低温轧制对高强高导Cu-0.5Cr合金显微组织和性能的影响

来源期刊:中国有色金属学报(英文版)2020年第9期

论文作者:张鹏超 史杰夫 于赢水 孙俊才 李廷举

文章页码:2472 - 2479

关键词:Cu-Cr合金;低温轧制;显微组织;力学性能;电导率

Key words:Cu-Cr alloy; cryorolling; microstructure; mechanical property; electrical conductivity

摘 要:分别采用低温轧制和常温轧制技术制备高强高导Cu-0.5Cr(质量分数,%)合金。研究Cu-0.5Cr合金经低温轧制/常温轧制和时效处理后的显微组织、力学性能和导电性能。研究结果表明,在低温轧制合金中可见明显的位错缠结。经低温轧制和时效处理后,合金中Cr颗粒尺寸更加细小,呈弥散分布。低温轧制合金的最大硬度为HV 167.4,显著高于常温轧制合金的。低温轧制合金在450 °C经120 min时效处理后达到最佳力学性能。低温轧制Cu-0.5Cr合金在450 °C经120 min时效处理后电导率达到92.5% IACS,略高于常温轧制合金的。

Abstract: Cu-0.5wt.%Cr alloy with high strength and high conductivity was processed by cryorolling (CR) and room temperature rolling (RTR), respectively. The microstructure, mechanical property and electrical conductivity of Cu-0.5Cr alloy after CR/RTR and aging treatment were investigated. The results indicate that obvious dislocation entanglement can be observed in matrix of CR alloy. The Cr particles in the alloy after CR and aging treatment possess finer particle size and exhibit dispersive distribution. The peak hardness of CR alloy is HV 167.4, significantly higher than that of RTR alloy. The optimum mechanical property of CR alloy is obtained after aging at 450 °C for 120 min. The conductivity of CR Cu-0.5Cr alloy reaches 92.5% IACS after aging at 450 °C for 120 min, which is slightly higher than that of RTR alloy.

Trans. Nonferrous Met. Soc. China 30(2020) 2472-2479

Peng-chao ZHANG1,2, Jie-fu SHI1, Ying-shui YU2,3, Jun-cai SUN1, Ting-ju LI2

1. Department of Materials Science and Engineering, Dalian Maritime University, Dalian 116026, China;

2. School of Materials Science and Engineering, Dalian University of Technology, Dalian 116024, China;

3. School of Mechanical and Power Engineering, Dalian Ocean University, Dalian 116023, China

Received 23 December 2019; accepted 16 July 2020

Abstract: Cu-0.5wt.%Cr alloy with high strength and high conductivity was processed by cryorolling (CR) and room temperature rolling (RTR), respectively. The microstructure, mechanical property and electrical conductivity of Cu-0.5Cr alloy after CR/RTR and aging treatment were investigated. The results indicate that obvious dislocation entanglement can be observed in matrix of CR alloy. The Cr particles in the alloy after CR and aging treatment possess finer particle size and exhibit dispersive distribution. The peak hardness of CR alloy is HV 167.4, significantly higher than that of RTR alloy. The optimum mechanical property of CR alloy is obtained after aging at 450 °C for 120 min. The conductivity of CR Cu-0.5Cr alloy reaches 92.5% IACS after aging at 450 °C for 120 min, which is slightly higher than that of RTR alloy.

Key words: Cu-Cr alloy; cryorolling; microstructure; mechanical property; electrical conductivity

1 Introduction

Cu and its alloys have attracted more attention in many fields due to the excellent mechanical property and electrical conductivity [1-3]. Cu-Cr alloy, a typical alloy with high strength and high conductivity, has been considered as an important candidate for electrical applications [4,5]. It has received a wide range of applications, such as railway contact wires, integrated circuit lead frame and electrode of resistance welding [6,7]. The mechanical property of Cu-Cr alloy can get remarkable improvement after aging due to the significant precipitation strengthening [8,9]. But the strengthening degree is limited due to the low solubility of Cr atoms in copper matrix [10].

Deformation strengthening is an effective way to improve the mechanical properties of copper alloy [11,12]. Especially, the ultrafine grained (UFG) microstructure and excellent mechanical property can be obtained through the processing of severe plastic deformation (SPD) [13,14]. HABIBI et al [15] have reported the nano-grained Cu with high strength and high conductivity produced by equal channel angular rolling process (ECAP). LEE et al [16] have studied the microstructure and property of CuNiSi alloy with high pressure torsion (HPT) treatment. The simultaneous strengthening and high electrical conductivity are obtained after HPT and aging treatment. A severe rotary swaging (RS) technology of Cu-Cr-Zr alloy was investigated by HUANG et al [17]. A perfect ultrafine grained microstructure with uniformly-distributed precipitates was characterized to be responsible for high strength and good electrical conductivity.

However, the SPD technology is difficult to apply in industrial application because of the disadvantages of high cost and low product efficiency. In order to overcome the deficiency of ECAP and HPT, cryorolling (CR) technology can be identified as an effective method to enhance the mechanical property of nonferrous alloy [18-20]. A high density of dislocations can form during rolling at an extreme low temperature and the dynamic recovery process can be suppressed [21]. Ultrafine grained microstructure, with micron or sub-micron sized grains, can be obtained in cryorolling process, which is beneficial to the superior mechanical property [22].

In the present study, cryorolling and room temperature rolling (RTR) were carried out on Cu-Cr alloy, respectively. The present work is focused on: (1) investigating the variation of microstructure between cryorolled and room temperature rolled Cu-Cr alloy at rolling and aging state; (2) studying the effect of CR technology on mechanical and electrical properties of Cu-Cr alloy in comparison with RTR technology.

2 Experimental

The Cu-0.5Cr alloy ingots were prepared with electrolytic copper (99.97 wt.%) and pure chromium (99.8 wt.%) in medium frequency induction furnace. The ingot size was about d40 mm × 150 mm. The ingots were homogenized at 850 °C and subsequently hot rolled at the same temperature to a thickness of 10 mm. Then, the plates were solution-treated at 920 °C for 30 min with water quenching. The solution-treated Cu-Cr alloy plates were room temperature rolled or cryorolled with 80% reduction, respectively. The reduction of the first two passes was 2 mm for each pass, and the subsequent reduction of each pass was about 1 mm. The final thickness of plate was nearly 2 mm. During cryorolling, the plates were dipped into liquid nitrogen until the system was stable. Then, the plates were kept in liquid nitrogen for 10 min before first pass and 5 min for each subsequent pass. The aging treatment was carried out under different conditions after rolling.

The microstructure of RTR and CR samples under different conditions was examined by metallographic microscope, field emission scanning electron microscope (FESEM) equipped with an energy dispersive X-ray spectrometer (EDS) and transmission electron microscope (TEM). For TEM study, the samples were ground to a thickness of 30 μm and then prepared by ion milling with an argon ion beam. The TEM study was carried out at an acceleration voltage of 200 kV and the corresponding selected area electron diffraction (SAED) was analyzed.

Microhardness was tested on Vickers hardness tester under a load of 200 g and a loading time of 15 s. The tensile test was conducted with a crosshead speed of 2 mm/min at room temperature using a computerized universal testing machine. The electrical conductivity was analyzed using conductivity measuring instrument and it was characterized by International Annealing Copper Standard (% IACS).

3 Results and discussion

3.1 Microstructure

The SEM morphology of as-cast Cu-Cr alloy has been analyzed in the previous work [23]. The coarse grain can be observed and the distinct particles precipitate on grain boundary. It can be found that the precipitate, about hundreds of nanometers in diameter, exhibit spherical morphology at high magnification. The spherical precipitate can be identified as Cr-rich particles from EDS analysis.

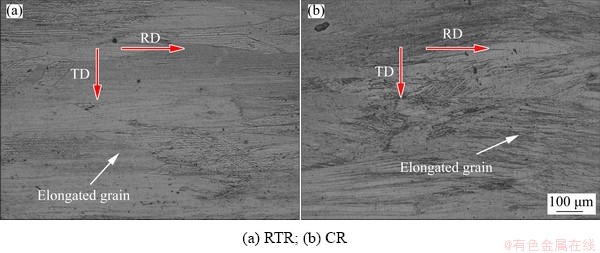

Metallographic microstructure of Cu-0.5Cr alloy after different rolling technology is exhibited in Fig. 1. The elongated grain can be clearly observed in RTR alloy (Fig. 1(a)), while that of CR alloy is more slender and the elongation direction of grains exhibits a certain deviation from the deformation direction (Fig. 1(b)).

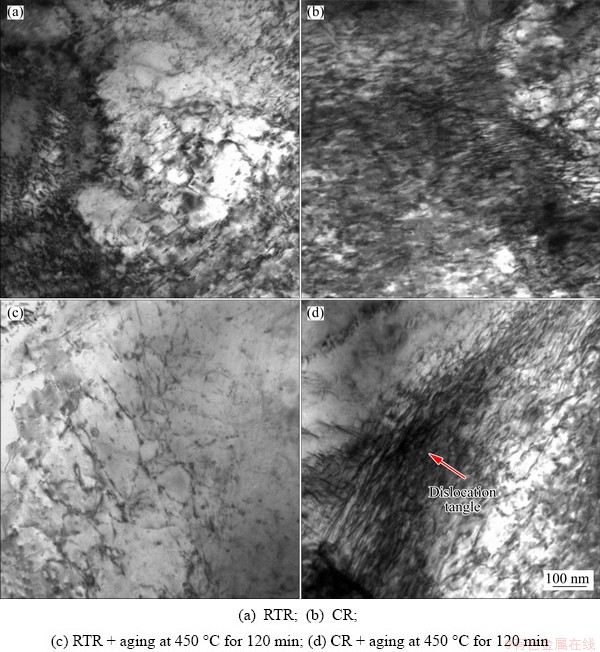

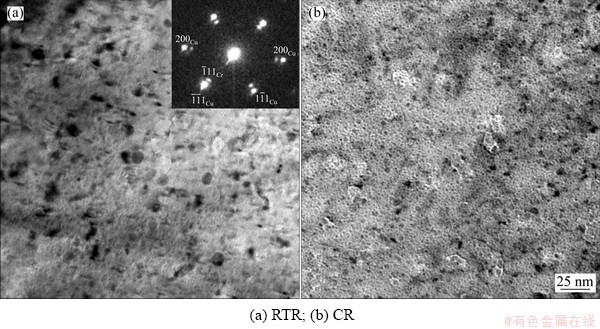

The dislocation distributions in matrix of Cu-Cr alloy after different rolling and aging processes are shown in Fig. 2. It can be seen that the dislocation density in CR alloy is significantly higher and the dislocation entanglement is more obvious than that in RTR alloy (Figs. 2(a, b)). The difference of dislocation density between the alloys can be attributed to the different degrees of dynamic recovery in rolling process. In RTR process, the heat generated from deformation process can serve as driving force for dynamic recovery to reduce dislocation density. During cryorolling process, the movement of dislocation is suppressed and a higher dislocation density is retained due to the decreased degree of dynamic recovery at lower temperature.

Fig. 1 Microstructures of Cu-0.5Cr alloy after different rolling technologies

Fig. 2 Dislocation distributions of Cu-0.5Cr alloy after different rolling and aging treatments

After aging at 450 °C, the dislocation density of RTR alloy is significantly decreased and only a small quantity of dislocations can be observed in TEM microstructure (Fig. 2(c)). The number of dislocations in CR alloy is also reduced, but the dislocation tangle can still be found in matrix (Fig. 2(d)).

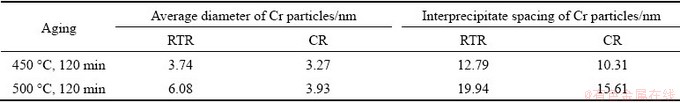

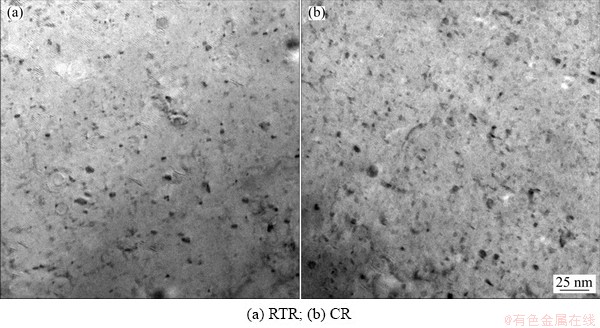

The TEM micrographs of Cu-0.5Cr alloy after different rolling processes and aging at 450 °C for 120 min are shown in Fig. 3. The size and interprecipitate spacing of Cr particles of RTR and CR alloy after aging treatment are displayed in Table 1. It can be found that Cr particles, with average diameter of 3.74 nm, precipitate from matrix in RTR alloy (Fig. 3(a)). The Cr particles in CR alloy present a more dispersed distribution, and the particles diameter is slightly less than that of RTR alloy (Fig. 3(b)). In addition, the Cr particles of CR alloy possess smaller interprecipitate spacing compared with those of RTR alloy.

Figure 4 shows the TEM micrograph of different rolling state Cu-0.5Cr alloy after aging at 500 °C for 120 min. The Cr particles of RTR alloy are obviously coarsened during aging process. The average size of Cr particles is 6.08 nm, but a few particles exceed 10 nm in diameter (Fig. 4(a)). The coarsening degree of Cr particles in CR alloy is lower, and the average diameter is less than 4 nm (Fig. 4(b)). The reason for this phenomenon is that the high density dislocation provides more nucleation sites, leading to the increase of particles number and reduction of coarsening degree. Ascribed to the lower degree of coarsening, the Cr particles in CR alloy exhibit more dispersed distribution and smaller interprecipitate spacing.

Table 1 Size and interprecipitate spacing of Cr particles of RTR and CR alloy after different aging treatments

Fig. 3 TEM images of Cu-0.5Cr alloy in different rolling states after aging at 450 °C for 120 min

Fig. 4 TEM images of Cu-0.5Cr alloy in different rolling states after aging at 500 °C for 120 min

The SAED pattern of TEM morphology of Cu-0.5Cr alloy after aging at 500 °C for 120 min is investigated (inset in Fig. 4(a)). Two diffraction spots with different fcc structures can be observed by SAED characterization. The Cu matrix with fcc structure is characterized by the outer spots. The inner spots represent Cr particles with fcc structure and the corresponding lattice parameter is calculated to be 0.4203 nm. Some scholars have found the similar result in the previous study. HUM et al [24] have predicted the phenomenon by theoretical calculation and get the result that lattice parameter of fcc Cr cluster is 0.413 nm. XIA et al [25] have drawn a conclusion that the lattice parameter of fcc Cr particle is 0.4219 nm, which is basically consistent with the result of this work. Therefore, it can be assumed that the fine precipitates in matrix are fcc Cr particles, which precipitate from matrix with the decrease of Cr solubility during aging process.

3.2 Mechanical property

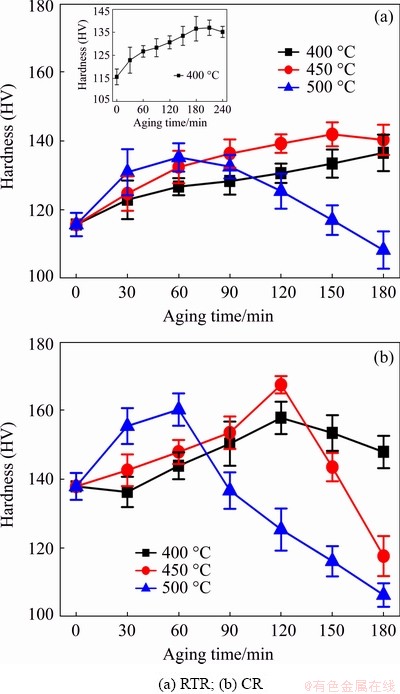

Figure 5(a) exhibits the hardness curves of RTR Cu-Cr alloy after different aging treatments. The hardness of Cu-Cr alloy at RTR state is HV 115.7. With aging at 500 °C, the hardness presents an increasing trend in the initial period of aging and the peak value is reached after aging for 60 min. The hardness exhibits a downward trend with prolonging the aging time further. At the aging temperature of 450 °C, the hardness exhibits steady rising in the early stage of aging and the peak value is obtained at the aging time of 150 min. At the aging temperature of 400 °C, the hardness of Cu-Cr alloy is always on the rising trend within the aging time of 180 min. But the hardness tends to be stable and then decreases with prolonging the aging time further at 400 °C (inset of Fig. 5(a)). During various aging treatments, the maximum hardness of RTR alloy is HV 141.9, corresponding to aging temperature of 450 °C and aging time of 150 min.

Figure 5(b) shows the hardness of cryorolled Cu-Cr alloy after different aging processes. The hardness value of Cu-Cr alloy after cryorolling is HV 137.9. The hardness curve of CR alloy aged at 500 °C is similar with that of RTR alloy. The peak value of CR alloy aged at 400 and 450 °C appears at the aging time of 120 min. In different aging processes, the maximum hardness of CR Cu-Cr alloy is HV 167.4, corresponding to aging temperature of 450 °C and aging time of 120 min.

Fig. 5 Hardness of different rolling processed Cu-0.5Cr alloys after aging treatment

It can be seen from different rolling processes that the hardness of CR alloy is obviously higher than that of RTR alloy. It is known from previous studies that the dynamic recovery process can be suppressed during cryorolling process. Meanwhile, a large number of dislocations are generated and entangled in matrix, enhancing the effect of work hardening. The change of hardness with aging treatment is related to the precipitation of Cr particles and dynamic recovery process. Numerous deformation energy stored during rolling process can act as the driving force to promote recovery process, which can reduce the hardness of alloy. Meanwhile, the precipitated Cr particles can perform the effect of precipitation hardening.

The hardness of CR alloy is slightly decreased in the initial stage of aging at 400 °C, which can be ascribed to the fact that the precipitation rate of Cr particles is slower than recovery rate in matrix. At the aging temperatures of 450 °C and 500 °C, the precipitation process of Cr particles is accelerated and the hardness shows upward trend in the initial stage.

The peak hardness of RTR Cu-Cr alloy appears at aging temperature of 450 °C and aging time of 150 min, while that of CR alloy appears at aging temperature of 450 °C and aging time of 120 min. The optimum aging time of CR alloy is shortened and peak value is higher. The reason for this phenomenon is: the higher dislocation density is obtained in matrix of CR alloy; the Cr particles of CR alloy present finer size and more uniform distribution, enhancing the effect of precipitation hardening.

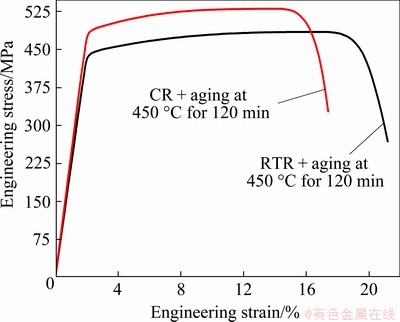

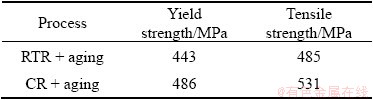

The tensile curves of Cu-Cr alloy after different rolling and aging processes are shown in Fig. 6. The detailed mechanical properties of RTR and CR alloys are listed in Table 2. Compared with RTR process, the yield strength (486 MPa) and tensile strength (531 MPa) of CR alloy are prominent after aging. According to the analysis of microstructure, it is the multiple results of more remarkable deformation strengthening and precipitation strengthening.

Fig. 6 Engineering stress-strain curves of RTR and CR Cu-Cr alloys after aging at 450 °C for 120 min

Table 2 Tensile properties of Cu-0.5Cr alloys after different rolling processes and aging at 450 °C for 120 min

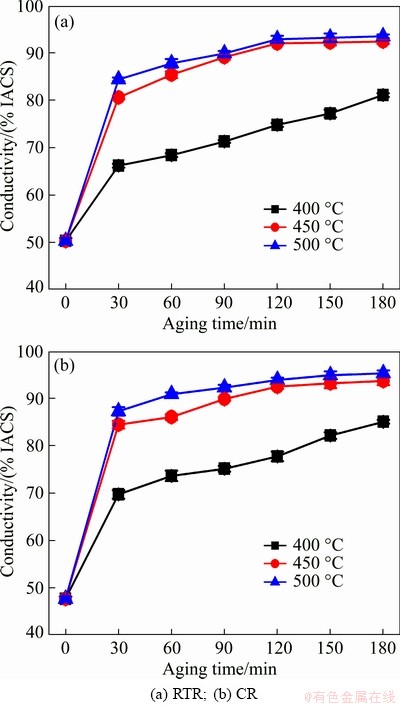

3.3 Electrical conductivity

The electrical conductivities of Cu-Cr alloy after hot rolling, solid solution treatment, RTR/CR and different aging treatments are shown in Fig. 7. The conductivity of alloy can be characterized by the contribution from four scattering mechanisms of resistivity [26]:

1/σalloy=ρalloy=ρpho+ρdef+ρint+ρimp (1)

where σalloy, ρalloy are conductivity and resistivity of Cu-Cr alloy, respectively. ρpho, ρdef, ρint and ρimp are resistivity contributions from phonon scattering, defect scattering, interface scattering and impurity scattering, respectively. Since phonon scattering only depends on temperature, the contribution from phonon scattering of both RTR and CR alloys is equal due to the same test temperature (25 °C). The variation of conductivity in aging process is mainly due to the change of impurity scattering. For alloy without aging, the conduction electrons are greatly scattered due to the destroyed lattice of Cu matrix by dissolved Cr atoms. In aging process, the impurity scattering is decreased ascribed to the reduction of solid solution atoms, while the interface scattering is increased by precipitated Cr particles. And the reduction in number of dislocations can weaken the degree of defect scattering. As a result, the conductivity exhibits obvious enhancement in the initial period of aging and gradually becomes stable with increasing the aging time.

Fig. 7 Electrical conductivities of different rolling processed Cu-0.5Cr alloy after aging treatment

The electrical conductivity curves of RTR and CR alloys after aging treatment are similar. For example, as shown in Fig. 7(a), a low conductivity of rolled Cu-Cr alloy (50.3% IACS) is displayed due to the massive dissolved Cr atoms. The conductivity of Cu-Cr alloy shows an obvious rising trend at the beginning of aging. It exhibits a steady upward trend in the whole aging time of 180 min at aging temperature of 400 °C. The decreased defect scattering and impurity scattering are the main reasons of conductivity variation in the aging treatment.

At higher aging temperature of 450 and 500 °C, the increasing trend becomes moderate after aging for 30 min and the peak value is reached at 120 min. With prolonging the aging time, the conductivity basically remains stable. The conductivity of alloy aged at 500 °C for 120 min (92.9% IACS) is slightly higher than that of the alloy aged at 450 °C for 120 min (92% IACS). The precipitation of Cr particles and annihilation of dislocations are accelerated at higher aging temperature, resulting in the higher conductivity of Cu-Cr alloy aged at 500 °C.

The conductivity curve of CR alloy (Fig. 7(b)) is similar with that of RTR alloy. The conductivity of CR alloy is 92.5% IACS after aging at 450 °C for 120 min, which is slightly higher than that of RTR alloy.

4 Conclusions

(1) The elongated grain of CR Cu-0.5Cr alloy is slenderer and obvious dislocation tangle can be observed in microstructure. The Cr particles of alloy after CR and aging treatment possess finer particle size and exhibit more dispersive distribution.

(2) The mechanical properties of Cu-0.5Cr alloy are remarkably improved by cryorolling process. The maximum hardness of CR alloy after aging is HV 167.4, which is obviously higher than that of RTR alloy. The optimum mechanical property of CR alloy is achieved after aging at 450 °C for 120 min. The yield strength and tensile strength are 486 and 531 MPa, respectively, which is the combined result of multiple strengthening mechanisms.

(3) The conductivity of CR Cu-0.5Cr alloy reaches 92.5% IACS after aging at 450 °C for 120 min, which is slightly higher compared with that of RTR alloy.

References

[1] GUO Ting-biao, WANG Jun-jie, WU Yi-bo, TAI Xiao-yang, JIA Zhi, DING Yu-tian. Fabricate of high-strength and high-conductivity Cu-Cr-Si alloys through ECAP-Bc and aging heat treatment [J]. Materials, 2020, 13: 1603.

[2] WANG Meng-han, YANG Yong-chao, TU Shun-li, WEI Kang. A modified constitutive model and hot compression instability behavior of Cu-Ag alloy [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 764-774.

[3] TONG Yun-xiang, LI Si-yuan, ZHANG Dian-tao, LI Li, ZHENG Yu-feng. High strength and high electrical conductivity CuMg alloy prepared by cryorolling [J]. Transactions of Nonferrous Metals Society of China, 2019, 29: 595-600.

[4] BIZJAK M, KARPE B, JAKSA G, KOVAC J. Surface precipitation of chromium in rapidly solidified Cu-Cr alloys [J]. Applied Surface Science, 2013, 277: 83-87.

[5] ISLAMGALIEV R K, NESTEROV K M, BOURGON J, CHAMPION Y, VALIEV R Z. Nanostructured Cu-Cr alloy with high strength and electrical conductivity [J]. Journal of Applied Physics, 2014, 115: 194301.

[6] PAN Zhen-ya, CHEN Jiang-biao, LI Jin-fu. Microstructure and properties of rare earth-containing Cu-Cr-Zr alloy [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1206-1214.

[7] CHENG J Y, SHEN B, YU F X. Precipitation in a Cu-Cr-Zr-Mg alloy during aging [J]. Materials Characterization, 2013, 81: 68-75.

[8] LIU P, KANG B X, CAO X G, HUANG J L, GU H C. Strengthening mechanisms in a rapidly solidified and aged Cu-Cr alloy [J]. Journal of Materials Science, 2000, 35: 1691-1694.

[9] CHBIHI A, SAUVAGE X, BLAVETTE D. Influence of plastic deformation on the precipitation of Cr in copper [J]. Journal of Materials Science, 2014, 49: 6240-6247.

[10] QUE Z P, LEE J H, JUNG H M, SHIN J H, HAN S Z, EUH K J. Microstructure evolution in Cu-1.54wt%Cr alloy during directional solidification [J]. Journal of Crystal Growth, 2013, 362: 58-61.

[11] BEACH J A, WANG M, BELLON P, DILLON S, IVANISENKO Y, BOLL T, AVERBACK R S. Self-organized, size-selection of precipitates during severe plastic deformation of dilute Cu-Nb alloys at low temperatures [J]. Acta Materialia, 2017, 140: 217-223.

[12] ZHANG P, AN X H, ZHANG Z J, WU S D, LI S X, ZHANG Z F, FIGUEIREDO R B, GAO N, LANGDON T G. Optimizing strength and ductility of Cu-Zn alloys through severe plastic deformation [J]. Scripta Materialia, 2012, 67: 871-874.

[13] LI Jing-hui, LI Fu-guo, ZHAO Chen, CHEN Han, MA Xin-kai, LI Jiang. Experimental study on pure copper subjected to different severe plastic deformation modes [J]. Materials Science and Engineering A, 2016, 656: 142-150.

[14] PURCEK G, YANAR H, DEMIRTAS M, SHANGINA D V, BOCHVAR N R, DOBATKIN S V. Microstructural, mechanical and tribological properties of ultrafine-grained Cu-Cr-Zr alloy processed by high pressure torsion [J]. Journal of Alloys and Compounds, 2020, 816: 152675.

[15] HABIBI A, KETABCHI M, ESKANDARZADEH M. Nano-grained pure copper with high-strength and high-conductivity produced by equal channel angular rolling process [J]. Journal of Materials Processing Technology, 2011, 211: 1085-1090.

[16] LEE S, MATSUNAGA H, SAUVAGE X, HORITA Z. Strengthening of Cu-Ni-Si alloy using high-pressure torsion and aging [J]. Materials Characterization, 2014, 90: 62-70.

[17] HUANG A H, WANG Y F, WANG M S, SONG L Y, LI Y S, GAO L, HUANG C X, ZHU Y T. Optimizing the strength, ductility and electrical conductivity of a Cu-Cr-Zr alloy by rotary swaging and aging treatment [J]. Materials Science and Engineering A, 2019, 746: 211-216.

[18] KRYMSKIY S, SITDIKOV O, AVTOKRATOVA E, MARKUSHEV M. 2024 aluminum alloy ultrahigh-strength sheet due to two-level nanostructuring under cryorolling and heat treatment [J]. Transactions of Nonferrous Metals Society of China, 2020, 30: 14-26.

[19] KUMAR R, DASHARATH S M, KANG P C, KOCH C C, MULA S. Enhancement of mechanical properties of low stacking fault energy brass processed by cryorolling followed by short-annealing [J]. Materials and Design, 2015, 67: 637-643.

[20] DASHARATH S M, KOCH C C, MULA S. Effect of stacking fault energy on mechanical properties and strengthening mechanisms of brasses processed by cryorolling [J]. Materials Characterization, 2015, 110: 14-24.

[21] PANIGRAHI S K, JAYAGANTHAN R. Effect of ageing on microstructure and mechanical properties of bulk, cryorolled, and room temperature rolled Al 7075 alloy [J]. Journal of Alloys and Compounds, 2011, 509: 9609-9616.

[22] KRISHNA K S V B R, VIGNESHWARAN S, CHANDRA SEKHAR K, AKELLA S S R, SIVAPRASAD K, NARAYANASAMY R, VENKATESWARLU K. Mechanical behavior and void coalescence analysis of cryorolled AA8090 alloy [J]. International Journal of Advanced Manufacturing Technology, 2017, 93: 253-259.

[23] ZHANG Peng-chao, JIE Jin-chuan, LI Hang, WANG Tong-min, LI Ting-ju. Microstructure and properties of TiB2 particles reinforced Cu-Cr matrix composite [J]. Journal of Materials Science, 2015, 50: 3320-3328.

[24] HUH S H, KIM H K, PARK J W, LEE G H. Critical cluster size of metallic Cr and Mo nanoclusters [J]. Physical Review B, 2000, 62: 2937-2943.

[25] XIA Cheng-dong, ZHANG Wan, KANG Zhan-yuan, JIA Yan-lin, WU Yi-feng, ZHANG Rui, XU Gen-ying, WANG Ming-pu. High strength and high electrical conductivity Cu-Cr system alloys manufactured by hot rolling-quenching process and thermomechanical treatments [J]. Materials Science and Engineering A, 2012, 538: 295-301.

[26] QU Lei, WANG En-gang, HAN Ke, ZUO Xiao-wei, ZHANG Lin, JIA Peng, HE Ji-cheng. Studies of electrical resistivity of an annealed Cu-Fe composite [J]. Journal of Applied Physics, 2013, 113: 173708.

张鹏超1,2,史杰夫1,于赢水2,3,孙俊才1,李廷举2

1. 大连海事大学 材料科学与工程系,大连 116026;

2. 大连理工大学 材料科学与工程学院,大连 116024;

3. 大连海洋大学 机械与动力工程学院,大连 116023

摘 要:分别采用低温轧制和常温轧制技术制备高强高导Cu-0.5Cr(质量分数,%)合金。研究Cu-0.5Cr合金经低温轧制/常温轧制和时效处理后的显微组织、力学性能和导电性能。研究结果表明,在低温轧制合金中可见明显的位错缠结。经低温轧制和时效处理后,合金中Cr颗粒尺寸更加细小,呈弥散分布。低温轧制合金的最大硬度为HV 167.4,显著高于常温轧制合金的。低温轧制合金在450 °C经120 min时效处理后达到最佳力学性能。低温轧制Cu-0.5Cr合金在450 °C经120 min时效处理后电导率达到92.5% IACS,略高于常温轧制合金的。

关键词:Cu-Cr合金;低温轧制;显微组织;力学性能;电导率

(Edited by Bing YANG)

Foundation item: Project (2016YFB0101206) supported by the National Key Research and Development Program of China; Project (3132019328) supported by the Fundamental Research Funds for the Central Universities, China

Corresponding author: Peng-chao ZHANG; E-mail: zpc@dlmu.edu.cn

DOI: 10.1016/S1003-6326(20)65393-6