturing processes limit the further spreading and using of this alloy.

A new low-cost and high-efficiency process, liquid-solid roll cladding(LSRC) process, for producing A500/steel bearing clad strip has been developed recently[13, 14]. As is the case of producing strip by direct twin-roll casting, however, the thickness of the clad strip produced by LSRC process is usually uneven. Therefore subsequent cold-rolling and annealing should be conducted in order to control the thickness of the clad strip precisely. Since the interfacial layer of A500/steel is intermetallic compound[15] and the differences of mechanical properties between A500 and steel are large, unreasonable cold-rolling and annealing process will result in not only a decrease in the interfacial bonding strength but even the splitting of the clad strip. It is thus meaningful to investigate the interfacial behavior of A500/steel clad strip during cold-rolling and annealing and further to determine the optimal process of cold-rolling and annealing.

2 EXPERIMENTAL

2.1 Materials

The steel strip with 1.2mm in thickness and 120mm in width was commercial 08Al. A500 bearing alloy whose nominal composition is Al-8Sn-2.5Si-2Pb-0.8Cu-0.2Cr was melted and refined in medium-frequency induction furnace. The A500/steel bimetal bearing strip was produced by LSRC process (the full details were given in Ref.[13]) and its thickness was 2.05mm.

2.2 Cold-rolling

The A500/steel clad strip was cold-rolled by a series of small passes and single pass with different deformations respectively. The pass reduction of multi-pass cold-rolling was less than 5%. Samples were then taken from the cold-rolled clad strips. The interfacial bonding strength was measured and the interfacial morphology was examined.

2.3 Annealing

The cold-rolled clad strips were annealed at the temperature of 350℃ for 1.5, 2.5, 3.5h with reference to Ref.[16]. Samples were then taken from the annealed clad strips. The interfacial bonding strength was measured and the interfacial morphology was examined.

2.4 Measurement of interfacial bonding strength

Since the thickness of the clad strip produced by LSRC process was thin, the lap-shear test defined in GB6396-86 and peel test could not be used to measure the interfacial bonding strength. Therefore repeated bending test was used to evaluate the interfacial bonding strength indirectly. The rectangular bending samples having 160mm×10mm in dimensions were prepared in accordance with GB235-82. The prepared samples were clamped vertically in the bending head and then bent alternately to left and right at 90° until the samples either split along the interface or broke.

3 RESULTS AND DISCUSSION

3.1 Results of cold-rolling

3.1.1 Interfacial layer

The interfacial metallographs of clad strips cold rolled to different deformations(ε) by a series of small passes are shown in Fig.1. It can be seen from Fig.1 that the interfacial layer does not take place any changes when the total deformation is less than 3.25%. When the total deformation is more than 7.32%, however, cracks begin to emerge within the interfacial layer and widen gradually with the increase in deformation, making the original continuous interfacial layer turn into isolated blocks and the base metals(A500 alloy and steel strip, especially A500 alloy) be extruded gradually into the cracks of the interface. A500-to-steel contact among the “blocks” of interfacial layer, however, does not occur with up to 46.2% total deformation. Although the interfacial layer breaks into blocks during cold-rolling, the clad strip does not split along the interface owing to the bond of the unbroken parts. It can also be seen from Fig.1 that the interfacial layer is thin(〈5μm) and there exist only transverse cracks within the interface.

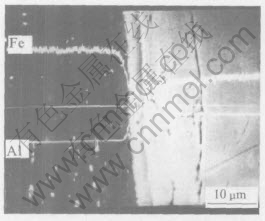

The metallographic examination of the split clad strips shows that the interfacial layers are thick (5-6μm). The thick interfacial layers produce not only transverse cracks but longitudinal ones during cold-rolling, which results in the crumbling of the thick interfacial layers(Fig.2) and the splitting of the clad strips.

The metallographic examination of the clad strips cold rolled by single-pass to different deformations shows that the interfacial behavior is the same as that of the clad strip cold rolled by multi-pass when the deformation is less than 33.2%(Fig.3). When the deformation is more than 33.2%, however, A500 alloy comes in contact with steel among the “blocks” of interfacial layer(Fig.4 and Fig.5) and rewelding between A500 and steel strip takes place. Therefore the clad strip does not split apart during cold rolling.

3.1.2 Interfacial bonding strength

The measuring results of bending numbers(N) of the clad strips cold rolled to different deformations(ε) are shown in Table 1. It can be seen from Table 1 that the interfacial bonding strength increases slightly first and then decreases gradually with the increase in deformation. The maximum interfacial bonding strength is reached at about 3.25% deformation. The reason for the variation law of the interfacial bonding strength is as follows. The expansion coefficient of A500 alloy is larger than that of steel, the contraction of A500 alloy is thus larger than that of steel during the cooling after LSRC, resulting in the formation of compressive residual stress in steel strip and tensile residual stress in A500 alloy. In the course of cold rolling the residual stress formed during cooling can be eliminated because the plastic deformation of A500 alloy is larger than that of steel strip, as a result the interfacial bonding strength rises. When the deformation is above about 7%, however, cracks begin to emerge within the interfacial layer and widen gradually with the increase in deformation(Fig.1), thus resulting in the gradual decrease in interfacial bonding strength. It should be point-ed out that A500 alloy gets fragile when the de-

Table 1 Bending numbers of clad strip cold rolled to different deformations

Fig.1 Interfacial morphologies of clad strip cold-rolled to different deformations by multi-pass

Fig.2 Interfacial morphology of split clad strip(ε=35.3%)

Fig.3 Interfacial morphology of clad strip cold-rolled in single pass (ε=23.8%)

Fig.4 Interfacial morphology of clad strip cold-rolled in single pass(ε=33.2%)

Fig.5 Interfacial morphology of clad strip cold-rolled in single pass(ε=43.6%)

formation is above about 35.3%, thus A500 alloy cracks before the clad strip splits along the interface during bending.

3.2 Results of annealing

3.2.1 Interfacial layer

The interface of the annealed clad strip is examined by using optical microscope and electron microscope in order to determine the variation law of the structure and thickness of interfacial layer during annealing. Fig.6 shows the interfacial morphology of the as-clad strip after annealing at 350℃ for 3.5h. It can be seen by comparing Fig.6 with Fig.1(a) that the thickness of the clad strips before and after annealing is basically the same. EPMA result shows that the interface is composed of 60.4%Al and 39.5%Fe. This composition of the interface corresponds typically to FeAl3, which is the same as that of the as-clad strip[17]. These results indicate that the structure and thickness of the interface before and after annealing do not change.

Fig.6 Interfacial morphology of as-clad strip after annealing at 350℃ for 3.5h

3.2.2 Interfacial bonding strength

The measuring results of bending numbers of the clad strips after cold rolled by both a series of small passes and single pass with different deformations and annealed at 350℃ for 1.5, 2.5, 3.5h are shown in Tables 2 and 3 respectively. It can be seen by comparing the data in Table 2 with those in Table 1 that after annealing the interfacial bonding strength of the as-clad strip increases slightly whereas that of the clad strips cold rolled by a series of small passes to different deformations does not change. By comparing the data in Table 3 with those in Table 1 it can be seen that the interfacial bonding strength of the clad strips before and after annealing does not change either when the pass reduction is less than 33.2%. But when the pass reduction is more than 33.2% the interfacial bonding strength of the clad strips increases greatly after annealing, especially when the annealing time is longer than 2.5h the separation of the clad strip is not observed before A500 alloy cracks. This means that the interfacial bonding strength of the clad strip has reached the strength of its weaker component A500 alloy already.

The above variation law of the interfacial bonding strength is related to the interfacial behavior during cold rolling and subsequent annealing. As stated above, in the course of cold rolling of a series of small passes and single pass with less than 33.2% deformation the interfacial layer fragments

Table 2 Bending numbers of clad strips cold rolled by multi-pass and annealed

Table 3 Bending numbers of clad strips cold rolled by single pass and annealed

into blocks gradually with the increase in deformation and A500 alloy does not come into contact with steel among the blocks. During the subsequent annealing the thickness and composition of the interfacial layer do not change and the inter-diffusion between Al and Fe at the cracks can not take place because of no A500-to-steel contact. Therefore the interfacial bonding strengths before and after annealing are basically the same. During cold rolling by single-pass with more than 33.2% deformation, however, the A500-to-steel contact occurs among the fragmented blocks of the interface and the subsequent annealing promotes the inter-diffusion between Al and Fe at the contact regions further. So the interfacial bonding strength increases. As can be seen from Table 3 that the bending numbers of the clad strips are determined by the properties of A500 alloy when the annealing time is above 2.5h. So the annealing process parameters are determined as 350℃ for 2.5h.

4 CONCLUSIONS

1) The interfacial bonding strength of the clad strips cold rolled by a series of small passes increases slightly when the total deformation is less than 7.32% and then decreases gradually with the increase in deformation.

2) Annealing has no effect on the interfacial bonding strength, interfacial composition, and the thickness of interfacial layer of the clad strips cold rolled by both a series of small passes and single-pass with less than 33.2% deformation.

3) More than 33.2% deformation of single-pass cold-rolling followed by annealing at 350℃ for 2.5h can improve the interfacial bonding strength of the clad strip to a great extent.

4) Only transverse cracks emerge within the interfacial layer and the clad strip does not split apart during cold rolling if the thickness of interfacial layer is less than 4-5μm; if the thickness of interfacial layer is more than 5-6μm, however, the interfacial layer crumbles and the clad strip split apart during cold rolling.

REFERENCES

[1]Pratt G C. Materials for plain bearings [J]. International Metallurgical Reviews, 1973, 18: 62-88.

[2]ZHANG Bao-yi. Plain Bearing Materials for Internal Combustion Engines [M]. Beijing: China Machine Press, 1989. 161-195. (in Chinese)

[3]Stuczynsky T. Metallurgical problems associated with the production of aluminium-tin alloys [J]. Materials & Design, 1997, 18(4): 369-372.

[4]Tamotsu N, Kamiya S. Aluminium-Tin Base Bearing Alloys [P]. GB2067219A,1981.

[5]Whitney W J. An advanced aluminium-tin-silicon engine bearing alloy and its performance characteristics [A]. SAE Tech [C]. Warrendale, USA, 1995. 950-953.

[6]MA Wei. Development and application of medium-tin aluminium alloy bearing material [J]. Internal Combustion Engine Parts, 2004(2): 17-19. (in Chinese)

[7]YUAN Ge-cheng, ZHANG Xin-ming, LOU Yan-xiong, et al. Tribological characteristics of new series Al-Sn-Si alloys [J]. Trans Nonferrous Met Soc China, 2003, 13(4): 774-780.

[8]ZHOU Jing-de. Study on Al-Sn-Si-Cu bearing alloy [J]. Light Alloy Fabrication Technology, 2000, 28(5): 44-46. (in Chinese)

[9]YUAN G C, LI Z J, LOU Y X, et al. Study on crystallization and microstructure for new series Al-Sn-Si alloys [J]. Materials Science & Engineering A, 2000, A280: 108-115.

[10]Ravi N V. Bimetal bearings spreads its wings [J]. MPR, 1999(1): 24.

[11]LI Xing-gang. Study on AlSn8Pb2Si2.5Cu0.8Cr0.2/Steel Clad Bearing Strip Produced by Liquid-Solid Roll Cladding [D]. Shenyang: Northeastern University, 2002. 13-15. (in Chinese)

[12]Harris S J, McCartney D G, Horlock A J, et al. Production of ultrafine microstructures in Al-Sn, Al-Sn-Cu and Al-Sn-Si-Cu alloys for tribological applications [J]. Materials Science Forum, 2000, 331: 519-526.

[13]LI Xing-gang, XU Guang-ming, LI Bao-mian, et al. Producing AlSn8Pb2Si2.5Cu0.8Cr0.2/steel clad strip by liquid-solid roll cladding [J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1172-1178. (in Chinese)

[14]ZHOU Yi-miao. Suggestion for the development of bimetal bearing strip [J]. Shanghai Nonferrous Metals, 2003, 24(4): 179-181. (in Chinese)

[15]LI Xing-gang, LI Bao-mian, XU Guang-ming, et al. Structure and interface of aluminium-tin-silicon alloy/steel clad bearing strip produced by liquid-solid roll cladding [J]. Journal of Northeastern University, 2002, 23(12): 1177-1180. (in Chinese)

[16]CHEN Ji-qing. Study on the heat treatment and structure of AlSn20Cu/steel clad strip [J]. Wuhan Iron and Steel Corporation Technology, 2003, 41(5): 5-8. (in Chinese)

[17]WANG Dong-gang. Study on the Process and Structure of AlSn8Pb2Si2.5Cu0.8Cr0.2/Steel Clad Bearing Strip Produced by Liquid-Solid Roll Cladding [D]. Shenyang: Northeastern University, 2004. 25-27. (in Chinese).

(Edited by YUAN Sai-qian)

Foundation item: Project(2002AA334060) supported by the National High-Tech Research and Development Program of China

Received date: 2004-10-28; Accepted date: 2005-01-19

Correspondence: LI Bao-mian, PhD; Tel: +86-24-83681735; E-mail: bmlee@mail.edu.cn