文章编号:1004-0609(2013)07-1907-07

AuSn20/Ni焊点的界面反应及剪切强度

韦小凤,王日初,彭超群,冯 艳

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用回流焊技术制备AuSn20/Ni焊点,通过扫描电子显微镜(SEM)及能谱分析(EDX)研究AuSn20/Ni焊点界面反应特征,探讨退火温度和时间对AuSn20/Ni焊点显微组织和剪切强度的影响。结果表明:AuSn20/Ni焊点在300 ℃钎焊90 s后,焊料内部产生ζ′-Au5Sn+δ-AuSn共晶组织和棒状(Ni,Au)3Sn2相。焊点在150 ℃退火时,界面反应速度较慢,金属间化合物(IMC)层厚度随着退火时间延长而缓慢增大;焊点的剪切强度随退火时间延长有较小幅度下降。在200 ℃退火时,AuSn20/Ni的界面反应速度较快,焊料/Ni界面形成(Au,Ni)Sn+(Ni,Au)3Sn2复合IMC层。焊点的剪切强度随退火时间延长呈较大幅度下降。从焊点力学可靠性方面考虑,AuSn20/Ni焊点不宜在200 ℃及以上温度长时间服役。

关键词:AuSn20/Ni焊点;界面反应;金属间化合物(IMC);剪切强度

中图分类号:TG156.21 文献标志码:A

Interfacial reaction and shear strength of AuSn20/Ni solder joints

WEI Xiao-feng, WANG Ri-chu, PENG Chao-qun, FENG Yan

(School of Metarials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The AuSn20/Ni solder joints were prepared by the reflow process. The effects of the aging temperature and time on the microstructure and shear strength were investigated by the scanning electron microscope (SEM) with an energy dispersive X-ray (EDX). The results show that, a fine lamellar eutectic ζ′-Au5Sn+δ-AuSn microstructure and needle-like (Ni,Au)3Sn2 intermetallics are formed at the AuSn20/Ni joint after reflow at 300 ℃ for 90 s. After aging at 150 ℃ for various times,the thickness of the IMC layer at AuSn20/Ni interface grows slightly with the aging time increasing from 150 h to 1 000 h, and the shear strength of the AuSn20/Ni joints declines accordingly. When aging at 200 ℃, the reaction rate of the AuSn20/Ni interface is faster than that when aging at 150 ℃. The thickness of the IMC layer grows rapidly with increasing the aging time while the shear strength of the joints declines almost lightly. Considering the mechanical reliability of the joints, the AuSn20/Ni joints cannot service at 200 ℃ or higher temperature for a long time.

Key words: AuSn20/Ni joints; interfacial reaction; intermetallic compound (IMC); shear strength

AuSn20(质量分数,%)共晶合金焊料由于具有高强度、低弹性模量和高热导率等优点而广泛应用于集成电路的微电子器件高可靠性气密封装[1-4]。但其熔点相对较高(280 ℃),不能与电子封装的有机材料在同一温度下配合使用。对于一些特殊的、同时要求力学及导热性能好以获得高可靠性的应用来说却是最好的选择[5-6],例如气密封盖、光电子封装工艺中的射频和隔直流封装、激光二极管管芯封装等。因此,研究AuSn20焊料的焊接性能对微电子封装具有重要的指导意义。

常规方法制备的AuSn20共晶合金焊料很脆,难以加工成为使用所需的薄片和环状产品。刘泽光等[7-8]率先采用叠层冷轧技术制备箔片状AuSn20焊料,其成分、相组成以及熔化特性与铸态AuSn20共晶合金一致,但对该工艺制备焊料的焊接性能、焊点的界面反应及界面金属间化合物(IMC)层的生长行为尚未做出系统研究。除焊料本身的性能外,焊料与基体材料间的界面反应对焊点的可靠性也具有重要的影响[9-15]。YOON等[9, 11]采用次序蒸镀的方法制备Au-Sn焊料,研究富Sn的Au-Sn焊料与Ni镀层的界面反应及焊点的剪切强度,得出焊料与基体的连接通常是通过界面的金属间化合物(IMC)来实现的,在服役过程中产品中焊点因热效应引起IMC长大[11],而IMC层的过度长大会降低焊点的热疲劳性能,使焊点可靠性下降[9];另外,IMC本身呈脆性,其异常长大使焊点界面处发生脱层,降低焊点的力学性能[15]。因此,研究焊点的界面反应及IMC的生长行为对焊点可靠性评估具有重要的参考价值。本文作者在前人工作的基础上完善了制备工艺,制备出符合使用性能要求的AuSn20共晶合金焊料,研究叠层冷轧-合金化退火方法制备的AuSn20焊料的焊接性能和AuSn20/Ni焊点的界面反应特征,通过固相老化退火来模拟焊点服役过程中的热效应,研究其对AuSn20/ Ni焊点显微组织及剪切强度的影响,为AuSn20焊料的使用寿命评估提供理论依据。

1 实验

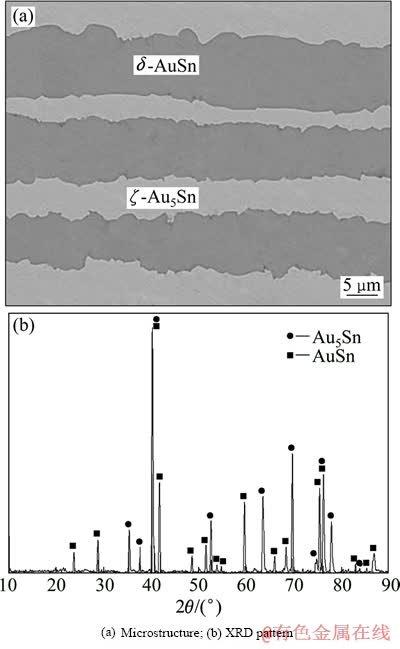

将纯度为99.999%的Au片和纯度为99.99%的Sn片,按Au/Sn/Au/Sn/Au/Sn/Au的次序7层叠合,在650 MPa压力下加压铆合300 s。经过多道次轧制制备0.05 mm厚的AuSn20箔带材钎料,第一道次的变形量大于50%,以保证Au/Sn界面的良好结合。叠轧后的AuSn20带材钎料经丙酮清洗、干燥后在245 ℃合金化退火14 h,得到组织稳定的均质AuSn20合金焊料,其微观组织及XRD谱如图1所示。然后,将磨光的Ni片在丙酮中清洗,再水洗干净。最后,将AuSn20焊料切成15 mm×10 mm×0.05 mm的片材,与镀Ni的Cu片按图2所示的示意图搭建AuSn20/Ni焊点,在真空条件下300 ℃加热焊接90 s后,水冷。钎焊后的AuSn20/Ni焊点在真空条件下150和200 ℃退火150、300、500和1 000 h。

AuSn20/Ni焊点经过磨平、抛光后,在Quanta 200型环境扫描电子显微镜观察其显微组织形貌,并结合EDX能谱和X射线衍射(XRD)分析IMC层的相组成。在CCS-44100型电子万能试验机上检测AuSn20/Ni焊点的剪切强度,剪切应变速率为0.01 s-1,并在扫描电子显微镜上观察其断口形貌。

图1 AuSn20焊料的微观组织形貌及XRD谱

Fig. 1 Microstructure and XRD pattern of AuSn20 solder

图2 焊点试样结构示意图

Fig. 2 Schematic illustration of joint (Unit: mm)

2 结果与讨论

2.1 AuSn20/Ni焊点的显微组织

图3(a)所示为AuSn20/Ni焊点在300 ℃钎焊90 s后的SEM像。从图3(a)可见,钎焊90 s后AuSn20焊料的叠层状组织消失,转变成为由共晶组织、粗大白色相、粗大灰色相和棒状黑色相组成。焊点的XRD谱如图3(b)所示。从图3(b)可见,焊点组织主要由Au5Sn、AuSn和Ni3Sn2组成。结合金锡二元相图[16]及能谱分析可知,共晶组织由灰色的δ(AuSn)和白色的ζ′(Au5Sn)两化合物相组成,粗大白色相的成分为81.23%Au-15.57%Sn-3.20%Ni (摩尔分数),其中x(Ni+Au):x(Sn)等于84.43:15.57,接近5:1,表明该反应产物为固溶少量Ni的Au5Sn相,因此标识为(Au,Ni)5Sn。粗大灰色相的成分为47.78%Au-48.97%Sn-3.25%Ni,其中x(Ni+Au):x(Sn)等于51.03:48.97,接近1:1,表明该反应产物为固溶少量Ni的AuSn相,因此标识为(Au,Ni)Sn。棒状黑色相的成分为43.39%Ni-18.13%Au-38.48%Sn,其中x(Ni+Au):x(Sn)等于61.52:38.48,接近3:2,表明该反应产物为固溶少量Au的Ni3Sn2相,因此标识为(Ni,Au)3Sn2。

图3 AuSn20/Ni焊点在300 ℃钎焊90 s的SEM像及其XRD谱

Fig. 3 SEM image and XRD pattern of AuSn20/Ni joint reflowed at 300 ℃ for 90 s

从Au-Ni-Sn三元室温等温截面[17](见图4)可知,Au-Ni-Sn三元系中的一些二元相,如AuSn、Au5Sn、Ni3Sn2以及Ni3Sn4等,对第三元素的固溶度范围都较大。图4所示为室温下Ni3Sn2中大约50%的Ni原子可以被Au取代,即Ni3Sn2中可以固溶大约30%的Au。这是由于Au与Ni的物理、化学性质及晶体结构相似,Au能够通过扩散进入Ni3Sn2相的晶格中取代部分Ni原子而形成(Ni,Au)3Sn2,Ni能够扩散进入AuSn和Au5Sn中形成(Au,Ni)Sn和(Au,Ni)5Sn。因此,在钎焊过程中,焊料融化形成共晶组织,基体表面的Ni往焊料快速扩散形成(Au,Ni)Sn粗化相,当[Ni]局部饱和后,Ni3Sn2相析出。长大过程中Au往其中扩散形成(Ni,Au)3Sn2。由于(Ni,Au)3Sn2相的析出消耗焊料中δ(AuSn)相,导致共晶组织局部破坏,产生游离的Au5Sn相,且Ni往其中扩散形成(Au,Ni)5Sn。

图4 Au-Ni-Sn三元室温等温截面[17]

Fig. 4 Isothermal section of Au-Ni-Sn ternary diagram at room temperature

2.2 老化退火对AuSn20/Ni焊点显微组织的影响

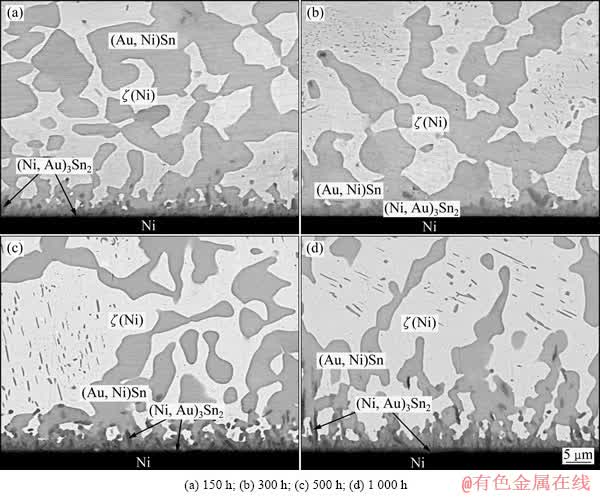

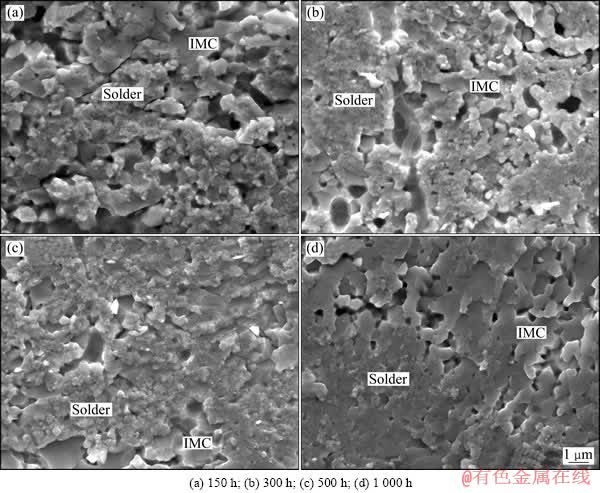

图5所示为AuSn20/Ni焊点在150 ℃老化退火不同时间的显微组织。从图5可见,在150 ℃退火后,焊料的细小共晶组织消失,形成粗大的(Au,Ni)Sn和ζ(Ni),在焊料/Ni界面处形成由(Au,Ni)Sn和(Ni,Au)3Sn2组成的IMC复合层,而且退火从150 h延长至1 000 h,焊点的显微组织变化较小。这是由于在150 ℃下退火时,Ni往焊料中扩散充当了一定的Au含量,使焊料成分偏离了共晶成分而进入ζ相区,因此共晶组织消失。150 ℃时Ni往焊料扩散的速度较慢, Ni原子在焊料分布较均匀,焊料内部难以产生局部Ni饱和,因此只有在靠近Ni侧的界面有少量(Ni,Au)3Sn2相析出。IMC层增长较缓慢,退火时间延长至1000 h, IMC层厚度较小而且平整,焊点与基体的界面结合良好。从图5还可以发现,(Ni,Au)3Sn2相总是连着(Au,Ni)Sn相,YOON等[1]研究表明(Ni,Au)3Sn2相的析出消耗焊料中的(Au,Ni)Sn相,导致焊料内部ζ相增多。

图5 AuSn20/Ni焊点在150 ℃老化退火不同时间的显微组织

Fig. 5 Microstructures of AuSn20/Ni joints aging at 150℃ for various times

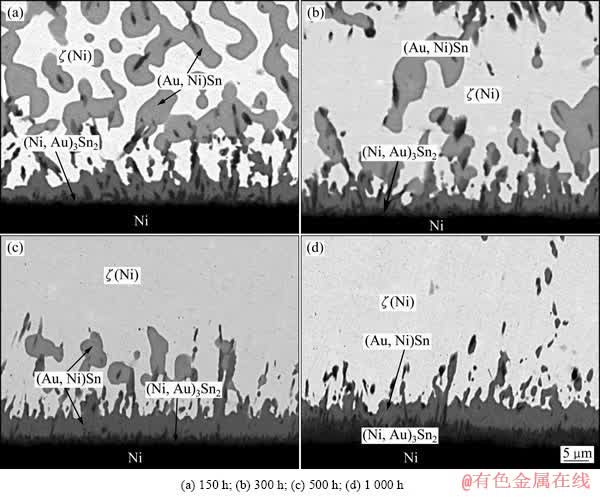

图6 AuSn20/Ni焊点在200 ℃老化退火不同时间的显微组织

Fig. 6 Microstructures of AuSn20/Ni joints aging at 200 ℃ for various times

图6所示为AuSn20/Ni焊点在200 ℃老化退火不同时间的显微组织。从图6可见,与150 ℃时的显微组织相比,此时焊点的显微组织变化较大。随着退火时间延长,界面IMC层的厚度逐渐增大,而δ-AuSn相逐渐减小,焊料中固溶了少量Ni的ζ相逐渐增大。当退火时间延长至500 h时,δ-AuSn相全部往界面迁移,在(Ni,Au)3Sn2层上方形成连续的(Au,Ni)Sn层,如图6(c)所示。当退火时间达1 000 h后,焊料内部基本是ζ(Ni)固溶体,(Ni,Au)3Sn2层上方的(Au,Ni)Sn层厚度减小,如图6(d)所示。在200 ℃下退火,基体表面Ni原子的扩散速度加快,加速了焊点的界面反应,因此界面(Ni,Au)3Sn2层的厚度随退火时间的延长有较大幅度的增大。由于(Ni,Au)3Sn2层的增长消耗了焊料中的(Au,Ni)Sn,而(Au,Ni)Sn是由δ-AuSn形成的,当焊料中δ-AuSn相消耗完全后,(Au,Ni)Sn层的厚度不再随退火时间的延长而增大,而基体表面Ni原子却持续穿过(Ni,Au)3Sn2层往焊料中扩散,在(Ni,Au)3Sn2/(Au,Ni)Sn界面处的Ni原子与(Au,Ni)Sn反应不断生成(Ni,Au)3Sn2相[5],因此,(Au,Ni)Sn 层的厚度逐渐减小,而(Ni,Au)3Sn2层厚度增大。

2.3 老化退火对AuSn20/Ni焊点剪切强度的影响

图7所示为退火温度和时间对AuSn20/Ni焊点剪切强度的影响。从图7中可以看到,老化退火后,焊点的剪切强度逐渐降低。150 ℃退火的焊点强度下降较缓慢,200 ℃退火的焊点剪切强度几乎直线下降,而且在150~500 h退火后焊点强度下降速度较快,退火500~1 000 h后强度下降缓慢。

图7 AuSn20/Ni焊点150 ℃和200 ℃退火不同时间后的剪切强度

Fig. 7 Shear strength of AuSn20/Ni aged at 150 ℃ and 200 ℃ for various times

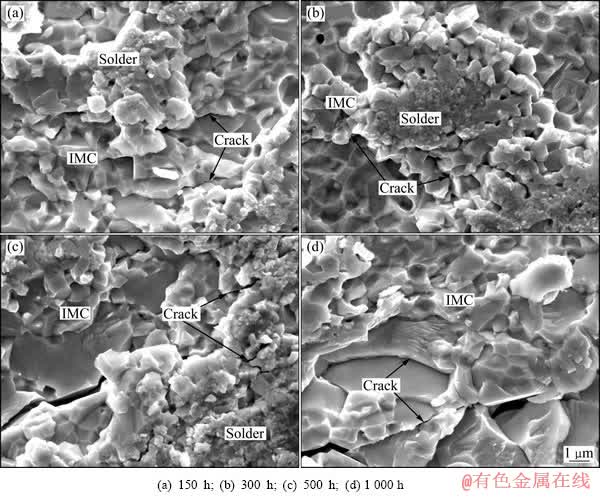

当AuSn20/Ni焊点在300 ℃钎焊90 s时,焊料/Ni界面IMC层厚度较小,而且界面结合良好,因此,焊料内部脆性的细小共晶组织成为焊点剪切性能的薄弱环节。此时,焊点剪切断裂发生在焊料内部,断口形貌如图8所示。由于焊料较薄,而且有少量(Ni,Au)3Sn2相弥散分布,起到一定的强化作用,因此焊点的剪切强度较高。在150 ℃退火后,焊料的共晶组织消失,焊料内部形成ζ(Ni)固溶体,脆性降低,界面处脆性的IMC (Ni,Au)3Sn2相聚集长大使强度下降,因此焊点强度的薄弱环节由焊料内部转移到边界。而由于(Ni,Au)3Sn2层厚度较小,断裂难以发生在内部,因此,焊点的剪切断裂发生在焊料/IMC界面处,其断口形貌如图9所示,表明150 ℃退火后焊点的剪切强度是焊料和IMC的力学性能以及焊料/IMC界面结合强度共同作用的结果。在150 ℃退火150~1 000 h,焊点的组织变化较小,界面(Ni,Au)3Sn2层厚度增长较小,所以焊点的剪切强度下降幅度较小。

图8 AuSn20/Ni焊点300 ℃钎焊90 s的剪切断口形貌

Fig. 8 SEM fracture morphologies of AuSn20/Ni joints reflowed at 300 ℃ for 90 s

图10所示为AuSn20/Ni焊点在200℃退火不同时间后焊点的剪切断口形貌。从图10中可以看到,随着退火时间延长,焊点的剪切断裂由焊料/IMC界面往IMC内部迁移,表明焊点的剪切强度逐渐取决于界面IMC层的性能。在200 ℃退火150 h后,界面形成连续的脆性(Ni,Au)3Sn2层,由于厚度较小,因此断裂机理与150 ℃退火的焊点相似。在剪切过程中焊点沿晶界发生脆性断裂,如图10(a)所示。随着退火时间延长,(Ni,Au)3Sn2相逐渐长大,大晶粒的晶界成为剪切断裂的裂纹源,加速了焊点的断裂,形成冰糖颗粒状的断口形貌,焊点的剪切强度直线下降,如图10(b)和(c)所示。当退火时间延长至1 000 h时,(Ni,Au)3Sn2相长大更加明显,在大颗粒处发生穿晶断裂,形成断裂解理面,此时断裂全部发生在IMC内部,焊点的剪切强度进一步下降,如图10(d)所示。表明在AuSn20/Ni焊点中,界面(Ni,Au)3Sn2相的聚集长大,IMC层厚度增大,直接导致焊点的剪切强度降低。从焊点的力学可靠性方面考虑,AuSn20/Ni焊点不适合在200 ℃或更高温度下长时间服役。

图9 AuSn20/Ni焊点150 ℃退火不同时间的剪切断口形貌

Fig. 9 SEM fracture morphologies of AuSn20/Ni joints aged at 150 ℃ for various times

图10 AuSn20/Ni焊点200 ℃退火不同时间的剪切断口形貌

Fig. 10 SEM fracture morphologies of AuSn20/Ni joints aged at 200 ℃ for various times

3 结论

1) AuSn20/Ni焊点在300 ℃钎焊90 s后,焊料内部产生层状ζ′-Au5Sn+δ-AuSn共晶组织、粗化的(Au,Ni)5Sn、(Au,Ni)Sn和针状 (Ni,Au)3Sn2相。焊料/Ni界面结合良好,焊点的剪切断裂发生在焊料内部,强度较高。

2) 焊点在150 ℃固相老化退火时, 焊点组织及界面处(Ni,Au)3Sn2 IMC层厚度随着退火延长变化较小,焊点的剪切强度随退火时间延长从47 MPa下降至43 MPa。

3) 在200 ℃固相老化退火时,AuSn20/Ni的界面处(Ni,Au)3Sn2相聚集长大,IMC层厚度增大,导致焊点的剪切强度随退火时间延长从47 MPa下降至36 MPa。从焊点力学可靠性方面考虑,AuSn20/Ni焊点不宜在200 ℃及以上长时间服役。

REFERENCES

[1] YOON J W, CHUN H S, JUNG S B. Liquid-state and solid-state interfacial reactions of fiuxless-bonded Au-20Sn/ENIG solder joint[J]. Journal of Alloys and Compounds, 2009, 469: 108-115.

[2] 周 涛, 汤姆·鲍勃, 马丁·奥德, 贾松良. 金锡焊料及其在电子器件封装领域中的应用[J]. 电子与封装, 2005, 5(8): 5-8.

ZHOU Tao, BOBAL T, OUD M, JIA Song-liang. An introduction to eutectic Au/Sn solder alloy and its preforms in microelectronics/optoelectronic packaging applications[J]. Electronics & Packaging, 2005, 5(8): 5-8.

[3] 刘泽光, 陈登权, 罗锡明, 许 昆. 微电子封装用金锡合金钎料[J]. 贵金属, 2005, 26(1): 62-65.

LIU Ze-guang, CHEN Deng-quan, LUO Xi-ming, XU Kun. Gold-tin alloy solder for the package of microelectronics[J]. Precious Metals, 2005, 26(1): 62-65.

[4] LEE K A, JIN Y M, SOHN Y H. Continuous Strip casting, microstructure and properties of Au-Sn soldering alloy[J]. Metals and Materials International, 2011, 17: 7-14.

[5] YOON J W, JUNG S B. Investigation of interfacial reaction between Au-Sn solder and Kover for hermetic sealing application[J]. Microelectronic Engineering, 2007, 84: 2634-2639.

[6] CHUNG H M, CHEN C M, LIN C P, CHEN C J. Microstructural evolution of the Au-20wt.%Sn solder on the Cu substrate during reflow[J]. Journal of Alloys and Compounds, 2009, 485: 219-224.

[7] 刘泽光, 陈登权, 许 昆, 罗锡明, 陈亮维. D-KH法制备金锡合金的组织与结构[J]. 贵金属, 2005, 26(3): 30-33.

LIU Ze-guang, CHEN Deng-quan, XU Kun, LUO Xi-ming, CHEN Liang-wei. Structure analysis of gold-tin alloy prepared by D-KH method[J]. Precious Metals, 2005, 26(3): 30-33.

[8] 刘泽光, 罗锡明, 陈登权. 金锡共晶合金箔带材制造方法: 中国, 03105811.6[P]. 2003-7-25.

LIU Ze-guang, LUO Xi-ming, CHEN Deng-quan. A prepared process of weld eutectic Au-Sn alloy: China, 03105811.6[P]. 2003-7-25.

[9] YOON J W, CHUN H S, NOH B I, KOO J M, KIM J W, LEE H J, JUNG S B. Mechanical reliability of Sn-rich Au-Sn/Ni flip chip solder joints fabricated by sequential electroplating method[J]. Microelectronics Reliability, 2008, 48: 1857-1863.

[10] XIA Y H, XIE X M. Reliability of lead-free solder joints with different PCB surface finishes under thermal cycling[J]. Journal of Alloys and Compounds, 2008, 454: 174-179.

[11] YOON J W, CHUN H S, KOO J M, LEE H J, JUNG S B. Microstructural evolution of Sn-rich Au-Sn/Ni flip-chip solder joints under high temperature storage testing conditions[J]. Scripta Materialia, 2007, 56: 661-664.

[12] XIA Y H, XIE X M. Endurance of lead-free assembly under board level drop test and thermal cycling[J]. Journal of Alloys and Compounds, 2008, 457: 198-203.

[13] LI D, LIU C Q, CONWAY P P. Characteristics of intermetallics and micromechanical properties during thermal ageing of Sn-Ag-Cu flip-chip solder interconnects[J]. Materials Science and Engineering A, 2005, 391: 95-103.

[14] YOON J W, CHUN H S, JUNG S B. Correlation between interfacial reactions and shear strengths of Sn-Ag-(Cu and Bi-In)/ENIG plated Cu solder joints[J]. Materials Science and Engineering A, 2008, 483/484: 731-734.

[15] YOON J W, JUNG S B. Interfacial reactions and shear strength on Cu and electrolytic Au/Ni metallization with Sn-Zn solder[J]. Journal of Material Research, 2006, 21: 1590-1599.

[16] MASSALSKI T B. Binary alloy phase diagrams[M]. Materials Park: ASM International, 1990: 433.

[17] ANHOCK S, OPPERMANN H, KALLMAYER C, ASCHENBRENNER R, THOMAN L, REICHEL H. Investigations of Au/Sn alloys on different end-metallizations for high temperature applications[C]//Proceedings of the 22nd IEEE/CPMT International Electronics Manufacturing Technology Symposium, Berlin, Germany. New York: IEEE, 1998: 156-165.

[18] LAURILA T, VUORINEN V, KIVILAHTI J K. Interfacial reactions between lead-free solders and common base materials[J]. Materials Science and Engineering R, 2005, 49: 1-60.

(编辑 何学锋)

基金项目:国家军品配套项目(JPPT-125-GH-039)

收稿日期:2012-06-20;修订日期:2013-05-09

通信作者:王日初,教授,博士;电话:0731-88836638;E-mail:wrc910103@163.com