文章编号:1004-0609(2011)09-2023-05

AZ31B镁合金板材快速气压胀形行为

王 刚, 王建珑, 张拓达, 张治朋

(哈尔滨工业大学(威海) 材料科学与工程学院,威海 264209)

摘 要:对板厚1.0 mm的细晶AZ31B镁合金板材进行快速气压胀形研究,在300~400 ℃的温度范围内进行了各种气压下300 s的快速气压胀形试验,研究温度和气压对AZ31B板材快速气压胀形能力的影响。结果表明:在不同温度下,胀形高度均随着气压的升高而增大,但气压升高到一定程度时,胀形时间不到300 s即产生破裂;胀形高度在胀形温度400 ℃时出现峰值为45 mm。在400 ℃和0.6 MPa条件下,胀形5 min时相对胀形高度达到1.13。胀形件壁厚分布不均匀,温度越高,壁厚分布不均匀度越高。最后,研究了不同温度下快速气压胀形时胀形件微观组织的演变规律。

关键词:AZ31B镁合金板;快速气压胀形;壁厚分布;组织演变

中图分类号:TG146. 22 文献标志码:A

WANG Gang, WANG Jian-long, ZHANG Tuo-da, ZHANG Zhi-peng

(College of Materials Science and Engineering, Harbin Institute of Technology at Weihai, Weihai 264209, China)

Abstract:QGBF behavior for AZ31B magnesium alloy sheet with 1.0 mm thick was studied. Half-sphere free gas bulging tests were performed at 300-400 ℃ for 300 s duration to study the effects of temperature and gas pressure on QGBF properties of AZ31B sheet. The results show that the bulging height increases with the gas pressure increasing at different temperatures, however, the bulging parts crack within 300 s when the forming temperature exceeds the threshold. And the bulging height exists peak value at 400 ℃ reaches 45 mm and the highest specific height can reach 1.13 under the condition of 400 ℃ and 0.6 MPa for 5 min duration. The thickness distribution of bulging parts is uniform, and the higher the temperature, the larger the unevenness of thickness distribution. Furthermore, the microstructure revolution in the quick gas blowing process was discussed by observing the microstructure at different temperatures.

Key words: AZ31B magnesium alloy sheet; quick gas blow forming; thickness distribution; microstructure evolution

轻量化是航空、航天、汽车等领域的发展趋势,镁合金必将大量代替铝合金及其它材料,随着镁合金板材轧制、板材热加工技术以及变形镁合金的发展,使镁合金壳形件和管形件大量应用成为可能。但镁合金板材在室温下塑性差,难以进行塑性成形,因此,镁合金板壳件热加工已经成为塑性加工界的热点。AZ31是应用最广的变形镁合金,国外PANICKER 等[1]研究了超塑性AZ31镁合金板材的微观组织演变和晶界滑移, KAYA等[2]开发了AZ31镁合金的非等温深冲工艺。TSAI等[3]试验用镁合金板材热冲压加工笔记本外壳,CESCHINI等[4]研究了双辊铸轧的AZ31镁合金板材的超塑性;国内CHENG等[5]、REN等[6]、张凯锋等[7]和WANG等[8]也在镁合金板材热拉深和超塑成形理论研究方面做了大量的研究工作。

快速气压胀形技术是近10年来发展起来的技术,使气压胀形技术用于大批量生产成为可能。目前,对铝合金的快速气压胀形研究较多,通用汽车公司开发了快速气压胀形专用的铝合金AA5083,并且美国通用汽车、日本本田汽车公司均已采用快速气压胀形技术生产了汽车覆盖件产品[9-10];对镁合金快速气压胀形的研究相对较少,CARTER等[11]对AZ31镁合金的快速气压胀形性以及应用进行了研究。SUN等[12]研究了气压加载曲线对AZ31B镁合金快速气压胀形的影响,并研究了5.1 μm的细晶AZ31镁合金板材的快速气压胀形盒形件,LIU和WU[13]研究了AZ31B镁合金管材的金属热态气压胀形技术,张晓蕾[14]、李海莲和王刚[15]分别研究了AZ80和ZK60镁合金板材的快速气压胀形相关塑性变形规律。

本文作者研究等通道挤压-轧制AZ31镁合金板材的快速气压胀形工艺基础,分析温度和气压对胀形高度的影响, 探索对AZ31镁合金进行快速气压胀形试验最适合的温度和气压,为该技术的广泛应用提供理论基础。

1 实验

试验所用材料为AZ31镁合金,经过等通道转角挤压后通过冷轧成1.0 mm 厚的薄板,晶粒尺寸为3.0 μm。合金成分(质量分数)为3.19%Al、0.334%Mn、0.81%Zn、0.005%Fe、0.02%Si、0.01%Be和0.005% Cu,其余为Mg。试验前用剪板机将板料裁成140 mm×140 mm 大小。试验所用凹模尺寸如下:内径80 mm,高度60 mm,凹横入口圆角半径5mm。

将AZ31镁合金板材放入凹模和进气板之间,然后将整套装置放入高温电阻炉中,并加热到一定温度。用WE600液压万能压力机将板材与模具压紧密封,由氩气钢瓶通入一定压力的氩气,使板料在一定温度和气压下胀形300 s或不足300 s时到胀破为止。胀形结束后,把胀形件取出,进行后续工作。对板厚1.0 mm的AZ31镁合金板材进行快速气压胀形试验,本试验选用的试验温度区间为300~400 ℃,气体压力为0.5~1.4 MPa。

胀形后制备金相试样,用ZJP-200型金相显微镜观察显微组织,从而分析材料的微观组织演变规律,胀形件取件位置分别为顶部、边部以及顶部与边部的中间位置。浸蚀剂配方为:1.5 g苦味酸+10 mL冰醋酸(35%)+25 mL无水乙醇+10 mL去离子水。

2 结果与分析

2.1 胀形高度

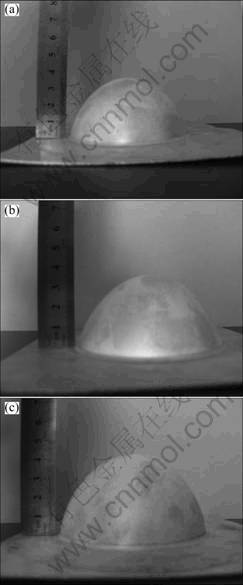

胀形结束后,用高度尺测量胀形件的高度,精确度为0.02 mm,为保证高度测量的精确性,在相互垂直的两个方向分别测量,然后取其平均值作为胀形高度数据。用胀形高度与半径的比值(高径比H/r)来表征胀形性能的好坏。胀形件照片见图1。

以胀形气压为横坐标,胀形高度为纵坐标绘制胀形气压对胀形高度曲线,每条曲线上最后一个点的数据为胀形时间不到300 s即破裂的胀形件的胀形高度,见图2。

在不同温度下,在300 s的时间内,胀形高度均随着气压的升高而增大,但气压升高到一定程度时,胀形时间不到300 s即产生破裂,因为过大的气压会使变形过程中的金属流变过快,从而导致爆裂;另一方面,气压过大使应变速率很大,再结晶来不及进行,无法通过细化晶粒来提高塑性。由图2可见,虽然胀形时间不到300 s即发生破裂,但胀形高度并未产生多大变化,所以有可能采用较高的气压,在更短的时间内成形。随着成形温度的升高,快速胀形所需气压变小,而胀形高度在胀形温度400 ℃时出现峰值。这是由于在400 ℃时,AZ31的滑移系增多,同时发生动态再结晶,使晶粒变得细小。由图2看出,在400 ℃ 和0.6 MPa条件下,胀形高度最大,达到45.04 mm,高径比为H/r=1.126。而在300 ℃和1.0 MPa条件下,胀形高度只有27.56 mm,高径比仅为0.68。

图1 不同条件下快速气压胀形的半球件照片

Fig. 1 Photos of quick gas blow formed hemisphere part under different conditions: (a) At 300 ℃ and 1.2 MPa; (b) At 350 ℃ and 0.8 MPa; (c) At 400 ℃ and 0.6 MPa

图2 温度和气压对胀形高度的影响

Fig.2 Influence of temperature and gas pressure on bulge height

综合来看,对于1.0 mm厚的AZ31镁合金板材,在400 ℃和0.6 MPa条件下的胀形高度最大,材料的塑性变形能力最强。

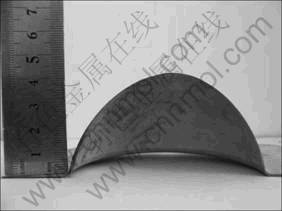

2.2 壁厚分布规律

快速气压胀形过程是一个板材体积不变,而面积发生改变的变形过程。随胀形高度的增加,胀形件逐渐变薄,成形后零件会发生厚度减薄不均匀的现象,胀形后板材的厚度越小表示变形量越大。图3所示为胀形件的线切割的截面图。测量前在胀形件上距中心点水平等距取不同部位的点,本试验相邻点之间的水平距离为4 mm,共取12个点,其中第1点是半球顶点。测量厚度所用的工具是百分表,精确度为0.01 mm。根据测得的数据绘制厚度分布曲线如图4所示。

由图4可知,随胀形件高度增加,胀形件厚度减小,胀形件顶端为最薄处,厚度减薄到0.3 mm以下,此处变形量最大。随温度升高,壁厚分布不均匀性增加。当温度为300 ℃时,板料胀形完毕后各处壁厚的差异明显比350和400 ℃条件下的壁厚差要小;而板料在400 ℃条件下进行变形时,半球件顶部厚度分布较为均匀,因为,在一定温度下,材料的应变速率敏感性指数m随温度升高而增大, 有助于提高成形性能。

图3 胀形件截面照片

Fig.3 Section photograph of hemisphere part

图4 胀形件厚度分布曲线

Fig.4 Thickness distribution curve of hemisphere part

2.3 组织演变

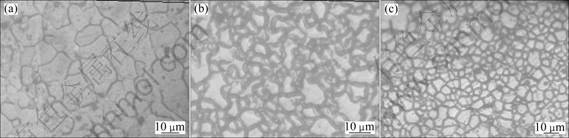

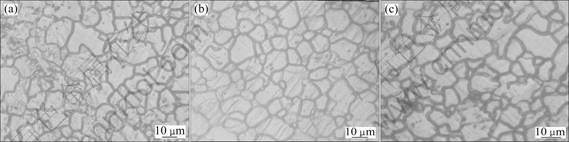

利用金相显微镜观察组织,所得的金相照片如图5~7所示。

由图5可看出,在300 ℃和1.2 MPa条件下胀形时,胀形件顶端的晶粒尺寸非常细小,平均晶粒尺寸仅4.5μm左右,且晶粒为均匀等轴晶。这是因为顶部的变形量较大,变形能释放诱发动态再结晶,使晶粒均匀细小。中间位置的晶粒比顶部的略大,平均晶粒尺寸为5.8 μm左右,大部分都是细小的晶粒;另外,一些较大的晶粒的存在表明动态再结晶进行得不彻底,细小的晶粒是动态再结晶产生的,这个位置的动态再结晶刚开始进行。边部位置是只加热不变形位置,晶粒较大,平均晶粒尺寸为20 μm左右,这是由于温度升高,晶粒开始长大造成的。

图5 在300 ℃和1.2 MPa条件下不同位置的显微组织

Fig.5 Microstructures at different positions under condition of 300 ℃ and 1.2 MPa: (a) Flange, thinning rate 0%; (b) Middle, thinning rate 33.8%; (c) Dome, thinning rate 73.6%

图6 在350 ℃和0.8 MPa条件下不同位置的显微组织

Fig.6 Microstructures at different positions under condition of 350 ℃ and 0.8 MPa: (a) Flange, thinning rate 0%; (b) Middle, thinning rate 34%; (c) Dome, thinning rate 73.7%

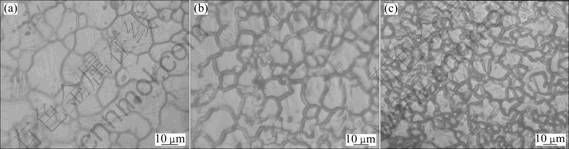

图7 在400 ℃和0.6 MPa条件下不同位置的显微组织

Fig.7 Microstructures at different positions under condition of 400 ℃ and 0.6MPa: (a) Flange, thinning rate 0%; (b) Middle, thinning rate 35.4%; (c) Dome, thinning rate 77.6%

如图6和7所示,在350 ℃和0.8 MPa及400 ℃和0.6 MPa条件下胀形时,胀形件的微观组织演变规律与图5所示的类似,只是平均晶粒尺寸较大。这是因为在较高的胀形温度下胀形,晶粒长大较快,导致晶粒细化趋势小于晶粒长大趋势。

由图7可以看出,虽然晶粒演变规律与较低温度下的演变规律类似,但胀形件各个位置的平均晶粒尺寸相差不大,均在10~15 μm左右,较原始晶粒(3.0 μm)长大较多,尤其顶部晶粒长大较明显。 因为与在300 ℃和350 ℃胀形相比,在400 ℃胀形时的变形程度增大有限,因此,在高温的作用下晶粒更容易长大。

3 结论

1) 对板厚1.0 mm的AZ31镁合金板材进行300 s的快速气压胀形试验时,胀形高度的大小由温度和气压共同决定;在同一温度下,随着胀形气压的增大,胀形高度增加;气压增加到一定程度后在不到300 s的时间内破裂。

2) 随着温度的升高,胀形高度增大,在400 ℃和0.6 MPa条件下,胀形高度最大,达到45.04 mm,高径比为H/r=1.126,说明所用AZ31B镁合金板材在400 ℃塑性最好。

3) 所有胀形件都是随着胀形高度的增大而壁厚不均匀程度增大, 胀形件的顶端处厚度最小。在300 ℃和1.2 MPa条件下,胀形件顶端的厚度仅为0.264 mm,厚度减薄率达到73.6%;

REFERENCES

[1] PANICKER R, CHOKSHI A H, MISHRA R K, VERMA R, KRAJEWSKIP E. Microstructural evolution and grain boundary sliding in a superplastic magnesium AZ31 alloy[J]. Acta Materialia, 2009, 57(13): 3683-3693.

[2] KAYA S, SPAMPINATO G, ALTAN T. An experimental study on nonisothermal deep drawing process using aluminum and magnesium alloys[J]. Journal of Manufacturing Science and Engineering, 2008, 130(6): 061001-061011.

[3] TSAI H K, LIAO C C, CHEN F K. Die design for stamping a notebook case with magnesium alloy sheets[J]. Journal of Materials Processing Technology, 2008, 201(1/3): 247-251.

[4] CESCHINI L, EL M M, MORRI A, SAMBOGNA G, SPIGARELLI S. Superplastic deformation of twin roll cast AZ31 magnesium alloy[J]. Materials Science Forum, 2009, 604/605: 267-277.

[5] CHENG Y Q, CHEN Z H, XIA W J. Drawability of AZ31 magnesium alloy sheet produced by equal channel angular rolling at room temperature[J]. Materials Characterization, 2007, 58(7): 617-622.

[6] REN L M, ZHANG S H, PALUMBO G, TRICARICO L. Warm deep drawing of magnesium alloy sheets—Formability and process conditions[J]. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2008, 222(11): 1347-1354.

[7] 张凯锋, 尹德良, 王国峰, 韩文波. 热轧AZ31镁合金超塑变形中的微观组织演变及断裂行为[J]. 航空材料学报, 2005(1): 34-37.

ZHANG Kai-feng, YIN De-liang, WANG Guo-feng, HAN Wen-bo. Microstructure evolution and fracture behavior in superplastic deformation of hot-rolled AZ31 Mg alloy[J]. Journal of Aeronautical Materials, 2005(1): 34-37.

[8] WANG L Y, SONG M J, LIU R C. Superplasticity and superplastic instability of AZ31B magnesium alloy sheet[J]. Transaction of Nonferrous Metals Society of China, 2006, 16(2): 327-332.

[9] KRAJEWSKI P, SCHROTH J. Overview of quick plastic forming technology [J]. Materials Science Forum, 2007, 551/552: 3-12.

[10] SAITO K, WATANABE J, YOKOYAMA O, NAKAO K. Application technology of aluminum blow forming for automotive closure panel[C]//Proceedings of the 6th EUROSPF Conference. Carcassonne, France, 2008, 6.

[11] CARTER J, KRAJEWSKI P, VERMA R. The hot blow forming of AZ31 Mg sheet:Formability assessment and application development [J]. JOM, 2008, 60(11): 77-81.

[12] SUN P H, WU H Y, TSAI H H, HUANG C C, TZOU M D. Effect of pressurization profile on the deformation characteristics of fine-grained AZ31B Mg alloy sheet during gas blow forming [J]. Journal of Materials Processing Technology, 2010, 210(12): 1673-1679.

[13] LIU Y, WU X. A Microstructure study on an AZ31 magnesium alloy tube after hot metal gas forming process[J]. Journal of Materials Engineering and Performance, 2007, 16(3): 354-359.

[14] 张晓蕾. AZ80镁合金板材气压胀形工艺基础研究[D]. 哈尔滨: 哈尔滨工业大学, 2009.

ZHANG Xiao-lei. Research on gas blow forming for AZ80 magnesium alloy sheet [D]. Harbin: Harbin Institute of Technology, 2009.

[15] 李海连, 王 刚. ZK60镁合金板材快速气压胀形研究[J]. 材料科学与技术, 2010, 18(增刊1): 124-128.

LI Hai-lian, WANG Gang. Research on quick blow forming of ZK60 magnesium alloy sheet [J]. Material Science and Technology, 2010, 18(Suppl 1): 124-128.

(编辑 何学锋)

基金项目:国家自然科学基金面上项目(50775052)

收稿日期:2010-08-25;修订日期:2011-03-07

通信作者:王 刚,副教授,博士;电话:0631-5687324;E-mail:wg@hitwh.edu.cn