高镁球团焙烧特性及其固结强化机理

范晓慧,谢路奔,甘敏,陈许玲,袁礼顺

(中南大学 资源加工与生物工程学院,湖南 长沙,410083)

摘要:分别以蛇纹石、MgO粉和菱镁石作为含镁添加剂,研究高镁球团的焙烧特性。研究结果表明:随着球团中MgO质量分数的增加,磁铁矿球团和赤铁矿球团的预热球和焙烧球强度都降低,表明MgO质量分数的提高不利于球团的固结;通过添加含钙和含硼物质,改善了高镁球团的预热球和焙烧球强度;随着球团矿碱度的提高,球团矿预热球和焙烧球强度都是先升高后降低,碱度为0.4~0.5时达到最大值,而随着球团硼质量分数的增加,球团预热球和焙烧球强度都升高;添加含钙和含硼物质可促进低熔点物质的形成,使球团产生适宜的液相量,加快Mg2+和Fe3+的扩散,促进含镁熔剂的矿化和Fe2O3再结晶,从而改善含镁球团的固结强度。

关键词:含镁球团;焙烧;离子扩散;强度;晶粒

中图分类号:TF046 文献标志码:A 文章编号:1672-7207(2013)02-0449-07

Roasting characteristics of magnesium pellets and mechanism of strengthening concretion

FAN Xiaohui, XIE Luben, GAN Min, CHEN Xuling, YUAN Lishun

(School of Minerals Processing & Bioengineering, Central South University, Changsha 410083, China)

Abstract: The roasting characteristics of magnesium pellets were studied. The results show that the mechanical strength of preheated and roasted pellets of magnetite pellets and hemetite pellets decrease as MgO content increases by adding serpentine, MgO powder and magnesite, which indicates that MgO content goes against the concretion strength of pellets. Adding calcium-containing and boron-containing materials can increase the strength of magnesium pellets. The strength of preheated and roasted pellets increases at first, and then decreases as the basicity increases, and reaches the maximum when basicity is 0.4-0.5. The strength increases as the boron content increases. The liquid generated by adding calcium-containing or boron-containing materials can improve the spread of Mg2+ and Fe3+, which is beneficial for magnesium additive mineralization and hematite recrystallization, and then improve the strength of magnesium pellets.

Key words: magnesium pellets; roast; ionic diffusion; strength; grain

高炉冶炼对炉渣化学成分有一定的要求[1-3],当炉渣碱度为1.0~1.2,Al2O3质量分数为13%~15%,MgO质量分数为10%~12%时,炉渣的性能最佳,高炉能达到较好的冶炼效果[4-7]。矿石中MgO质量分数不足以提供炉渣所需的MgO,因此通常要往高炉炉料中添加含镁熔剂。直接向高炉内添加含镁熔剂是不经济、不科学的,因为主要的含镁熔剂白云石、菱镁石加入高炉后,碳酸盐分解吸热,使高炉焦比明显上升[8-10]。因此,MgO需要加入到烧结矿和球团矿这2种熟料中再进入高炉。生产低硅烧结矿时,一般控制MgO质量分数在2.0%以下,这不能满足高炉对MgO的需求。部分MgO需要添加到球团矿中。研究表明:含镁球团有很好的冶金性能[11-13],但含镁球团具有难焙烧和强度差的特点,给工业生产带来困难[14-15],因此,对含镁球团的深入研究很有必要。

1 原料物化性能与研究方法

1.1 原料物化性能

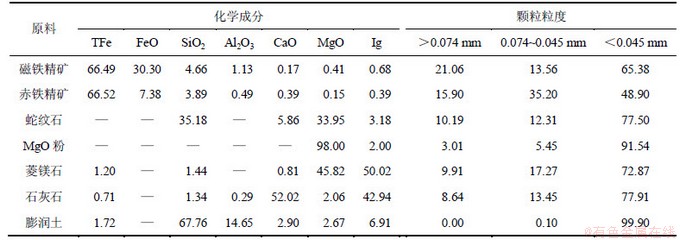

原料物化性能见表1。试验采用2种有代表性的铁精矿,磁铁精矿和赤铁精矿。2种铁精矿铁品位都比较高,除SiO2外其他杂质含量较少;蛇纹石除MgO含量高外,SiO2质量分数也达到了35.18%;MgO粉为分析纯试剂,MgO质量分数为98%;菱镁石主要矿物为MgCO3,MgO质量分数为45.82%;石灰石主要矿物为CaCO3,CaO质量分数为52.02%。磁铁精矿粒度低于0.074 mm的质量分数达到79%;赤铁精矿粒度低于0.074 mm的质量分数在80%以上;其他钙、镁添加剂粒度都较细,粒度低于0.074 mm的质量分数在80%以上。

球团粘结剂采用膨润土。膨润土物理性能较好,各指标如下:胶质价为100 mL/(15 g),膨胀容为49.2 mL/g,2 h吸水率为510.3%,蒙脱石质量分数为90.1%。

另外,采用硼砂作为含硼添加剂,分子式为Na2B4O7·10H2O。硼砂熔点低,熔点为741 ℃。

1.2 试验方法

1.2.1 球团制备、焙烧的试验方法

造球试验是在圆盘造球机中进行的,其主要技术参数为:圆盘直径Ф=1 000 mm,转速22 r/min,边高h=150 mm,倾角α=47°。预热焙烧试验是在卧式管炉中进行的,它由2个管炉对接而成;铁铬铝丝电阻炉作预热用,硅炭管电阻炉作焙烧用。将制备好的球团干燥2 h后进行预热、焙烧试验,其条件为:在950 ℃下预热10 min,在1 250 ℃下焙烧10 min。

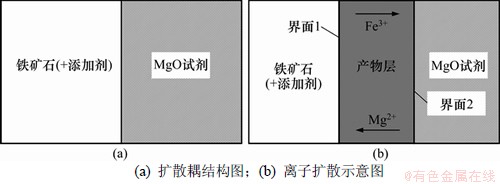

1.2.2 离子扩散的研究方法

将铁矿石或铁矿石与石灰石的混合物和MgO试剂分别在125 MPa的压力下压块成型,并在1 300 ℃的温度下焙烧10 h,煅烧后将团块进行退火处理,然后将团块切片,并将横断面研磨、抛光成镜面。将2个团块的镜面紧密接触制备成扩散耦,如图1(a)所示。

将扩散耦在1 300 ℃下焙烧1 h,冷却后用树脂固化,然后沿扩散方向进行切片,研磨断面并抛光。通过显微镜观察图1(b)中产物层研究离子的扩散。

表1 原料的物化性能(质量分数)

Table 1 Chemical composition of materials %

图1 扩散耦示意图

Fig.1 Diffusion-coupling

2 试验结果与分析

2.1 含镁球团焙烧的特性

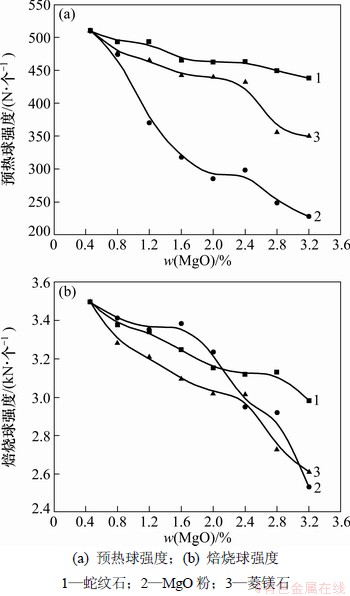

在膨润土质量分数为2.0%的情况下,通过添加单一的含镁添加剂来改变球团MgO质量分数。MgO对磁铁矿球团预热球和焙烧球强度的影响如图2所示。由图2可知:随着MgO质量分数的增加,3种含镁添加剂都使得磁铁矿球团预热球和焙烧球强度降低。

图2 MgO质量分数对磁铁精矿球团预热球和焙烧球强度的影响

Fig.2 Influence of MgO on preheated and roasted magnetite pellets

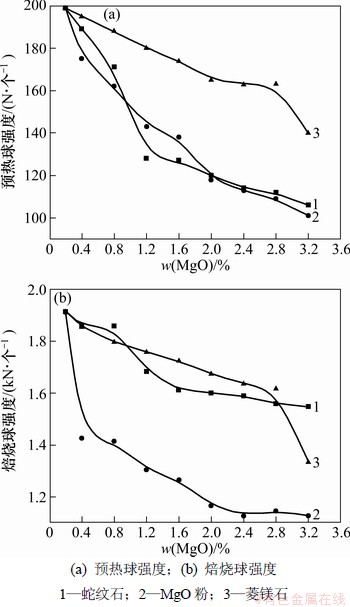

MgO质量分数对赤铁矿球团预热球和焙烧球强度影响如图3所示。从图3可见:随着MgO质量分数的增加,3种含镁添加剂同样使得赤铁精矿球团预热球和焙烧球强度降低。

2.2 MgO影响球团强度的原因

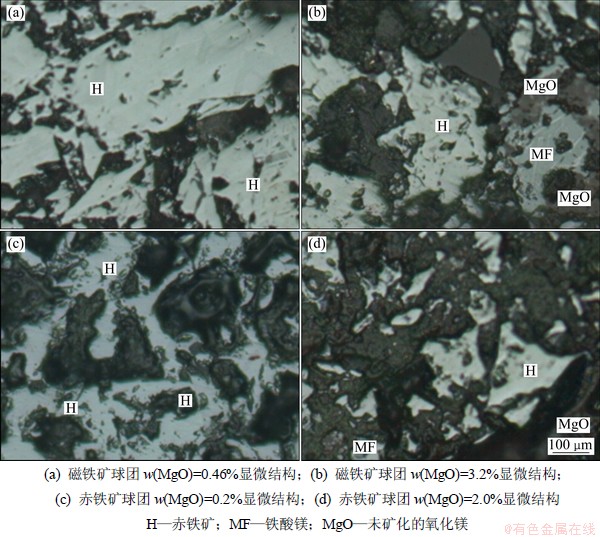

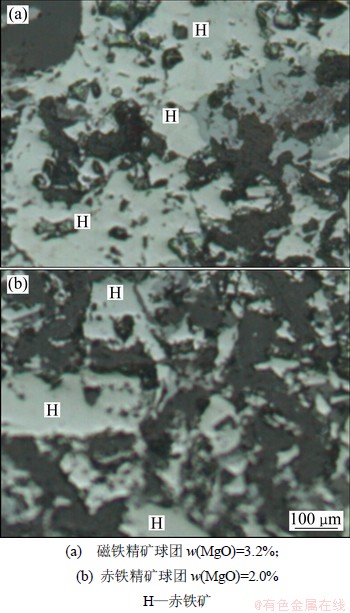

针对不加含镁添加剂的低镁球团和添加含镁添加剂的高镁球团,研究了2种球团的显微结构,结果如图4所示。由图4可见:低镁球团中,球团矿物组成比较单一,主要为赤铁矿,且赤铁矿结晶较好;而在高镁球团中生成了MgO·Fe2O3,并有未矿化的MgO,阻碍了赤铁矿与赤铁矿间的接触,不利于结晶长大,赤铁矿晶粒细小。

图3 MgO质量分数对赤铁精矿球团预热球和焙烧球强度的影响

Fig.3 Influence of MgO content on preheated and roasted hematite pellets

2.3 强化含镁球团焙烧固结的措施

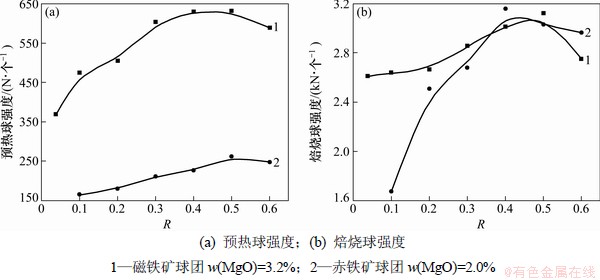

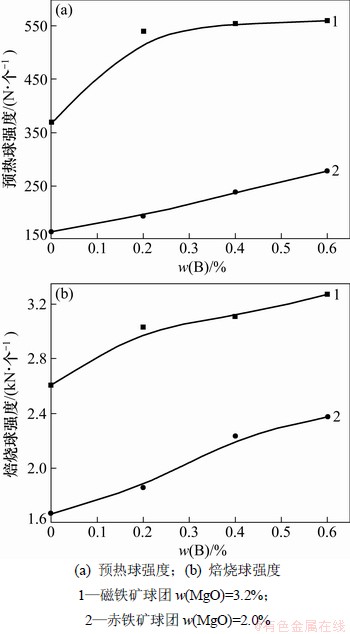

研究了添加含钙和含硼添加剂对高镁球团强度的影响,结果如图5和图6所示。从图5和图6可见:对于MgO质量分数为3.2%的磁铁矿球团,随着碱度的提高,球团的预热球和焙烧球强度都是先升高后降低,在R=0.4~0.5时球团焙烧强度达到最大值;随着硼质量分数的增加,球团预热球和焙烧球的强度都升高;当硼砂质量分数达到0.2%后,再继续增加其质量分数对球团预热强度的提高不再明显,当硼质量分数由0.2%提高到0.6%,球团预热球强度由540 N/个提高到560 N/个。

图4 MgO质量分数对球团显微结构的影响

Fig.4 Influence of MgO content on microstructure of pellets

图5 碱度与球团预热球和焙烧球强度的关系

Fig.5 Influence of basicity on preheated and roasted pellets

对于MgO质量分数为2.0%的赤铁矿球团,随着碱度的提高,球团的预热球强度和焙烧球强度也是先升高后降低,球团焙烧强度同样在碱度R=0.4~0.5时达到最大值。提高碱度对赤铁矿球团焙烧强度的提高效果明显;当赤铁矿球团碱度由0.1提高到0.4时,球团强度提高了将近1.5 kN/个。随着硼质量分数的增加,球团预热球、焙烧球强度也都升高,当硼质量分数由0提高到0.6%时,球团焙烧强度提高了700 N/个。

图6 硼质量分数对球团预热球和焙烧球强度的影响

Fig.6 Influence of boron content on preheated and roasted pellets

2.4 含镁球团焙烧固结强化的机理

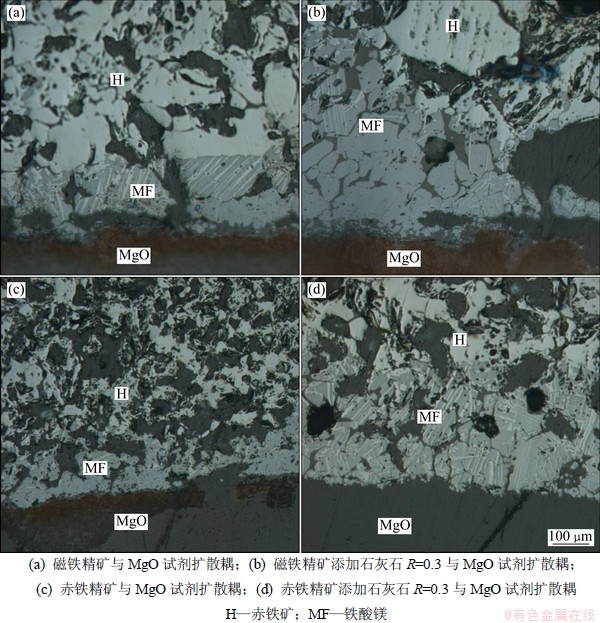

为了分析含钙和含硼添加剂对球团矿强度的影响,分别针对磁铁精矿和赤铁精矿研究含钙和含硼添加剂对球团显微结构和离子扩散的影响。

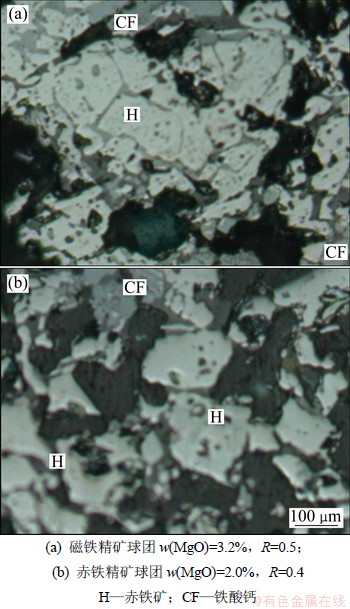

含钙添加剂对球团显微结构的影响如图7所示。与图4(b)和(d) 2种高镁球团显微结构相比,加入石灰石后,球团矿中出现低熔点的矿物即铁酸钙,未矿化的MgO消失,球团赤铁矿晶粒明显有长大且晶粒都交织在一起,此时球团强度最好。

含硼添加剂对球团显微结构如图8所示。硼砂与铁酸钙一样,熔点低,在焙烧过程中以液相形式存在。球团中加入硼砂后,球团赤铁矿晶粒发育良好,赤铁矿晶粒大且相互连成一片,MgO完全矿化,球团中没有出现未矿化的MgO。

以石灰石为代表,将石灰石与铁精矿混匀后,与MgO粉制成扩散耦,研究了添加剂对离子扩散的影响,结果见图9。由图9可知:添加了石灰石的扩散耦产物层铁酸镁要比不添加时的厚。石灰石的加入促进了Mg2+的扩散,Mg2+迁移能力变强,能够扩散到更远的距离,有利于含镁物质的矿化。这对球团强度的提高是有利的。

图7 碱度对球团显微结构的影响

Fig.7 Influence of basicity on microstructure of pellets

图8 硼质量分数0.6%时的球团显微结构

Fig.8 Microstructure of pellets with 0.6% of boron

图9 碱度对离子扩散的影响

Fig.9 Influence of basicity on ionic diffusion

由图7~9可知:含钙和含硼添加剂通过加快Mg2+扩散和促进赤铁矿晶粒聚集长大以提高高镁球团强度。含钙和含硼添加剂的加入,使得球团在焙烧过程中生成低熔点物质并以液相形式存在,在有液相存在时,Mg2+和Fe3+有更强的迁移能力,能够扩散到更远的距离,有利于含镁熔剂的矿化和赤铁矿晶粒的长大。这对球团强度的提高有促进作用。

3 结论

(1) 分别以蛇纹石、MgO试剂、菱镁石3种物质作为含镁添加剂,无论是赤铁矿球团还是磁铁矿球团,其预热球和焙烧球强度都随着MgO质量分数的增加而降低。

(2) 随碱度的升高,含镁球团预热球和焙烧球强度先升高后降低,碱度在0.4~0.5时球团强度最大。随着硼质量分数的升高,2种高镁球团预热球和焙烧球强度都升高。

(3) 含钙和含硼添加剂都可以使球团在焙烧过程产生一定的液相。在有液相存在的情况下,Mg2+和Fe3+有更强的迁移能力,能够扩散到更远的距离,有利于含镁熔剂的矿化和赤铁矿晶粒的长大。对球团强度的提高有促进作用。

参考文献:

[1] 张丙怀, 刁岳川. 富三氧化二铝高炉炉渣的流动性[J].钢铁研究学报, 2005, 17(4): 14-25.

ZHANG Binghuai, DIAO Yuechuan. Fluidity of high alumina blast furnace slag[J]. Journal of Iron and Steel Research, 2005, 17(4): 14-25.

[2] 姜鑫, 吴钢生. MgO对烧结工艺及烧结矿冶金性能的影响[J]. 钢铁, 2006, 41(3): 8-11.

JIANG Xin, WU Gangsheng. Effect of MgO on sintering process and metallurgical properties of sinter[J]. Iron and Steel, 2006, 41(3): 8-11.

[3] 张玉柱. MgO含量和碱度对高炉渣的黏度的影响[J]. 材料与冶金学报, 2005, 4(4): 253-256.

ZHANG Yuzhu. The influences of MgO and basicity on the viscosity of BF slag[J]. Journal of Materials and Metallurgy, 2005, 4(4): 253-256.

[4] 关雪芳. 提高烧结矿MgO含量的途径及高炉冶炼效果[J]. 烧结球团, 2001, 26(2): 1-5.

GUAN Xuefang. The way of heightening MgO of sinter and the effects of metallurgy in BF[J]. Sintering and Palletizing, 2001, 26(2): 1-5.

[5] 杨双平. 翼钢高炉炉渣的冶金性能研究[J]. 钢铁研究, 2008, 36(4): 9-20.

YANG Shuangping. Study on metallurgical properties of blast furnace slag at Yigang[J]. Research on Iron & Steel, 2008, 36(4): 9-20.

[6] 孙金铎. 合理烧结矿R的探讨[J]. 钢铁, 2001, 36(8): 1-4.

SUN Jintuo. Investigation on rational basicity of sinter[J]. Iron and Steel, 2001, 36(8): 1-4.

[7] 郭豪. 适宜太钢4 350 m3高炉炉渣的成分[J]. 钢铁研究学报, 2008, 20(9): 58-63.

GUO Hao. Slag component suitable for 4 350 m3 BF of Taigang[J]. Journal of Iron and Steel Research, 2008, 20(2): 58-63.

[8] 朱秉辰. 加古川2号高炉70%球团矿操作[J]. 钢铁研究, 1994, 5: 63-64.

ZHU Bingchen. The operation with 70 percent of pellets in Jiaguchuan BF[J]. Research on Iron and Steel, 1994, 5: 63-64.

[9] 杨双平. 翼钢烧结矿的冶金性能[J]. 钢铁冶金学报, 2008, 20(12): 59-63.

YANG Shuangping. Metallurgical performance of sintered ore at Yicheng Steel Company[J]. Journal of Iron and Steel Research, 2005, 20(12): 59-63.

[10] 洪灶熬. 造块工艺中的添加剂[J]. 马钢科研, 1999(1): 6-11.

HONG Zaoao. The additives of pelleting[J]. Research of Ma-gang, 1999(1): 6-11.

[11] 范晓慧, 甘敏, 陈许铃, 等. 低碱度镁质氧化球团的试验研究[J]. 钢铁, 2009, 44(3): 6-10.

FAN Xiaohui, GAN Min, CHEN Xuling, et al. Experiments of low-basicity magnesian oxided pellets[J]. Iron and Steel, 2009, 44(3): 6-10.

[12] 吴钢生. 碱性含镁球团矿的应用及合理炉料结构研究[J]. 钢铁, 2006, 41(12): 19-26.

WU Gangsheng. Use of magnesium-bearing basic pellet and reasonable burden design[J]. Iron and Steel, 2006, 41(12): 19-25.

[13] 范晓慧, 甘敏. 从炼铁精料探讨氧化球团技术的发展方向[C]//全国烧结球团技术交流年会论文集. 长沙: 全国烧结球团信息网, 2009: 4-7.

FAN Xiaohui, GAN Min. Discussion development direction of oxidized pellets technology from high quality burden for ironmaking[C]//Conference on Sintering & Pelletizing Technology. Changsha: Sintering & Pelletizing Information Network, 2009: 4-7.

[14] 张永明.含 MgO熔剂性球团矿特点及生产实践[J]. 烧结球团, 1998, 23(2): 1-5.

ZHANG Yongming. Characteristic and production practice of fluxed pellets contents MgO[J]. Sintering and Palletizing, 1998, 23(2): 1-5.

[15] 李圣辉. 含镁添加剂用于铁矿球团的试验研究[J]. 烧结球团, 2011, 36(1): 33-39.

LI Shenghui. Experimental study on application of Mg-bearing additives in iron ore pellet[J]. Sintering and Palletizing, 2011, 36(1): 33-39.

(编辑 何运斌)

收稿日期:2012-02-19;修回日期:2012-06-06

基金项目:教育部新世纪优秀人才支持计划基金资助项目(NCET-05-0630);湖南省研究生学位论文创新资助项目(1343/74333001114) ; 中南大学优秀博士学位论文扶植项目(2010ybfz058);国家自然科学基金与上海宝钢集团公司“钢铁联合研究基金”资助项目(51174253)

通信作者:范晓慧(1969-),女,河北昌黎人,博士,教授,从事铁矿石造块研究;电话:13508480582;E-mail:csufanxiaohui@126.com