含硼磁铁矿强化巴西赤铁矿球团的制备

朱德庆,周文涛,潘建,陈栋

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:研究含硼磁铁矿配比对巴西赤铁矿球团生球质量、预热焙烧性能和成品球团冶金性能的影响。结果表明:配加30%和50%(质量分数)含硼磁铁矿后,生球的落下强度增加,爆裂温度显著提高;球团预热温度降低50℃左右,焙烧温度降低120 ℃以上;成品球团矿还原度从72.40%分别提高到87.95%和78.71%,低温还原粉化指数RDI+3.15从87.79%分别提高到97.38%和99.62%,还原膨胀率从36.25%分别降到12.50%和4.00%;焙烧性能得到提高的原因是Fe3O4氧化生成的新生Fe2O3晶体具有较大的活性,B2O3有利于含硼的镁铁橄榄石液相生成,这两者能够促进球团再结晶和晶粒长大;还原度提高的原因是B3+半径很小,易扩散进入Fe2O3晶格中,产生晶格畸变,使得Fe2O3易于还原;铁酸镁和含硼的镁铁橄榄石液相的生成,有利于还原膨胀和低温还原粉化性能的提高。

关键词:巴西赤铁矿;含硼磁铁矿;球团焙烧;冶金性能;还原度

中图分类号:TF046 文献标志码:A 文章编号:1672-7207(2014)02-0348-08

Improving pelletization of Brazilian hematite by adding boron-containing magnetite

ZHU Deqing, ZHOU Wentao, PAN Jan, CHEN Dong

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: The effects of adding ratio of boron-containing magnetite on Brazilian hematite green balls quality, preheating and roasting behaviors and metallurgical properties of product pellets were studied. The results show that the drop strength and thermal shock temperature of green balls increase, and the preheating and roasting temperatures of pellets decrease by about 50 ℃ and 120 ℃ respectively, by adding 30% and 50% (mass fraction) boron-containing magnetite. After adding 30% and 50% boron-containing magnetite, the reduction index (RI) of product pellets increases from 72.40% to 87.95% and 78.71%, the reduction degradation index (RDI+3.15) increases from 87.79% to 97.38% and 99.62%, and the reduction swelling index (RSI) decreases from 36.25% to 12.50% and 4.00%, respectively. The reason for improving the roasting behaviors is that the new Fe2O3 crystalloid from oxidation of magnetite is more active than original hematite, and B2O3 is beneficial to form liquid phases of hortonolite, both of which enhance recrystallization and grain growth of Fe2O3 crystalloids. The RI of product pellets is improved because the radius of B3+ is very small and B3+ is liable to diffuse into the crystal lattice of Fe2O3, which leads to lattice distortion. And lattice distortion makes Fe2O3 be reduced easily. In addition, the formations of magnesium ferrite and hortonolite is beneficial to improve the RSI and RDI+3.15 of product pellets respectively.

Key words: Brazilian hematite; boron-containing magnetite; pellet roasting behaviours; metallurgical properties; reduction index

随着现代高炉炼铁向着高产、低耗和长寿目标发展,高炉对入炉炉料要求越来越高。酸性球团矿具有铁品位高、粒度均匀、冷态强度高和还原性好等优点,与高碱度烧结矿搭配构成合理的炉料结构,能够达到增产节焦、降低炼铁成本的目的[1-3]。国内用于球团矿生产的原料主要是磁铁精矿。进入21世纪后,随着我国球团矿需求量快速增加,高品位磁铁精矿资源供不应求,每年需从国外进口大量赤铁精矿,尤其是巴西赤铁精矿。巴西赤铁精矿具有铁品位高、脉石和有害杂质含量少等优点,但其焙烧性能较差,球团焙烧温度高达1 300~1 350 ℃,焙烧区间窄[3-5]。目前改善巴西赤铁精矿球团焙烧性能的途径主要有[6]:(1) 内配燃料;(2) 配加熔剂;(3) 配加磁铁矿;(4) 配加含硼添加剂。赤铁矿球团内配燃料的适宜添加量范围较窄,仅为1.0%左右,且改善球团焙烧性能的效果不明显[7-9]。赤铁矿球团配加熔剂有利于提高球团矿抗压强度及改善冶金性能,但是,我国长期以来一直使用高碱度烧结矿配加酸性球团矿的炉料结构,因此,熔剂性球团的使用受到了限制[3, 7]。赤铁矿球团配加磁铁矿,焙烧过程中Fe3O4氧化生成的新生Fe2O3晶粒表面原子具有较强的迁移能力,促进赤铁矿再结晶和晶粒长大,能够显著提高球团矿强度[3-5, 10-11]。也有研究发现[6, 12]:配加0.4%的硼砂能够显著降低球团焙烧温度,但成品球团矿还原膨胀性能变差;而配加硼砂和MgO复合添加剂后,球团焙烧温度降低,并且还原膨胀得到改善。含硼磁铁矿是一种富含B2O3和MgO的磁铁精矿,B2O3和磁铁矿能够改善赤铁矿球团的焙烧性能,而MgO有利于球团冶金性能的改善[13-15]。我国辽宁凤城的硼铁矿资源较为丰富,已探明的储量2.83亿t,占全国铁矿储量的1%左右。硼铁矿是一种多元素共生矿,各元素共生关系密切,主要有用矿物硼镁石和磁铁矿嵌布粒度极细,连晶复杂,从而导致硼铁矿中硼和铁难以彻底分离[16-17]。选矿—高炉法在技术经济上不可行,难以实现工业化生产[17-21]。在此,本文作者针对含硼磁铁矿利用困难以及巴西赤铁矿焙烧性能和冶金性能差的特点,研究添加含硼磁铁矿对巴西赤铁矿球团生球质量、球团预热焙烧性能和成品球团矿冶金性能的影响,揭示含硼磁铁矿的作用机理,以便为巴西赤铁矿球团焙烧性能和冶金性能的改善以及含硼磁铁矿的有效利用提供合理途径。

1 原料性能及研究方法

1.1 原料性能

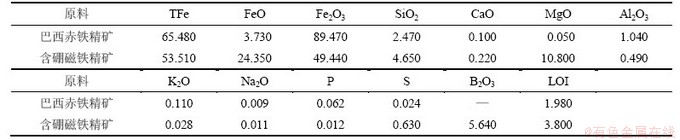

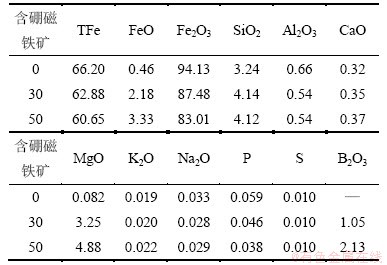

试验所用含铁原料为巴西铁资源公司提供的赤铁精矿和辽宁某地的含硼磁铁精矿,其化学成分见表1。由表1可知:巴西赤铁精矿铁品位高,SiO2等脉石成分以及P和S等有害杂质含量低,是一种优质的赤铁精矿;而含硼磁铁精矿铁品位低,FeO含量高,MgO,B2O3和有害杂质S含量也较高,是一种复杂难利用磁铁精矿。

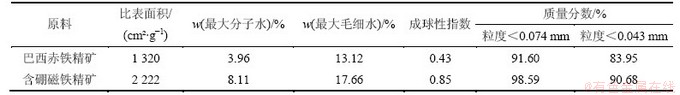

含铁原料的物理性质见表2。由表2可知,巴西赤铁精矿和含硼磁铁精矿粒度较细,满足造球对原料粒度的要求[3, 15]。这2种铁精矿比表面积分别为1 320 cm2/g和2 222 cm2/g,成球性指数分别为0.43和0.85。含硼磁铁精矿比表面积大,成球性指数高,属于优等成球性原料[3];而巴西赤铁矿比表面积较小,成球性指数低,造球前采用高压辊磨预处理,提高其比表面积和成球性指数。

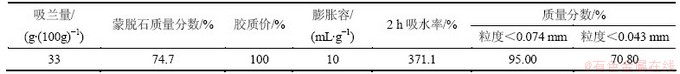

膨润土的化学成分和物理性能分别见表3和表4。由表4可知:根据膨润土GB/T 20973—2007标准,该膨润土粒度<0.074 mm的质量分数为95%,膨胀容为10 mL/g,胶质价为100%,2 h吸水率达到371.1%,满足冶金球团用膨润土二级标准,适合作为球团黏结剂。

表1 含铁原料的化学成分(质量分数)

Table 1 Chemical compositions of iron ores %

表2 含铁原料的物理性质

Table 2 Physical properties of iron ores

表3 膨润土的化学成分(质量分数)

Table 3 Chemical compositions of bentonite %

表4 膨润土的物理性质

Table 4 Physical properties of bentonite

1.2 研究方法

试验采用3种配矿方案提供造球原料:方案(1),100%巴西赤铁精矿;方案(2),30%含硼磁铁精矿+ 70%巴西赤铁精矿;方案(3),50%含硼磁铁精矿+50%巴西赤铁精矿。造球前分别对这3种配矿方案的混合料进行高压辊磨预处理,使其比表面积达到1 700 cm2/g左右,满足造球对原料比表面积的要求[3]。

试验流程模拟工业生产中的链篦机—回转窑工艺。称取4 kg高压辊磨后的混合料(按干质量计),配加一定量的膨润土和水,混匀后在圆盘造球机内造球,控制造球时间12 min。取直径 10~15 mm的生球,测其落下强度、抗压强度和爆裂温度。把剩余的生球在105 ℃左右的温度下干燥4 h,取直径为12.5 mm左右的干球,在卧式管炉中进行预热焙烧,测定预热球团和焙烧球团的抗压强度,并对成品球团矿的化学成分、冶金性能和矿相进行检测和分析。

高压辊磨预处理采用中南大学实验室直径×长度为250 mm×120 mm高压辊磨机,转速为40 r/min,辊磨压力为3.5 t,入磨料水分为8.0%。

圆盘造球机主要技术参数:直径为1 000 mm,转速为26 r/min,边高为200 mm,倾角为47°。

球团预热焙烧设备采用直径×长度为50 mm×600 mm的卧式管炉,球团抗压强度的检测采用中南大学实验室的ZQYC-智能型球团抗压测量仪。

成品球团矿矿物组成和显微结构的鉴定和分析采用Leica DMRXE光学显微镜,扫描电镜和X线衍射。

2 结果与分析

2.1 生球制备

生球质量对球团矿的产质量有重要影响。制备粒度适宜,落下强度、抗压强度和爆裂温度高的生球是提高作业率和生产优质球团矿的前提。

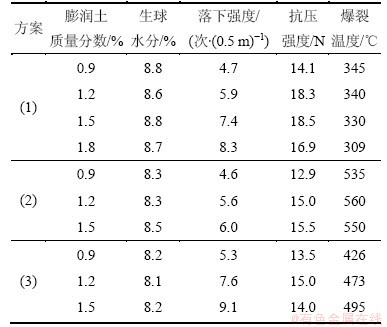

膨润土用量对生球质量的影响见表5。原料为100%巴西赤铁矿的球团,随着膨润土用量的增加,生球落下强度逐渐增大,生球爆裂温度有小幅度的降低。这是因为膨润土能够改善造球物料的粒度组成,使生球内毛细管径变小,毛细力增大;膨润土的加入也增加了颗粒之间的分子黏结力[3]。因此,膨润土能够提高生球的落下强度。在生球干燥过程中,膨润土能够减缓水分的蒸发,并能形成强度较好的干燥外壳,对生球的爆裂温度有利,但膨润土的配入使生球变致密,内部蒸汽扩散阻力增大,这又不利于生球的爆裂温度的提高[3]。巴西赤铁矿高压辊磨后粒度变细,生球毛细管径较小,后者起主导作用,从而导致生球爆裂温度随着膨润土用量的增加而有所降低。

表5 膨润土质量分数对生球质量的影响

Table 5 Effect of bentonite ratio on quality of green balls

随着含硼磁铁精矿配比的增加,生球的落下强度增加;抗压强度虽有所降低,但能够满足生产的要求。在配加30%和50%含硼磁铁矿后,生球的爆裂温度显著提高,膨润土质量分数为1.2%时,爆裂温度分别提高220 ℃和133 ℃,这对生球的干燥非常有利。这是因为硼铁矿粒度较细,小颗粒填充于大颗粒之间,使得生球毛细孔变小,毛细力增大,生球落下强度提高。但配加50%含硼磁铁矿时,颗粒之间填充更加紧密,不利于水分的扩散,使得爆裂温度比配加30%含硼磁铁矿的球团的低。

2.2 球团焙烧

链篦机—回转窑生产氧化球团时,预热球团在回转窑内焙烧的过程中,会受到较大的冲击力和摩擦力,因此要求预热球团具有一定的机械强度来抵抗在回转窑中焙烧时的冲击与磨损。

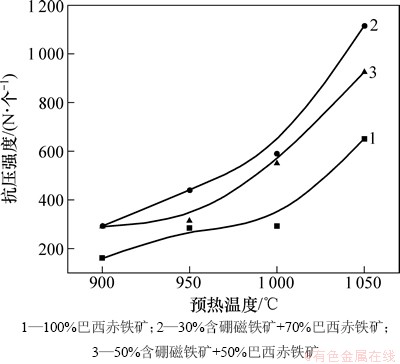

预热温度对预热球团抗压强度的影响见图1。从图1可见:随着预热温度的增加,预热球团抗压强度逐渐增加;配加30%和50%含硼磁铁矿的球团,在预热温度1 000 ℃时,预热球团抗压强度分别为591N/个和547 N/个;而原料为100%巴西赤铁矿的球团,在1 000 ℃的预热温度下,预热球团抗压强度仅为292 N/个,只有当预热温度提高到1 050 ℃时,抗压强度才达到651 N/个。这是因为配加含硼磁铁矿后,预热过程中Fe3O4氧化生成的新生Fe2O3晶格中的原子具有极大的活性,不仅能在晶体内发生扩散,并且毗邻的氧化物晶体也发生扩散迁移,在颗粒之间形成连接桥,有助于球团强度的提高[3]。B2O3是低熔点物质,易形成液相,液相能够使颗粒靠近、拉紧,并重新排列,使球团产生收缩,结构致密化;液相冷却过程中凝固,在球团内部颗粒之间起着黏结作用,从而有利于预热球团抗压强度的提高[3]。因此,配加含硼磁铁矿能够降低球团的预热温度,其降低幅度在50 ℃左右。

图1 预热温度对预热球团抗压强度的影响 (预热时间为10 min)

Fig. 1 Effect of preheating temperature on compressive strength of preheated pellets(preheating for 10 min)

在相同的预热条件下,配加30%含硼磁铁矿的预热球团抗压强度比配加50%含硼磁铁矿的预热球团抗压强度高,这是因为含硼磁铁矿S含量较高,预热过程中S的脱除,一方面阻碍了磁铁矿的氧化,使其活性较高的Fe2O3的生成量减少;另一方面,生成的SO2向球团外部排出,使得球团孔隙率增加,结构变松散,降低了预热球团的抗压强度。

预热时间对预热球团抗压强度的影响见图2。由图2可知:随着预热时间的增加,100%巴西赤铁矿球团抗压强度逐渐增加,这是由于时间延长,Fe2O3晶体扩散增强,促进了Fe2O3微晶键连接,从而使预热球团抗压强度增加。配加含硼磁铁矿后,随着时间的延长,预热球团抗压强度迅速增加,在预热时间为7 min时达到最大;超过7 min后,预热球团抗压强度基本不变。这是因为配加含硼磁铁矿后,加快了固体颗粒之间微晶键的形成,使得抗压强度迅速增大。

图2 预热时间对预热球团抗压强度的影响

Fig. 2 Effect of preheating time on compressive strength of preheated pellets

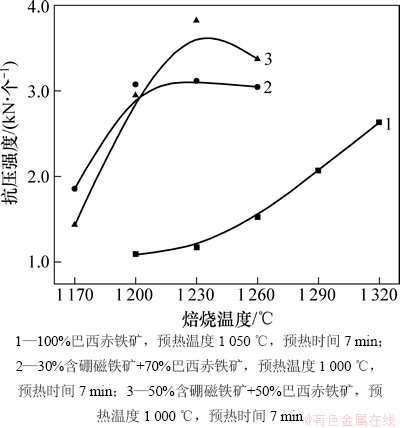

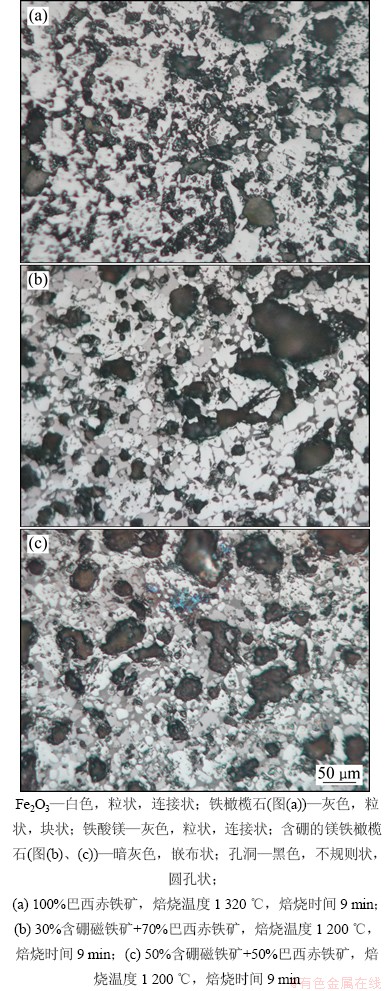

焙烧温度对焙烧球团抗压强度的影响见图3。可见:随着焙烧温度的增加,100%巴西赤铁矿球团抗压强度逐渐增大。这是因为100%巴西赤铁矿球团的固结形式主要是Fe2O3再结晶和晶粒长大(见图4(a)),温度的升高有利于Fe2O3固体颗粒扩散增强,颗粒接触面增加,颗粒之间距离缩小,再结晶和聚晶长大加快,有利于球团强度的提高[3]。配加30%和50%含硼磁铁矿后,抗压强度先增大后减小,在1 230 ℃左右,抗压强度达到最大。这是因为含硼磁铁矿含有较多Fe3O4和熔点较低的B2O3,由Fe3O4氧化生成的新生Fe2O3晶粒具有较强的迁移能力,促进Fe2O3再结晶和晶粒长大,有利于焙烧球团抗压强度的提高;B2O3熔点较低,熔化后形成的液相能够促进高熔点的镁铁橄榄石液相的生成(见图4(b)和(c)),少量液相能使颗粒靠近、拉紧,使球团致密化,并且加快了高熔点铁酸镁的生成,促进固体颗粒重结晶和晶粒长大,有利于球团固相固结。但是超过一定温度时,含硼的镁铁橄榄石液相过多,阻碍了Fe2O3晶粒之间以及Fe2O3和铁酸镁晶粒之间直接接触,并且液相沿晶界渗透,使已聚集成大晶体的固结“粉碎化”,在冷却过程中,橄榄石液相的结晶速度慢,易生成脆性大的玻璃相,使球团抗压强度降低。

在焙烧温度1 320 ℃,焙烧9 min时,100%巴西赤铁矿球团的抗压强度为2 632 N/个,而配加30%和50%含硼磁铁矿后,在1 200 ℃的焙烧温度下,球团抗压强度分别为3 077 N/个和2 948 N/个。可见,配加30%和50%含硼磁铁矿能够显著降低巴西赤铁矿球团焙烧温度,其降低幅度在120 ℃以上。

在焙烧温度1 200 ℃以下,配加50%含硼磁铁矿的焙烧球团抗压强度低于配加30%含硼磁铁矿焙烧球团的抗压强度,这是由于含硼磁铁矿中MgO含量较高,MgO通过固相反应生成的镁铁橄榄石和铁酸镁熔点较高,在较低的焙烧温度下,难以熔化生成液相,以固体的形式填充在Fe2O3颗粒之间,阻碍了球团的固相固结。因此,配加50%含硼磁铁矿的球团抗压强度反而较低。

图3 焙烧温度对焙烧球团抗压强度的影响 (焙烧时间为9 min)

Fig. 3 Effect of roasting temperature on compressive strength of fired pellets (roasting for 9 min)

图4 光学显微镜下焙烧球团矿微观结构

Fig. 4 Mineral phases of fired pellets under optical microscope

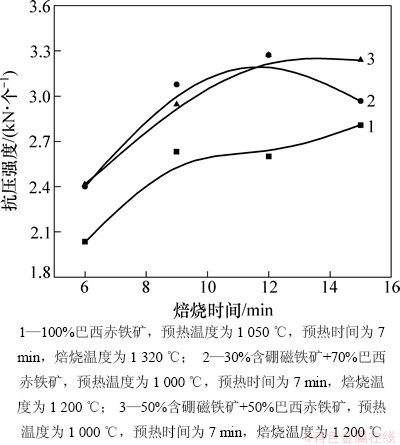

焙烧时间对焙烧球团抗压强度的影响见图5。随着焙烧时间的增加,100%巴西赤铁矿球团抗压强度逐渐增加,而配加30%和50%含硼磁铁矿后,焙烧球团的抗压强度先增加后降低,在焙烧时间12 min左右达到最大。这是因为:100%赤铁矿球团再结晶和晶粒长大速度慢,需要更长的焙烧时间使其充分结晶。而配加含硼磁铁矿的球团,液相量随着焙烧时间的延长逐渐增多,少量的液相加快固相扩散,有利于尽快实现固相固结。因此,可缩短焙烧时间,而过多的液相,则不利于固相固结。

图5 焙烧时间对焙烧球团抗压强度的影响

Fig. 5 Effect of roasting time on compressive strength of fired pellets

2.3 成品球团矿冶化性能

成品球团矿的化学成分见表6。从表6可见:随着含硼磁铁矿配入量的增多,铁品位逐渐下降,这主要是由于含硼磁铁矿铁品位较低,含有较高的MgO和B2O3。但MgO是高炉炉渣需要的成分,球团矿中含有一定量的MgO对高炉炼铁是有利的。在高炉炼铁时,球团中B2O3主要进入渣中,B2O3有助熔作用,能够降低炉渣的熔点和提高炉渣的流动性,有助于炉渣脱硫。成品球团矿中,P和S等有害杂质含量较低,球团矿能够满足高炉炼铁的要求。

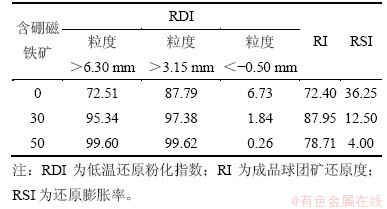

成品球团矿的冶金性能见表7。从表7可见:配加含硼磁铁矿后,成品球团矿的还原度提高,100%巴西赤铁矿球团还原度为72.40%,而配加30%和50%含硼磁铁矿后,成品球团矿还原度分别提高到87.95%和78.71%。配加含硼磁铁矿后,虽然一部分易还原的Fe2O3生成铁酸镁,但铁酸镁的还原性也较好,对还原度的不利影响较小;而半径很小的B3+可以扩散进入Fe2O3晶粒中,导致Fe2O3晶格畸变,使得Fe2O3易于还原[6],因而,配加含硼磁铁矿后,还原度升高。而配加50%含硼磁铁矿后,生成的镁铁橄榄石液相增多,铁酸镁和一部分Fe2O3被含硼的镁铁橄榄石所包围,暴露在孔隙周围易还原的铁氧化物减少(图4(c)),导致还原阻力增大,并且镁铁橄榄石还原性较差,因而还原度相比于配加30%含硼磁铁矿的球团矿有所降低。

100%巴西赤铁矿球团还原膨胀率较大,为36.25%,属于异常膨胀,会影响高炉顺行。配加30%和50%含硼磁铁矿后,球团矿还原膨胀率分别降低到12.50%和4.00%,有利于高炉顺行[15]。含硼磁铁矿中MgO含量较高,在焙烧过程中形成了大量稳定的铁酸镁(图4(b)、(c)),铁酸镁在还原过程中不会发生Fe2O3转变成Fe3O4的反应,而生成的是FeO和MgO的固溶体。另外,由于Mg2+的半径小于Fe2+的半径,Mg2+能均匀分布在浮氏体内,不会引起局部化学还原反应,抑制了球团的还原膨胀[15]。

表6 成品球团矿的化学成分(质量分数)

Table 6 Chemical compositions of product pellets %

表7 成品球团矿的冶金性能(质量分数)

Table 7 Metellurgical performance of product pellets %

100%巴西赤铁矿球团的低温还原粉化指数RDI+3.15为87.79%,配加含硼磁铁矿后,成品球团矿RDI+3.15分别提高到97.38%和99.62%,这将有利于炼铁过程中高炉透气性的改善。这是因为配加含硼铁精矿球团在焙烧时形成含硼的镁铁橄榄石(见图4(b),(c))在还原的过程中,仍起到一定的黏结作用,抑制了球团的粉化。

3 结论

(1) 配加含硼磁铁矿能够强化巴西赤铁矿球团生球的制备,改善球团焙烧性能和冶金性能。配加30%和50%含硼磁铁矿后,生球的落下强度增加,爆裂温度显著提高,在膨润土用量为1.2%时,爆裂温度分别提高220 ℃和133 ℃;预热温度降低50 ℃左右,焙烧温度降低120 ℃以上,成品球团矿还原度从72.40%分别提高到87.95%和78.71%,低温还原粉化指数RDI+3.15从87.79%分别提高到97.38%和99.62%,还原膨胀率从36.25%分别降到12.50%和4.00%。含硼磁铁矿和巴西赤铁矿搭配使用生产球团矿,也是解决含硼磁铁矿难利用的一条有效途径。

(2) 焙烧性能提高的原因是:含硼磁铁矿中含有较多的Fe3O4,MgO和低熔点的B2O3,Fe3O4氧化生成的新生Fe2O3晶体表面原子具有较强的迁移能力,有利于Fe2O3再结晶和晶粒长大;B2O3熔化后形成的液相促进高熔点的镁铁橄榄石液相生成,液相有助于颗粒之间靠近、拉紧,并且促进铁酸镁的生成以及固体颗粒的重结晶和晶粒长大,从而有利于球团强度的提高。

(3) 还原度提高的原因是因为B3+半径很小,易扩散进入Fe2O3晶体中,产生晶格畸变,使得Fe2O3易于还原;球团焙烧时生成大量稳定的铁酸镁,铁酸镁还原时不发生Fe2O3向Fe3O4的转变,而是生成FeO和MgO的固溶体,抑制了从Fe2O3到Fe3O4过程中晶格的膨胀,改善了球团的还原膨胀性能;添加含硼磁铁矿的球团生成的橄榄石粘结相增多,在还原的过程中也起着一定的黏结作用,抑制了粉化,使球团矿的还原粉化性能得到改善。

参考文献:

[1] 刘文权. 对我国球团矿生产发展的认识和思考[J]. 炼铁, 2006, 25(3): 10-13.

LIU Wenquan. Knowledge and view on development of pellet production in China[J]. Ironmaking, 2006, 25(3): 10-13.

[2] 叶匡吾. 努力推进我国球团矿的生产[J]. 烧结球团, 2007, 32(5): 1-5.

YE Kuangwu. Heavily push forward the pellets production of our country[J]. Sintering and Pelleting, 2007, 32(5): 1-5.

[3] 傅菊英, 姜涛, 朱德庆. 烧结球团学[M]. 长沙: 中南工业大学出版社, 1996: 251-312.

FU Juying, JIANG Tiao, ZHU Deqing. Principle of sintering and pelletizing[M]. Changsha: Central South University of Technology Press, 1996: 251-312.

[4] 黄柱成, 张元波, 陈耀明, 等. 以赤铁矿为主配加磁铁矿制备的氧化球团矿显微结构[J]. 中南工业大学学报(自然科学版), 2003, 34(6): 606-610.

HUANG Zhucheng, ZHANG Yuanbo, CHEN Yaoming, et al. Micostructure of oxidized pellet mainly made from hematite with magnetite[J]. Journal of Central South University of Technology (Natural Science), 2003, 34(6): 606-610.

[5] 黄柱成, 张元波, 朱尚朴, 等. 以赤铁矿为主配加磁铁矿制备氧化球团的研究[J]. 钢铁, 2004, 39(4): 9-14.

HUANG Zhucheng, ZHANG Yuanbo, ZHU Shangpu, et al. Study on mainly made from hematite based on oxidized pellets[J]. Iron and Steel, 2004, 39(4): 9-14.

[6] 李慧敏. 含硼复合添加剂强化巴西赤铁矿球团制备及机理研究[D]. 长沙: 中南大学资源加工与生物工程学院, 2009: 17, 41.

LI Huimin. Study on the process and mechanism of improving the pelletization of Brazilian hematite by adding boron bearing compound additives[D]. Changsha: Central South University. School of Minerals Processing and Bioengineering, 2009: 17, 41.

[7] 朱德庆, 沈文俊, 潘建, 等. 碱度和内配燃料对赤铁矿球团强度的影响[J]. 金属矿山, 2011(6): 104-108.

ZHU Deqing, SHEN Wenjun, PAN Jian, et al. Research on influence of the alkalinity and the fuel flux to the intensity of hematite pellets[J]. Metal Mine, 2011(6): 104-108.

[8] 姜涛, 何国强, 李晓芹, 等. 焙烧气氛对内配碳赤铁矿球团焙烧行为的影响[J]. 中南大学学报(自然科学版), 2009, 40(4): 851-856.

JIANG Tao, HE Guoqiang, LI Xiaoqin, et al. Effects of atmosphere on roasting behaviors of carbon-burdened hematite pellets[J]. Journal of Central South University (Science and Technology), 2009, 40(4): 851-856.

[9] 李晓芹. 内配碳在赤铁矿氧化球团制备中的行为研究[D]. 长沙: 中南大学钢铁冶金系, 2009: 48-56.

LI Xiaoqin. Behaviores of carbon in preparation of oxidized pellet from hematite concentrate[D]. Changsha: Central South University. Department of Ferrous Metallurgy, 2009: 48-56.

[10] Jiang T, Zhang Y B, Huang Z C, et al. Preheating and roasting characteristics of hematite-magnetite(H-M) concentrate pellets[J]. Ironmaking and Steelmaking, 2008, 35(1): 21-26.

[11] 陈耀明, 李建. 氧化球团中Fe2O3的结晶规律[J]. 中南大学学报(自然科学版), 2007, 38(1): 70-73.

CHEN Yaoming, LI Jian. Crystal rule of Fe2O3 in oxidized pellet[J]. Journal of Central South University (Science and Technology), 2007, 38(1): 70-73.

[12] 周友连, 许斌, 李骞, 等. 复合添加剂对赤铁矿球团性能影响的机理研究[J]. 矿业工程, 2011, 31(1): 66-69.

ZHOU Youlian, XU Bin, LI Qian, et al. Mechanism research for influence of compound additives on the properties of hematite pellets[J]. Mining and Metallurgical Engineering, 2011, 31(1): 66-69.

[13] 姜涛, 何国强, 李光辉, 等. 脉石成分对铁矿球团还原膨胀性能的影响[J]. 钢铁, 2007, 42(5): 7-11.

JIANG Tao, HE Guoqiang, LI Guanghui, et al. Effect of gangue composition on reduction swelling of iron ore pellets[J]. Iron and Steel, 2007, 42(5): 7-11.

[14] Dwarapudi S, Ghosh T K, Shankar A, et al. Effect of pellet basicity and MgO content on the quality and microstructure of hematite pellets[J]. International Journal of Mineral Processing, 2011, 99(1/2/3/4): 43-53.

[15] 傅菊英, 朱德庆. 铁矿氧化球团基本原理、工艺及设备[M]. 长沙: 中南大学出版社, 2007: 69-70, 227-232.

FU Juying, ZHU Deqing. Principle, technics and equipments of iron ore oxidized pellets[M]. Changsha: Central South University Press, 2007: 69-70, 227-232.

[16] 张丽清, 刘素兰, 朱建新, 等. 硼铁矿资源综合利用研究现状与进展[J]. 矿产综合利用, 2000(3): 34-36.

ZHANG Liqing, LIU Sulan, ZHU Jianxin, et al. On the comprehensive utilization of ludwigite resources[J]. Multipurpose Utilization of Mineral Resources, 2000(3): 34-36.

[17] 刘然, 薛向欣, 姜涛, 等. 硼铁矿综合利用概况与展望[J]. 矿产综合利用, 2006(2): 33-36.

LIU Ran, XUE Xiangxin, JIANG Tao, et al. Comprehensive utilization of ludwigite and its prospect[J]. Multipurpose Utilization of Mineral Resource, 2006(2): 33-36.

[18] 赵庆杰, 王常任. 硼铁矿的开发利用[J]. 辽宁化工, 2001, 30(7): 297-299.

ZHAO Qingjie, WANG Changren. Develop and application of paigeite[J]. Liaoning Chemical Industry, 2001, 30(7): 297-299.

[19] 李艳军, 韩跃新. 辽宁凤城硼铁矿资源的开发与利用[J]. 金属矿山, 2006(7): 8-11.

LI Yanjun, HAN Yuexin. Exploitation and utilization of boron-iron ore resource in Fengcheng, Liaoning[J]. Metal Mine, 2006(7): 8-11.

[20] 储满生, 李壮年, 柳政根, 等. 硼铁矿清洁高效综合利用新工艺[C]//中国金属学会2010年非高炉炼铁学术年会暨钒钛磁铁矿综合利用技术研讨会论文集. 攀枝花: 中国金属学会, 2010: 437-441.

CHU Mansheng, LI Zhuangnian, LIU Zhenggen, et al. New process for clean and efficient utilization of paigeite[C]//Symposium of The Chinese Society for Metal 2010’s Annual Conference on Non-blast Furnace and Comgrehensive Utilization of Vanadium Titano-magnetite. Panzhihua: The Chinese Society for Metal, 2010: 437-441.

[21] 赵庆杰, 何长清, 王常任, 等. 硼铁矿磁选分离综合利用新工艺[J]. 东北大学学报(自然科学版), 1996, 17(6): 588-592.

ZHAO Qingjie, HE Changqing, WANG Changren, et al. New process of multipurpose utilization of ludwigte[J]. Journal of Northeastern University (Natural Science), 1996, 17(6): 588-592.

(编辑 赵俊)

收稿日期:2013-03-12;修回日期:2013-07-10

基金项目:国家科技部火炬计划项目(2011GH561685)

通信作者:朱德庆(1964-),男,湖南安乡人,博士,教授,博士生导师,从事烧结球团、直接还原及资源综合利用等研究;电话:0731-88836942;E-mail:dqzhu@mail.csu.edu.cn