碱度及MgO质量分数对球团焙烧及冶金性能的影响

朱德庆,高子富,潘建,春铁军,杨聪聪

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:为了改善球团性能及降低COREX能耗,在球团制备过程中加入熔剂。通过调节球团碱度(0.8~2.2)及MgO质量分数(0.5%~2.5%),研究球团焙烧行为及其冶金性能。结果表明:当MgO质量分数为0.25%~1.50%时,随着碱度从0.8提高到1.2,焙烧球团抗压强度升高,达到最大值;随后碱度(1.6~2.2)增加,焙烧球团抗压强度下降;当球团中MgO质量分数升高到2.5%时,焙烧球团抗压强度随着碱度(0.8~2.2)升高而急剧下降;当碱度(0.8~2.2)固定时,随着MgO质量分数增加,球团抗压强度呈下降趋势。同时提高碱度和MgO质量分数可改善球团冶金性能;制备的含镁熔剂性球团(w(MgO)=0.25%~2.5%,碱度R=0.8~1.6)荷重还原度均在79%以上,还原膨胀率低于15%,低温还原粉化指数RDI-3.15 mm大部分低于5%,软化温度>940 ℃,熔化温度>1 260 ℃,为优良的COREX入炉炉料。

关键词:COREX;熔剂性球团;抗压强度;冶金性能

中图分类号:TF046 文献标志码:A 文章编号:1672-7207(2013)10-3963-08

Influence of pellet basicity and MgO content on roasting and metallurgical properties of pellets

ZHU Deqing, GAO Zifu, PAN Jian, CHUN Tiejun, YANG Congcong

(School of Minerals Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract: In order to improve the properties of pellets and reduce the energy consumption of COREX, flux was added to the pellets in the process of production. Flux pellets were prepared with varying basicity (0.8-2.2) and MgO content (0.5%-2.5%) and the roasting behaviour of pellets and metallurgical properties were studied. The results show that the compressive strength of the pellets increases to the maximum with increasing basicity (0.8-1.2) under MgO content ranging from 0.25% to 1.5%. Pellets compressive strength decreases with increasing basicity (1.6-2.2) when MgO content is 2.5%. Pellets compressive strength decreases with increasing MgO content as the basicity (0.8-2.2) is fixed. The increasing basicity and MgO content in pellets could improve metallurgical properties. The prepared magnesium-bearing fluxed pellets (w(MgO)=0.25%-2.5%), R=0.8-1.6) have high reduction degree under load (>79%), low reduction swelling index (<15%), low temperature degradation indices (<5%), high softening temperature (>940 ℃) and melting temperature (>1 260 ℃). So the pellets is a good charging raw material for COREX.

Key words: COREX; fluxed pellets; compressive strength; metallurgical properties

COREX熔融还原炼铁工艺,融合了成熟的气基竖炉直接还原铁生产技术和高炉炼铁技术。其中预还原竖炉相当于高炉炉身的中上部,熔融气化炉相当于高炉的炉缸与炉腹部分。预还原竖炉避免了影响料柱透气性和气流分布的软熔带。与高炉相比,具有流程短、成本低、使用非焦煤、能量利用高和环境污染少等优点。COREX主要以球团矿、块矿或者两者的混合作为主要铁矿原料,为了在终还原炉内形成合适的炉渣成分,满足碱度要求,保证冶炼的正常进行和铁水质量,需要在预还原竖炉中加入石灰石、白云石和硅砂等生熔剂,以使碳酸盐的预热和部分分解在还原竖炉中完成,然后,随海绵铁一起加入熔融气化炉[1-5],因此,导致COREX工艺能耗和燃料比升高,影响预还原炉料的金属化率。COREX预还原竖炉中,由于煤气有较强的还原势,且普通球团矿和块矿均为酸性物料,在预还原过程中出现低熔点物质;另外,赤铁矿酸性球团在还原过程中易粉化和膨胀,造成炉料粘结,导致炉况不顺[6-7]。国内外研究表明:含镁熔剂性球团具有良好的高炉冶金性能[8-9],但用于COREX的研究鲜见报道。本文通过开展制备含镁熔剂性球团的研究,考察碱度、MgO质量分数及其交互作用对球团焙烧性能及高温冶金性能的影响,改善COREX工艺用球团的冶金性能,以便为强化COREX竖炉预还原提供理论指导。

1 原料性能及研究方法

1.1 原料性能

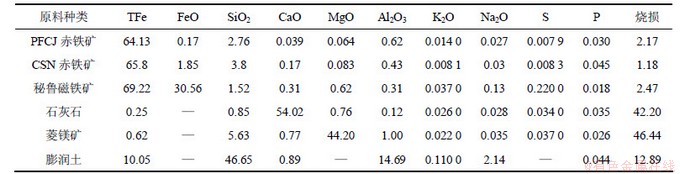

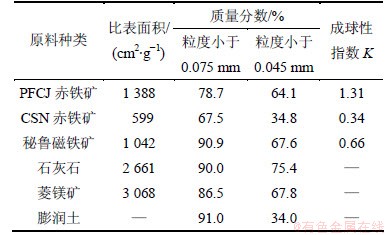

本研究采用3种含铁精矿,即巴西PFCJ赤铁矿、巴西CSN赤铁矿和秘鲁磁铁精矿,采用石灰石和菱镁矿调节球团矿的碱度和MgO含量,黏结剂为膨润土。原料化学成分如表1所示。由化学成分可知:3种含铁精矿品位都比较高,磁铁矿铁品位高达69.22%,是优质球团原料;FeO质量分数为30.56%,有利于改善球团焙烧性能。3种铁精矿中SiO2及Al2O3质量分数比较低,有害元素质量分数更低。石灰石主要矿物为CaCO3,CaO质量分数为54.02%。菱镁矿主要矿物为MgCO3,SiO2质量分数为5.63%。

表2所示为原料物理性质,由此可见秘鲁磁铁矿最细,CSN赤铁矿粒度较粗。PFCJ赤铁矿成球性指数K为1.31,属优等成球性。CSN赤铁矿成球性指数K为0.34,属弱成球性。秘鲁磁铁精矿K为0.66,有良好成球性。PFCJ赤铁矿有比较高的比表面积,其次是秘鲁磁铁矿,CSN赤铁矿的比表面积最小,只有599 cm2/g,其规律与成球性指数相对应。但3种铁精矿比表面积均小于造球原料要求,还需要进行预处理,增大其比表面积,改善其成球形。石灰石、菱镁矿比表面积达到球团制备要求。膨润土物理性能较好,胶质价为99.5%,膨胀容为61.5 mL/g,2 h吸水率为616%,属优质膨润土。

1.2 研究方法

试验流程包括生球制备、生球干燥、球团预热和焙烧、球团矿冶金性能检测和矿相分析。含铁原料是按巴西PFCJ赤铁矿、CSN赤铁矿、磁铁矿以质量比为45:25:30混匀,再经高压辊磨预处理,使混合料比表面积达到1 500~1 600 cm2/g后用于造球。固定造球混合料中的SiO 2质量分数为3%,膨润土配比固定为1.0%,根据碱度(0.8,1.2,1.6,2.0,2.2)和MgO质量分数(0.25%,0.5%,1.5%和2.5%)调节要求,计算石灰石和菱镁矿在造球原料中的添加量。含铁混合料、膨润土及熔剂按一定质量比混匀后在圆盘造球机中造球,固定造球水分质量分数为8.5%,造球时间为12 min。取合格生球(生球抗压强度>10 N/个,落下强度>5次/(0.5 m)、爆裂温度>350 ℃)在105 ℃烘箱内烘干4 h,制备干球。在卧式管炉中进行干球的预热和焙烧试验,测定预热和焙烧球团抗压强度,优化预热和焙烧工艺参数。对制备的成品球进行化学分析、微观结构分析和冶金性能检测,模拟COREX预还原竖炉气氛、温度来研究球团矿冶金性能。荷重还原性测定参照ISO 11258和ISO 7992标准,持续给予试样14 N/cm2的荷重,还原气体组成为68% CO,23% H2及9% CO2;模拟COREX竖炉上部工况条件测定低温还原粉化指数,方法参照ISO 4696—1984标准,还原气体组成为35% CO,50% CO2和15% H2;还原膨胀率参照GB/T 13240—91在800 ℃下测定;模拟COREX还原气氛,测定球团的软化和熔化温度。

表1 原料化学成分(质量分数)

Table 1 Chemical composition of raw material %

表2 原料物理性能

Table 2 Physical properties of raw material

2 结果及分析

2.1 自然MgO质量分数下碱度对球团预热焙烧行为的影响

2.1.1 碱度对预热球团抗压强度的影响

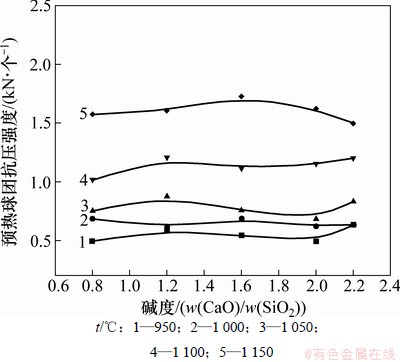

图1所示为自然MgO质量分数下碱度及预热温度对预热球团抗压强度的影响。由图1可见:当预热温度固定时,碱度对预热球抗压强度影响较小;碱度固定时,随着预热温度的提高,预热球团抗压强度明显提高。这是因为预热温度的提高,可以加速固相扩散反应[10],预热球团抗压强度增加。预热温度对预热球团抗压强度影响较大。碱度在0.8~2.2范围内,预热温度为950 ℃时,预热球团抗压强度均高于500 N/个。但预热球团抗压强度如需达到1 kN/个,则预热温度需高于1 100 ℃。

图1 自然MgO质量分数下碱度及预热温度对预热球团抗压强度的影响(w(MgO)=0.25%,预热时间12 min)

Fig. 1 Effect of basicity and preheating temperature on compressive strength of preheated pellets under nature MgO content (w(MgO)=0.25%, preheating for 12 min)

2.1.2 碱度对焙烧球团抗压强度的影响

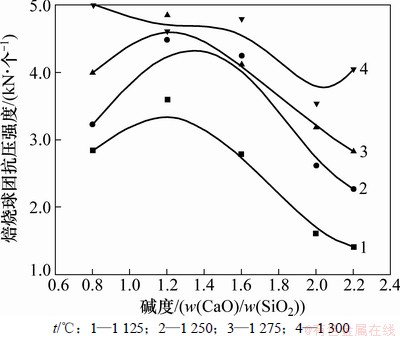

碱度及焙烧温度对球团抗压强度的影响如图2所示。在碱度一定时,随着焙烧温度升高,焙烧球团抗压强度升高。在相同焙烧温度下,随碱度增加,焙烧球团抗压强度先增加后下降;当碱度为1.2时,焙烧球团抗压强度最大。随着球团碱度增加,出现对固结有利的铁酸钙粘结相,所以焙烧球团抗压强度增加。当碱度升高到2.0~2.2时,焙烧温度为1 275~1 300 ℃时球团中铁酸钙分解及出现较多的液相,球团相互粘结,导致球团抗压强度降低。

图2 自然MgO质量分数下碱度及焙烧温度对焙烧球团抗压强度的影响(w(MgO)=0.25%,预热温度为1 100 ℃,预热时间为12 min,焙烧时间为15 min)

Fig. 2 Effect of basicity and firing temperature on compressive strength of fired pellets under nature MgO content (w(MgO)=0.25%, preheating at 1 100 ℃ for 12 min, firing for 15 min )

2.2 碱度及MgO质量分数对球团预热焙烧行为的影响

2.2.1 碱度及MgO质量分数对预热球团抗压强度的影响

碱度及MgO质量分数对预热球团抗压强度的影响如图3所示。从图3可见:MgO质量分数固定时,碱度对预热球团抗压强度影响与自然MgO质量分数时规律类似,呈先小幅增长再下降趋势,碱度为1.2时预热球团抗压强度达到最大值;当碱度固定时,预热球团抗压强度随着MgO质量分数增加明显下降。但是,在预热温度1 150 ℃下,碱度在0.8~2.0,MgO质量分数在0.25%~2.5%范围内大部分预热球团抗压强度在1 kN/个以上。 在预热阶段主要反应为球团矿内磁铁矿氧化成赤铁矿,石灰石和菱镁矿等碳酸盐分解,球团中孔隙增加;另外MgO在磁铁矿中的固溶延迟了磁铁矿的氧化及固结,导致预热球团抗压强度变小[11]。因此,随着MgO质量分数增加时,预热球团抗压强度下降。

图3 碱度及MgO质量分数对预热球团抗压强度的影响 (预热温度为1 150 ℃,预热时间为12 min)

Fig. 3 Effect of basicity and MgO content on compressive strength of preheated pellets (preheating at 1 150 ℃ for 12 min)

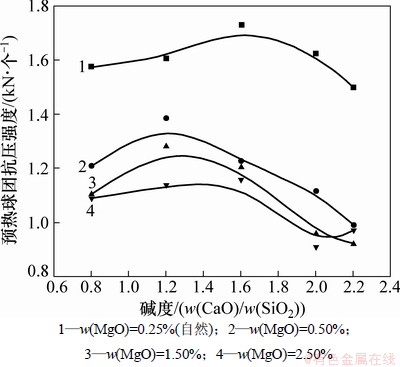

2.2.2 碱度及 MgO质量分数对焙烧球团抗压强度的影响

碱度及MgO质量分数对焙烧球团抗压强度的影响如图4所示。碱度固定时,随着MgO质量分数增加,焙烧球团抗压强度呈下降趋势;当MgO质量分数为0.25%~1.5%时,随着碱度从0.8提高到1.2,焙烧球团抗压强度升高,达到最大值,随后,碱度增加焙烧球团抗压强度急剧下降;当球团中MgO质量分数为2.5%时,焙烧球团抗压强度随着碱度升高而急剧下降。在一定范围内,碱度与MgO质量分数有交互作用。

在球团焙烧阶段,熔剂的添加使球团孔隙增多, MgO可以减缓磁铁矿的氧化及固结,导致赤铁矿再结晶减少而磁铁矿再结晶增多,从而焙烧球抗压强度降低[12];MgO能够活化赤铁矿分解,MgO的存在可以降低赤铁矿的分解温度,加快赤铁矿的分解速度,赤铁矿的分解使得球团晶粒难以聚集长大,球团强度下降;当焙烧温度为1 250 ℃时,碱度为0.8,1.2和1.63组球团抗压强度大部分大于2.5 kN/个,达到了COREX-3000生产要求;当碱度为2.0和2.2时,球团抗压强度呈下降趋势,抗压强度大部分在2.5 kN/个以下。建议球团碱度在0.8~1.6范围内,适宜的MgO质量分数应控制在2.5%以下。

图4 碱度及MgO质量分数对焙烧球团抗压强度的影响 (预热温度为1 150 ℃,预热时间为12 min,焙烧温度为1 250 ℃,焙烧时间为15 min)

Fig. 4 Effect of basicity and MgO content on compressive strength of fired pellets (preheating at 1 150 ℃ for 12 min, firing at 1 250 ℃ for 15 min)

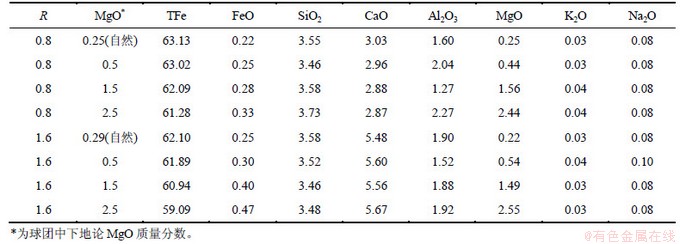

2.3 碱度和MgO质量分数对球团化学成分及微观结构的影响

通过添加石灰石、菱镁矿调节碱度和MgO质量分数,成品球团矿化学成分见表3。从表3可见:随着MgO质量分数及碱度增加,成品球团铁品位从63.1%逐渐下降59.0%;碱度越高,MgO质量分数升高时,球团铁品位越低。

碱度及MgO质量分数对焙烧球团微观结构的影响如图5所示。从图5可见:当MgO质量分数为自然质量分数时,碱度由0.8增加到1.6,赤铁矿再结晶充分,铁酸钙粘结相增多,晶粒增大,孔洞减少,因此,球团抗压强度增加;当碱度一定时,MgO质量分数增加,球团中铁酸镁增多,孔隙增加,结晶程度下降,导致球团抗压强度降低;当MgO质量分数为2.5%时,碱度增加,球团结晶变得完善,孔洞变小,大量铁酸镁形成,球团抗压强度略有下降。

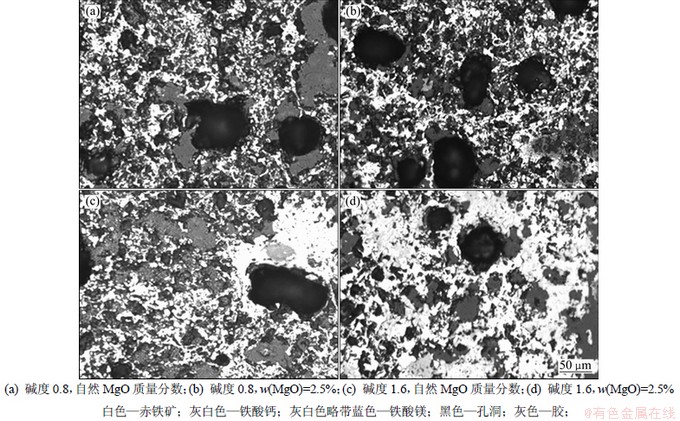

2.4 碱度及MgO质量分数对COREX球团冶金性能的影响

2.4.1 荷重还原度

碱度及MgO质量分数对球团孔隙率及荷重还原度的影响如图6所示。从图6可见:2组碱度球团孔隙率和荷重还原度都随着MgO质量分数增加而增加;球团MgO质量分数相同时,碱度升高,孔隙率和还原度也相应升高。

表3 不同MgO质量分数下成品球团化学成分

Table 3 Chemical composition of fired pellets with varying MgO content of two basicity %

图5 不同碱度及MgO质量分数的焙烧球团微观结构

Fig. 5 Microstructure of fried pellets with different basicities and MgO contents

由于添加的菱镁矿、石灰石在球团预热焙烧过程中不断分解,所以,球团孔隙率随着熔剂添加量增加而增加;球团孔隙率上升,有利于还原气体扩散;MgO的加入使球团生成高熔点的铁酸镁,预还原过程中球团中的Fe2O3与上升的还原气体阻碍减小,接触面积增大,从而提高了间接还原率,还原度随着MgO质量分数增加而增加[13];提高碱度,球团孔隙率提高,同时球团中出现较多易还原的铁酸钙物质,球团还原度增加。当碱度0.8时,当MgO质量分数为自然质量分数时,还原度为79.0%;当碱度为1.6,MgO质量分数为2.5%时,还原度增加到97.0%;碱度和MgO交互作用可以提高球团荷重还原度。总体来看,球团碱度为0.8~1.6,MgO为0.25%~2.5%范围内,提高碱度和MgO质量分数都可以使球团还原度升高,均在79%以上。

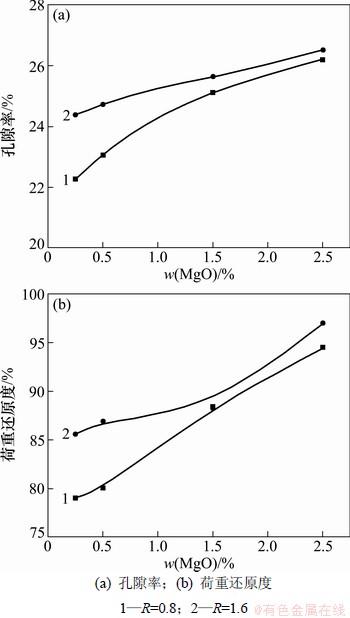

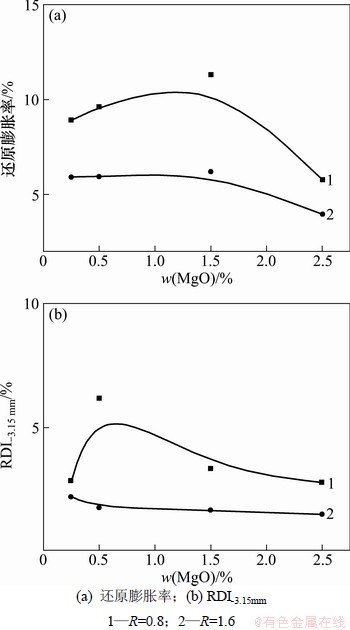

2.4.2 还原膨胀率及低温还原粉化指数

在COREX预还原过程中,球团中的赤铁矿还原为磁铁矿时,还原前后晶胞增大破坏球团的结构,产生体积膨胀。低温还原粉化指数反映球团在COREX预还原竖炉上部550 ℃左右低温区域时还原时产生粉末的趋势。如图7所示。从图7可见:随着MgO质量分数增加,碱度0.8的球团还原膨胀率和低温还原粉化指数(RDI-3.15mm)先小幅升高再下降;碱度1.6的球团随着MgO含量增加还原膨胀、粉化呈小幅下降趋势,还原膨胀从5.9%下降到4.0%,还原粉化指数RDI-3.15mm从2.2%下降到1.5%;固定MgO质量分数时,R=0.8球团还原膨胀、粉化性能较R=1.6的大,但还原膨胀总体都远低于15%,RDI-3.15mm大部分在5%以下,达到生产要求,显示出含镁熔剂性球团具有较低的还原膨胀率和良好的低温还原粉化性能。

图6 碱度及MgO含量对球团孔隙率(a)及荷重还原度(b)的影响

Fig. 6 Effect of basicity and MgO content on porosity (a) and reduction degree under load (b) of pellets

球团中添加的MgO,在焙烧过程中形成稳定的铁酸镁,还原时生成的是FeO和MgO的固熔体,避免了Fe2O3还原为Fe3O4产生的晶型转变,从而降低球团的还原膨胀[8]。固定MgO质量分数,碱度增高,球团在焙烧过程中有较多的铁酸钙生成。铁酸钙还原过程中,在钙浮氏体表面生成金属铁层[14]。这种金属铁在铁酸盐颗粒周围形成同心铁层,抑制了球团矿膨胀。

图7 碱度及MgO质量分数对球团还原膨胀率及低温还原粉化指数的影响

Fig. 7 Effect of basicity and MgO content on reduction swelling index and reduction degradation index of pellets

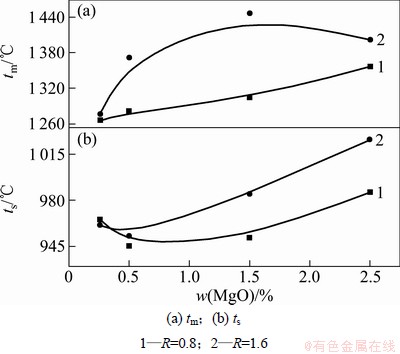

2.4.3 高温软熔性能

COREX工艺避免了类似高炉的软熔带[15],但球团矿软化温度及熔化温度对COREX有重要影响,2组碱度MgO含量对软化温度(ts)、熔化温度(tm)的影响示于图8。随着MgO质量分数增加,软化开始温度、熔化终了温度呈逐渐上升趋势,且R=1.6球团增幅比R=0.8球团大。软化开始温度均在940 ℃以上,远高于COREX预还原竖炉里还原温度(800~850 ℃),在预还原过程中不易产生软化粘结,防止料柱粘结,保证炉况顺行。

图8 2组碱度下MgO含量对球团软化温度(Ts)和熔化温度(Tm)的影响

Fig. 8 Effect of basicity and MgO content on softening temperature and melting temperature of pellets

含镁球团在还原过程中生成熔点较高的MgO·FeO固溶体,MgO进入浮氏体提高浮氏体熔点,而CaO添加可以形成易还原的铁酸钙,促进球团矿还原,产生较多熔点高的金属铁,因此,碱度增加也可以提高软化温度[16]。随着MgO质量分数和碱度增加,球团还原过程中产生更多熔点相对较高的金属铁,因此,球团熔化温度会增高。从图8可以看出:熔化终了温度在1 260~1 450 ℃之间,熔化温度的提高在一定程度上会影响球团在终还原炉里的熔化速度,进而影响后续工艺,但在COREX实际运行时都会加入酸性矿石,可以降低熔化温度,保证COREX稳定运行。

3 结论

(1) 当MgO质量分数为自然含量(0.25%)时,碱度在0.8~2.2范围内,预热球团抗压强度大于1 kN/个所需预热温度为1 100 ℃。MgO质量分数增加到0.5%~2.5%,碱度在0.8~2.2范围内,预热球团抗压强度大于1 kN/个所需预热温度需提高到1 150 ℃。

(2) MgO质量分数为0.25%~1.5%时,随着碱度从0.8提高到1.2,焙烧球团抗压强度升高,达到最大值;随后碱度增加(1.2~1.6)焙烧球团抗压强度急剧下降;当碱度进一步升高到2.0以后,球团焙烧过程中甚至出现液相,焙烧球团抗压强度下降。球团中MgO质量分数升高到2.5%时,焙烧球团抗压强度随着碱度升高而急剧下降。在一定范围内,碱度与MgO质量分数有交互作用。建议球团碱度在0.8~1.6范围内,MgO质量分数小于2.5%。

(3) 当MgO质量分数为自然含量(0.25%)时,随着碱度从0.8增加到1.6,球团孔隙率由22.3%增高到24.4%,荷重还原度从79.0%增加到85.6%,还原膨胀率变小到5.9%,低温还原粉化指数变小到2.2%。当碱度为1.6,MgO质量分数增加到2.5%时,焙烧球团中形成铁酸镁,孔隙率增加到26.5%,荷重还原度升高到97.0%,还原膨胀率为4.0%,低温还原粉化指数为1.5%,软化及熔化温度升高。

(4) MgO质量分数为0.25%~2.5%,碱度为0.8~1.6时的熔剂性球团具有良好冶金性能,荷重还原度均在79%以上,还原膨胀率低于15%,低温还原粉化指数大部分小于5%,软化温度大于940 ℃,熔化温度大于1 260 ℃,为优良的COREX入炉炉料。

参考文献:

[1] 王燕, 周鹤松. COREX熔融还原炼铁工艺简介[J]. 科技创新导报, 2009, 29: 35-26.

WANG Yan, ZHOU Hesong. Introduction of COREX smelting reduction ironmaking technology[J]. Technology Innovation Herald, 2009, 29: 35-26.

[2] 王定武. COREX熔融还原工艺的技术经济分析[J]. 中国冶金, 2002, 3: 19-20.

WANG Dingwu. Technical and economic analysis of COREX smelting reduction process[J]. China Metllurgy, 2002, 3: 19-20.

[3] 王琳, 陈丽华, 吕海鸥. COREX熔融还原工艺的发展状况[J]. 沈阳工程学院学报, 2006, 2(4): 373-376.

WANG Lin, CHEN Lihua, L Haiou. Development of COREX smelting reduction processes[J]. Journal of Shenyang Institute of Engineering: Natural Science, 2006, 2(4): 373-376.

Haiou. Development of COREX smelting reduction processes[J]. Journal of Shenyang Institute of Engineering: Natural Science, 2006, 2(4): 373-376.

[4] 陈炳庆, 张瑞祥, 周渝生. COREX熔融还原炼铁技术[J]. 钢铁, 1988, 33(2): 1-6.

CHEN Bingqing, ZHANG Ruixiang, ZHOU Yusheng. Technology of COREX smelting reduction ironmaking[J]. Iron & Steel, 1988, 33(2): 1-6.

[5] 张汉泉, 朱德庆. 熔融还原的现状及今后的发展方向[J]. 钢铁研究, 2001(5): 59-62.

ZHANG Hanquan, ZHU Deqing. Present situation and trend of development about smelting reduction[J]. Research on Iron & Steel, 2001(5): 59-62.

[6] 姚永林, 余帆, 邓立波. COREX熔融还原运行情况及发展方向分析[J]. 山西冶金, 2010(4): 5-7.

YAO Yonglin, YU Fan, DENG Libo. COREX operation and development direction analysis[J]. Shanxi Metallurgy, 2010(4): 5-7.

[7] 方觉, 郝素菊. 非高炉炼铁工艺与理论[M]. 北京: 冶金工业出版社, 2002: 146-176.

FANG Jue, HAO Suju. The technology and theory of non-blast furnace ironmaking[M]. Beijing: Metallurgical Industry Press, 2002: 146-176.

[8] Mustafa S S. The influence of CaO on the precipitation behavior of iron in the reduction of iron oxide[J]. Scandinavian Journal of Metallurgy, 2001, 30: 1-7.

[9] Dwarapud S, Ranjan M. Influence of oxide and silicate melt phases on the RDI of iron ore pellets suitable for shaft furnace of direct reduction process[J]. ISIJ, 2010, 50(11): 1581-1589.

[10] 傅菊英, 姜涛, 朱德庆. 烧结球团学[M]. 长沙: 中南工业大学出版社, 1996: 281-289.

FU Juying, JIANG Tao, ZHU Deqing. Principles of sintering and pelletizing[M]. Changsha: Centre South University Press, 1996: 281-289.

[11] Dwarapud S, Tamal K, Shankar A. Effect of pellet basicity and MgO content on the quality and microstructure of hematite pellets[J]. Mineral Processing, 2011, 99: 43-53.

[12] 张一敏. 球团理论与工艺[M]. 北京: 冶金工业出版社1997: 114-148.

ZHANG Yimin. Theory and technology of pellets[M]. Beijing, Metallurgical Industry Press, 1997: 114-148.

[13] Panigraphy S C, Jena B C, Riguard M. Characterization of bonding and crystalline phases in fluxed pellets using peat moss and bentonite as binders[J]. Metallurgical Transactions B, 1990, 21: 463-471.

[14] 傅菊英, 朱德庆. 铁矿氧化球团基本原理、工艺及设备[M]. 长沙: 中南大学出版社, 2005: 227-233.

FU Juying, ZHU Deqing. Iron ore oxidized pellets basic principles, processes and equipment[M]. Changsha: Centre South University Press, 2005: 227-233.

[15] 杨天钧, 黄典冰, 孔令坛. 熔融还原[M]. 北京: 冶金工业出版社, 1998: 67-77.

YANG Tianjun, HUANG Dianbing, KONG Lingtan. Smelting and reduction[M]. Beijing, Metallurgical Industry Press, 1998: 67-77.

[16] 宋招权. MgO对球团矿质量的影响[J]. 烧结球团, 2001, 26(6): 22-24.

SONG Zhaoquan. The influence of MgO on the quality of pellets[J]. Sintering & Pellets, 2001, 26(6): 22-24.

(编辑 何运斌)

收稿日期:2012-09-16;修回日期:2012-12-08

基金项目: 国家火炬计划重点项目(2011GH561685)

通信作者:朱德庆(1964-),男,湖南安乡人,博士,教授,从事烧结球团、直接还原及资源综合利用研究;电话:0731-88836942;E-mail:dqzhu@csu.edu.cn