文章编号:1004-0609(2016)-03-0623-07

Cu/Al复合带固-液铸轧热-流耦合数值模拟及界面复合机理

黄华贵,季 策,董伊康,杜凤山

(燕山大学 国家冷轧板带装备及工艺工程技术研究中心,秦皇岛 066004)

摘 要:双金属层状复合带固-液铸轧成形是集快速凝固与轧制复合为一体的短流程新工艺,为揭示固相覆层金属带材与基体熔体在双辊铸轧区内的复合机理,以d160 mm×150 mm双辊实验铸轧机为对象,利用Fluent商用软件建立Cu/Al固-液铸轧复合过程二维热-流耦合计算模型,研究铸轧速度、浇注温度、铜带厚度和预热温度对熔池流场、KISS点位置与复合界面温度分布的影响规律。Cu/Al固-液铸轧复合实验结果表明,铸轧区内固-液接触区、固-半固态粘连区、固-固轧制复合区界面结合效果呈现递进式强化规律,显示出温度和轧制压力对界面复合的重要作用,对成形工艺制定具有重要的指导意义。

关键词:固-液铸轧复合;Cu/Al复合带;双辊铸轧;热-流耦合;复合界面

中图分类号:TG335 文献标志码:A

Cu/Al复合带兼具有铜的导电率高、导热性好、接触电阻低和铝质轻、耐蚀和经济等优点,被广泛应用于建筑装饰、电力电子、装备散热、化工、军工等领域[1-4]。针对我国铜资源匮乏而铝产能严重过剩的 现状,“以铝代铜”已成为化解铝过剩产能、节约贵金属的有效途径之一。

固-液铸轧复合成形技术[5]是近年来发展起来的一种短流程新工艺,它将固相覆层金属带材与液态基体金属同时喂入双辊铸轧机的两个结晶辊间,快速凝固后,在高温和压力作用下直接铸轧复合成形。与传统的静液挤压法、轧制复合法、包覆焊接法等[6-8]相比,该工艺更具高效节能优势,因而受到了国内外学者的广泛关注。韩国学者BAE等[9]利用该方法进行了镁合金和纯铝的复合实验,得到铝-镁-铝三明治夹层复合板,获得良好的耐腐蚀性;GRYDIN等[10]制备了扩散层厚度为3 μm的钢/铝复合板,研究了其复合界面的成分及厚度影响,并对试件进行了冲压、拉伸以及包覆轧制实验,充分说明了固-液铸轧复合生产双金属复合板的优越性;池慧[11]在固液复合基础上,提出了一种双金属板带柔性连续铸轧复合工艺,运用Marc软件及其二次开发,建立了Cu/Al轧制的热力耦合模型,并且成功试制出长为400 mm的纯铝/铝合金复合板坯。

目前,围绕镁合金、铝合金或钢的双辊铸轧流场-温度场耦合研究已有大量文献报道。BAE等[12]采用有限元与有限差分法结合的数值方法,研究了镁合金铸轧过程中不同铸速、熔池高度对熔池流场和温度场的影响。SAHOO等[13]在考虑凝固以及标准湍流模型的前提下,研究了铝合金高速铸轧过程中不同铸速、过热度对坯壳凝固速度的影响,并通过二次枝晶间距的实验验证了其数学模型的正确性。然而,由于固-液铸轧复合工艺中引入了固相覆层金属带材,将金属熔体与铸轧结晶辊隔离开来,导致金属熔体两侧传热边界不一致,亟待弄清非对称传热边界条件下铸轧区熔池流场和温度场的变化规律,以及双金属结合界面温度分布规律。

为此,本文作者以二辊d160 mm×150 mm铸轧机为研究对象,开展Cu/Al复合带固-液铸轧热-流耦合数值模拟研究,分析不同铸轧速度、铜带预热温度、铜带厚度和浇注温度对KISS点高度、偏移及结合界面温度影响的宏观规律,并将其作为理论指导开展固-液铸轧复合实验,分析复合机理。

1 固-液铸轧复合多场耦合数值模拟

1.1 固-液铸轧复合工艺概述

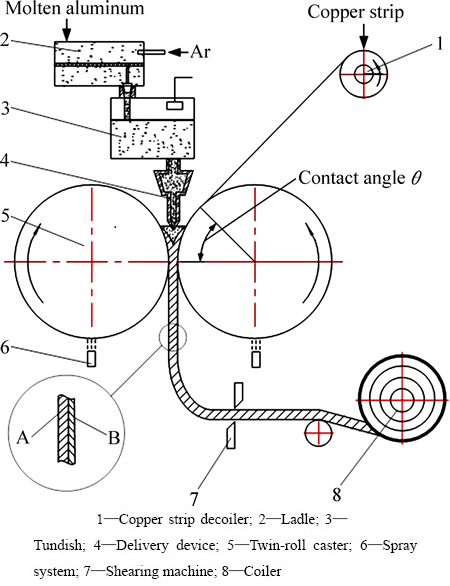

如图1所示,将铜带和铝液同时喂入双辊铸轧机的辊缝内,在铸轧区高温固-液接触和固相轧制共同作用下实现复合界面的冶金结合,完成层状双金属复合带材的高效连续生产。其中,开卷机主要用于铜带的喂入接触角和入口张力控制,前箱、中间包和布流器用于将铝液向铸轧辊缝内均匀布流。

图1 层状金属复合带固-液铸轧复合工艺示意图

Fig. 1 Schematic diagram of laminated strip solid-liquid cast-rolling bonding

1.2 基本假设及基本控制方程

本研究中数值模拟的对象为稳态铸轧复合过程温度场和流场,为简化数学模型、参数和边界条件,作出如下假设:1) 铸轧辊视为刚体,不发生塑性变形,且铸轧辊做匀速转动;2) 铝液、半固态铝液视为不可压缩的牛顿流体;3) 忽略铜带在铸轧过程中的变形,且与熔池内金属接触良好;4) 耦合接触面间无滑移;5) 液面受铸嘴限制,保持水平固定,熔池内液流动为强制湍流为主;6) 只考虑对流传热和热传导,忽略辐射换热对铸轧中流场、温度场的影响。

模拟计算区域中时均化的质量、动量、能量方程可写成如式(1)所示的通用形式[13]。

(1)

(1)

式中:ψ代表各独立变量;x和y方向的速度分量u和v;湍动能k;湍流耗散率ε及热焓h。Γ及S代表各变量的扩散率及源项。

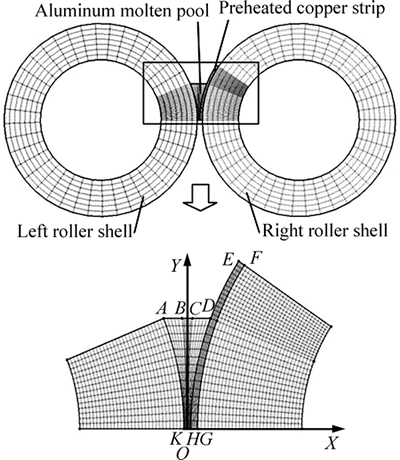

1.3 材料参数

采用工业纯铝(L2)和紫铜带作为研究对象,铸轧辊辊套材质为合金钢,相关材料热物性参数[14]如表1所列。

表1 材料热物性参数

Table 1 Thermophysical parameters of the materials

此外,工业纯铝(L2)的凝固区间为887~933 K,凝固潜热为393.56 kJ/kg,液态时黏度为1.18×10-3 kg/(m·s)。

1.4 几何模型

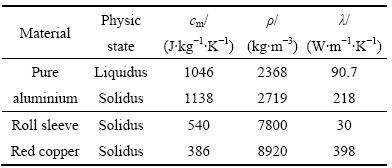

如图2所示,由于铸轧区不具有对称性,最终得到的简化模型包含左铸轧辊套、铝液熔池、预热铜带、右铸轧辊套4个计算域。

图2 网格划分结果示意图

Fig. 2 Schematic diagram of meshing results

模拟涉及的参数包括:轧辊直径160 mm,辊套厚30 mm,熔池入口宽度为3 mm,熔池高度30 mm,出口复合带中组元铝的厚度为2 mm。铸轧速度v分别为2.4 m/min、3.6 m/min、4.8 m/min,铜带预热温度TCu分别为300 K、673 K、1073 K,铜带入口厚度HCu分别为0.2 mm、1 mm、2 mm,浇注温度TAl分别为953 K、963 K、973 K。

为提高计算精度与收敛速度,对熔池和固态板坯计算域内网格加密,且计算域间耦合边界网格节点相对应。

1.5 边界条件

如图2所示,模型边界条件包括:

1) 熔池入口边界(BC),设为速度入口边界,沿入口方向,按式(2)计算:

(2)

(2)

式中:vin为铝液注入速度(m/s);Tin为铝液浇注温度。入口速度的大小根据质量守恒由入口流量和出口流量一致得出。

2) 熔池出口边界(KH),设为速度出口边界,沿出口方向,由铸轧速度确定。

3) 板坯入口边界(EF),设置壁面温度,由铜板坯预热温度决定。

4) 铸轧辊的内表面,和冷却水发生对流换热,设为对流换热边界,按式(3)计算。

(3)

(3)

式中:Tw为冷却水温度;kd为铸轧辊的导热系数;hw为铸轧辊辊套内表面与冷却水间的对流换热系数,取8 kW/(m2·K)。

5) 由无相对滑移的假设,左铸轧辊与熔池接触面、铜带与右铸轧辊外表面切向速度相同。

6) 牵引速度只有当液体的体积参数小于1时才使用,故可对整个铝液熔池计算域设置连续铸轧的牵引速度。

7) 设置左铸轧辊套、右铸轧辊套、预热铜带的旋转角速度,由铸轧速度确定。

8) 计算域间的交界面设为耦合壁面。由于铸轧区内金属液与铸轧辊表面间属于非理想接触,接触热阻可等效为微观量级的气隙热阻,本实验中气隙厚度为2 μm。

9) 其余边界均设置为绝热壁面边界条件。

2 模拟结果分析

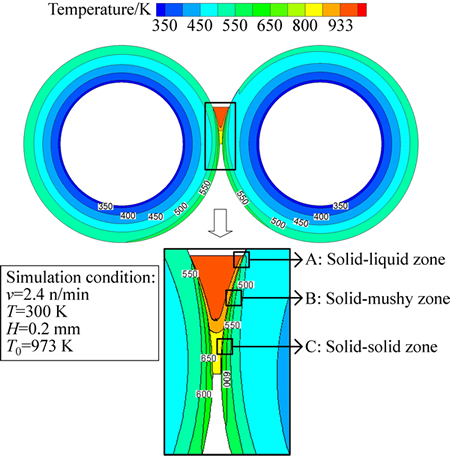

稳态固-液铸轧复合过程典型温度分布模拟结果如图3所示。由于有铜侧和无铜侧与铸轧辊接触换热效果不同,引起铸轧辊温度场不同和KISS点位置偏移。下面根据图4~图7的模拟结果,分析铸轧速度v、铜带预热温度TCu、铜带厚度HCu、铝液浇注温度TAl的影响。

图3 整体温度分布云图

Fig. 3 Overall distribution of temperature contours

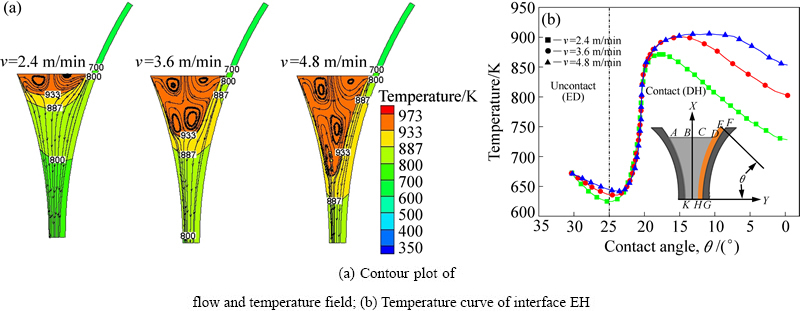

2.1 铸轧速度对流场、温度场影响

铜带预热温度673 K,铜带厚1 mm,铝液浇注温度973 K,铸轧速度为变量时,铸轧区温度场、流场及复合界面温度曲线如图4所示。从图4中可以看出,铸轧速度提高,缩短了铸轧区内接触时间,KISS点位置显著下降,偏移量减少(见图4(a)),且熔池内环流数量增多,范围扩大,具有良好流动性,DH末段界面温度显著提高(见图4(b))。

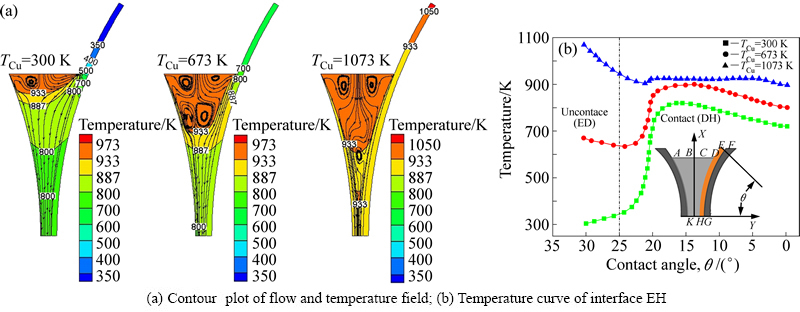

2.2 铜带预热温度对流场、温度场影响

铸轧速度2.4 m/min,铜带厚1 mm,铝液浇注温度973 K,铜带预热温度为变量时,铸轧区温度场、流场及复合界面温度曲线如图5所示。从图5中可以看出,铜带预热温度逐渐提高,触辊阶段ED和与铝液接触阶段DH逐渐由冷却作用转为加热作用,因此KISS点位置降低并且逐渐偏向铜带侧,甚至出现轧漏现象(见图5(a)),熔池内环流数量增多,范围扩大,金属流动性增强,ED和DH温度均整体显著提高(见图5(b))。

图4 铸轧速度v对流场、温度场的影响(TCu=673 K,HCu=1 mm,TAl=973 K)

Fig. 4 Influence of cast-rolling speed v on flow and temperature field (TCu= 673 K, HCu=1 mm, TAl=973 K)

图5 铜带预热温度TCu对流场、温度场影响(v=2.4 m/min,HCu=1 mm,TAl=973 K)

Fig. 5 Influence of preheating temperature TCu on flow and temperature field (v=2.4 m/min, HCu=1 mm, TAl=973 K)

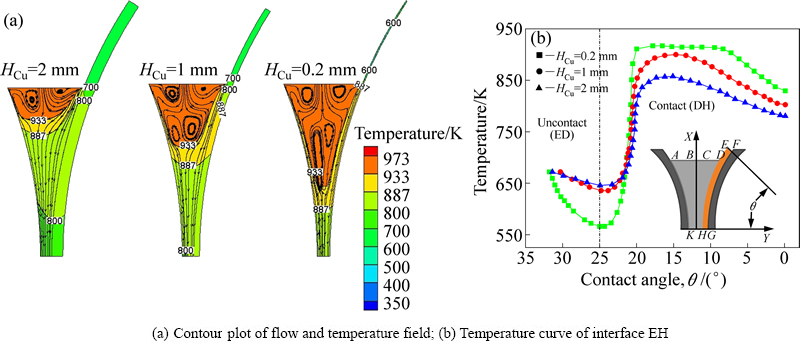

2.3 铜带厚度对流场、温度场影响

铸轧速度2.4 m/min,铜带预热温度673 K,铝液浇注温度973 K,铜带厚度为变量时,铸轧区温度场、流场及复合界面温度曲线如图6所示。从图6可以看出,随着厚度的减薄,单位长度的铜带冷却能力减弱,因此KISS点位置降低并且逐渐由无铜侧偏向有铜侧(见图6(a));熔池内环流数量增多,范围扩大,金属流动性增强,ED和与DH末段界面温度显著提高(见图6(b))。

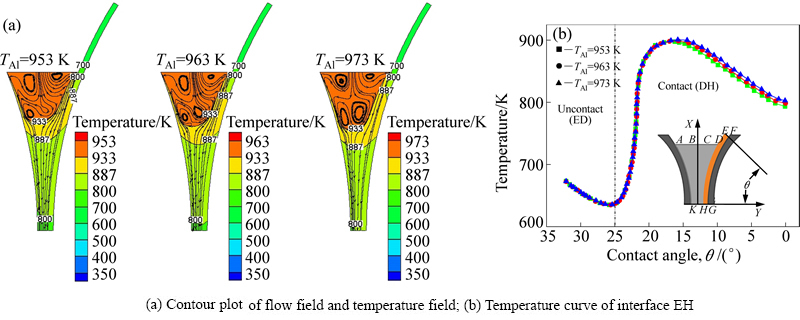

2.4 浇注温度对流场、温度场影响

当铸轧速度2.4 m/min、铜带预热温度673 K、铜带厚1 mm、铝液浇注温度为变量时,铸轧区温度场、流场及复合界面温度曲线如图7所示。从图7中可以看出,浇注温度少量提高不会引起KISS点位置显著偏移及升降,但会改善熔池内金属的流动性(见图7(a)),并且DH末段界面温度有微量提高(见图7(b))。

3 固-液铸轧实验及界面结合机理分析

将固-液铸轧过程流场-温度场耦合数值模拟结果作为理论指导,以d160 mm×150 mm双辊实验铸轧机(见图8)为平台,采用工业纯铝和工业紫铜带作为实验材料,通过开展Cu/Al复合带固-液铸轧复合成形实验,进一步揭示温度和变形量对界面结合效果的影响机理。

图6 铜带厚度HCu对流场、温度场影响 (v=2.4 m/min,TCu=673 K,TAl=973 K)

Fig. 6 Influence of copper strip thickness HCu on flow and temperature field (v=2.4 m/min, TCu=673 K, TAl=973 K)

图7 浇注温度TAl对流场、温度场影响 (v=2.4 m/min,TCu=673 K,HCu=1 mm)

Fig. 7 Influence of pouring temperature TAl on flow and temperature field (v=2.4 m/min, TCu=673 K, HCu=1 mm)

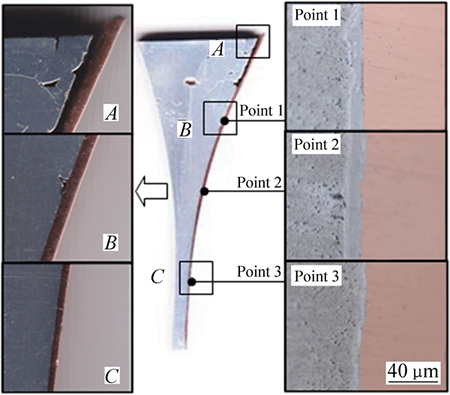

实验工况取铜带厚度0.5 mm、温度300 K,铸轧速度2.4 m/min,铝液浇注温度为973 K。采用铸轧过程中急停轧卡和快速冷却的方式,以获得铸轧区切片,并在金相显微镜下观察其界面微观形貌,结果如图9所示。综合数值模拟及切片分析结果,根据界面两侧金属状态及结合效果,可将固-液铸轧复合变形区划分为以下3个区域,其各自特点如下:

1) 固-液接触换热区(见图9中A区):铜带与铝液接触后激烈换热,试样中由于铝液急停时快速凝固而存在缩孔、疏松等明显缺陷,复合界面由于自由冷却时收缩性能不一致出现开裂。

2) 固-半固态铸造粘连区(见图9中B区):高温下铜带光洁表面析出并附着固态铝,形成半固态区,铜带被加热至更高温度,铜铝的相互扩散得到促进。铜铝反应扩散形成金属间化合物及液态扩散层、冷却过程中界面层的相变[15-16]等,在位置1处形成厚度约为10 μm的扩散层。但界面仅为互相粘连,结合力低,可轻易撕开。

3) 固-固轧制复合区(见图9中C区):在KISS点以下,固相铜、铝带开始进入异温热轧复合过程。初始复合界面在位置2承受高温下巨大的轧制压力和塑性变形,复合界面层破裂,露出新鲜金属开始嵌合,当压力达到一定程度,表面原子被激活并形成原子键结合。并随着压下量的增加,逐渐形成薄且均匀的复合界面,进一步提高界面的结合强度[17],最终在位置3处获得5 μm均匀复合界面,形成高强度冶金结合。

图8 双辊实验铸轧机

Fig. 8 Experimental twin-roll caster

图9 铸轧区切片宏观形貌及复合界面

Fig. 9 Macro-morphology of cast-rolling zone slices and scanned pictures of bonding interface

4 结论

1) 提高铸轧速度和铜带预热温度,减薄铜带厚度,可减小KISS点向无铜带侧的偏移并降低其高度,提高复合界面温度,熔池内液态区域范围扩大,环流数量增多,利于组织成分的均匀化;提高铝液浇注温度,虽不会明显提高复合界面温度和改变KISS点位置,但有利于改善铸轧区内金属液流动性。

2) 固-液铸轧复合区域可分为固-液接触换热区、固-半固态铸造粘连区、固-固轧制复合区,且从3个区域内复合界面的显微形貌演变可以看出,温度和轧制变形量(轧制压力)对界面结合效果起主导作用。

3) KISS点高度决定了3个区域的空间分配,KISS点位置过高,无法形成充分的固-液区,铝液与铜带接触过早凝固,不利于铜铝间的扩散与初步复合,甚至会因轧制力过大而造成轧卡或轧裂现象;反之,KISS点过低时则固-固区显著缩短甚至出现轧漏事故,初始形成的铜铝复合界面不能获得足够的塑性变形,不利于形成优良晶粒组织与均匀的复合界面。实验结果表明,KISS点以熔池高度的1/2~2/3为宜。

REFERENCES

[1] PERRARD W. Strategies for optimizing cable design and performance through the use of bimetallic wire[J]. Wire Journal International, 2001, 34(7): 154-159.

[2] GIBSON A. The economics of copper clad aluminum bimetallic cables[J]. Wire & Cable Technology International, 2005, 33(4): 82-83.

[3] 刘 腾, 刘 平, 王渠东. 铜铝双金属复合材料的研究进展[J]. 材料导报, 2013, 27(10): 1-5, 22.

LIU Teng, LIU Ping, WANG Qu-dong. Research progress on copper/aluminum bimetal composite[J]. Materials Review, 2013, 27(10): 1-5, 22.

[4] 张建宇, 姚金金, 曾祥勇, 韩艳秋, 吴春京. 铜包铝复合材料研究进展[J]. 中国有色金属学报, 2014, 24(5): 1275-1284.

ZHANG Jian-yu, YAO Jin-jin, ZENG Xiang-yong, HAN Yan-qiu, WU Chun-jing. Research process of copper cladding aluminum composites[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1275-1284.

[5] HUDSON E B. Direct casting of sheetlike metal structures: U.S. Patent 2128941[P]. 1938-9-6.

[6] 李小兵, 祖国胤, 王 平. 退火温度对异步轧制铜/铝复合板界面组织及力学性能的影响[J]. 中国有色金属学报, 2013, 23(5): 1202-1207.

LI Xiao-bing, ZU Guo-yin, WANG Ping. Effects of annealing temperature on microstructure and mechanical properties of Cu/Al clad sheet fabricated by asymmetrical roll bonding[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1202-1207.

[7] 王秋娜, 刘新华, 刘雪峰, 谢建新. 退火温度对冷静液挤压铜包铝线材组织和力学性能的影响[J]. 金属学报, 2008, 44(6): 675-680.

WANG Qiu-na, LIU Xin-hua, LIU Xue-feng, XIE Jian-xin. Effects of annealing temperature on the microstructures and properties of copper cladding aluminum wire prepared by cold hydrostatic extrusion[J]. Acta Metallurgica Sinica, 2008, 44(6): 675-680.

[8] LI Xiao-bing, ZU Guo-yin, WANG Ping. Microstructural development and its effects on mechanical properties of Al/Cu laminated composite[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(1): 36-45.

[9] BAE J H, RAO A K P, KIM K H, KIM N J. Cladding of Mg alloy with Al by twin-roll casting[J]. Scripta Materialia 2011, 64(9): 836-839.

[10] GRYDIN O, GERSTEIN G,  F, SCHAPER M, DANCHENKO V. Twin-roll casting of aluminum-steel clad strips[J]. Journal of Manufacturing Processes, 2013, 15(4): 501-507.

F, SCHAPER M, DANCHENKO V. Twin-roll casting of aluminum-steel clad strips[J]. Journal of Manufacturing Processes, 2013, 15(4): 501-507.

[11] 池 慧. 双金属复合板带双辊连续铸轧制备工艺关键技术研究[D]. 秦皇岛: 燕山大学, 2013.

CHI Hui. The research on the key technologies of cladding strip continuous casting process using a twin roll caster[D]. Qinhuangdao: Yanshan University, 2013.

[12] BAE J W, KANG C G, KANG S B. Mathematical model for the twin roll type strip continuous casting of magnesium alloy considering thermal flow phenomena[J]. Journal of Materials Processing Technology, 2007, 191(1): 251-255.

[13] SAHOO S, KUMAR A, DHINDAW B K, GHOSH S. Modeling and experimental validation of rapid cooling and solidification during high-speed twin-roll strip casting of Al-33 wt pct Cu[J]. Metallurgical and Materials Transactions B, 2012, 43(4): 915-924.

[14] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南工业大学出版社, 1989: 153-154.

WANG Zhu-tang, TIAN Rong-zhang. Aluminum alloy and processing manual[M]. Changsha: Central South University Press, 1989: 153-154.

[15] 吴永福, 刘新华, 谢建新. 连铸直接成形矩形断面铜包铝复合材料界面及其在轧制中的变化[J]. 中国有色金属学报, 2013, 23(1): 191-200.

WU Yong-fu, LIU Xin-hua, XIE Jian-xin. Interface of copper cladding aluminum composite materials with rectangle section fabricated by horizontal core-filling continuous casting and its evolvement in rolling process[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 191-200.

[16] 张红安, 陈 刚. 铜/铝复合材料的固-液复合法制备及其界面结合机理[J]. 中国有色金属学报, 2008, 18(3): 414-420.

ZHANG Hong-an, CHEN Gang. Fabrication of Cu/Al compound materials by solid-liquid bonding method and interface bonding mechanism[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(3): 414-420.

[17] CHEN C Y, CHEN H L, HWANG W S. Influence of interfacial structure development on the fracture mechanism and bond strength of aluminum/copper bimetal plate[J]. Materials Transaction, 2006, 47(4): 1232-1239.

Thermal-flow coupled numerical simulation and experimental research on bonding mechanism of Cu/Al composite strip by solid-liquid cast-rolling

HUANG Hua-gui, JI Ce, DONG Yi-kang, DU Feng-shan

(National Engineering Research Center for Equipment and Technology of Cold Strip Rolling,

Yanshan University, Qinhuangdao 066004, China)

Abstract: Bimetallic layered composite strip with solid-liquid cast-rolling process is a new short flow technology which combined rapid solidification with composite rolling. Taking the d160 mm×150 mm experimental twin-roll caster as research object, a two-dimensional thermal-flow coupled model for Cu/Al solid-liquid cast-rolling process was established with commercial software Fluent to reveal the bonding mechanism between the solid copper strip and molten aluminum in twin roll casting zone. From the simulation results, the influences of cast-rolling speed, casting temperature, copper strip thickness and preheat temperature on the flow field in molten pool, KISS point location and the temperature distribution of bonding interface were studied. A Cu/Al solid-liquid cast-rolling bonding experiment was carried out. The experimental results indicate that the interface bonding effect is enhanced gradually from the solid-liquid contact zone to solid-mushy adhesion zone and solid-solid roll bonding zone, and the temperature and contact pressure play an important role on the metallurgical bonding effect of Cu/Al interface. It provides an important guidance to design this new forming process.

Key words: solid-liquid bonding by cast-rolling; Cu/Al composite strip; twin-roll casting; thermal-flow coupled; bonding interface

Foundation item: Projects (51474189, 51374184) supported by the National Natural Science Foundation of China; Project (QN2015214) supported by the Educational Commission of Hebei Province of China

Received date: 2015-06-29; Accepted date: 2015-12-08

Corresponding author: HUANG Hua-gui; Tel: +86-335-8077352; E-mail: hhg@ysu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金面上项目(51474189,51374184);河北省高等学校科学技术研究项目(QN2015214)

收稿日期:2015-06-29;修订日期:2015-12-08

通信作者:黄华贵,教授,博士;电话:0335-8077352;E-mail:hhg@ysu.edu.cn